(1) Sling identification. You must mark or code each sling to show the rated capacities for each type of hitch and type of synthetic web material.

(2) Webbing. You must ensure that synthetic webbing is of uniform thickness and width and selvage edges are not split from the webbing's width.

(3) Fittings. Fittings must be:

(a) Of a minimum breaking strength equal to that of the sling; and

(b) Free of all sharp edges that could in any way damage the webbing.

(4) Attachment of end fittings to webbing and formation of eyes. Stitching must be the only method used to attach end fittings to webbing and to form eyes. You must ensure that the thread is in an even pattern and contains a sufficient number of stitches to develop the full breaking strength of the sling.

(5) Environmental conditions. When synthetic web slings are used, you must take the following precautions:

(a) You must not use nylon web slings where fumes, vapors, sprays, mists or liquids of acids or phenolics are present.

(b) You must not use polyester and polypropylene web slings where fumes, vapors, sprays, mists or liquids of caustics are present.

(c) You must not use web slings with aluminum fittings where fumes, vapors, sprays, mists or liquids of caustics are present.

(6) Safe operating temperatures. You must not use synthetic web slings of polyester and nylon at temperatures in excess of 180°F. You must not use polypropylene web slings at temperatures in excess of 200°F.

(7) Repairs.

(a) You must not use synthetic web slings which are repaired unless repaired by a sling manufacturer or an equivalent entity.

(b) Each repaired sling must be proof tested by the manufacturer or equivalent entity to twice the rated capacity prior to its return to service. You must retain a certificate of the proof test and make it available for examination.

(c) You must not use slings, including webbing and fittings, which have been repaired in a temporary manner.

(8) Removal from service. You must immediately remove synthetic web slings from service if any of the following conditions are present:

(a) Acid or caustic burns;

(b) Melting or charring of any part of the sling surface;

(c) Snags, punctures, tears or cuts;

(d) Broken or worn stitches; or

(e) Distortion of fittings.

|

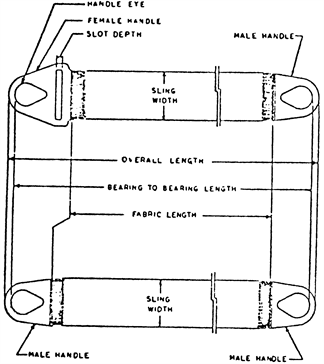

Figure D-1

Metal Mesh Sling (Typical)

|

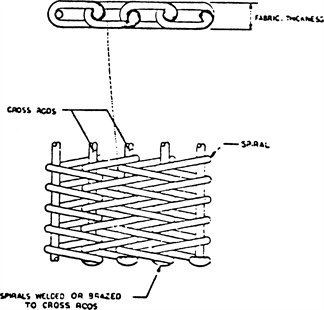

Figure D-2

Metal Mesh Construction

|

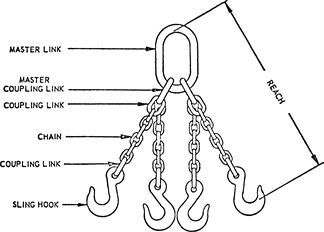

Figure D-3

Major Components of a Quadruple Sling

TABLE D-1

MINIMUM ALLOWABLE CHAIN SIZE

AT ANY POINT OF LINK

Chain Size, Inches | Minimum Allowable Chain Size, Inches | ||||||||

1/4 | . . . . | 13/64 | |||||||

3/8 | . . . . | 19/64 | |||||||

1/2 | . . . . | 25/64 | |||||||

5/8 | . . . . | 31/64 | |||||||

3/4 | . . . . | 19/32 | |||||||

7/8 | . . . . | 45/64 | |||||||

1 . . . . | 13/16 | ||||||||

1- 1/8 | . . . . | 29/32 | |||||||

1- 1/4 | . . . . | 1 | |||||||

1- 3/8 | . . . . | 1- 3/32 | |||||||

1- 1/2 | . . . . | 1- 3/16 | |||||||

1- 3/4 | . . . . | 1-13/32 | |||||||

|

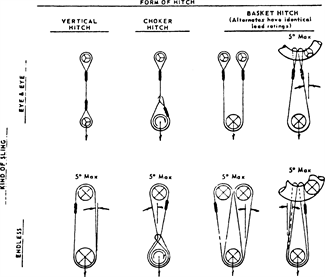

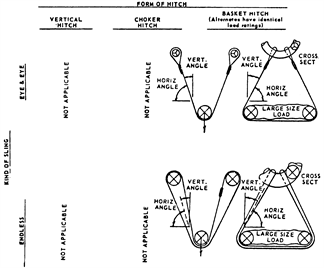

Notes: | Angles of 5° or less from the vertical may be considered vertical angles. |

For slings with legs more than 5° off vertical, the actual angle as shown in Figure D-5 must be considered. |

EXPLANATION OF SYMBOLS: Minimum diameter of curvature |

| Represents a contact surface which must have a diameter of curvature at least double the diameter of the rope. |

| Represents a contact surface which must have a diameter of curvature at least double the diameter of the rope. |

| Represents a load in a choker hitch and illustration the rotary force on the load and/or the slippage of the rope in contact with the load. Diameter of curvature of load surface must be at least double the diameter of the rope. |

Figure D-4

Basic Sling Configurations with Vertical Legs

|

Notes: | For vertical angles of 5° or less, refer to Figure D-4 "basic sling configuration with vertical legs." |

See Figure D-4 for explanation of symbols.

Figure D-5

Sling Configurations with Angled Legs

|

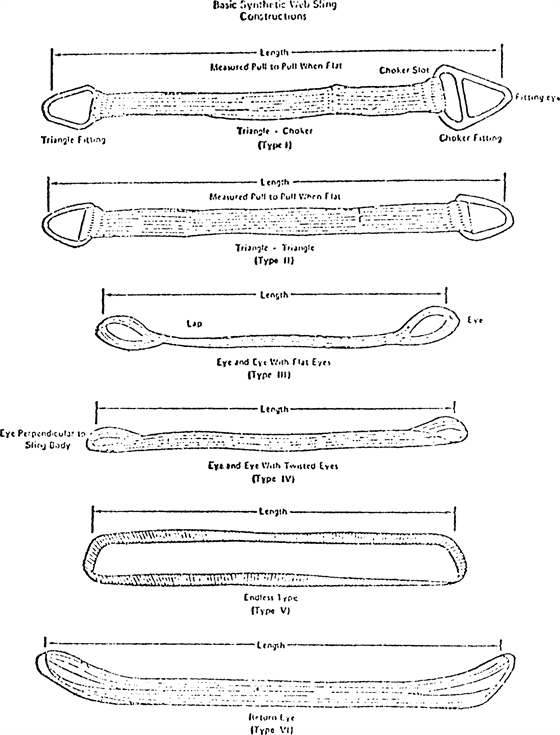

Figure D-6

Basic Synthetic Web Sling Constructions