WSR 13-22-063

PROPOSED RULES

DEPARTMENT OF

LABOR AND INDUSTRIES

[Filed November 4, 2013, 3:24 p.m.]

Original Notice.

Preproposal statement of inquiry was filed as WSR 13-11-109.

Title of Rule and Other Identifying Information: WAC 296-901-140 Hazard communication; chapter 296-24 WAC, General safety and health standards; chapter 296-62 WAC, General Occupational health standards; chapter 296-67 WAC, Safety standards for process safety management of highly hazardous chemicals; chapter 296-155 WAC, Safety standards for construction work; chapter 296-304 WAC, Safety standards for ship repairing, shipbuilding and shipbreaking; chapter 296-828 WAC, Hazardous chemicals in laboratories; chapter 296-835 WAC, Dipping and coating operations (dip tanks); chapter 296-843 WAC, Hazardous waste operations; chapter 296-848 WAC, Arsenic; chapter 296-849 WAC, Benzene; chapter 296-855 WAC, Ethylene oxide; and chapter 296-856 WAC, Formaldehyde. In addition, several internal references will need to be updated throughout all applicable chapters.

Hearing Location(s): Department of Labor and Industries, 7273 Linderson Way S.W., Room S117, Tumwater, WA 98501, on January 7, 2014, at 9:00 a.m.

Date of Intended Adoption: February 18, 2014.

Submit Written Comments to: Beverly Clark, P.O. Box 44620, Olympia, WA 98504-4620, e-mail Beverly.Clark@lni.wa.gov, fax (360) 902-5619, by 5:00 p.m. on January 10, 2014.

Assistance for Persons with Disabilities: Contact Beverly Clark by December 31, 2013, at Beverly.Clark@lni.wa.gov or (360) 902-5516.

Purpose of the Proposal and Its Anticipated Effects, Including Any Changes in Existing Rules: In 2012, the Occupational Safety and Health Administration (OSHA) adopted the final rules updating its hazard communication standard into alignment with the globally harmonized system of classification and labeling of chemicals (GHS). OSHA's rule also modified other existing OSHA standards that contain hazard classification and communication provisions to be internally consistent and aligned with the GHS modifications to the hazard communication standard. The department's rules are required to be at-least-as-effective-as OSHA. Under Phase I hazard communication rule making in 2013, the department created a new rule, WAC 296-901-140, incorporating all the elements of the existing department hazard communication rules into one rule to be consistent with OSHA's hazard communication standard employers, chemical manufacturers, importers, and distributors. This rule making, Phase II, modifies other existing department rules to align with the GHS changes as required by OSHA's rule. In addition, this rule making makes changes to WAC 296-901-140 to reflect minor corrections made to OSHA's rule in February 2013 and other necessary technical corrections.

Phase I Rule Making: In 2012, OSHA adopted the final rules updating its hazard communication standard into alignment with the GHS. The effective dates of OSHA's rule[s] are delayed and phased in. The department rules are required to be at-least-as-effective-as OSHA. The scope of OSHA's hazard communication standard includes requirements for employers as well as chemical manufacturers, importers, and distributors. Prior to the Phase I rule making, department's comparable requirements were in separate rules, as follows:

Employer Requirements: WAC 296-800-170 Employer chemical hazard communication (core rules) and chapter 296-307 WAC, Part Y-1, Employer chemical hazard communication (agriculture).

Chemical Manufacturer, Importer, and Distributor Requirements: Chapter 296-839 WAC, Content and distribution of material safety data sheets (MSDS) and label information and chapter 296-307 WAC, Part Y-2, Material safety data sheets and label preparation (agriculture).

Trade Secrets: Chapter 296-816 WAC, Protecting trade secrets and chapter 296-62 WAC, Part B-1, Trade secrets (applies only to agriculture).

In addition, other department rules specific to activities and workplaces reference the requirements in WAC 296-800-170.

Under the Phase I rule making the department created a new rule, WAC 296-901-140, incorporating all the elements of the existing department rules into one rule to be consistent with OSHA's hazard communication standard. During the transition period, there is the option to comply with the applicable requirements in the existing rules or the requirements in the new rule or both (see Table 1). Upon completion of the transition period, the existing standards will be repealed (see Table 2).

Phase II Rule Making: OSHA's 2012 rule also modified other existing OSHA standards that contain hazard classification and communication provisions to be internally consistent and aligned with the GHS modifications to the hazard communication standard. This rule making modifies other existing department rules to align with the GHS changes as required by OSHA's rule. In addition, this rule making makes changes to WAC 296-901-140 to reflect minor corrections made to OSHA's rule in February 2013 and other necessary technical corrections.

Table 1 Effective Dates:

Effective Completion Date |

Requirement(s) |

Who |

|

June 1, 2014 |

Train employees on the new label elements and safety data sheet (SDS) format. |

Employers. |

|

June 1, 2015 |

Compliance with all provisions of the WAC 296-901-140 final rule, except as listed below. |

Chemical manufactures [manufacturers], importers, distributors, and employers. |

|

June 1, 2016 |

Update alternative workplace labeling and hazard communication program as necessary, and provide additional employee training for newly identified physical or health hazards. |

Employers. |

|

December 1, 2015 |

The distributor must not ship containers labeled by the chemical manufacturer or importer unless it is a GHS label. |

Distributors. |

|

Transition period to the effective completion dates noted above. |

May comply with the applicable requirements in the following rules: |

Chemical manufacturers, importer[s], distributors, and employers. |

|

• |

WAC 296-800-170 Employer chemical hazard communication (core rules). |

||

• |

Chapter 296-307 WAC, Part Y-1, Employer chemical hazard communication (agriculture). |

||

• |

Chapter 296-839 WAC, Content and distribution of MSDS and label information. |

||

• |

Chapter 296-307 WAC, Part Y-2, MSDS and label preparation (agriculture). |

||

• |

Chapter 296-816 WAC, Protecting trade secrets. |

||

• |

Chapter 296-62 WAC, Part B-1, Trade secrets (applies only to agriculture). |

||

Or the requirements in the new hazard communication standard in WAC 296-901-140, or both. |

|||

Table 2 Proposed Schedule for Related Rule Changes:

Rule Change |

Proposed Schedule |

Phase I - Adopt WAC 296-901-140 Hazard communication. |

Adopted March 5, 2013. |

Phase II - Amend other existing DOSH rules to align with the GHS changes as required by OSHA's rule. |

April 2014. |

Repeal existing rules and delete, repeal, and change all references to the existing rules. |

As applicable, no later than June 1, 2016. |

Amended Sections:

Chapter 296-24 WAC, Part E—Hazardous materials, flammable and combustible liquids, spray finishing:

WAC 296-24-32003 Bulk oxygen systems.

• | Changed the title of Part E by removing the words "and combustible." |

• | Removed the words "or combustible." |

• | Changed reference in subsection (3)(a) and (r). |

• | Changed the word "combustible" to "flammable" in subsection (3)(g) and (h). |

WAC 296-24-33001 Definitions.

• | Removed the words "or combustible." |

• | Changed the definition of flammable aerosol, flashpoint, and flammable liquid to match OSHA's new definitions. Also removed the words "or combustible" wherever it was found. |

WAC 296-24-33003 Scope.

• | Removed the words "and combustible." |

• | Removed "200°F" and replaced it with "at or below 199.4°F (93°C)." |

WAC 296-24-33005 Tank storage.

• | Removed the words "or combustible." |

• | Removed "Class IA" and replaced it with "Category 1." |

• | Removed "Class IB and IC" and replaced it with "Category 2 flammable liquids and Category 3." |

• | Removed "Class I or Class 2" and replaced it with "Category 1, 2, or 3 flammable." |

• | Removed "Class II or Class III" and replaced it with "Category 3 flammable liquids with a flashpoint at or above 100°F (37.8°C) or Category 4 flammable liquids." |

WAC 296-24-33007 Piping, valves, and fittings.

• | Removed the words "or combustible." |

WAC 296-24-33009 Container and portable tank storage.

• | Removed the words "or combustible" and "and combustible." |

• | Removed "Class I or Class 2" and replaced it with "Category 1, 2, or 3 flammable." |

• | Table H-12 had the title changed by adding "for flammable" and the headings of "Class IA, IB, IC, II, III" were removed and replaced with "Category 1, 2, 3 and 4." |

• | Removed "Class IA or IB" and replaced it with "Category 1 or 2." Removed "Class I or II" and replaced it with "Category 1, 2, or 3 flammable." Removed "Class III" and replaced it with "Category 4 flammable." |

WAC 296-24-33011 Industrial plants.

• | Removed the words "or combustible" and "and combustible." |

• | Removed "Class IA or IB" and replaced it with "Category 1 or 2." Removed "Class I or II" and replaced it with "Category 1, 2, or 3 flammable." Removed "Class III" and replaced it with "Category 4 flammable." |

• | Removed "Class I or Class 2" and replaced it with "Category 1, 2, or 3 flammable." |

WAC 296-24-33013 Bulk plants.

• | Removed the words "or combustible." |

• | Removed "Class IA or IB" and replaced it with "Category 1 or 2." |

• | Removed "Class I or II" and replaced it with "Category 1, 2, or 3 flammable." Removed "Class III" and replaced it with "Category 4 flammable." |

• | Removed "Class I or Class 2" and replaced it with "Category 1, 2, or 3 flammable." |

WAC 296-24-33015 Service stations.

• | Removed the words "or combustible." |

• | Removed "Class IA or IB" and replaced it with "Category 1 or 2." |

• | Removed "Class I or II" and replaced it with "Category 1, 2, or 3 flammable." Removed "Class III" and replaced it with "Category 4 flammable." |

• | Removed "Class I or Class 2" and replaced it with "Category 1, 2, or 3 flammable." |

WAC 296-24-33017 Processing plants.

• | Removed the words "or combustible." |

• | Removed "Class IA or IB" and replaced it with "Category 1 or 2." |

• | Removed "Class I or II" and replaced it with "Category 1, 2, or 3 flammable." Removed "Class III" and replaced it with "Category 4 flammable." |

• | Removed "Class I or Class 2" and replaced it with "Category 1, 2, or 3 flammable." |

WAC 296-24-33019 Refineries, chemical plants, and distilleries.

• | Removed the words "or combustible." |

WAC 296-24-370 Spray finishing using flammable and combustible materials.

• | Removed the words "and combustible" from the title. |

WAC 296-24-37005 Electrical and other sources of ignition.

• | Removed the words "or combustible." |

• | Add[ed] "or liquids with a flashpoint greater than 199.4°F (93°C)" in subsection (9). |

WAC 296-24-37009 Flammable and combustible liquids—Storage and handling.

• | Changed the title to read "Flammable and combustible liquids and liquids with a flashpoint greater than 199.4°F (93°C)." |

• | Removed the words "or combustible" and "and combustible." |

• | Added in the phrase "with a flashpoint greater than 199.4°F (93°C)." |

Chapter 296-24 WAC, Part I—Welding, cutting and brazing:

WAC 296-24-71501 General.

• | Added OSHA identical language requirements relating to hazard communication. This language provides employees information about the hazardous chemicals to which they are exposed, by means of a hazard communication program, labels, other forms of warning, safety data sheets, and training located in this section. These requirements are federally driven and consistent with the provisions of the United Nations GHS, Revision 3. |

• | Changed numbering in the rest of the subsections due to the new language being added. |

Chapter 296-32 WAC, Safety standards for telecommunications:

WAC 296-32-230 Training.

• | Changed a reference from WAC 296-800-170 to 296-901-140. |

Chapter 296-45 WAC, Safety standards for electrical workers:

WAC 296-45-035 Definitions.

• | Changed a reference in the definition of IDLH from WAC 296-800-170 to 296-901-140. |

WAC 296-45-055 Employer's responsibility.

• | Changed a reference from WAC 296-800-170 to 296-901-140. |

Chapter 296-52 WAC, Safety standards for possession, handling, and use of explosives:

WAC 296-52-69095 Ammonium nitrate.

• | Removed the words "and combustible." |

Chapter 296-54 WAC, Safety standards—Logging operations:

WAC 296-54-507 Employer's responsibilities.

• | Changed a reference in subsection (4). |

WAC 296-54-519 Miscellaneous requirements.

• | Removed the phrase "and combustible." |

Chapter 296-56 WAC, Safety standards—Longshore, stevedore and waterfront related operations:

WAC 296-56-60001 Scope and applicability.

• | Changed a reference from WAC 296-800-170 to 296-901-140. |

WAC 296-56-60235 Welding, cutting and heating (hot work) (see also definition of "hazardous cargo, material, substance or atmosphere").

• | Removed the phrase "and combustible." |

Chapter 296-59 WAC, Safety standards for ski area facilities and operations:

WAC 296-59-005 Incorporation of other standards.

• | Changed a reference from WAC 296-800-170 to 296-901-140. |

Chapter 296-62 WAC, Part C-1—Retain department of transportation labeling:

WAC 296-62-05520 Retain readily visible DOT labeling.

• | Changed a reference from WAC 296-800-170 to 296-901-140. |

Chapter 296-62 WAC, Part F—Carcinogens:

WAC 296-62-07302 List of carcinogens.

• | Changed the title to read "Communication of hazards." |

• | Added OSHA identical language requirements relating to hazard communication. This language provides employees information about the hazardous chemicals to which they are exposed, by means of a hazard communication program, labels, other forms of warning, safety data sheets, and training located in this section. These requirements are federally driven and consistent with the provisions of the United Nations GHS, Revision 3. |

• | Added additional clarifying information on each carcinogen to make them identical to OSHA. |

• | Changed numbering. |

WAC 296-62-07306 Requirements for areas containing carcinogens listed in WAC 296-62-07302.

• | Changed a reference in subsection (2)(d)(vi). |

WAC 296-62-07310 Signs, information and training.

• | Changed information on signs to allow employers to be compliant with new and old signs until June 1, 2016. |

• | Removed language from subsection (2) container contents, identification through subsection (3) lettering. |

• | Changed numbering. |

WAC 296-62-07329 Vinyl chloride.

• | Added OSHA identical language requirements relating to hazard communication. This language provides employees information about the hazardous chemicals to which they are exposed, by means of a hazard communication program, labels, other forms of warning, safety data sheets, and training located in this section. These requirements are federally driven and consistent with the provisions of the United Nations GHS, Revision 3. |

• | Changed information on signs to allow employers to be compliant with new and old signs until June 1, 2016. |

• | Changed information on labels to allow employers to be compliant with new and old labels until June 1, 2015. |

• | Changed numbering. |

WAC 296-62-07336 Acrylonitrile.

• | Added OSHA identical language requirements relating to hazard communication. This language provides employees information about the hazardous chemicals to which they are exposed, by means of a hazard communication program, labels, other forms of warning, safety data sheets, and training located in this section. These requirements are federally driven and consistent with the provisions of the United Nations GHS, Revision 3. |

• | Changed the word "assure" to "ensure." |

• | Changed information on signs to allow employers to be compliant with new and old signs until June 1, 2016. |

• | Changed information on labels to allow employers to be compliant with new and old labels until June 1, 2015. |

• | Changed numbering. |

WAC 296-62-07342 1,2-Dibromo-3-chloropropane.

• | Added OSHA identical language requirements relating to hazard communication. This language provides employees information about the hazardous chemicals to which they are exposed, by means of a hazard communication program, labels, other forms of warning, safety data sheets, and training located in this section. These requirements are federally driven and consistent with the provisions of the United Nations GHS, Revision 3. |

• | Changed the word "assure" to "ensure." |

• | Changed information on signs to allow employers to be compliant with new and old signs until June 1, 2016. |

• | Changed information on labels to allow employers to be compliant with new and old labels until June 1, 2015. |

• | Changed numbering. |

WAC 296-62-07373 Communication of EtO hazards to employees.

• | Changed the title to read "Communication of EtO hazards." |

• | Added OSHA identical language requirements relating to hazard communication. This language provides employees information about the hazardous chemicals to which they are exposed, by means of a hazard communication program, labels, other forms of warning, safety data sheets, and training located in this section. These requirements are federally driven and consistent with the provisions of the United Nations GHS, Revision 3. |

• | Changed information on signs to allow employers to be compliant with new and old signs until June 1, 2016. |

• | Changed information on labels to allow employers to be compliant with new and old labels until June 1, 2015. |

• | Removed the words "MSDS" and put in "SDS." |

• | Changed numbering. |

• | Changed reference from WAC 296-62-05413 to 296-901-14014. |

WAC 296-62-07425 Communication of cadmium hazards to employees.

• | Changed the title to read "Communication of cadmium hazards." |

• | Added OSHA identical language requirements relating to hazard communication. This language provides employees information about the hazardous chemicals to which they are exposed, by means of a hazard communication program, labels, other forms of warning, safety data sheets, and training located in this section. These requirements are federally driven and consistent with the provisions of the United Nations GHS, Revision 3. |

• | Changed information on signs to allow employers to be compliant with new and old signs until June 1, 2016. |

• | Changed information on labels to allow employers to be compliant with new and old labels until June 1, 2015. |

• | Removed the words "MSDS" and put in "SDS." |

• | Changed numbering. |

WAC 296-62-07460 Butadiene.

• | Changed the title to read "1,3-Butadiene." |

• | Moved the definition of "director" so it was in alphabetical order. |

• | Added OSHA identical language requirements relating to hazard communication. This language provides employees information about the hazardous chemicals to which they are exposed, by means of a hazard communication program, labels, other forms of warning, safety data sheets, and training located in this section. These requirements are federally driven and consistent with the provisions of the United Nations GHS, Revision 3. |

• | Changed reference from WAC 296-800-170 to 296-901-140. |

WAC 296-62-07470 Methylene chloride.

• | Changed the note to Table 1 to read "Note to subsection (4)(c)" instead of subsection (3)(c). |

• | Added OSHA identical language requirements relating to hazard communication. This language provides employees information about the hazardous chemicals to which they are exposed, by means of a hazard communication program, labels, other forms of warning, safety data sheets, and training located in this section. These requirements are federally driven and consistent with the provisions of the United Nations GHS, Revision 3. |

• | Changed reference from WAC 296-800-170 to 296-901-140. |

WAC 296-62-07473 Appendix A.

• | Removed the words "MSDS" and put in "SDS." |

• | Added language "These materials, mixtures or solutions would be classified and labeled in accordance with WAC 296-901-140." |

Chapter 296-62 WAC, Part I—Air contaminants (specific):

WAC 296-62-07521 Lead.

• | In subsection (8)(b)(vii), changed the word "assure" to "ensure." |

• | Changed information on labels to allow employers to be compliant with new and old labels until June 1, 2015. |

• | In subsection (14), added OSHA identical language requirements relating to hazard communication. This language provides employees information about the hazardous chemicals to which they are exposed, by means of a hazard communication program, labels, other forms of warning, safety data sheets, and training located in this section. These requirements are federally driven and consistent with the provisions of the United Nations GHS, Revision 3. |

• | Changed information on signs to allow employers to be compliant with new and old signs until June 1, 2016. |

WAC 296-62-07540 Formaldehyde.

• | Removed the words "MSDS" and put in "SDS." |

• | Changed reference from chapter 296-839 WAC to WAC 296-901-140. |

• | Changed reference from WAC 296-800-170 to 296-901-140. |

• | Changed the phrase "material safety data sheets" to "safety data sheets." |

WAC 296-62-07544 Appendix B—Sampling strategy and analytical methods for formaldehyde.

• | Removed the words "MSDS" and put in "SDS." |

WAC 296-62-07601 Scope and application.

• | Changed a reference from WAC 296-800-170 to 296-901-140. |

WAC 296-62-07621 Communication of hazards to employees.

• | Changed the title to "Communication of hazards." |

• | Added OSHA identical language requirements relating [to] chemical manufacturers, importers, and employers on providing employees information about the hazardous chemicals to which they are exposed, by means of a hazard communication program, labels, other forms of warning, safety data sheets, and training located in this section. These requirements are federally driven and consistent with the provisions of the United Nations GHS, Revision 3. |

• | Changed information on signs to allow employers to be compliant with new and old signs until June 1, 2016. |

• | Changed information on labels to allow employers to be compliant with new and old labels until June 1, 2015. |

• | Changed a reference from WAC 296-800-170 to 296-901-140. |

• | Changed numbering. |

Chapter 296-62 WAC, Part I.1—Asbestos, tremolite, anthophyllite, and actinolite:

WAC 296-62-07717 Protective work clothing and equipment.

• | Added language "The employer shall ensure that" to subsections (2)(d) and (3)(f). |

• | Changed the reference in subsection (2)(d). |

WAC 296-62-07721 Communication of hazards to employees.

• | Changed the title to read "Communication of hazards." |

• | Removed language "general industry requirements" from subsection (1) and added language "the same hazard communication …" |

• | Added OSHA identical language requirements relating to hazard communication. This language provides employees information about the hazardous chemicals to which they are exposed, by means of a hazard communication program, labels, other forms of warning, safety data sheets, and training located in this section. These requirements are federally driven and consistent with the provisions of the United Nations GHS, Revision 3. |

• | Deleted the language in subsection (4) and made subsection (5) the new subsection (4). |

• | Changed information on signs to allow employers to be compliant with new and old signs until June 1, 2016. |

• | Added new language to subsection (4)(d). |

• | Subsection (6) is now subsection (5) warning labels which has added OSHA identical language. |

• | Changed information on labels to allow employers to be compliant with new and old labels until June 1, 2015. |

• | Removed the phrase "material safety data sheets" and put in "safety data sheets." |

• | Changed numbering. |

Chapter 296-62 WAC, Part I.2—Hexavalent chromium:

WAC 296-62-08017 Protective work clothing and equipment.

• | Added the words "The employer shall ensure that" in subsection (2)(d). |

• | Changed a reference from WAC 296-800-170 to 296-901-140. |

WAC 296-62-08021 Housekeeping.

• | Changed a reference from WAC 296-800-170 to 296-901-140. |

WAC 296-62-08025 Communication of chromium (VI) hazards to employees.

• | Changed the title to read "Communication of chromium (VI) hazards.["] |

• | Changed a reference from WAC 296-800-170 to 296-901-140. |

• | Added OSHA identical language requirements relating [to] chemical manufacturers, importers, and employers on providing employees information about the hazardous chemicals to which they are exposed, by means of a hazard communication program, labels, other forms of warning, safety data sheets, and training located in this section. These requirements are federally driven and consistent with the provisions of the United Nations GHS, Revision 3. |

Chapter 296-62 WAC, Part N—Cotton dust:

WAC 296-62-14533 Cotton dust.

• | Added the words "of this section" into subsection (1)(c) and (13)(e). |

• | Added the word "subsection" into subsection (5)(c)(iii). |

• | Changed information on signs to allow employers to be compliant with new and old signs until June 1, 2016. |

Chapter 296-62 WAC, Part O—Coke ovens:

WAC 296-62-20021 Precautionary signs and labels.

• | Changed the title to "Communication of hazards." |

• | Changed information on signs to allow employers to be compliant with new and old signs until June 1, 2016. |

• | Changed information on labels to allow employers to be compliant with new and old labels until June 1, 2015. |

• | Deleted an old compliance date of January 20, 1978. |

Chapter 296-62 WAC, Part R—Hazardous drugs:

WAC 296-62-50035 Safe handling practices.

• | Changed a reference from WAC 296-800-170 to 296-901-140. |

Chapter 296-63 WAC, Right to know fee assessment:

WAC 296-63-009 Exemption requests.

• | Changed a reference from WAC 296-800-170 to 296-901-140. |

Chapter 296-67 WAC, Safety standards for process safety management of highly hazardous chemicals:

WAC 296-67-001 Process safety management of highly hazardous chemicals.

• | Changed reference from WAC 296-800-170 to 296-901-14006. |

• | Added the words "with a flashpoint below 100°F (37.8°C).["] |

WAC 296-67-005 Definitions.

• | Changed the reference in the definition of trade secret from chapter 296-62 WAC, Part B-1 to WAC 296-901-14030, Appendix E-Definition of "trade secret." |

WAC 296-67-291 Appendix C—Compliance guidelines and recommendations for process safety management (nonmandatory).

• | Removed the phrase "material safety data sheets" and put in "safety data sheets." |

• | Removed the words "MSDS" and put in "SDS." |

• | Changed a reference from WAC 296-800-170 to 296-901-140. |

Chapter 296-78 WAC, Safety standards for sawmills and woodworking operations:

WAC 296-78-515 Management's responsibility.

• | Changed a reference from WAC 296-800-170 to 296-901-140. |

WAC 296-78-71015 Tanks and chemicals.

• | Removed the words "or combustible" in subsection (5)(b) and (c). |

Chapter 296-115 WAC, Safety requirements for charter boats:

WAC 296-115-050 General requirements.

• | Removed the words "or combustible" in subsection (4)(c). |

WAC 296-115-060 Operations.

• | Removed the words "or combustible" in subsection (3)(f). |

Chapter 296-155 WAC, Part B-1—Occupational health and environmental control:

WAC 296-155-17323 Communication of hazards to employees.

• | Changed the title to "Communication of hazards." |

• | Added OSHA identical language requirements relating [to] chemical manufacturers, importers, and employers on providing employees information about the hazardous chemicals to which they are exposed, by means of a hazard communication program, labels, other forms of warning, safety data sheets, and training located in this section. These requirements are federally driven and consistent with the provisions of the United Nations GHS, Revision 3. |

• | Changed information on signs to allow employers to be compliant with new and old signs until June 1, 2016. |

• | Changed information on labels to allow employers to be compliant with new and old labels until June 1, 2015. |

• | Removed the phrase "material safety data sheets" and put in "safety data sheets." |

• | Removed the words "MSDS" and put in "SDS." |

• | Changed reference from WAC 296-800-170 to 296-901-14016. |

• | Changed numbering of subsections. |

WAC 296-155-174 Cadmium.

• | Removed the phrase "material safety data sheets" and put in "safety data sheets." |

• | Removed the words "MSDS" and put in "SDS." |

• | Changed reference from WAC 296-800-170 to 296-901-140. |

• | Changed information on signs to allow employers to be compliant with new and old signs until June 1, 2016. |

• | Changed information on labels to allow employers to be compliant with new and old labels until June 1, 2015. |

WAC 296-155-17609 Exposure assessment.

• | Changed a reference from WAC 296-800-170 to 296-901-140. |

WAC 296-155-17615 Protective work clothing and equipment.

• | Subsection (2)(g) changed the word "assure" to "ensure." |

• | Changed information on labels to allow employers to be compliant with new and old labels until June 1, 2015. |

WAC 296-155-17625 Employee information and training.

• | Changed the title to "Communication of hazards." |

• | Removed the phrase "material safety data sheets" and put in "safety data sheets." |

• | Removed the words "MSDS" and put in "SDS." |

• | Changed reference from WAC 296-800-170 to 296-901-140. |

• | Added language concerning hazards to be addressed. |

WAC 296-155-17627 Signs.

• | Changed information on signs to allow employers to be compliant with new and old signs until June 1, 2016. |

• | Changed the word "assure" to "ensure." |

WAC 296-155-17652 Appendix B to WAC 296-155-176 Employee standard summary.

• | Corrected the spelling of "preassignment." |

• | Changed information on signs to allow employers to be compliant with new and old signs until June 1, 2016. |

Chapter 296-155 WAC, Part B-2—Hazard communication:

WAC 296-155-180 Hazard communication.

• | Changed reference from WAC 296-800-170 to 296-901-140. |

Chapter 296-155 WAC, Part C—Personal protective and life saving equipment:

WAC 296-155-20301 Definitions.

• | Changed reference from WAC 296-800-170 to 296-901-140. |

Chapter 296-155 WAC, Part D—Fire protection and prevention:

WAC 296-155-250 Definitions applicable to this part.

• | Deleted the definition for combustible liquid. |

• | Changed the definitions for flammable liquid and flashpoint to reflect OSHA's updated definitions. |

• | Changed numbering. |

WAC 296-155-260 Fire protection.

• | Removed the phrase "or combustible." |

WAC 296-155-265 Fire prevention.

• | Removed the phrase "or combustible." |

WAC 296-155-270 Flammable and combustible liquids.

• | Changed the title to read "Flammable liquids." |

• | Removed the phrase[s] "and combustible" and "or combustible." |

• | In subsection (2)(c) added the words "Category 1, 2, or 3" and "Category 4 flammable." |

• | In subsections (2)(d)(vi), (5)(b), (6)(a), (7)(g)(i), and (ii) added the words "Category 1, 2, or 3." |

Chapter 296-304 WAC, Safety standards for ship repairing, shipbuilding and shipbreaking:

WAC 296-304-01001 Definitions.

• | Changed the definition of flammable liquid. |

WAC 296-304-01009 Precautions for hot work.

• | Changed a reference from WAC 296-800-170 to 296-901-140. |

WAC 296-304-06013 Hazardous materials.

• | Changed a reference from WAC 296-800-170 to 296-901-140. |

• | Changed the address for OSHA to reflect their current location. |

WAC 296-304-06017 Retention of DOT markings, placards, and labels.

• | Changed a reference from chapter 296-839 WAC to WAC 296-901-14012 and 296-901-14014. |

Chapter 296-800 WAC, First-aid summary:

WAC 296-800-15030 Make sure emergency washing facilities are functional and readily accessible.

• | Changed a reference in the reference section from WAC 296-800-170 to 296-901-140. |

Chapter 296-800 WAC, Personal protective equipment (PPE):

WAC 296-800-16055 Make sure your employees use appropriate head protection.

• | Changed Class 1 to "Category 1 or 2" and added in language about Category 3 flammable liquids. |

Chapter 296-800 WAC, Using standards from national organizations and federal agencies:

WAC 296-800-370 Definitions.

• | Deleted the definition for combustible liquid. |

• | Changed the reference WAC 296-800-170 to 296-901-140 in several definitions. |

• | Removed the words "MSDS" and put in "SDS." |

• | Changed the definition of flammable, flashpoint, and physical hazard to reflect OSHA's new definitions. |

• | Deleted the definition of material safety data sheet and replaced it with safety data sheet. |

Chapter 296-802 WAC, Employee medical and exposure records:

WAC 296-802-100 Scope.

• | Changed a reference in the reference section. |

WAC 296-802-40015 Provide employee exposure records.

• | Changed a reference in the note. |

Chapter 296-809 WAC, Confined spaces:

WAC 296-809-800 Definitions.

• | Changed a reference in the hazardous atmosphere definition. |

• | Removed the phrase "material safety data sheets" and replaced it with "safety data sheets." |

Chapter 296-811 WAC, Fire brigades:

WAC 296-811-600 Definitions.

• | Removed the phrase "or combustible." |

Chapter 296-824 WAC, Emergency response:

WAC 296-824-70005 Follow the appropriate postemergency response requirements.

• | Changed a reference in Table 10. |

WAC 296-824-800 Definitions.

• | Changed the definition of health hazard to reflect OSHA's new definition. |

• | Removed the phrase "material safety data sheets" and replaced it with "safety data sheets." |

Chapter 296-828 WAC, Hazardous chemicals in laboratories:

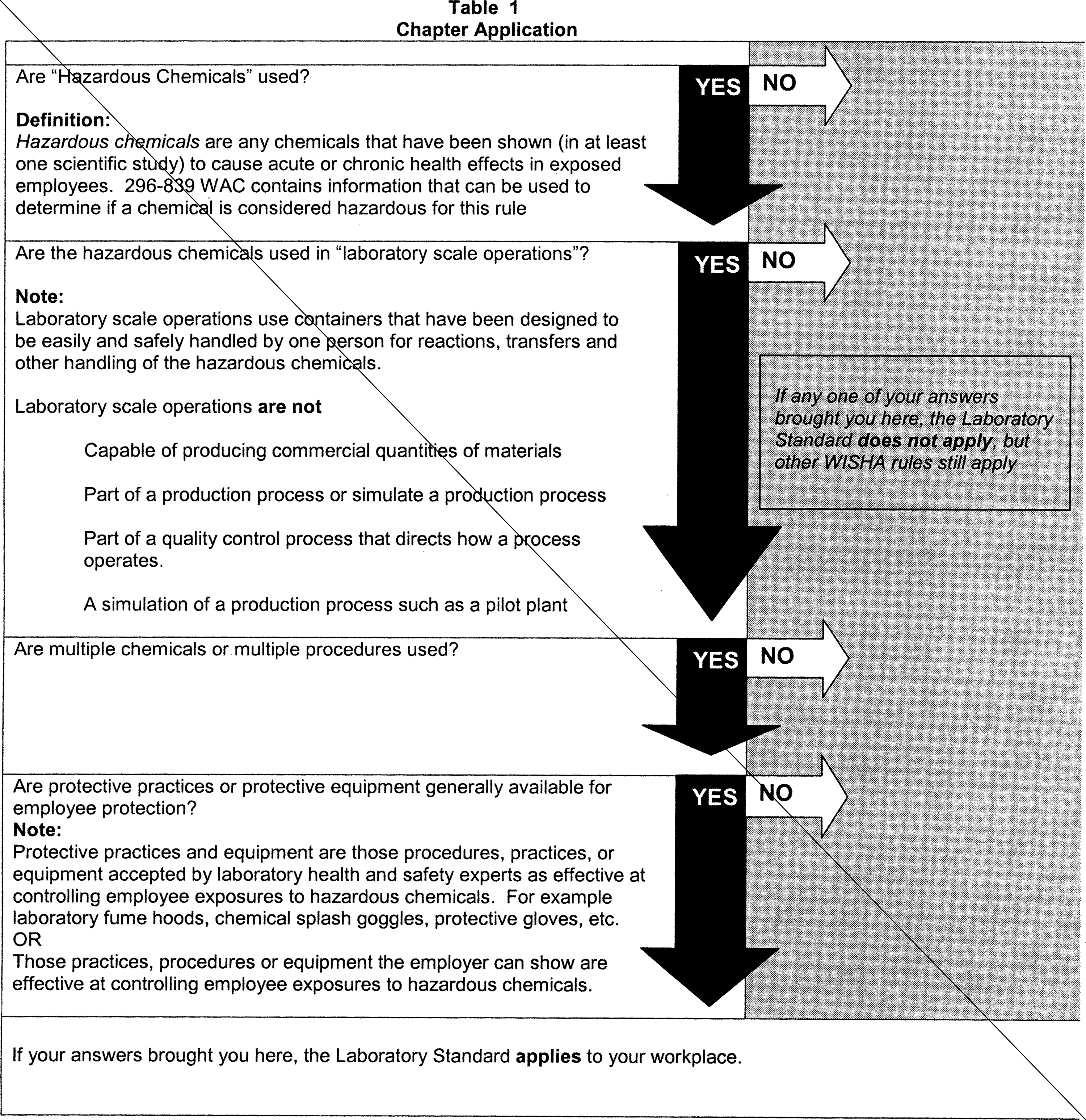

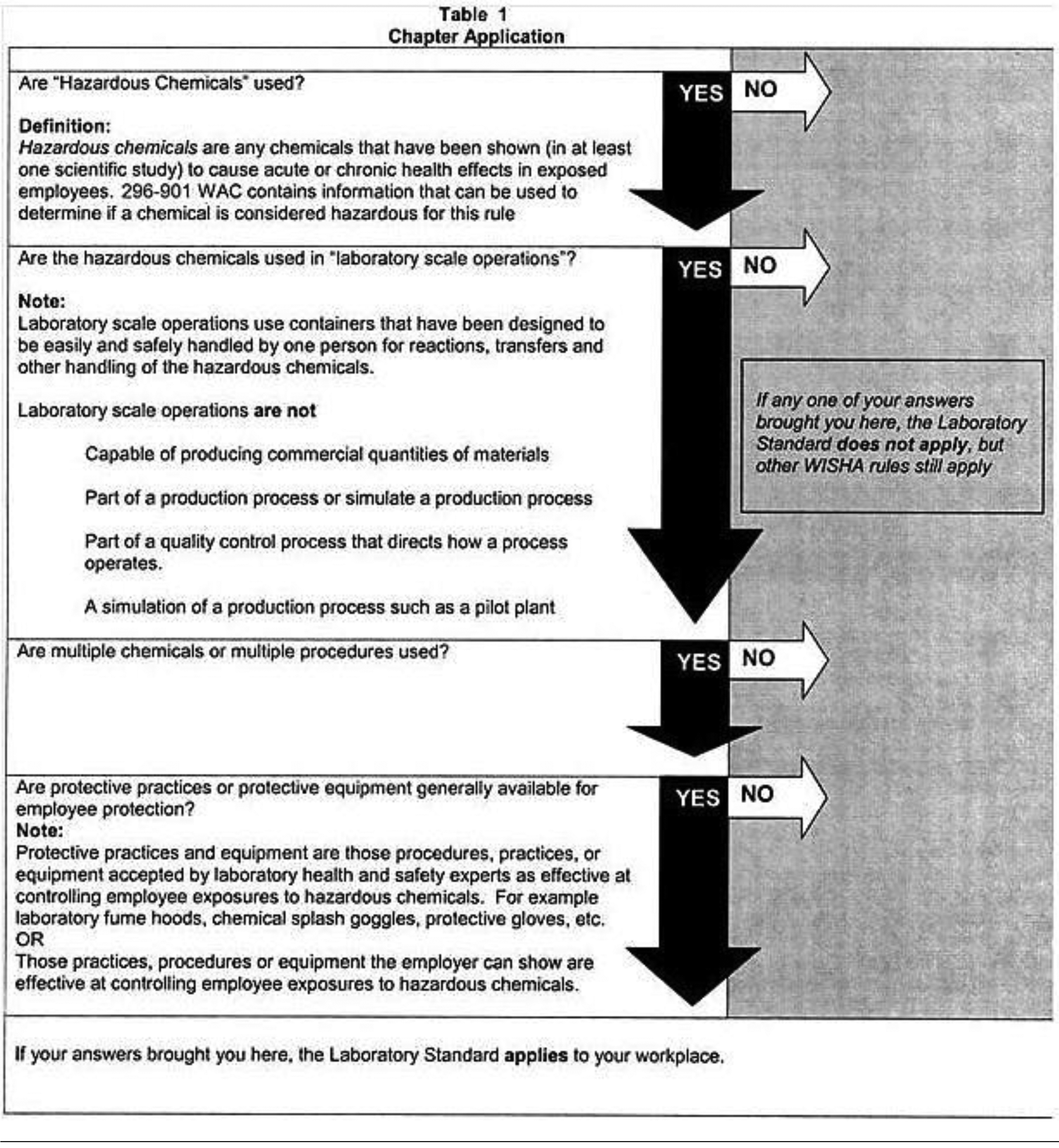

WAC 296-828-100 Scope.

• | Changed a reference in Table 1. |

WAC 296-828-200 Using hazardous chemicals in laboratories.

• | Removed the phrase "material safety data sheets" and put in "safety data sheets." |

• | Removed the words "MSDS" and put in "SDS." |

WAC 296-828-20015 Training.

• | Removed the phrase "material safety data sheets" and put in "safety data sheets." |

• | Removed the words "MSDS" and put in "SDS." |

WAC 296-828-20020 Labeling and material safety data sheets (MSDSs).

• | Changed the title to read "Labeling and safety data sheets (SDSs)." |

• | Removed the phrase "material safety data sheets" and put in "safety data sheets." |

• | Removed the words "MSDS" and put in "SDS." |

WAC 296-828-20025 Chemicals produced in laboratories.

• | Changed a reference in Table 3 from chapter 296-839 WAC, MSDS and label preparation to WAC 296-901-14014 Safety data sheets and 296-901-14012 Labels and other forms of warning. |

WAC 296-828-300 Definitions.

• | Changed the definition of hazardous chemical, physical hazard, reproductive toxin, and SDS to reflect OSHA changes. |

• | Added a definition for health hazard and mutagen. |

Chapter 296-835 WAC, Dipping and coating operations (dip tanks):

WAC 296-835-11015 Take additional precautions if you recirculate ventilation system exhaust air into the workplace.

• | Added "This section applies if exhaust air from dipping or coating operations that use flammable liquids, or liquids with flashpoints greater than 199.4°F (93°C) is recirculated back into the work environment. |

• | Removed the words "or combustible" and added "or liquids with flashpoints greater than 199.4°F (93°C). |

WAC 296-835-120 Additional requirements for dip tanks using flammable or combustible liquids.

• | Changed the title to read "Additional requirements for dip tanks using flammable liquids or liquids with flashpoints greater than 199.4°C [F] (93°C). Summary." |

• | Removed the words "or combustible" and added "or liquids with flashpoints greater than 199.4°F (93°C)." |

WAC 296-835-12020 Provide fire protection in the vapor area.

• | Removed the words "and combustible liquid fires" and added "… liquids and liquids with flashpoints greater than 199.4°F (93°C)." |

WAC 296-835-13005 Meet specific requirements if you use a hardening or tempering tank.

• | Removed the words "or combustible" and added "or liquids with flashpoints greater than 199.4°F (93°C)." |

WAC 296-835-140 Definitions.

• | Removed the definition for combustible liquid. |

• | Changed the definition for flammable liquid and flashpoint to meet the new requirements for OSHA. |

Chapter 296-841 WAC, Airborne contaminants:

WAC 296-841-100 Scope.

• | Removed the phrase "material safety data sheets" and put in "safety data sheets." |

• | Removed the words "MSDS" and put in "SDS." |

WAC 296-841-20003 Employee protective measures.

• | Removed the phrase "material safety data sheets" and put in "safety data sheets." |

• | Removed the words "MSDS" and put in "SDS." |

WAC 296-841-20005 Exposure evaluations.

• | Removed the phrase "material safety data sheets" and put in "safety data sheets." |

• | Removed the words "MSDS" and put in "SDS." |

WAC 296-841-300 Definitions.

• | Removed the word "material" in the definition of toxic substance. |

Chapter 296-842 WAC, Respirators:

WAC 296-842-12005 Develop and maintain a written program.

• | Changed the reference in Table 3 from WAC 296-800-170 to 296-901-140. |

Chapter 296-843 WAC, Hazardous waste operations:

WAC 296-843-17005 Control employee exposure to site health and safety hazards.

• | Removed the phrase "material safety data sheets" and put in "safety data sheets." |

• | Removed the words "MSDS" and put in "SDS." |

• | Changed the reference in the note section from WAC 296-800-180 to 296-901-14014. |

WAC 296-843-20020 Training for postemergency response.

• | Changed the reference in the reference section from WAC 296-800-170 to 296-901-140. |

WAC 296-843-300 Definitions.

• | Changed the definition for health hazard and SDS to meet OSHA requirements. |

WAC 296-848-20010 Preventive practices.

• | Changed information on labels to allow employers to be compliant with new and old labels until June 1, 2015. |

• | Changed a reference in the reference section. |

Chapter 296-848 WAC, Arsenic:

WAC 296-848-300 Training, exposure monitoring, and medical monitoring.

• | Added in the number and title of the new section under the important statement. |

WAC 296-848-30005 Training.

• | Changed a reference in the reference section. |

WAC 296-848-40025 Exposure control areas.

• | Changed information on signs to allow employers to be compliant with new and old signs until June 1, 2016. |

WAC 296-848-40040 Personal protective equipment (PPE).

• | Changed information on labels to allow employers to be compliant with new and old labels until June 1, 2015. |

WAC 296-848-500 Definitions.

• | Removed the phrase "material safety data sheets" and put in "safety data sheets." |

• | Removed the words "MSDS" and put in "SDS." |

Chapter 296-849 WAC, Benzene:

WAC 296-849-100 Scope.

• | Changed the reference in Table 1 from WAC 296-800-17030 to 296-901-14016. |

WAC 296-849-110 Basic rules.

• | Changed the wording for the title to WAC 296-849-11010 to communication of hazards. |

WAC 296-849-11010 Preventive practices.

• | Changed the title to "Communication of hazards." |

• | Added OSHA identical language requirements relating chemical manufacturers, importers, and employers on providing employees information about the hazardous chemicals to which they are exposed, by means of a hazard communication program, labels, other forms of warning, safety data sheets, and training located in this section. These requirements are federally driven and consistent with the provisions of the United Nations GHS, Revision 3. |

• | Changed information on labels to allow employers to be compliant with new and old labels until June 1, 2015. |

• | Changed the reference in the reference section from chapter 296-800 WAC and WAC 296-800-17025 to 296-901-14012 and 296-901-14014. |

WAC 296-849-11020 Exposure control areas.

• | Deleted the signage wording and put in a reference to WAC 296-849-11010. |

WAC 296-849-11050 Training.

• | Changed references from chapter 296-800 WAC and WAC 296-800-17025 to 296-901-14012 and 296-901-14014. |

• | Changed the reference in the reference section from chapter 296-800 WAC and WAC 296-800-17030 to 296-901-14016. |

WAC 296-849-190 Definitions.

• | Removed the phrase "material safety data sheets (MSDS)" and put in the phrase "safety data sheets (SDS)" in the definition of benzene. |

Chapter 296-855 WAC, Ethylene oxide:

WAC 296-855-20010 Preventive practices.

• | Changed information on labels to allow employers to be compliant with new and old labels until June 1, 2015. |

WAC 296-855-20020 Exposure control areas.

• | Changed information on signs to allow employers to be compliant with new and old signs until June 1, 2016. |

WAC 296-855-20090 Training.

• | Changed reference from WAC 296-800-170 to 296-901-140. |

WAC 296-855-500 Definitions.

• | Removed the phrase "material safety data sheets" and put in "safety data sheets." |

• | Removed the words "MSDS" and put in "SDS." |

Chapter 296-856 WAC, Formaldehyde:

WAC 296-856-20010 Preventive practices.

• | Removed the phrase "material safety data sheets" and put in "safety data sheets." |

• | Removed the words "MSDS" and put in "SDS." |

• | Added reference to chapter 296-901 WAC. |

• | Changed references from WAC 296-80-170 and chapter 296-839 WAC to WAC 296-901-140, 296-901-14022, and 296-901-14024. |

WAC 296-856-20020 Training.

• | Removed the words "MSDS" and put in "SDS." |

WAC 296-856-20030 Personal protective equipment (PPE).

• | Removed the words "MSDS" and put in "SDS." |

• | Changed information on labels to allow employers to be compliant with new and old labels until June 1, 2015. |

• | Changed information on signs to allow employers to be compliant with new and old signs until June 1, 2016. |

WAC 296-856-40020 Establishing exposure control areas.

• | Changed information on signs to allow employers to be compliant with new and old signs until June 1, 2016. |

WAC 296-856-500 Definitions.

• | Removed the words "MSDS" and put in "SDS." |

• | Removed the phrase "material safety data sheets" and put in "safety data sheets." |

Chapter 296-863 WAC, Forklifts and other powered industrial trucks:

WAC 296-863-700 Definitions.

• | Corrected the spelling of "ignitable" in the definition of classified location or hazardous location. |

• | Changed the definition of flammable liquid and flashpoint to reflect OSHA's new definitions. |

• | Moved the definition of listed by report so it is now in alphabetical order. |

Chapter 296-901 WAC, Globally harmonized system for hazard communication:

WAC 296-901-14006 Definitions.

• | Removed the word "must" and replaced it with "should" in the definition of hazard category and precautionary statement. |

• | Corrected the reference in the definition of physical hazard to read WAC 296-901-14024. |

WAC 296-901-14008 Hazard classification.

• | Removed subsection[s] (4) through (6) to be as-effective-as OSHA. |

WAC 296-901-14014 Safety data sheets.

• | Removed the word "must" and replaced it with "should" in the note under subsection (11). |

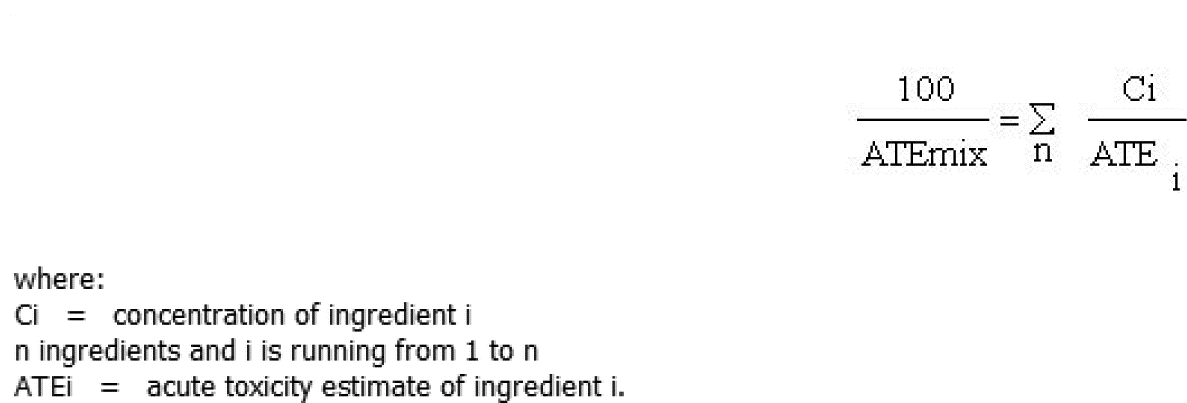

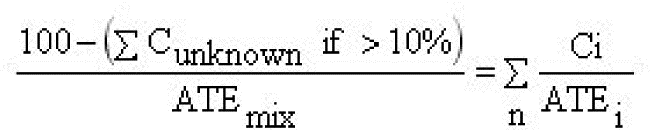

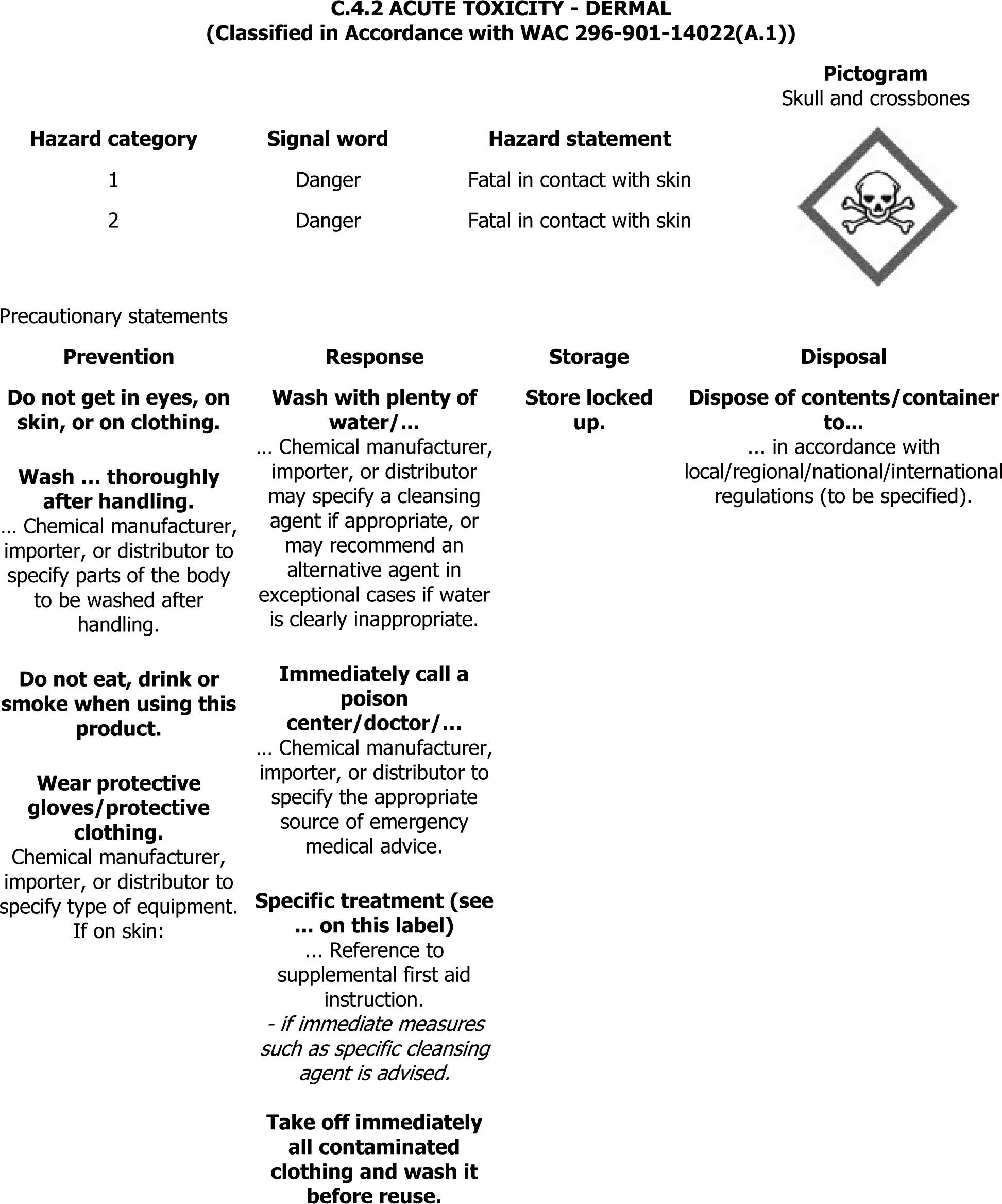

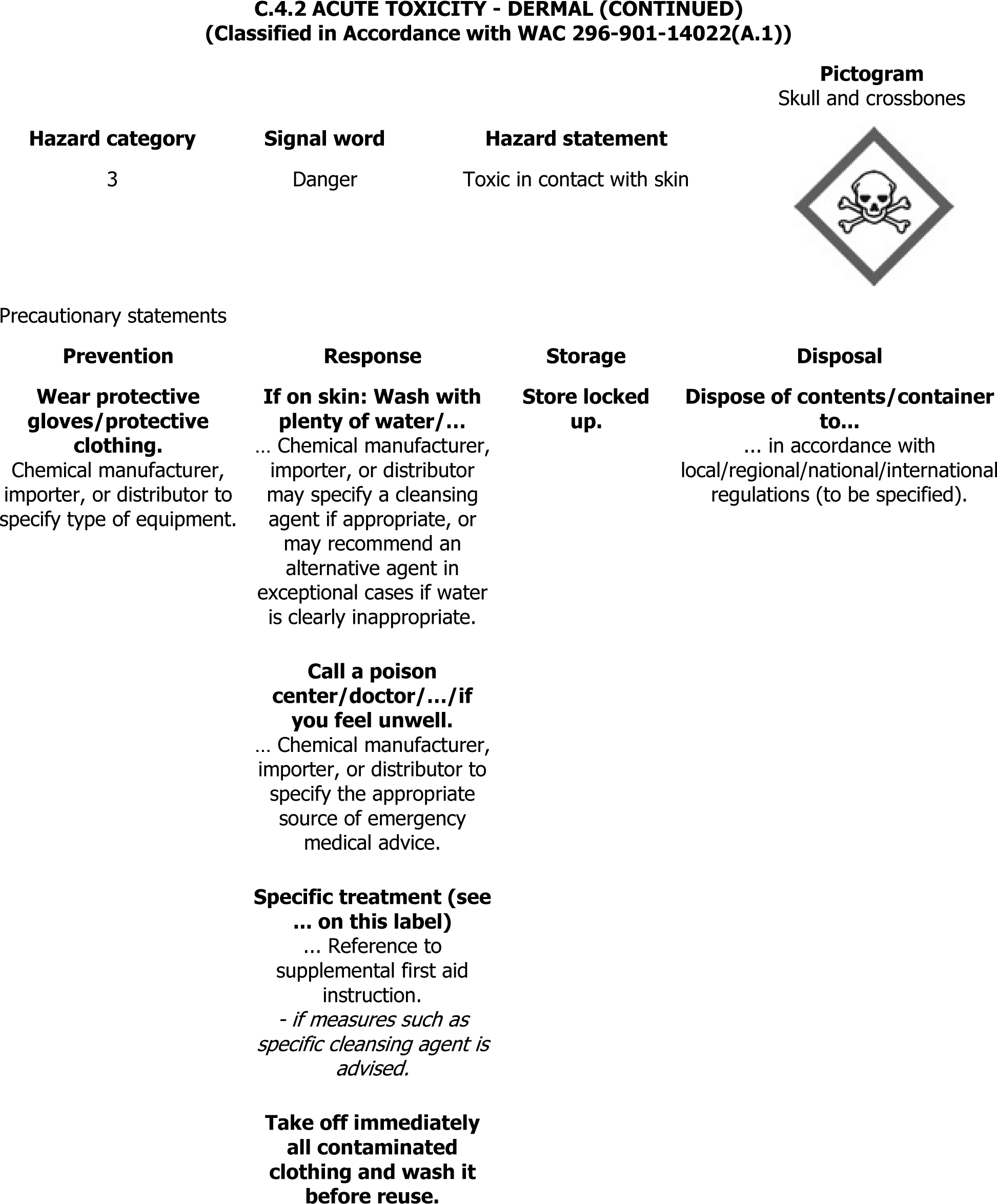

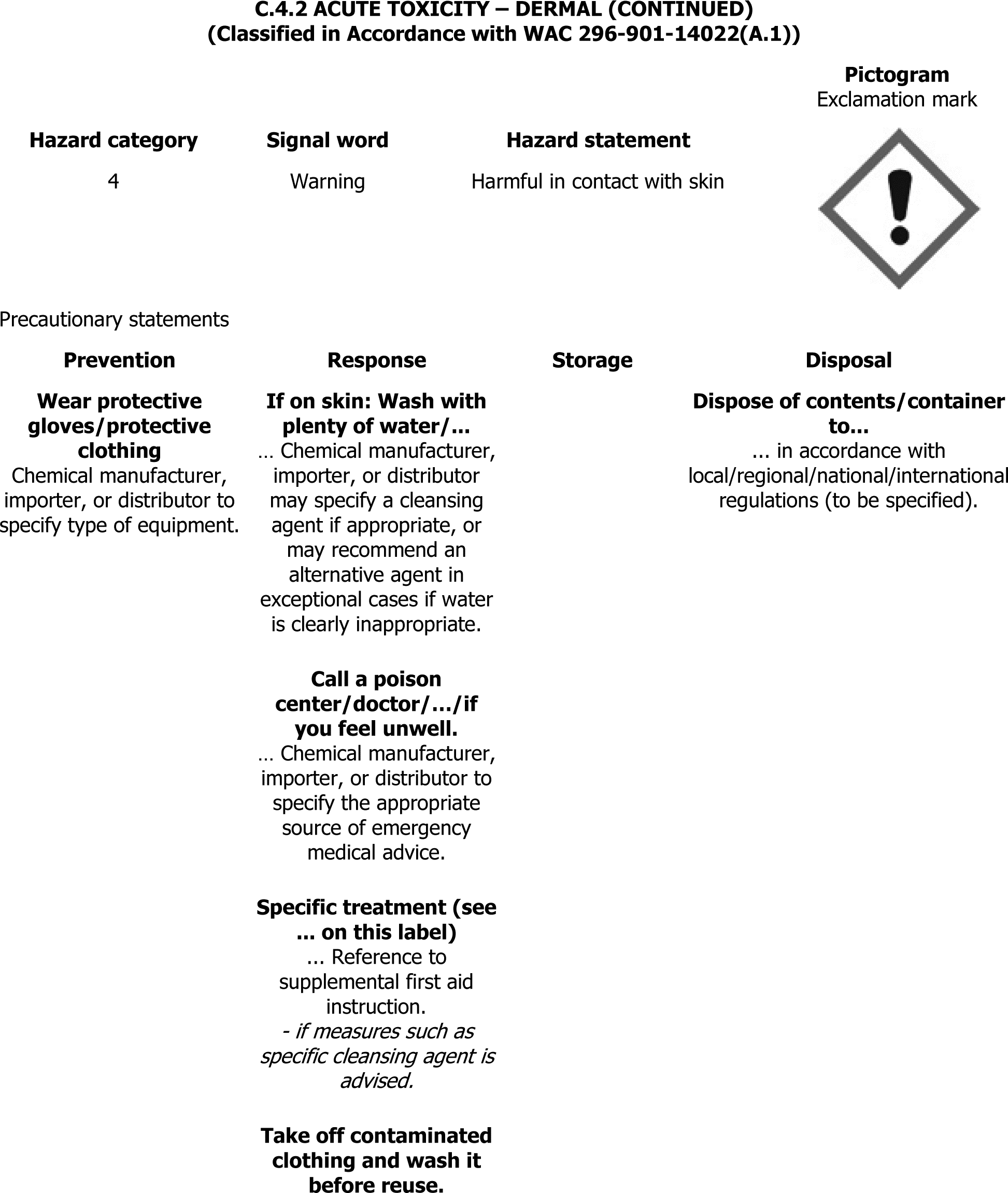

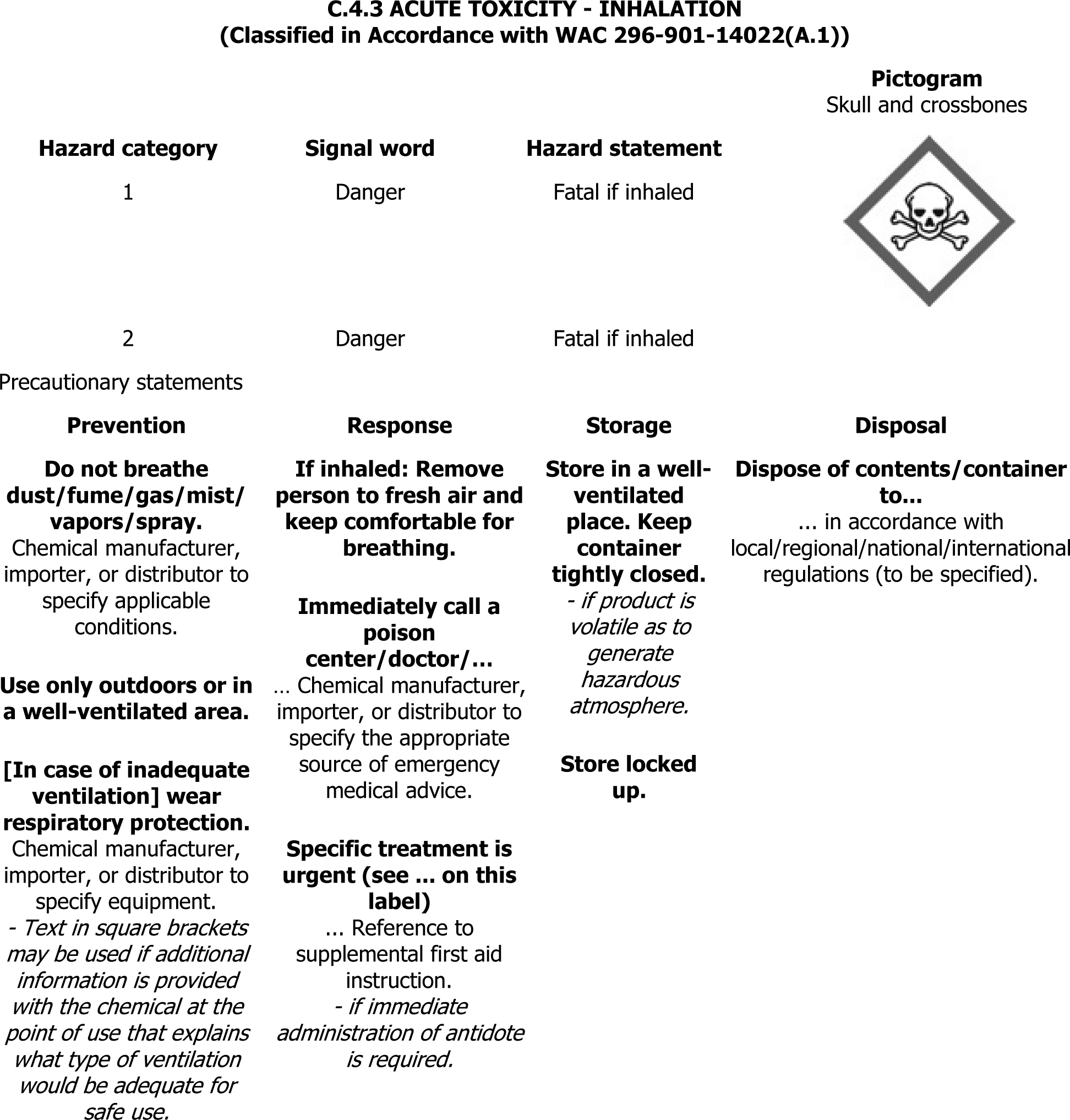

WAC 296-901-14022 Appendix A—Health hazard criteria (mandatory).

• | In A.0.5.1.5, added subsection (a)(ii) C + B. |

• | Changed the symbol "≥" to "≤" in Table A.1.1 and Table A.8.2. |

• | Corrected the spelling of "fulfill" in A.2.2.2.2. |

• | Changed the symbol ">" to "≥" in A.2.4.3.1 and A.3.4.3.1 |

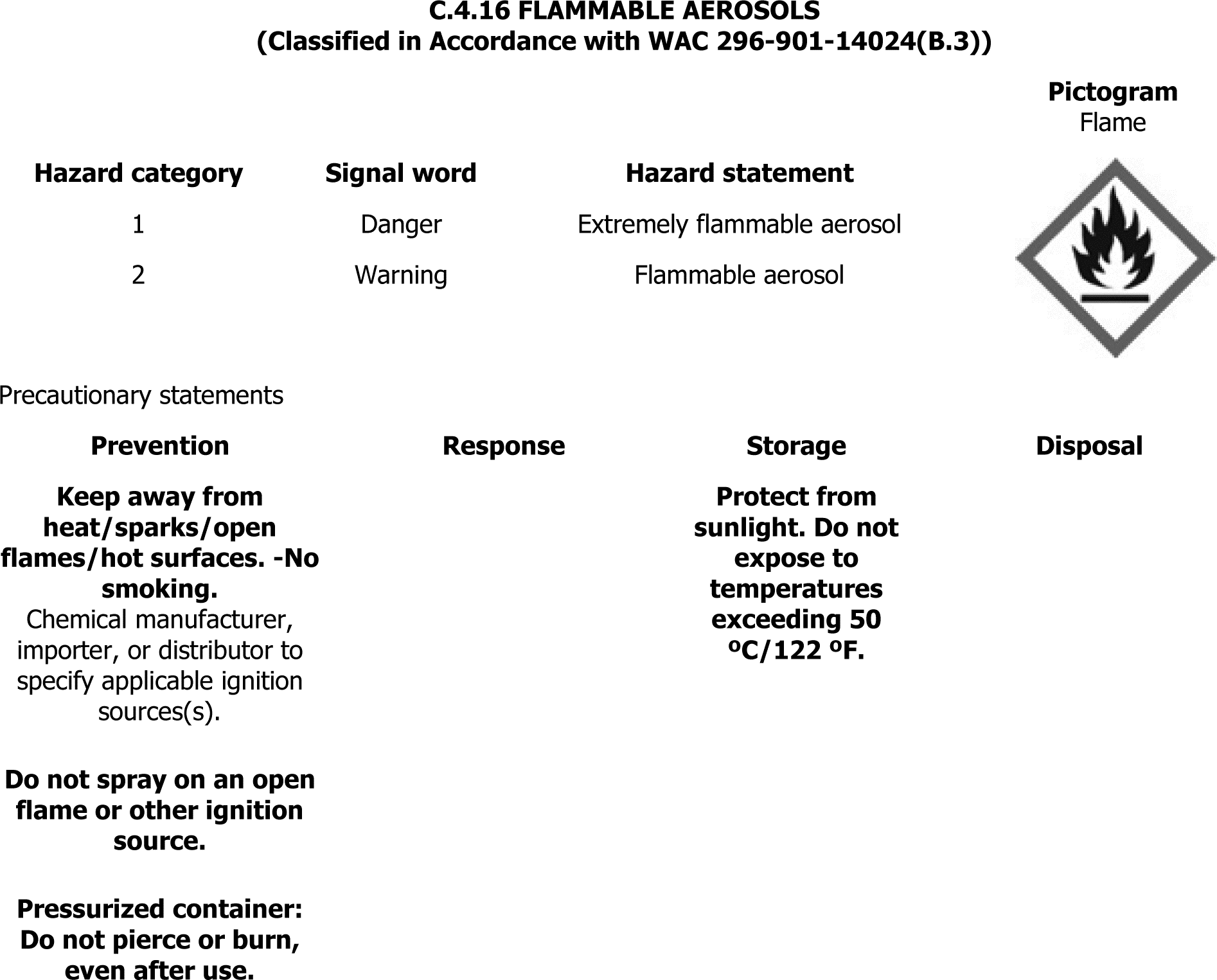

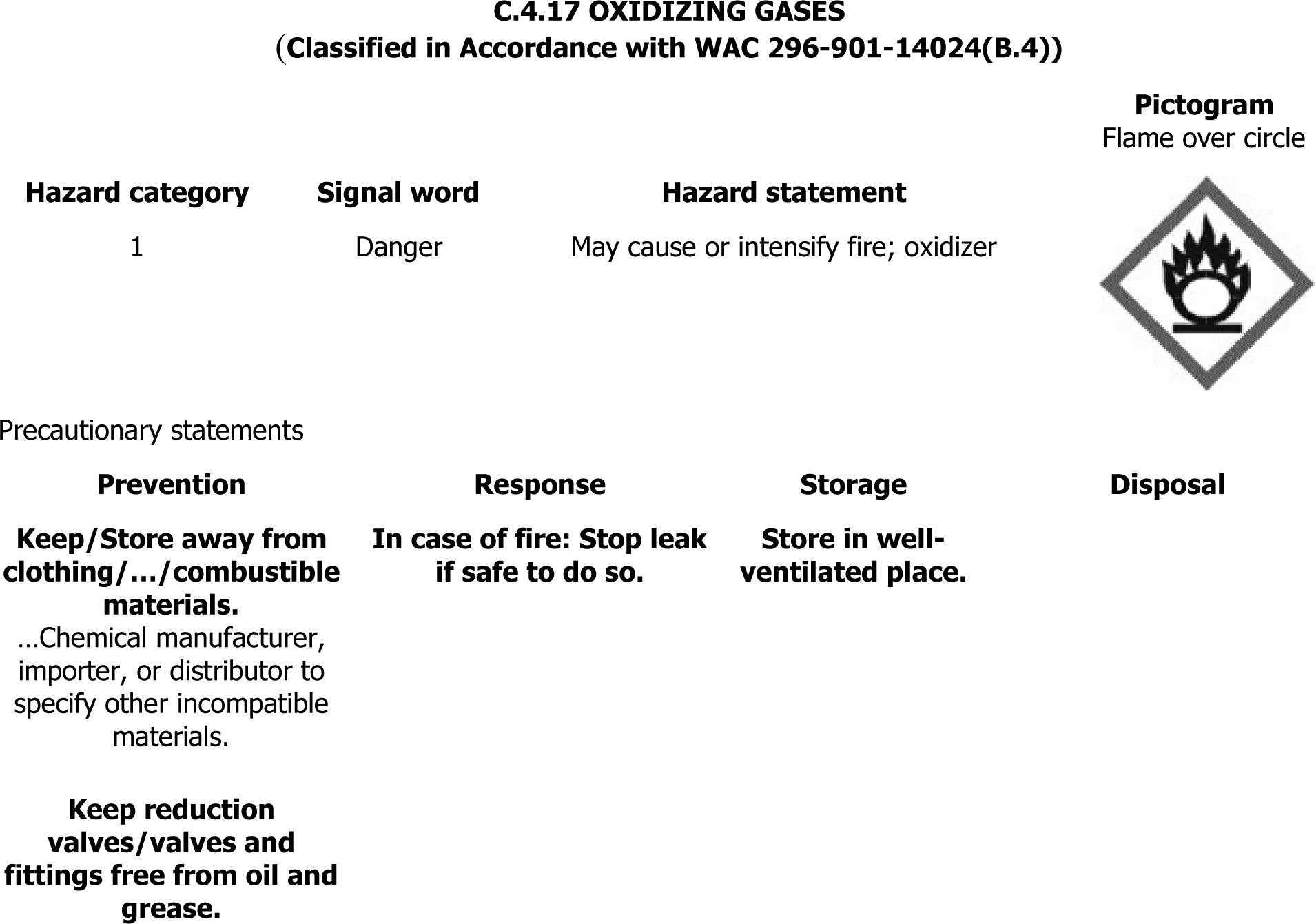

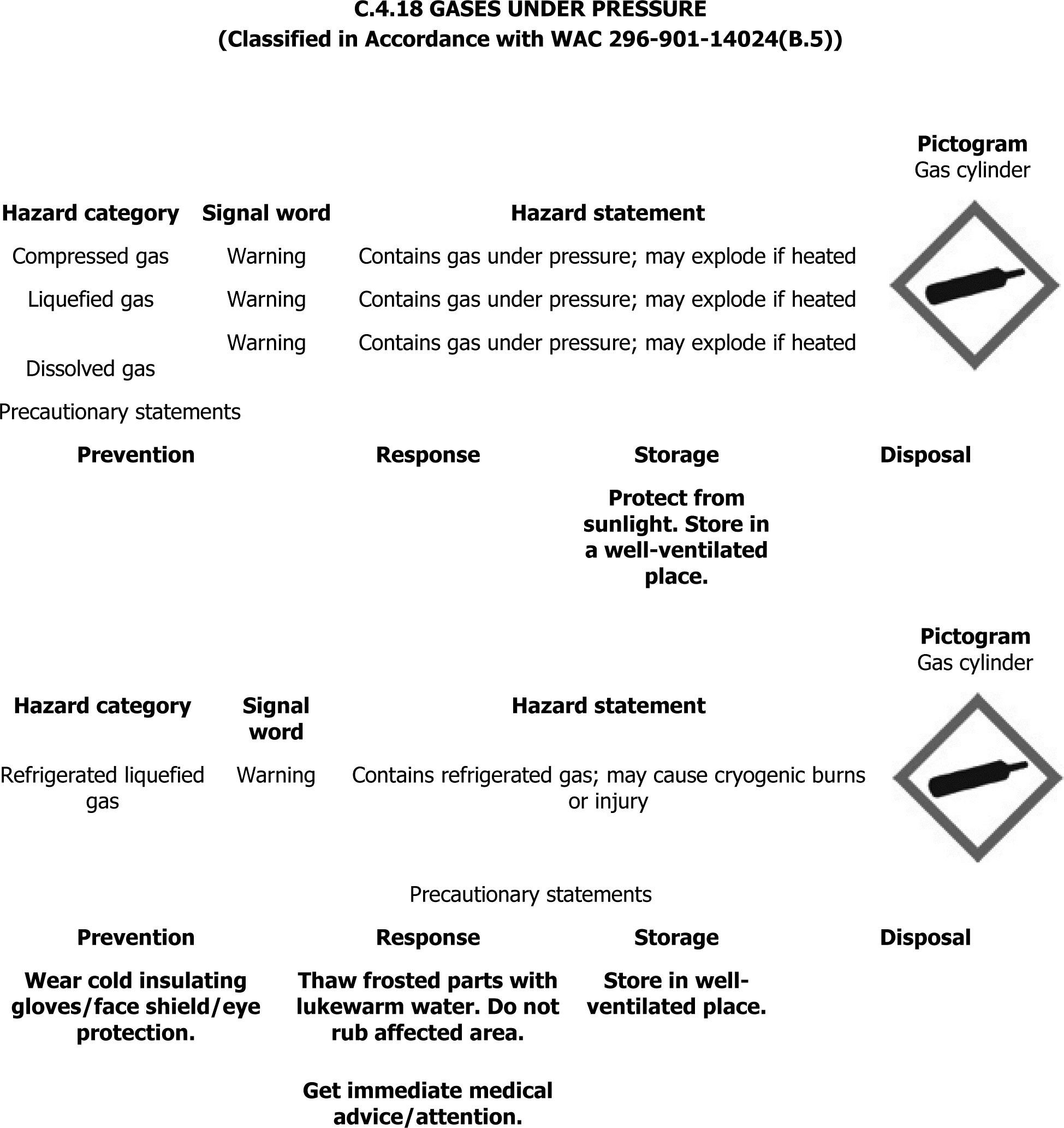

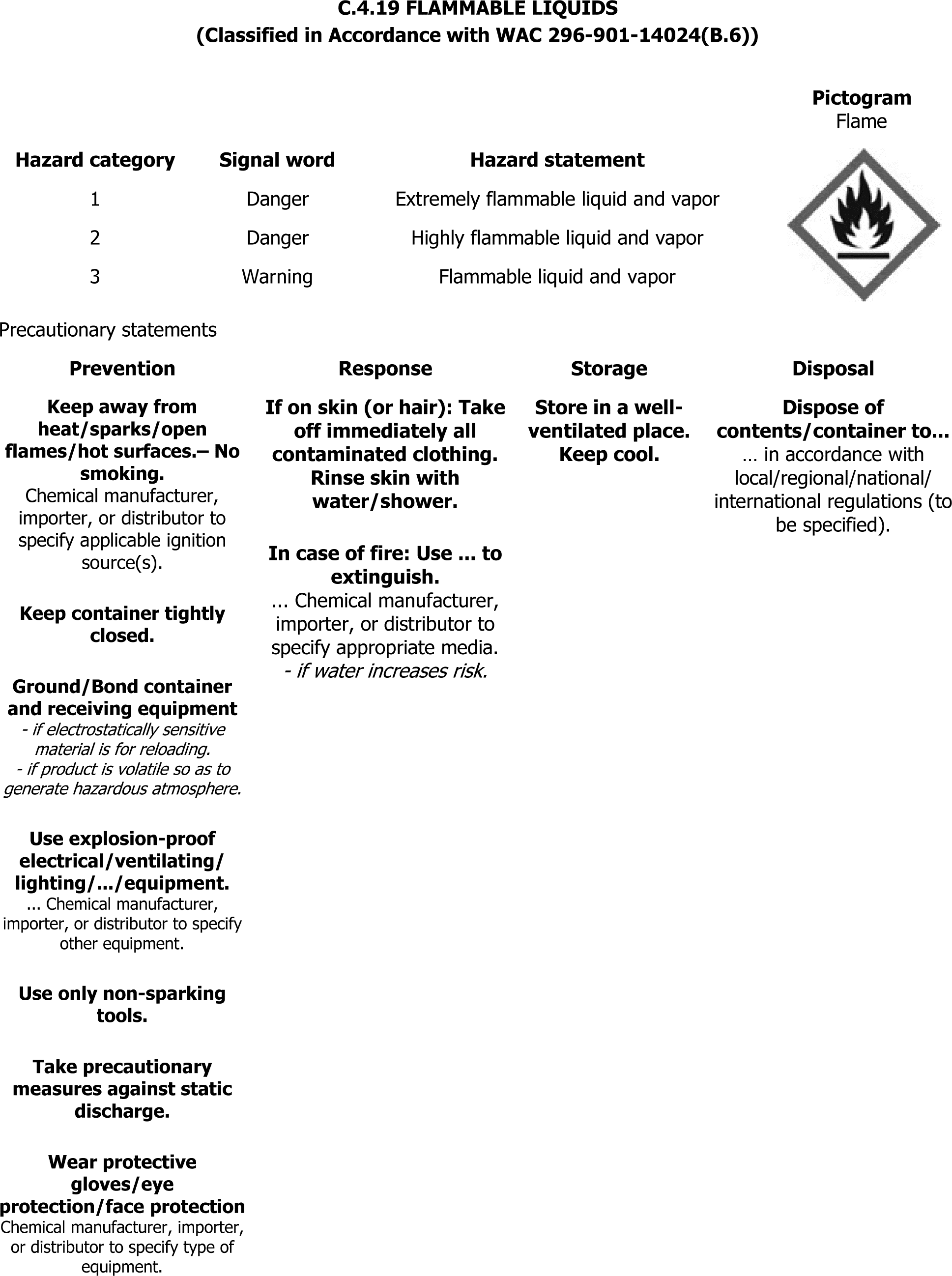

WAC 296-901-14024 Appendix B—Physical hazard criteria (mandatory).

• | Changed "≥" to "≤" in Table B.3.1. |

• | Deleted a "-" that was inadvertently put into Table B.7.1. |

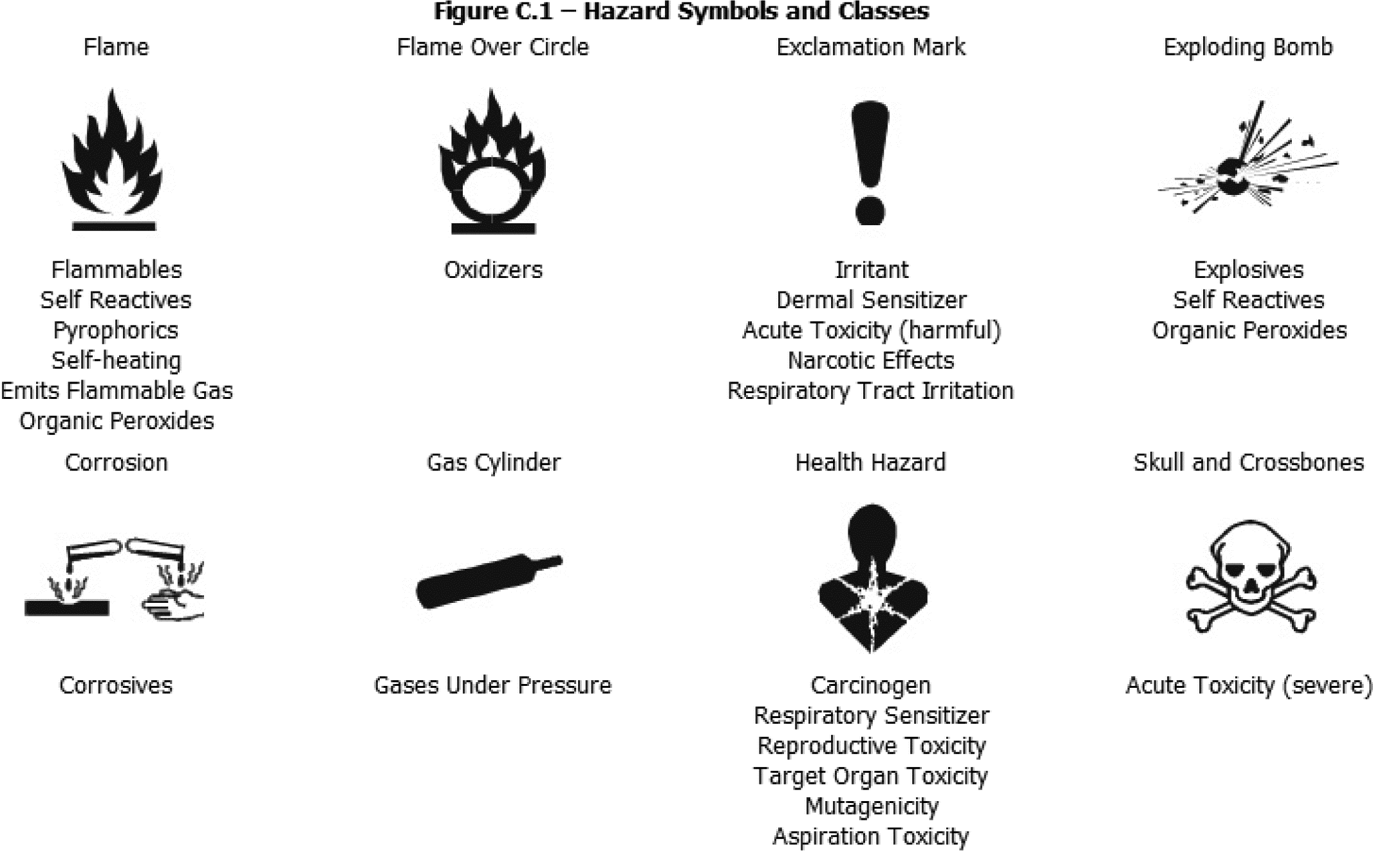

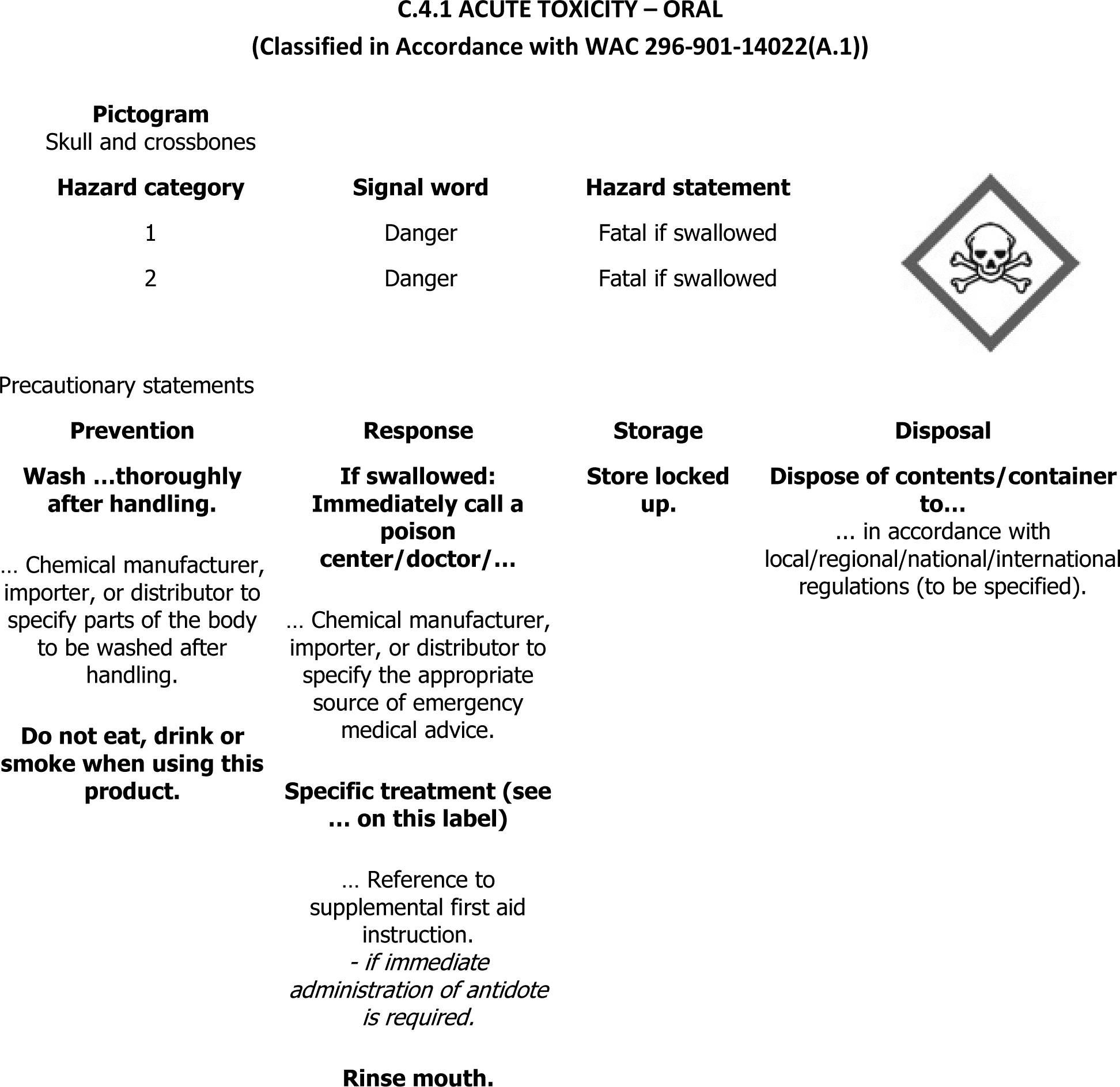

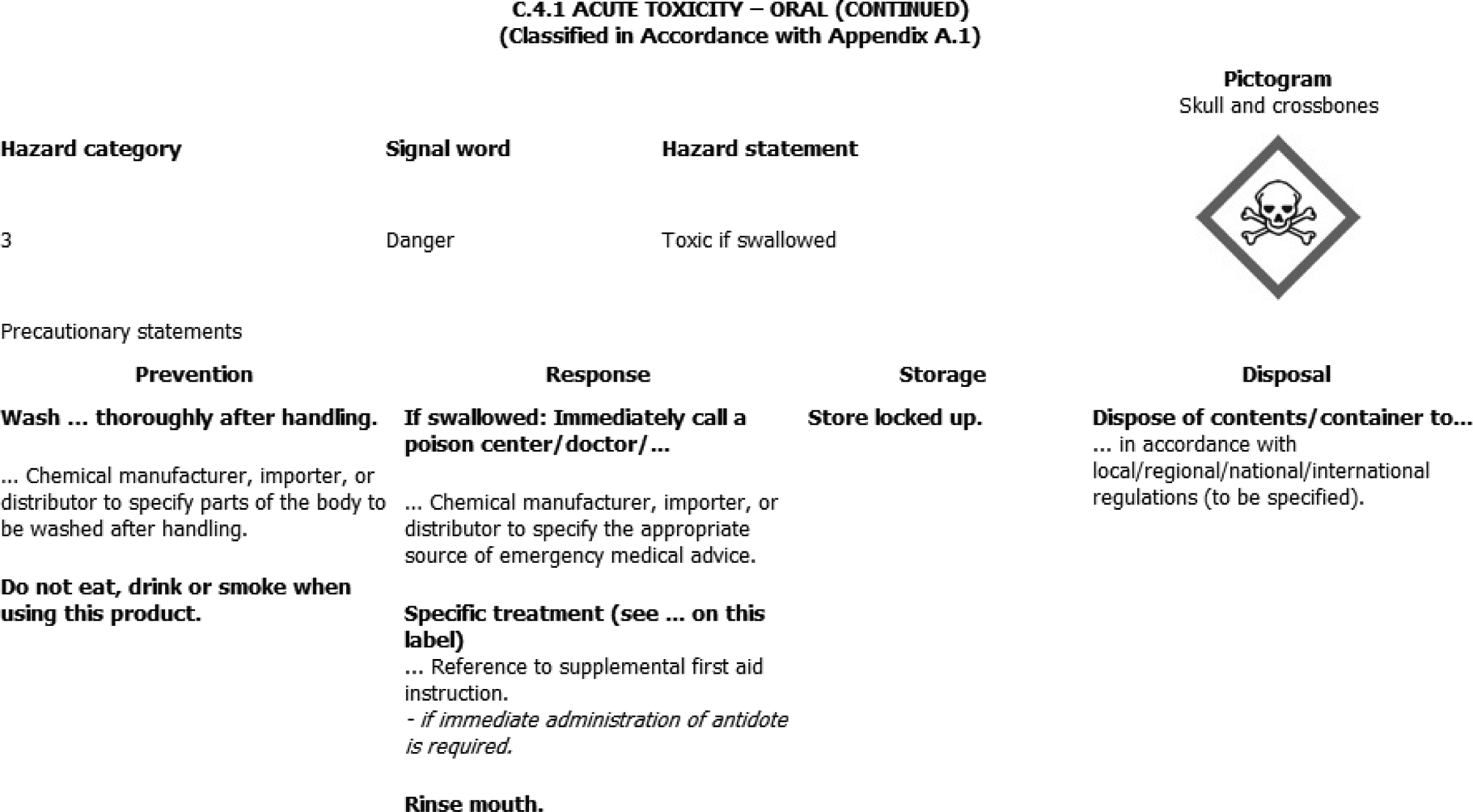

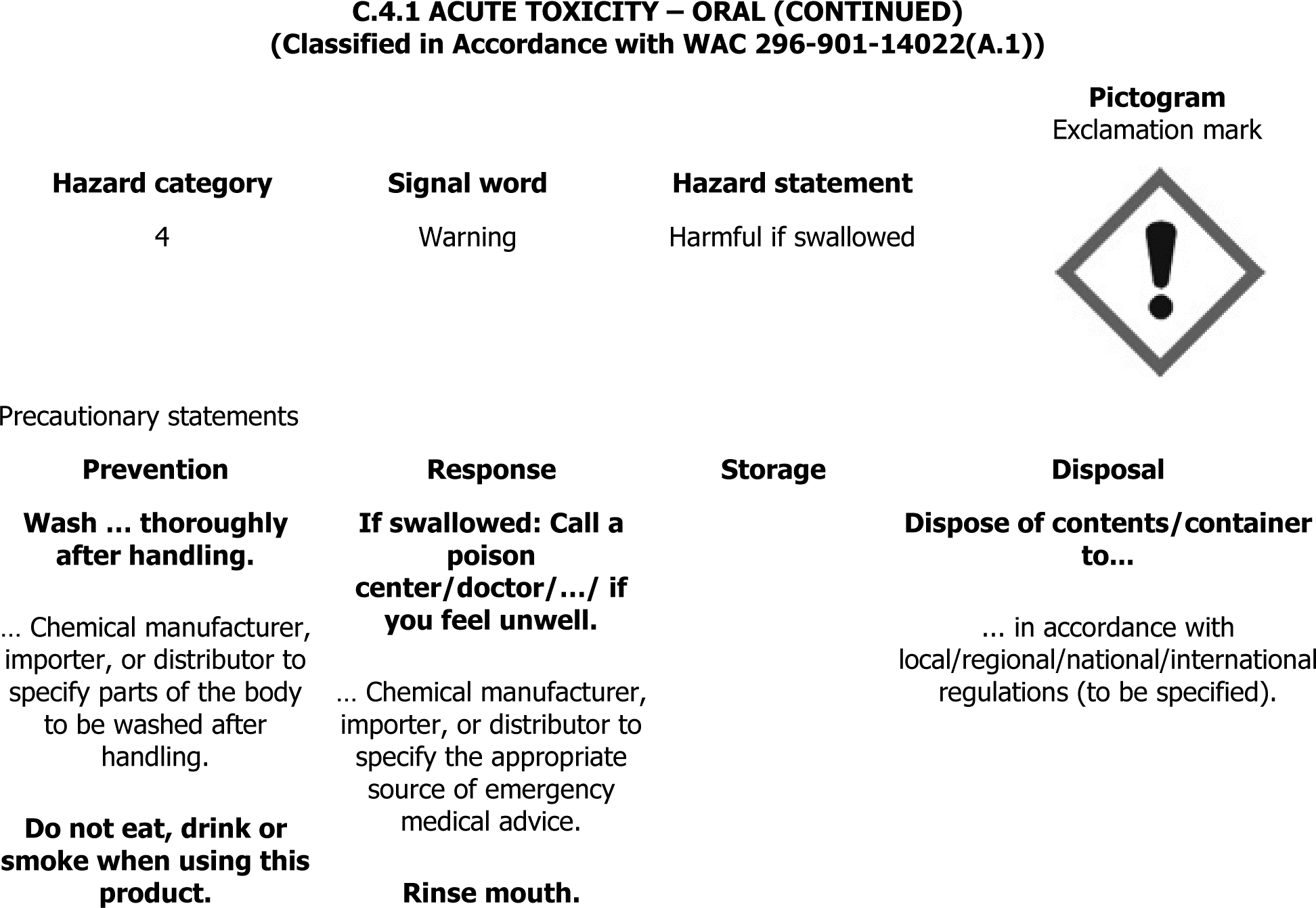

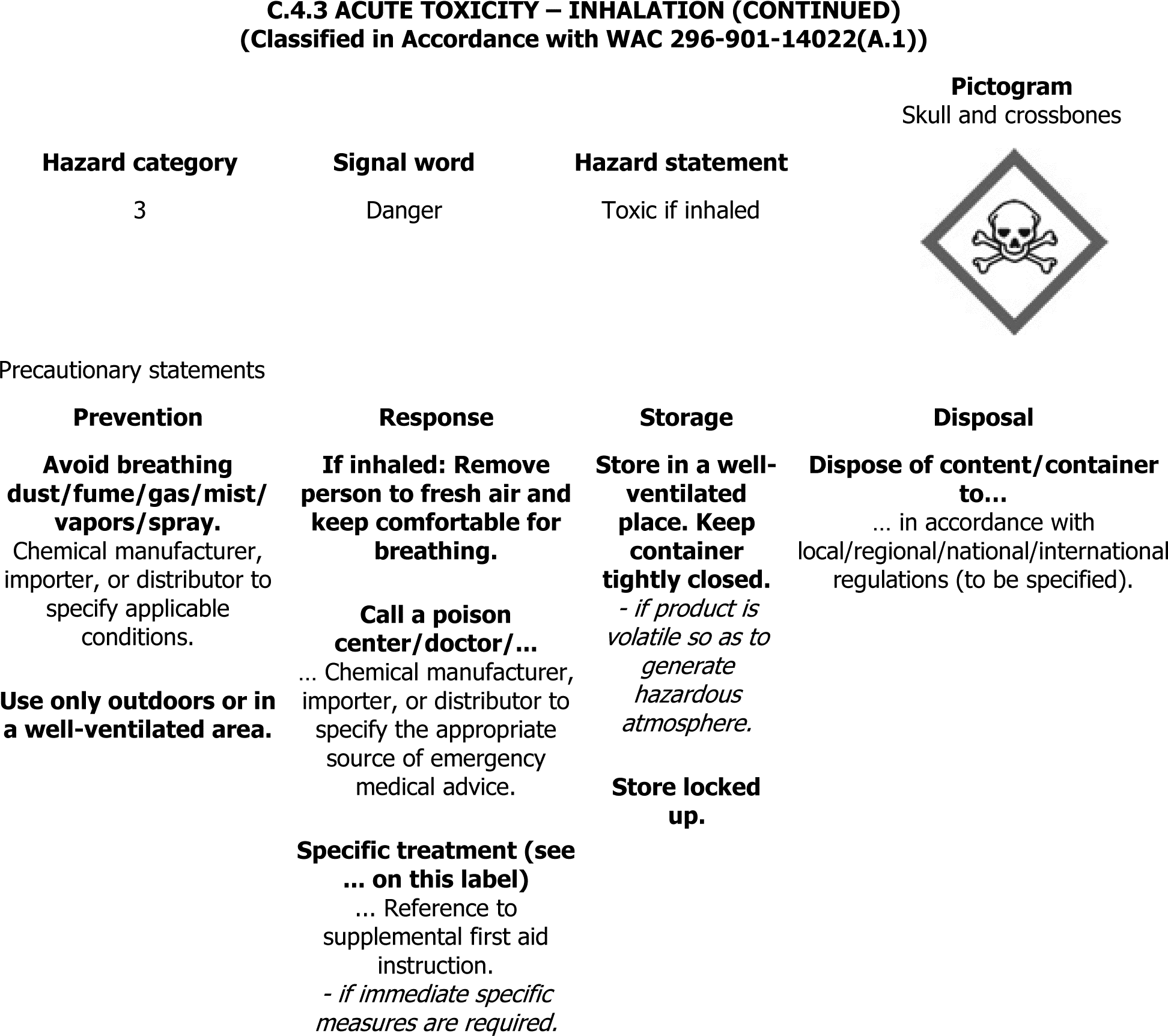

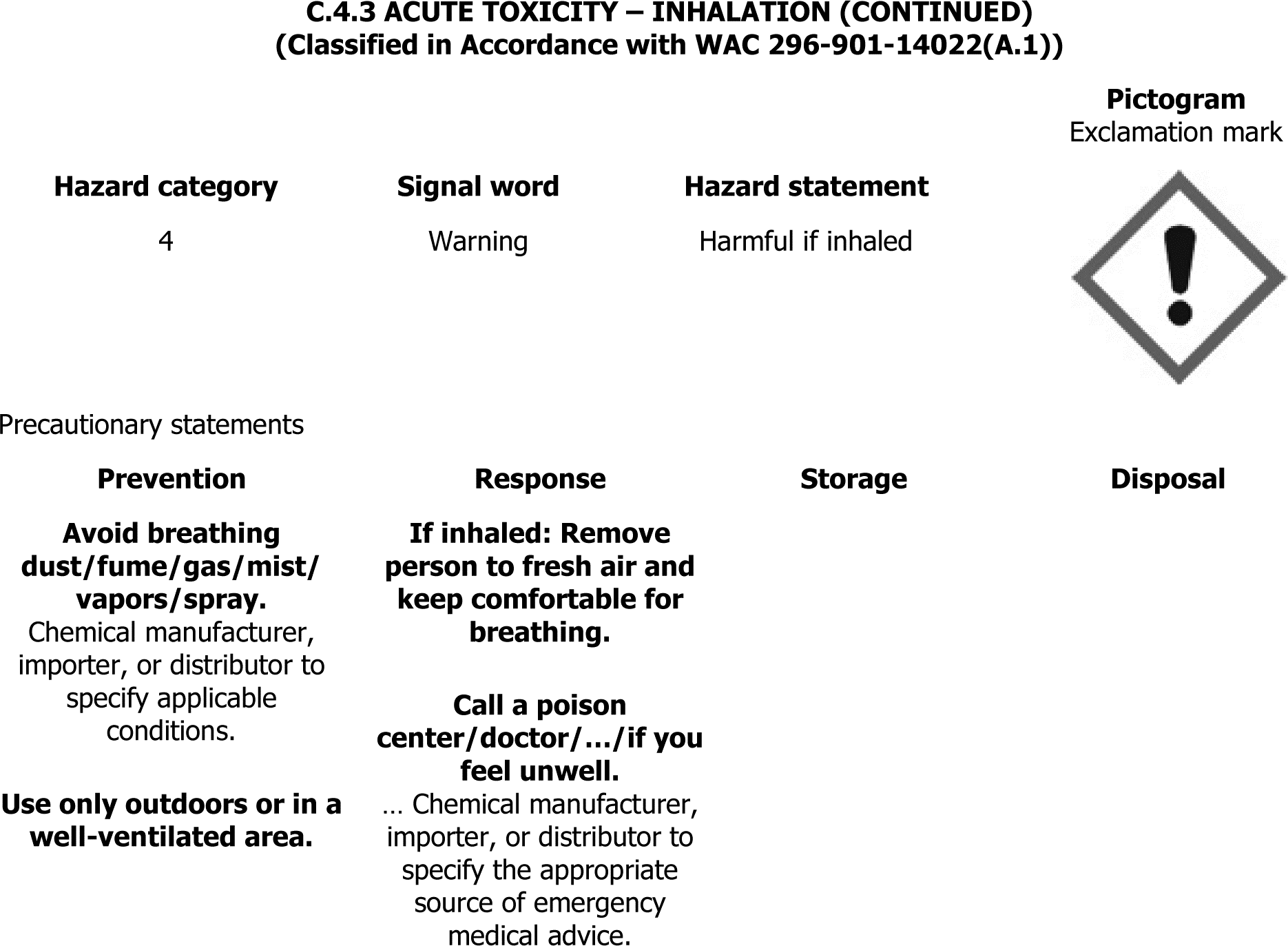

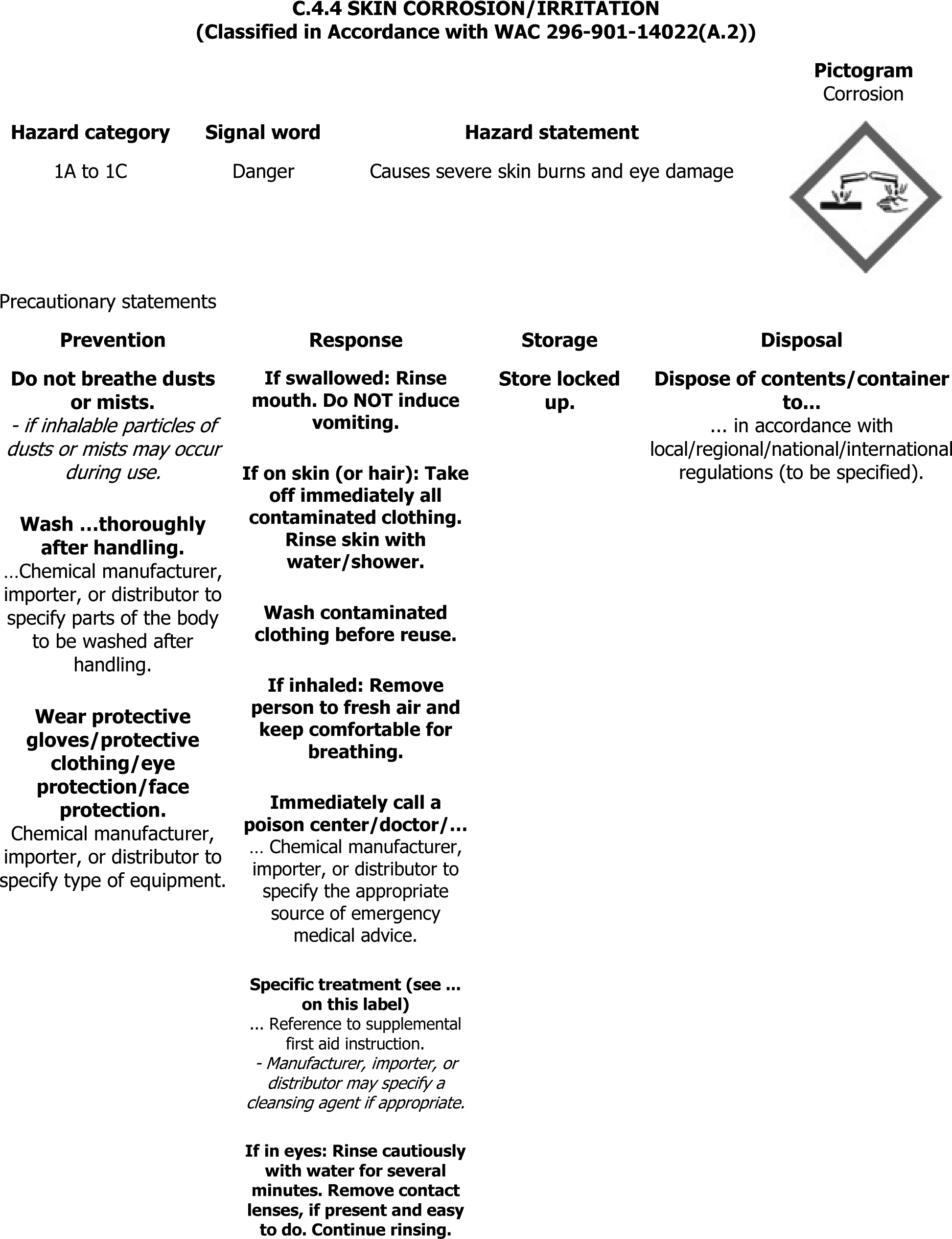

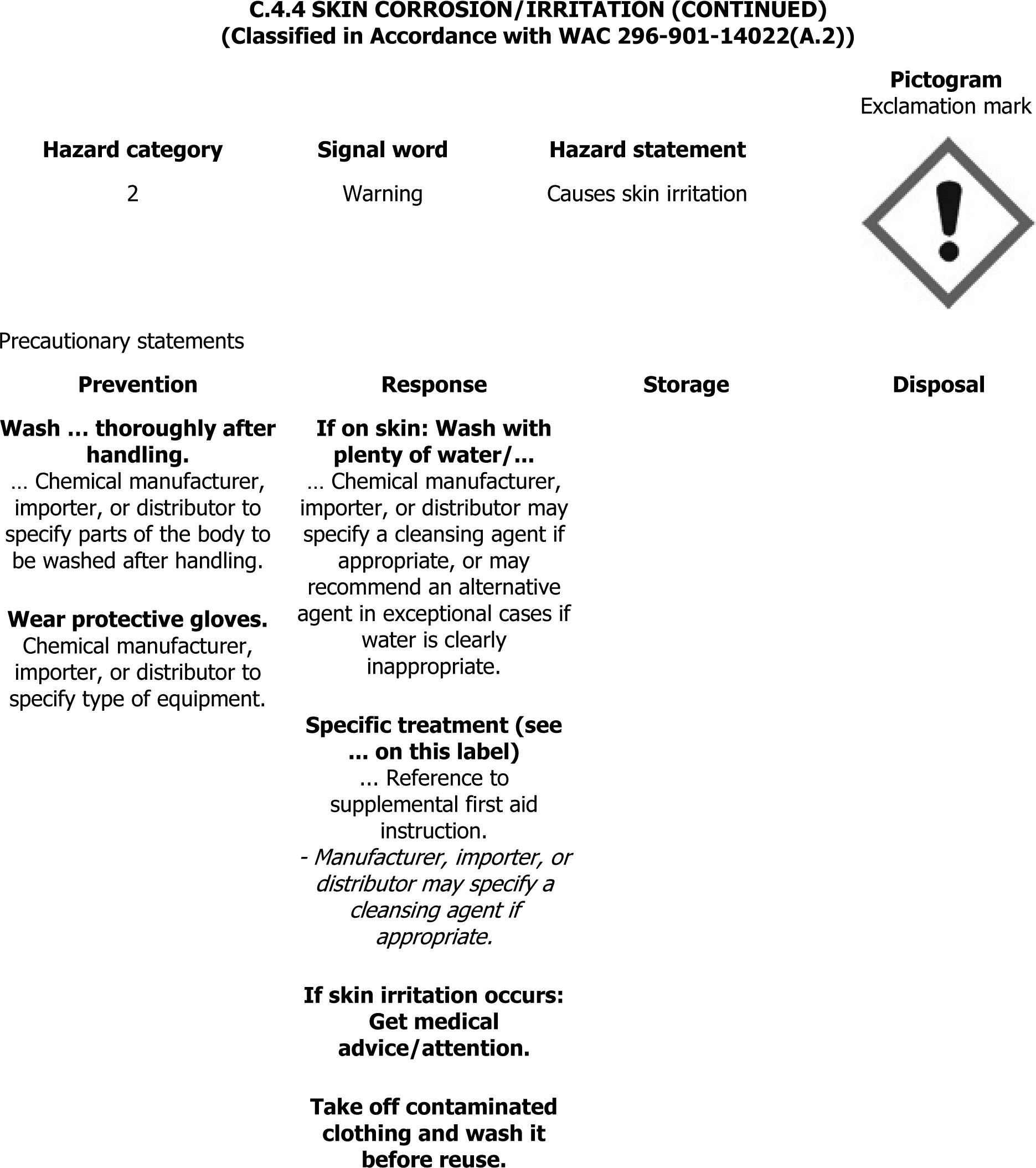

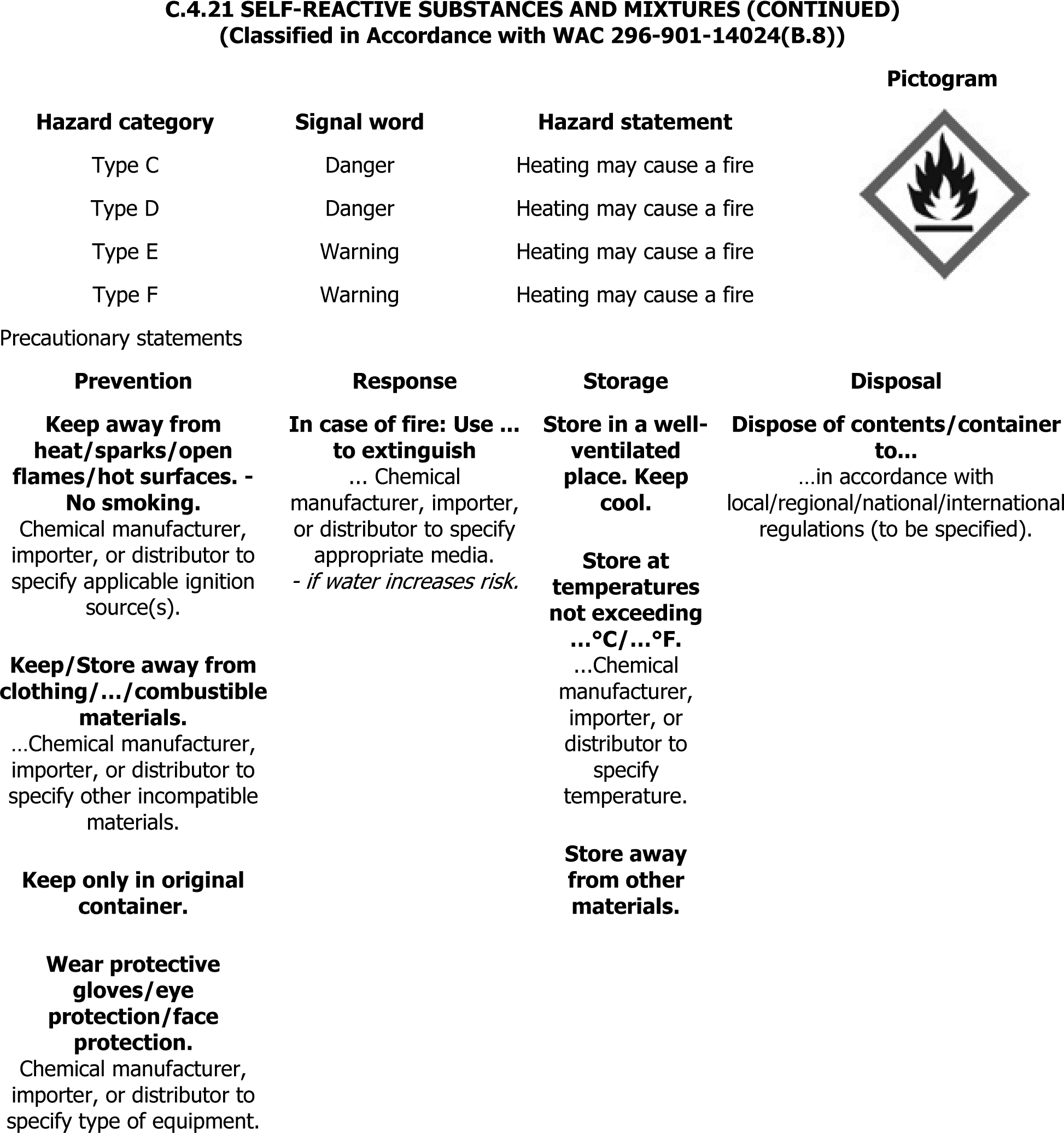

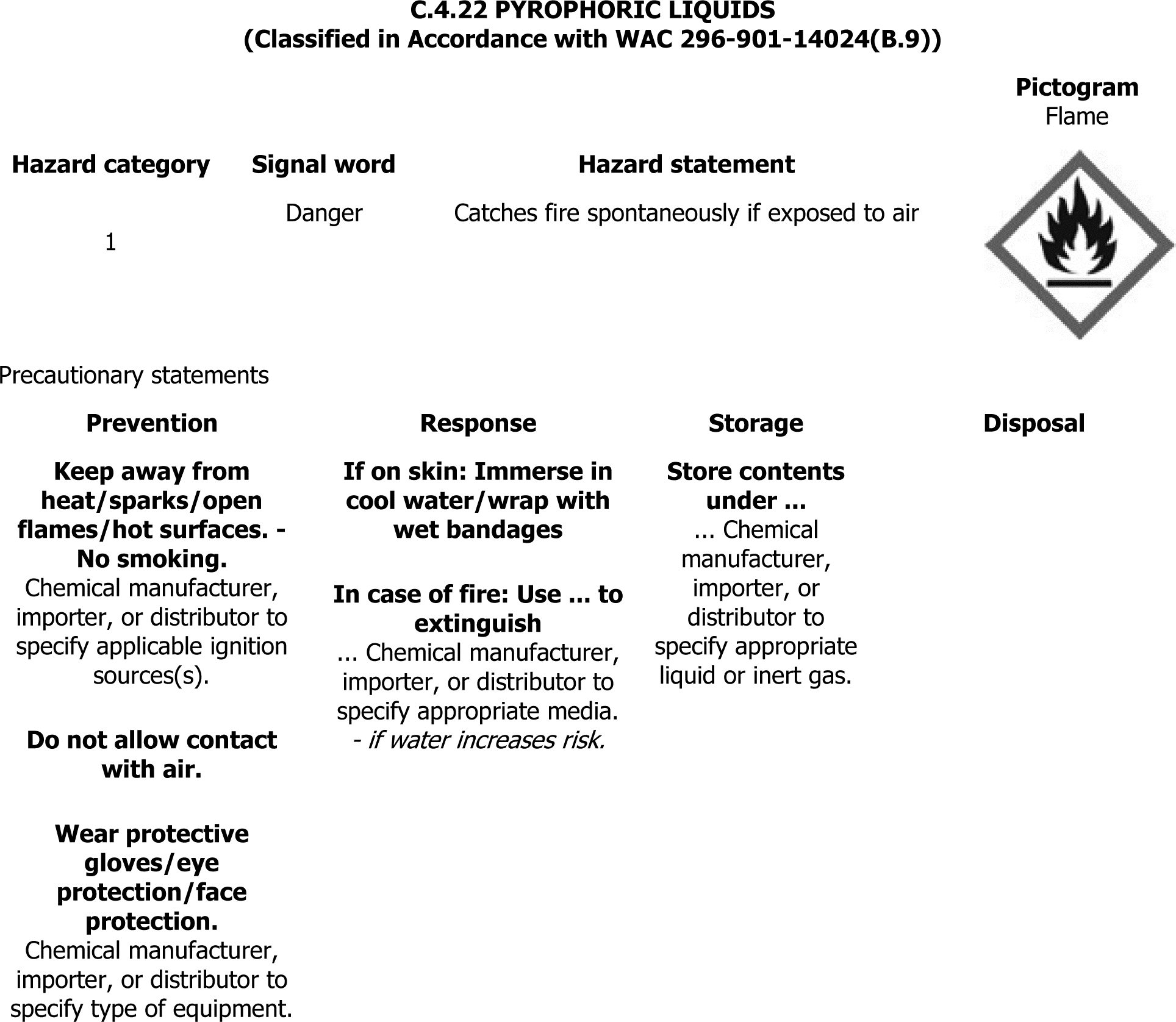

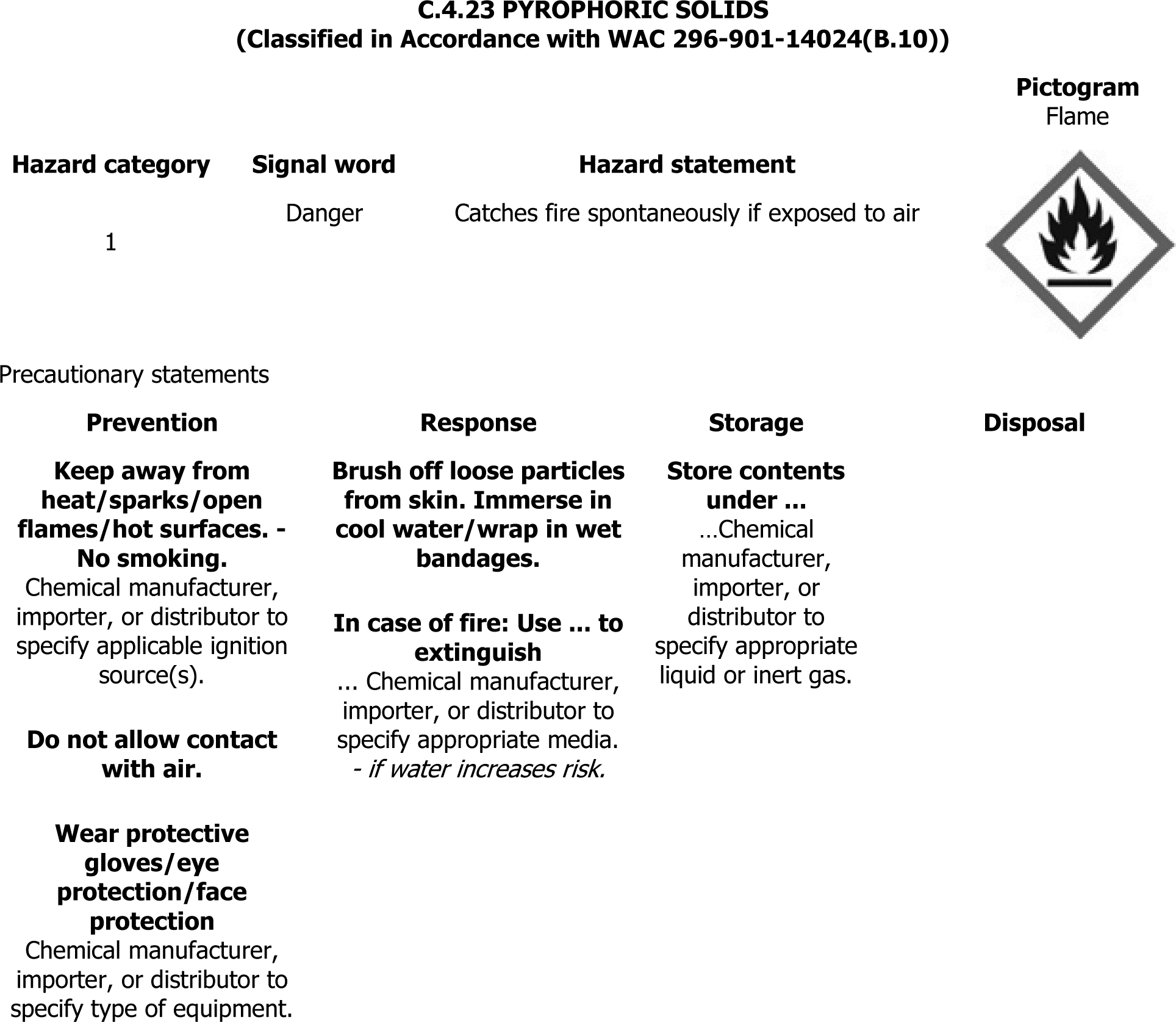

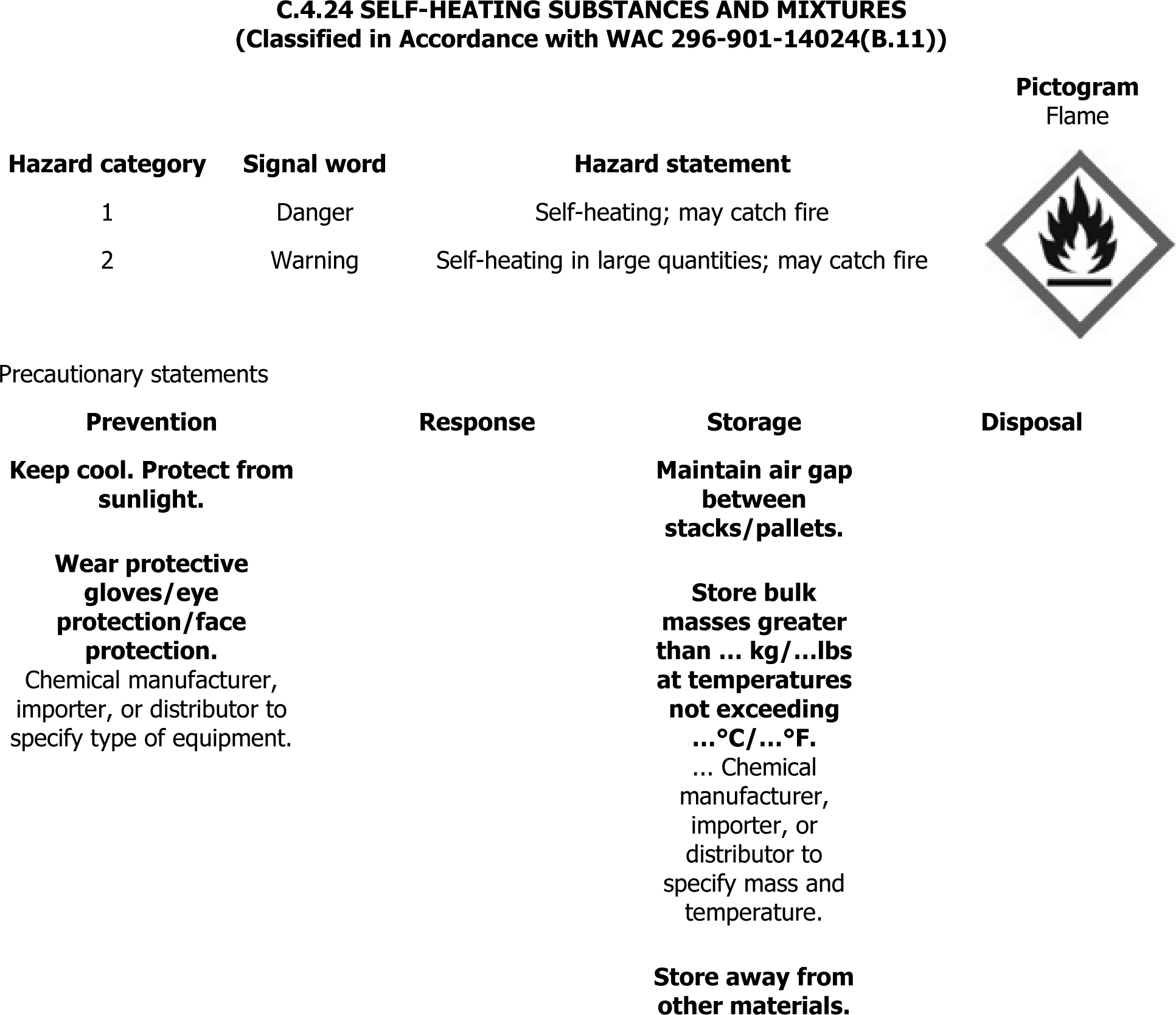

WAC 296-901-14026 Appendix C—Allocation of label elements (mandatory).

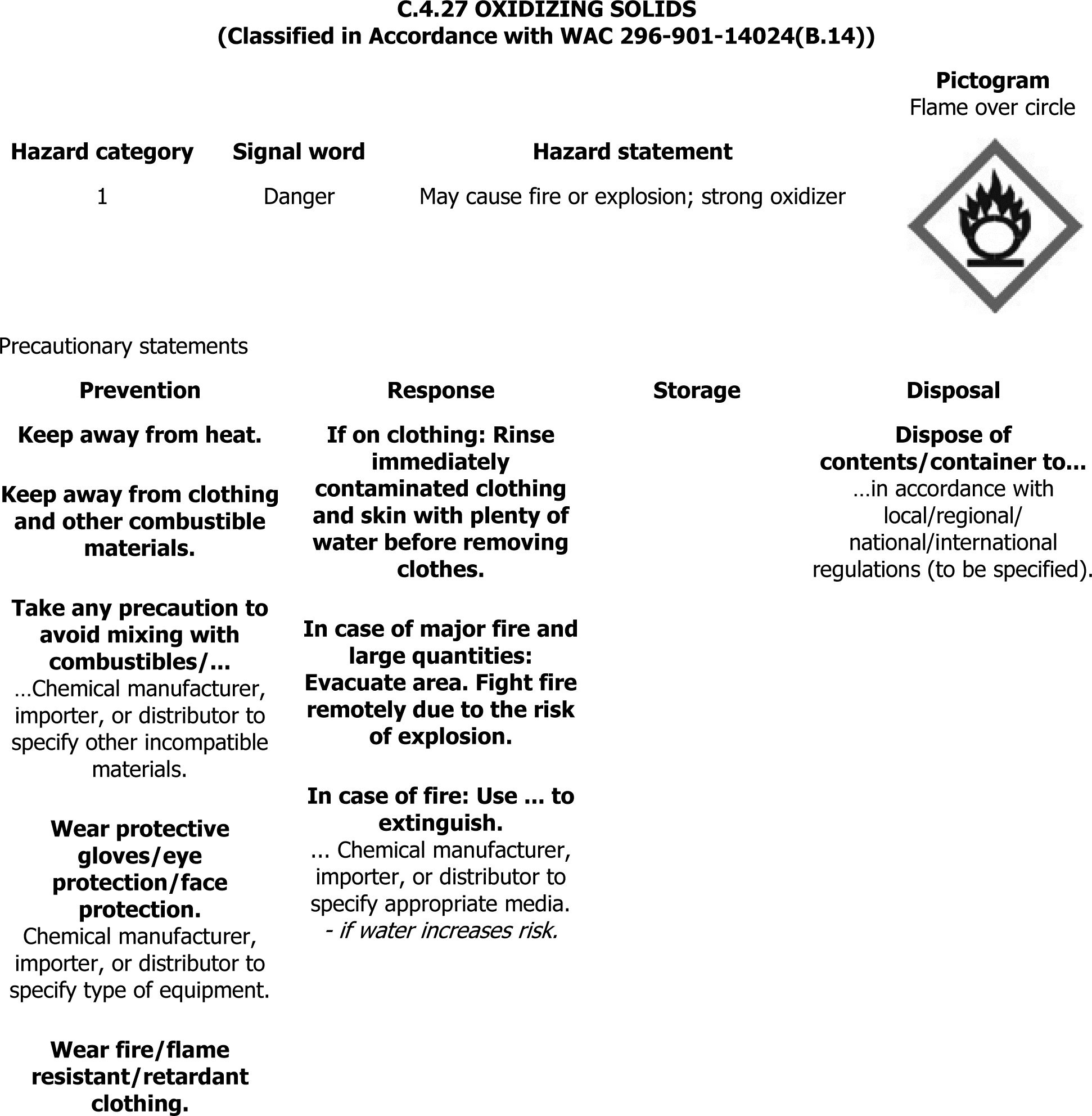

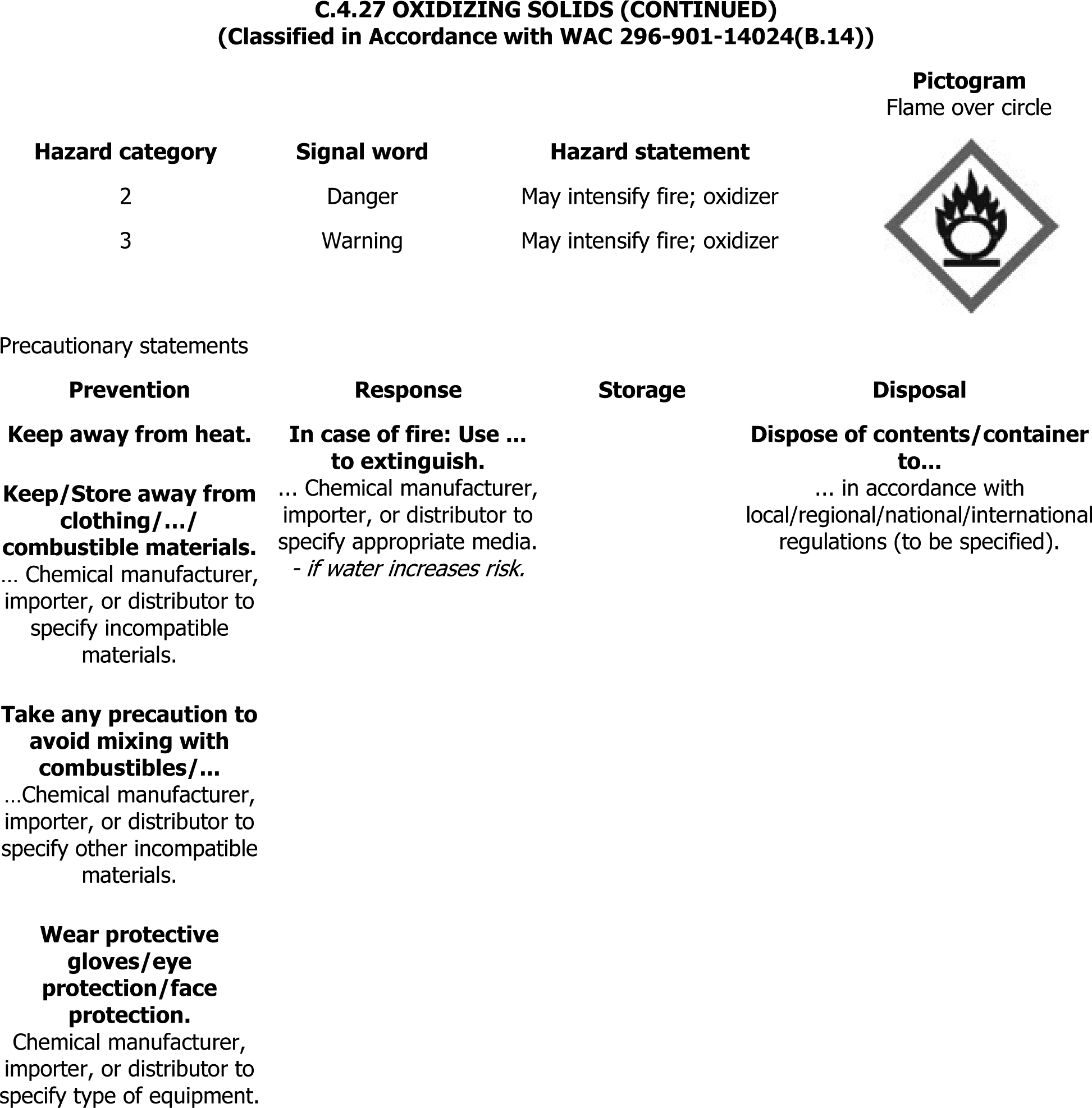

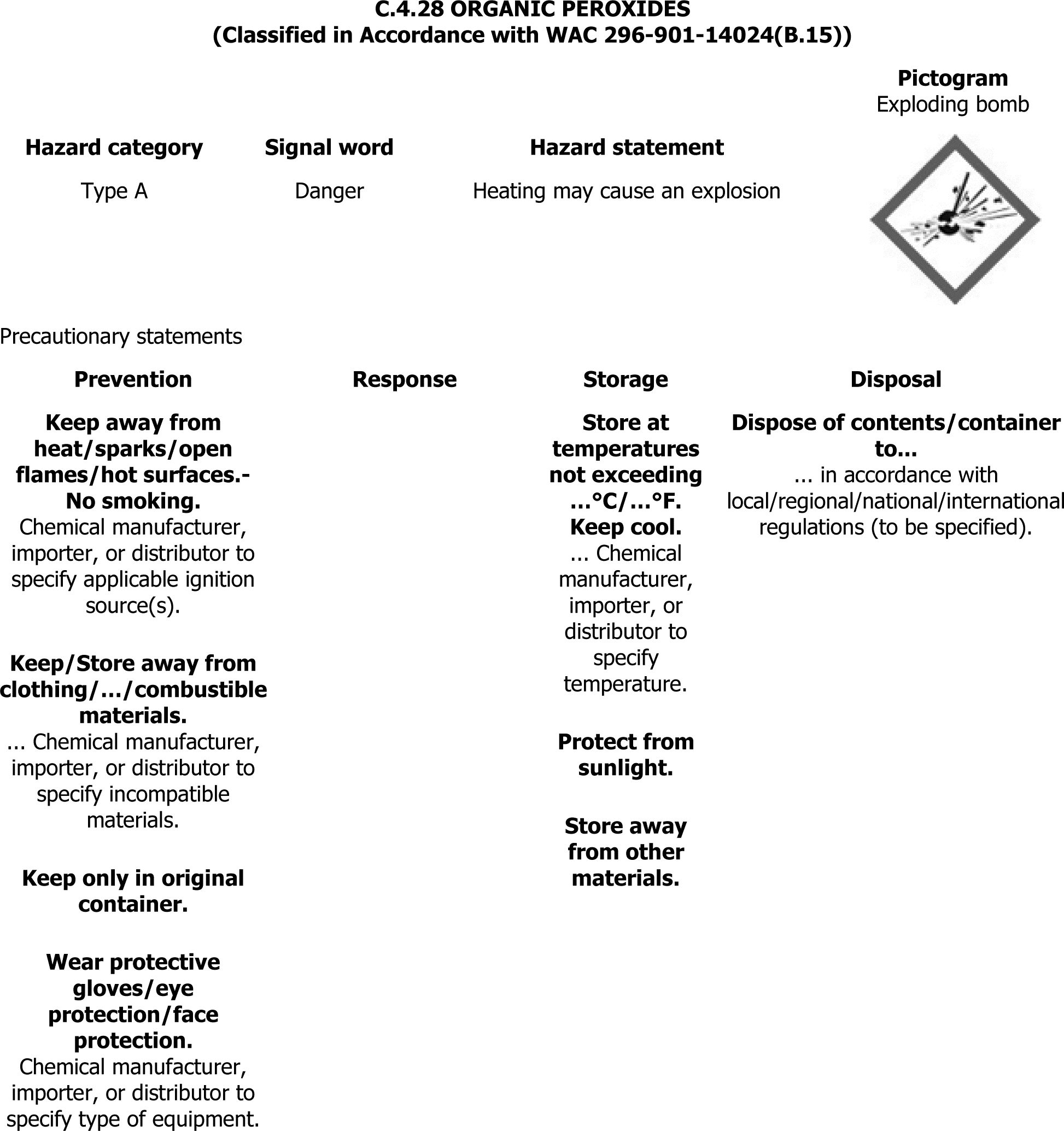

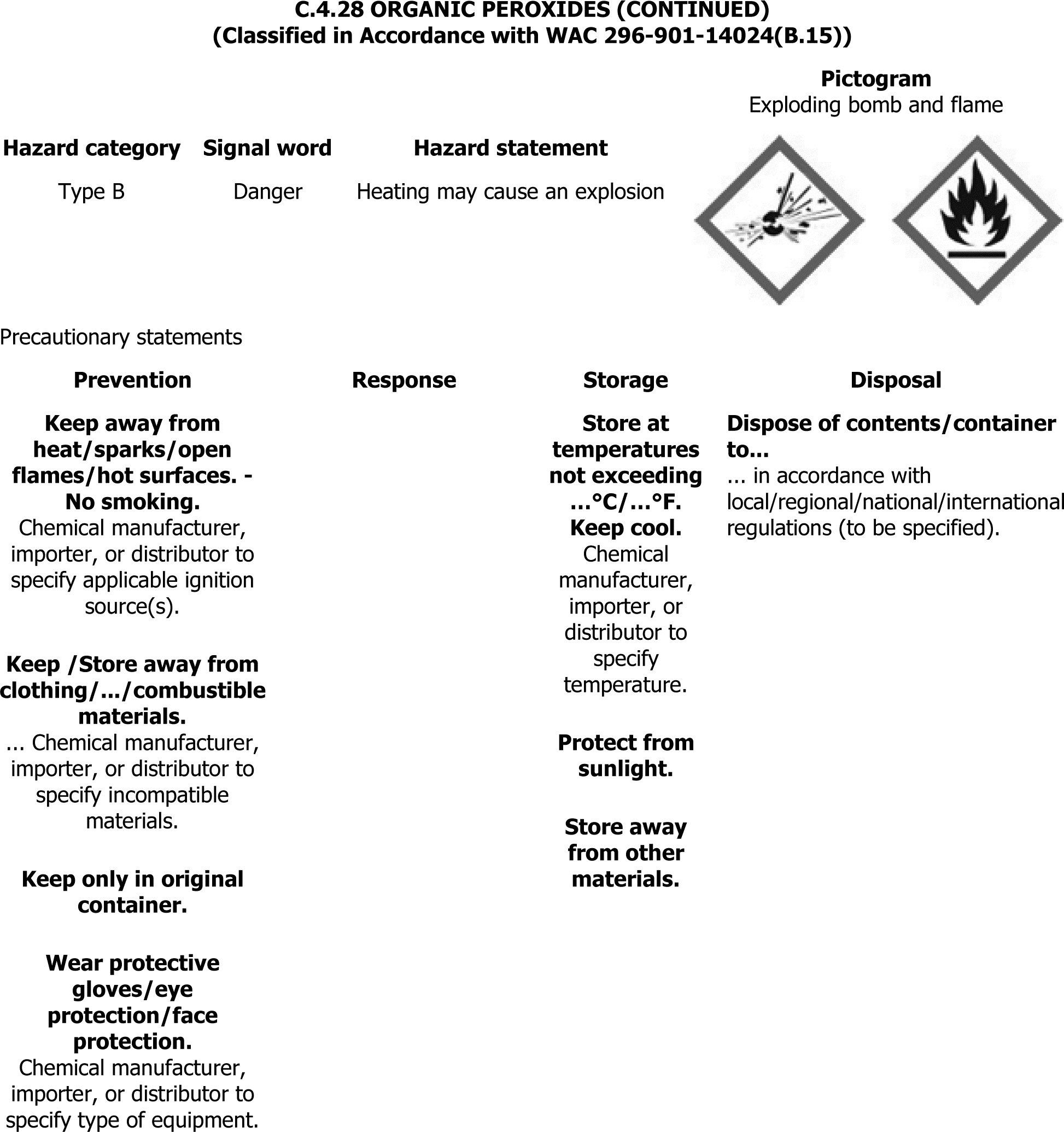

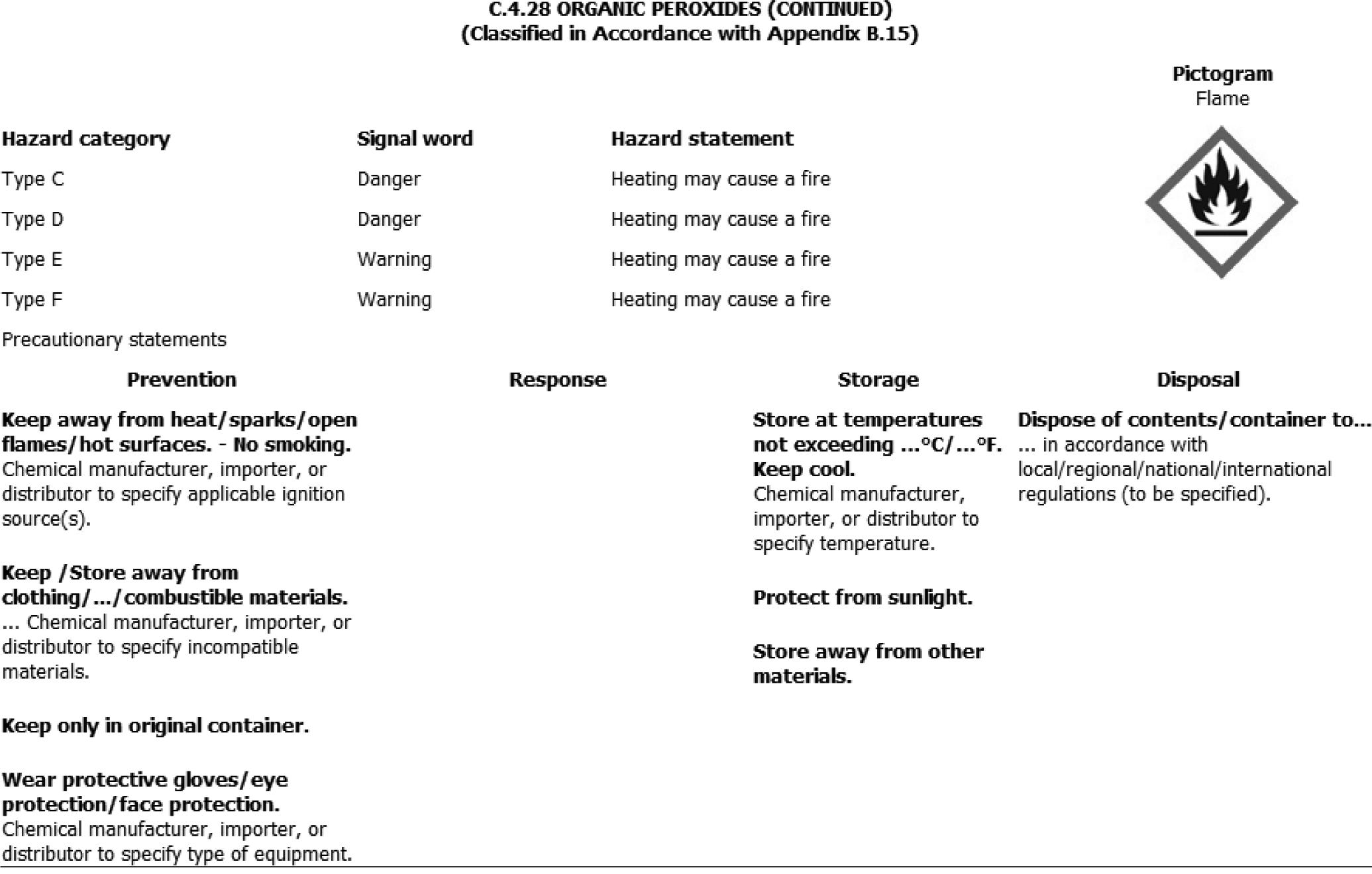

• | Added in illustration C.4.28 Organic Peroxides (continued) as it was inadvertently left out. |

• | Changed the references from OSHA to DOSH numbering in the footnotes. |

WAC 296-901-14028 Appendix D—Safety data sheets (mandatory).

• | Changed "=" to ["]≥["] in Table D-1 (2)(d). |

WAC 296-901-14032 Appendix F—Guidance for hazard classifications regarding carcinogenicity (nonmandatory).

• | In Part A and Part D, changed "a2u globulin" to "α2u-globulin." |

New Sections:

Chapter 296-848 WAC, Arsenic:

WAC 296-848-30007 Communication of hazards.

• | Requirements relating [to] chemical manufacturers, importers, and employers on providing employees information about the hazardous chemicals to which they are exposed, by means of a hazard communication program, labels, other forms of warning, safety data sheets, and training located in this section. These requirements are federally driven and consistent with the provisions of the United Nations GHS, Revision 3. |

Chapter 296-855 WAC, Ethylene oxide:

WAC 296-855-420 Communication of hazards.

• | Requirements relating [to] chemical manufacturers, importers, and employers on providing employees information about the hazardous chemicals to which they are exposed, by means of a hazard communication program, labels, other forms of warning, safety data sheets, and training located in this section. These requirements are federally driven and consistent with the provisions of the United Nations GHS, Revision 3. |

Chapter 296-856 WAC, Formaldehyde:

WAC 296-856-420 Communication of hazards.

• | No requirements in this section. |

WAC 296-856-42010 Hazard communication—General.

• | Requirements relating [to] chemical manufacturers, importers, and employers on providing employees information about the hazardous chemicals to which they are exposed, by means of a hazard communication program, labels, other forms of warning, safety data sheets, and training located in this section. These requirements are federally driven and consistent with the provisions of the United Nations GHS, Revision 3. |

Reasons Supporting Proposal: OSHA adopted the final rules updating its hazard communication standard into alignment with GHS. The department is required to update our rules to be at-least-as-effective-as OSHA.

Statutory Authority for Adoption: RCW 49.17.010, 49.17.040, 49.17.050, and 49.17.060.

Statute Being Implemented: Chapter 49.17 RCW.

Rule is necessary because of federal law, 29 C.F.R. 1910 Subpart Z.

Name of Proponent: Department of labor and industries, governmental.

Name of Agency Personnel Responsible for Drafting: Jeff Killip, Tumwater, Washington, (360) 902-5530; Implementation and Enforcement: Anne F. Soiza, Tumwater, Washington, (360) 902-5090.

No small business economic impact statement has been prepared under chapter 19.85 RCW. The proposed changes are exempt under RCW 19.85.061 because they are solely for the purpose of conformity or compliance with federal statute, 29 C.F.R. 1910 Subpart Z and DOSH is required to be as [at]-least-as-effective-as OSHA. Additionally, no new costs are imposed by this proposed rule.

A cost-benefit analysis is not required under RCW 34.05.328. Changes are exempt when: Explicitly and specifically dictated by federal statute; correct typographical errors or clarifies language without changing its effect; or are adopted from national consensus codes, RCW 34.05.328 (5)(b)(iii) - (v). No new costs are imposed by this proposed rule.

November 4, 2013

Joel Sacks

Director

PART E

HAZARDOUS MATERIALS, FLAMMABLE ((AND COMBUSTIBLE)) LIQUIDS, SPRAY FINISHING

Hazardous Materials

AMENDATORY SECTION (Amending WSR 91-24-017, filed 11/22/91, effective 12/24/91)

WAC 296-24-32003 Bulk oxygen systems.

(1) Definitions. As used in this section: A bulk oxygen system is an assembly of equipment, such as oxygen storage containers, pressure regulators, safety devices, vaporizers, manifolds, and interconnecting piping, which has storage capacity of more than 13,000 cubic feet of oxygen, normal temperature and pressure (NTP), connected in service or ready for service, or more than 25,000 cubic feet of oxygen (NTP) including unconnected reserves on hand at the site. The bulk oxygen system terminates at the point where oxygen at service pressure first enters the supply line. The oxygen containers may be stationary or movable, and the oxygen may be stored as gas or liquid.

(2) Location.

(a) General. Bulk oxygen storage systems shall be located above ground out of doors, or shall be installed in a building of noncombustible construction, adequately vented, and used for that purpose exclusively. The location selected shall be such that containers and associated equipment shall not be exposed by electric power lines, flammable ((or combustible)) liquid ((lines,)) or ((flammable)) gas lines.

(b) Accessibility. The system shall be located so that it is readily accessible to mobile supply equipment at ground level and to authorized personnel.

(c) Leakage. Where oxygen is stored as a liquid, noncombustible surfacing shall be provided in an area in which any leakage of liquid oxygen might fall during operation of the system and filling of a storage container. For purposes of these standards, asphaltic or bituminous paving is considered to be combustible.

(d) Elevation. When locating bulk oxygen systems near above ground flammable ((or combustible)) liquid storage which may be either indoors or outdoors, it is advisable to locate the system on ground higher than the flammable ((or combustible)) liquid storage.

(e) Dikes. Where it is necessary to locate a bulk oxygen system on ground lower than adjacent flammable ((or combustible)) liquid storage suitable means shall be taken (such as by diking, diversion curbs, or grading) with respect to the adjacent flammable ((or combustible)) liquid storage to prevent accumulation of liquids under the bulk oxygen system.

(3) Distance between systems and exposures.

(a) General. The minimum distance from any bulk oxygen storage container to exposures, measured in the most direct line except as indicated in (((3)))(f) and (g) of this ((section)) subsection shall be as indicated in (((3)(b) to)) (b) through (r) of this ((section)) subsection inclusive.

(b) Combustible structures. Fifty feet from any combustible structures.

(c) Fire resistive structures. Twenty-five feet from any structures with fire-resistive exterior walls or sprinklered buildings or other construction, but not less than one-half the height of adjacent side wall of the structure.

(d) Openings. At least ((10)) ten feet from any opening in adjacent walls of fire resistive structures. Spacing from such structures shall be adequate to permit maintenance, but shall not be less than ((1)) one foot.

(e) Flammable liquid storage above ground.

Distance (feet) |

Capacity (gallons) |

|||

50 |

_____ |

0-1000 |

||

90 |

_____ |

1001 or more |

||

(f) Flammable liquid storage below ground.

Distance measured horizontally from oxygen storage container to flammable liquid tank (feet) |

Distance from oxygen storage container to filling and vent connections or openings to flammable liquid tank (feet) |

Capacity gallons |

|||||

15 |

_____ |

50 |

_____ |

0-1000 |

|||

30 |

_____ |

50 |

_____ |

1001 or more |

|||

(g) ((Combustible)) Flammable liquid storage above ground.

Distance (feet) |

Capacity (gallons) |

||||

25 |

_____ |

0-1000 |

|||

50 |

_____ |

1001 or more |

|||

(h) ((Combustible)) Flammable liquid storage below ground.

Distance measured horizontally from oxygen storage container to ((combustible)) flammable liquid tank (feet) |

Distance from oxygen storage container to filling and vent connections or openings to ((combustible)) flammable liquid tank (feet) |

||||

15 |

_____ |

40 |

|||

(i) Flammable gas storage. (Such as compressed flammable gases, liquefied flammable gases and flammable gases in low pressure gas holders):

Distance (feet) |

Capacity (cu. ft. NTP) |

||||

50 |

_____ |

Less than 5000 |

|||

90 |

_____ |

5000 or more |

|||

(j) Highly combustible materials. Fifty feet from solid materials which burn rapidly, such as excelsior or paper.

(k) Slow-burning materials. Twenty-five feet from solid materials which burn slowly, such as coal and heavy timber.

(l) Ventilation. Seventy-five feet in one direction and ((35)) thirty-five feet in approximately 90° direction from confining walls (not including firewalls less than ((20)) twenty feet high) to provide adequate ventilation in courtyards and similar confining areas.

(m) Congested areas. Twenty-five feet from congested areas such as offices, lunchrooms, locker rooms, time clock areas, and similar locations where people may congregate.

(n) Public areas. Fifty feet from places of public assembly.

(o) Patients. Fifty feet from areas occupied by nonambulatory patients.

(p) Sidewalks. Ten feet from any public sidewalk.

(q) Adjacent property. Five feet from any line of adjoining property.

(r) Exceptions. The distances in (((3)))(b), (c), (e) ((to)) through (k) inclusive, and (p) and (q) of this ((section)) subsection do not apply where protective structures such as firewalls of adequate height to safeguard the oxygen storage systems are located between the bulk oxygen storage installation and the exposure. In such cases, the bulk oxygen storage installation may be a minimum distance of ((1)) one foot from the firewall.

(4) Storage containers.

(a) Foundations and supports. Permanently installed containers shall be provided with substantial noncombustible supports on firm noncombustible foundations.

(b) Construction—Liquid. Liquid oxygen storage containers shall be fabricated from materials meeting the impact test requirements of paragraph UG-84 of ASME Boiler and Pressure Vessel Code, Section VIII—Unfired Pressure Vessels—1968. Containers operating at pressures above ((15)) fifteen pounds per square inch gage (p.s.i.g.) shall be designed, constructed, and tested in accordance with appropriate requirements of ASME Boiler and Pressure Vessel Code, Section VII—Unfired Pressure Vessels—1968. Insulation surrounding the liquid oxygen container shall be noncombustible.

(c) Construction—Gaseous. High-pressure gaseous oxygen containers shall comply with one of the following:

(i) Designed, constructed, and tested in accordance with appropriate requirements of ASME Boiler and Pressure Vessel Code, Section VIII—Unfired Pressure Vessels—1968.

(ii) Designed, constructed, tested, and maintained in accordance with DOT specifications and regulations.

(5) Piping, tubing, and fittings.

(a) Selection. Piping, tubing, and fittings shall be suitable for oxygen service and for the pressures and temperatures involved.

(b) Specification. Piping and tubing shall conform to Section 2—Gas and Air Piping Systems of Code for Pressure Piping, ANSI, B31.1-1967 with addenda B31.10a-1969.

(c) Fabrication. Piping or tubing for operating temperatures below -20°F shall be fabricated from materials meeting the impact test requirements of paragraph UG-84 of ASME Boiler and Pressure Vessel Code, Section VIII—Unfired Pressure Vessels—1968, when tested at the minimum operating temperature to which the piping may be subjected in service.

(6) Safety relief devices.

(a) General. Bulk oxygen storage containers, regardless of design pressure shall be equipped with safety relief devices as required by the ASME code or the DOT specifications and regulations.

(b) DOT containers. Bulk oxygen storage containers designed and constructed in accordance with DOT specification shall be equipped with safety relief devices as required thereby.

(c) ASME containers. Bulk oxygen storage containers designed and constructed in accordance with the ASME Boiler and Pressure Vessel Code, Section VIII—Unfired Pressure Vessel—1968 shall be equipped with safety relief devices meeting the provisions of the Compressed Gas Association Pamphlet "Safety Relief Device Standards for Compressed Gas Storage Containers," S-1, Part 3.

(d) Insulation. Insulation casings on liquid oxygen containers shall be equipped with suitable safety relief devices.

(e) Reliability. All safety relief devices shall be so designed or located that moisture cannot collect and freeze in a manner which would interfere with proper operation of the device.

(7) Liquid oxygen vaporizers.

(a) Mounts and couplings. The vaporizer shall be anchored and its connecting piping be sufficiently flexible to provide for the effect of expansion and contraction due to temperature changes.

(b) Relief devices. The vaporizer and its piping shall be adequately protected on the oxygen and heating medium sections with safety relief devices.

(c) Heating. Heat used in an oxygen vaporizer shall be indirectly supplied only through media such as steam, air, water, or water solutions which do not react with oxygen.

(d) Grounding. If electric heaters are used to provide the primary source of heat, the vaporizing system shall be electrically grounded.

(8) Equipment assembly and installation.

(a) Cleaning. Equipment making up a bulk oxygen system shall be cleaned in order to remove oil, grease or other readily oxidizable materials before placing the system in service.

(b) Joints. Joints in piping and tubing may be made by welding or by use of flanged, threaded, slip, or compression fittings. Gaskets or thread sealants shall be suitable for oxygen service.

(c) Accessories. Valves, gages, regulators, and other accessories shall be suitable for oxygen service.

(d) Installation. Installation of bulk oxygen systems shall be supervised by personnel familiar with proper practices with reference to their construction and use.

(e) Testing. After installation all field erected piping shall be tested and proved gas tight at maximum operating pressure. Any medium used for testing shall be oil free and nonflammable.

(f) Security. Storage containers, piping, valves, regulating equipment, and other accessories shall be protected against physical damage and against tampering.

(g) Venting. Any enclosure containing oxygen control or operating equipment shall be adequately vented.

(h) Placarding. The bulk oxygen storage location shall be permanently placarded to indicate: "OXYGEN—NO SMOKING—NO OPEN FLAMES," or an equivalent warning.

(i) Electrical wiring. Bulk oxygen installations are not hazardous locations as defined and covered by chapter 296-24 WAC Part L. Therefore, general purpose or weatherproof types of electrical wiring and equipment are acceptable depending upon whether the installation is indoors or outdoors. Such equipment shall be installed according to chapter 296-24 WAC Part L.

(9) Operating instructions. For installations which require any operation of equipment by the user, legible instructions shall be maintained at operating locations.

(10) Maintenance.

(((a))) The equipment and functioning of each charged bulk oxygen system shall be maintained in a safe operating condition in accordance with the requirements of this section. Wood and long dry grass shall be cut back within ((15)) fifteen feet of any bulk oxygen storage container.

AMENDATORY SECTION (Amending Order 73-5, filed 5/9/73 )

WAC 296-24-330 Flammable ((and combustible)) liquids.

AMENDATORY SECTION (Amending WSR 88-23-054, filed 11/14/88)

WAC 296-24-33001 Definitions.

The following definitions are applicable to all sections of this chapter which include WAC 296-24-330 in the section number.

(1) Aerosol shall mean a material which is dispensed from its container as a mist, spray, or foam by a propellant under pressure.

(2) Atmospheric tank shall mean a storage tank which has been designed to operate at pressures from atmospheric through 0.5 p.s.i.g.

(3) Automotive service station shall mean that portion of property where flammable ((or combustible)) liquids used as motor fuels are stored and dispensed from fixed equipment into the fuel tanks of motor vehicles and shall include any facilities available for the sale and service of tires, batteries, and accessories, and for minor automotive maintenance work. Major automotive repairs, painting, body and fender work are excluded.

(4) Basement shall mean a story of a building or structure having one-half or more of its height below ground level and to which access for firefighting purposes is unduly restricted.

(5) Boiling point shall mean the boiling point of a liquid at a pressure of 14.7 pounds per square inch absolute (p.s.i.a.) (760 mm.). Where an accurate boiling point is unavailable for the material in question, or for mixtures which do not have a constant boiling point, for purposes of this section the ten percent point of a distillation performed in accordance with the Standard Method of Test for Distillation of Petroleum Products, ASTM D-86-62, may be used as the boiling point of the liquid.

(6) Boilover shall mean the expulsion of crude oil (or certain other liquids) from a burning tank. The light fractions of the crude oil burnoff producing a heat wave in the residue, which on reaching a water strata may result in the expulsion of a portion of the contents of the tank in the form of froth.

(7) Bulk plant shall mean that portion of a property where flammable ((or combustible)) liquids are received by tank vessel, pipelines, tank car, or tank vehicle, and are stored or blended in bulk for the purpose of distributing such liquids by tank vessel, pipeline, tank car, tank vehicle, or container.

(8) Chemical plant shall mean a large integrated plant or that portion of such a plant other than a refinery or distillery where flammable ((or combustible)) liquids are produced by chemical reactions or used in chemical reactions.

(9) Closed container shall mean a container as herein defined, so sealed by means of a lid or other device that neither liquid nor vapor will escape from it at ordinary temperatures.

(10) Crude petroleum shall mean hydrocarbon mixtures that have a flash point below 150°F and which have not been processed in a refinery.

(11) Distillery shall mean a plant or that portion of a plant where flammable ((or combustible)) liquids produced by fermentation are concentrated, and where the concentrated products may also be mixed, stored, or packaged.

(12) Fire area shall mean an area of a building separated from the remainder of the building by construction having a fire resistance of at least one hour and having all communicating openings properly protected by an assembly having a fire resistance rating of at least one hour.

(13) Fire resistance or fire resistive construction shall mean construction to resist the spread of fire.

(14) Flammable aerosol shall mean ((an)) a flammable aerosol ((which is required to be labeled "Flammable" under the Federal Hazardous Substances Labeling Act (15 U.S.C. 1261))) as defined under WAC 296-901-14024, Appendix B—Physical hazard criteria. For the purposes of WAC 296-24-33009, such aerosols are considered ((Class IA)) Category 1 flammable liquids.

(15) "Flashpoint" means the minimum temperature at which a liquid gives off vapor within a test vessel in sufficient concentration to form an ignitable mixture with air near the surface of the liquid, and shall be determined as follows:

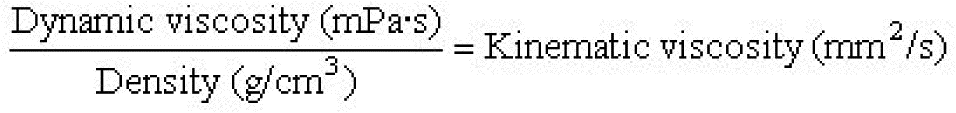

(a) For a liquid which has a viscosity of less than 45 SUS at 100°F (37.8°C), does not contain suspended solids, and does not have a tendency to form a surface film while under test, the procedure specified in the Standard Method of Test for Flashpoint by Tag Closed Tester (ASTM D-56-70), WAC 296-901-14024, Appendix B—Physical hazard criteria, shall be used.

(b) For a liquid which has a viscosity of 45 SUS or more at 100°F (37.8°C), or contains suspended solids, or has a tendency to form a surface film while under test, the Standard Method of Test for Flashpoint by Pensky-Martens Closed Tester (ASTM D-93-71) or an equivalent method as defined by WAC 296-901-14024, Appendix B—Physical hazard criteria, shall be used, except that the methods specified in Note 1 to section 1.1 of ASTM D-93-71 may be used for the respective materials specified in the note.

(c) For a liquid that is a mixture of compounds that have different volatilities and flashpoints, its flashpoint shall be determined by using the procedure specified in (a) or (b) of this subsection on the liquid in the form it is shipped. ((If the flashpoint, as determined by this test, is 100°F (37.8°C) or higher, an additional flashpoint determination shall be run on a sample of the liquid evaporated to ninety percent of its original volume, and the lower value of the two tests shall be considered the flashpoint of the material.))

(d) Organic peroxides, which undergo autoaccelerating thermal decomposition, are excluded from any of the flashpoint determination methods specified in this section.

(16) Hotel shall mean buildings or groups of buildings under the same management in which there are sleeping accommodations for hire primarily used by transients who are lodged with or without meals including but not limited to inns, clubs, motels, and apartment hotels.

(17) Institutional occupancy shall mean the occupancy or use of a building or structure or any portion thereof by persons harbored or detained to receive medical, charitable or other care or treatment, or by persons involuntarily detained.

(18) Liquid shall mean, for the purpose of these standards, any material which has a fluidity greater than that of 300 penetration asphalt when tested in accordance with ASTM Test for Penetration for Bituminous Materials, D-5-65. When not otherwise identified, the term liquid shall include both flammable ((and combustible)) liquids.

(19) "Combustible liquid" means any liquid having a flashpoint at or above 100°F (37.8°C). Combustible liquids shall be divided into two classes as follows:

(a) "Class II liquids" shall include those with flashpoints at or above 100°F (37.8°C) and below 140°F (60°C), except any mixture having components with flashpoints of 200°F (93.3°C) or higher, the volume of which make up ninety-nine percent or more of the total volume of the mixture.

(b) "Class III liquids" shall include those with flashpoints at or above 140°F (60°C). Class III liquids are subdivided into two subclasses:

(i) "Class IIIA liquids" shall include those with flashpoints at or above 140°F (60°C) and below 200°F (93.3°C) except any mixture having components with flashpoints of 200°F (93.3°C) or higher, the total volume of which make up ninety-nine percent or more of the total volume of the mixture.

(ii) "Class IIIB liquids" shall include those with flashpoints at or above 200°F (93.3°C). This section does not cover Class IIIB liquids. Where the term "Class III liquids" is used in this section, it shall mean only Class IIIA liquids.

(c) When a combustible liquid is heated for use to within 30°F (16.7°C) of its flashpoint, it shall be handled in accordance with the requirements for the next lower class of liquids.

(20) "Flammable liquid" means any liquid having a flashpoint at or below ((100°F (37.8°C), except any mixture having components with flashpoints of 100°F (37.8°C), or higher, the total of which make up ninety-nine percent or more of the total volume of the mixture)) 199.4°F (93°C). Flammable liquids ((shall be known as Class I liquids. Class I liquids)) are divided into ((three classes)) four categories as follows:

(a) ((Class IA)) Category 1 shall include liquids having flashpoints below ((73°F (22.8°C))) 73.4°F (23°C) and having a boiling point at or below ((100°F (37.8°C))) 95°F (35°C).

(b) ((Class IB)) Category 2 shall include liquids having flashpoints below ((73°F (22.8°C))) 73.4°F (23°C) and having a boiling point ((at or)) above ((100°F (37.8° C))) 95°F (35°C).

(c) ((Class IC)) Category 3 shall include liquids having flashpoints at or above ((73°F (22.8°C))) 73.4°F (23°C) and at or below ((100°F (37.8°C))) 140°F (60°C). When a Category 3 liquid with a flashpoint at or above 100°F (37.8°C) is heated for use to within 30°F (16.7°C) of its flashpoint, it must be handled in accordance with the requirements for a Category 3 liquid with a flashpoint below 100°F (37.8°C).

(d) Category 4 must include liquids having flashpoints above 140°F (60°C) and at or below 199.4°F (93°C). When a Category 4 flammable liquid is heated for use to within 30°F (16.7°C) of its flashpoint, it must be handled in accordance with the requirements for a Category 3 liquid with a flashpoint at or above 100°F (37.8°C).

(e) When liquid with a flashpoint greater than 199.4°F (93°C) is heated for use to within 30°F (16.7°C) of its flashpoint, it must be handled in accordance with the requirements for a Category 4 flammable liquid.

(21) Unstable (reactive) liquid shall mean a liquid which in the pure state or as commercially produced or transported will vigorously polymerize, decompose, condense, or will become self-reactive under conditions of shocks, pressure, or temperature.

(22) Low-pressure tank shall mean a storage tank which has been designed to operate at pressures above 0.5 p.s.i.g. but not more than 15 p.s.i.g.

(23) Marine service station shall mean that portion of a property where flammable ((or combustible)) liquids used as fuels are stored and dispensed from fixed equipment on shore, piers, wharves, or floating docks into the fuel tanks or self-propelled craft, and shall include all facilities used in connection therewith.

(24) Mercantile occupancy shall mean the occupancy or use of a building or structure or any portion thereof for the displaying, selling, or buying of goods, wares, or merchandise.

(25) Office occupancy shall mean the occupancy or use of a building or structure or any portion thereof for the transaction of business, or the rendering or receiving of professional services.

(26) Portable tank shall mean a closed container having a liquid capacity over sixty United States gallons and not intended for fixed installation.

(27) Pressure vessel shall mean a storage tank or vessel which has been designed to operate at pressures above 15 p.s.i.g.

(28) Protection for exposure shall mean adequate fire protection for structures on property adjacent to tanks, where there are employees of the establishment.

(29) Refinery shall mean a plant in which flammable ((or combustible)) liquids are produced on a commercial scale from crude petroleum, natural gasoline, or other hydrocarbon sources.

(30) Safety can shall mean an approved container, of not more than five gallons capacity, having a spring-closing lid and spout cover and so designed that it will safely relieve internal pressure when subjected to fire exposure.

(31) Vapor pressure shall mean the pressure, measured in pounds per square inch (absolute) exerted by a volatile liquid as determined by the "Standard Method of Test for Vapor Pressure of Petroleum Products (Reid Method)," American Society for Testing and Materials ASTM D323-68.

(32) Ventilation as specified in these standards is for the prevention of fire and explosion. It is considered adequate if it is sufficient to prevent accumulation of significant quantities of vapor-air mixtures in concentration over one-fourth of the lower flammable limit.

(33) Storage: Flammable ((or combustible)) liquids shall be stored in a tank or in a container that complies with WAC 296-24-33009(2).

(34) Barrel shall mean a volume of forty-two United States gallons.

(35) Container shall mean any can, barrel, or drum.

(36) Approved unless otherwise indicated, approved, or listed by a nationally recognized testing laboratory. Refer to federal regulation 29 C.F.R. 1910.7 for definition of nationally recognized testing laboratory.

(37) Listed see subsection (36) of this section.

(38) "SUS" means Saybolt Universal Seconds as determined by the Standard Method of Test for Saybolt Viscosity (ASTM D-88-56), and may be determined by use of the SUS conversion tables specified in ASTM Method D2161-66 following determination of viscosity in accordance with the procedures specified in the Standard Method of Test for Viscosity of Transparent and Opaque Liquids (ASTM D445-65).

(39) "Viscous" means a viscosity of 45 SUS or more.

Note: | The volatility of liquids is increased when artificially heated to temperatures equal to or higher than their flashpoints. When so heated Class II and III liquids shall be subject to the applicable requirements for Class I or II liquids. These standards may also be applied to high flashpoint liquids when so heated even though these same liquids when not heated are outside of its scope. |

AMENDATORY SECTION (Amending WSR 95-22-015, filed 10/20/95, effective 1/16/96)

WAC 296-24-33003 Scope.

This section applies to the handling, storage, and use of flammable ((and combustible)) liquids with a flash point at or below ((200°F)) 199.4°F (93°C). This section does not apply to:

(1) Bulk transportation of flammable ((and combustible)) liquids;

(2) Storage, handling, and use of fuel oil tanks and containers connected with oil burning equipment;

(3) Storage of flammable ((and combustible)) liquids on farms.

(4) Liquids without flashpoints that may be flammable under some conditions, such as certain halogenated hydrocarbons and mixtures containing halogenated hydrocarbons;

(5) Mists, sprays, or foams, except flammable aerosols covered in WAC 296-24-33009; or

(6) Installations made in accordance with requirements of the following standards:

(a) National Fire Protection Association Standard for Drycleaning Plants, NFPA No. 32-1970;

(b) National Fire Protection Association Standard for the Manufacture of Organic Coatings, NFPA No. 35-1970;

(c) National Fire Protection Association Standard for Solvent Extraction Plants, NFPA No. 36-1967; or

(d) National Fire Protection Association Standard for the Installation and Use of Stationary Combustion Engines and Gas Turbines, NFPA No. 37-1970.

AMENDATORY SECTION (Amending WSR 06-05-027, filed 2/7/06, effective 4/1/06)

WAC 296-24-33005 Tank storage.

(1) Design and construction of tanks.

(a) Materials.

(i) Tanks shall be built of steel except as provided in (((1)))(a)(ii) through (v) of this ((section)) subsection.

(ii) Tanks may be built of materials other than steel for installation underground or if required by the properties of the liquid stored. Tanks located above ground or inside buildings shall be of noncombustible construction.

(iii) Tanks built of materials other than steel shall be designed to specifications embodying principles recognized as good engineering design for the material used.

(iv) Unlined concrete tanks may be used for storing flammable ((or combustible)) liquids having a gravity of 40°API or heavier. Concrete tanks with special lining may be used for other services provided the design is in accordance with sound engineering practice.

(v) Tanks may have combustible or noncombustible linings.

(vi) Special engineering consideration shall be required if the specific gravity of the liquid to be stored exceeds that of water or if the tanks are designed to contain flammable ((or combustible)) liquids at a liquid temperature below 0°F.

(b) Fabrication.

(i) Tanks may be of any shape or type consistent with sound engineering design.

(ii) Metal tanks shall be welded, riveted, and caulked, brazed, or bolted, or constructed by use of a combination of these methods. Filler metal used in brazing shall be nonferrous metal or an alloy having a melting point above 1000°F and below that of the metal joined.

(c) Atmospheric tanks.

(i) Atmospheric tanks shall be built in accordance with acceptable good standards of design. Atmospheric tanks may be built in accordance with:

(A) Underwriters' Laboratories, Inc., Subjects No. 142, Standard for Steel Aboveground Tanks for Flammable and Combustible Liquids, 1968; No. 58, Standards for Steel Underground Tanks for Flammable and COMBUSTIBLE Liquids, Fifth Edition, December 1961; or No. 80, Standard for Steel Inside Tanks for Oil-Burner Fuel, September 1963.

(B) American Petroleum Institute Standards No. 650, Welded Steel Tanks for Oil Storage, Third Edition, 1966.