WSR 14-01-088

PROPOSED RULES

DEPARTMENT OF

LABOR AND INDUSTRIES

[Filed December 17, 2013, 10:03 a.m.]

Original Notice.

Expedited Rule Making-Proposed notice was filed as WSR 13-13-064.

Title of Rule and Other Identifying Information: eRules, chapter 296-829 WAC, Helicopters used as lifting machines; chapter 296-832 WAC, Late night retail worker crime prevention; chapter 296-876 WAC, Ladders, portable and fixed; and chapter 296-878 WAC, Window cleaning, SSB 5679.

NEW SECTIONS:

WAC 296-829-099 Definitions, 296-876-099 Definitions, and 296-878-099 Definitions, move the definitions section to the front of the rule and consolidated all definitions in one place.

AMENDED SECTIONS:

WAC 296-829-100 Scope.

Make word "Exemption" all caps. Number items in the exemption.

WAC 296-829-200 Design and installation requirements for helicopters.

Create summary table with links to subsections.

WAC 296-829-20005 Follow Federal Aviation Administration (FAA) requirements.

Consolidate requirement into a single sentence.

WAC 296-829-20010 Install and test hooks on helicopters correctly.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-829-300 Maintenance.

Create summary table with links to subsections.

WAC 296-829-30005 Keep landing and deposit areas safe.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-829-30010 Follow safe refueling procedures.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-829-400 Operating the helicopter.

Create summary table with links to subsections.

WAC 296-829-40005 Hold daily briefings.

Consolidate requirement into a single sentence.

WAC 296-829-40010 Make sure employees are dressed correctly.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-829-40015 Make sure loads are attached correctly.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-829-40020 Make sure the load is handled correctly.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-832-200 Training.

Create summary table with links to subsections.

WAC 296-832-20005 Provide crime prevention training to your employees.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-832-20010 Provide crime prevention retraining to your employees annually.

Consolidate requirement into a single sentence.

WAC 296-832-300 Store safety.

Create summary table with links to subsections.

WAC 296-832-30005 Have a safe in your store.

Consolidate requirement into a single sentence.

WAC 296-832-30010 Post a notice about your store's safe and cash register.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed. Number Notes items.

WAC 296-832-30015 Provide outside lighting.

Consolidate requirement into a single sentence. Number Notes items.

WAC 296-876-100 Scope.

Make word "Exemption" all caps. Number items in the exemption.

WAC 296-876-150 Training

Create summary table with link to subsection.

WAC 296-876-15005 Training.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-876-200 Design and construction.

Create summary table with link to subsection.

WAC 296-876-20005 Design and construction.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed. Move "Special purpose ladder" definition to WAC 296-876-099 Definitions.

WAC 296-876-300 Ladder care.

Create summary table with links to subsections.

WAC 296-876-30005 Condition and inspection.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-876-30010 Repair.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-876-30015 Storage.

Consolidate requirement into a single sentence. Remove bullet from Note text.

WAC 296-876-30020 Transport.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-876-400 Portable ladder use.

Create summary table with links to subsections.

WAC 296-876-40005 Designed use.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed. Number Note items. Move "Maximum intended load" definition and "Ladder type" definition and table to WAC 296-876-099 Definitions.

WAC 296-876-40010 Workplace activities or traffic.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-876-40015 Support.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

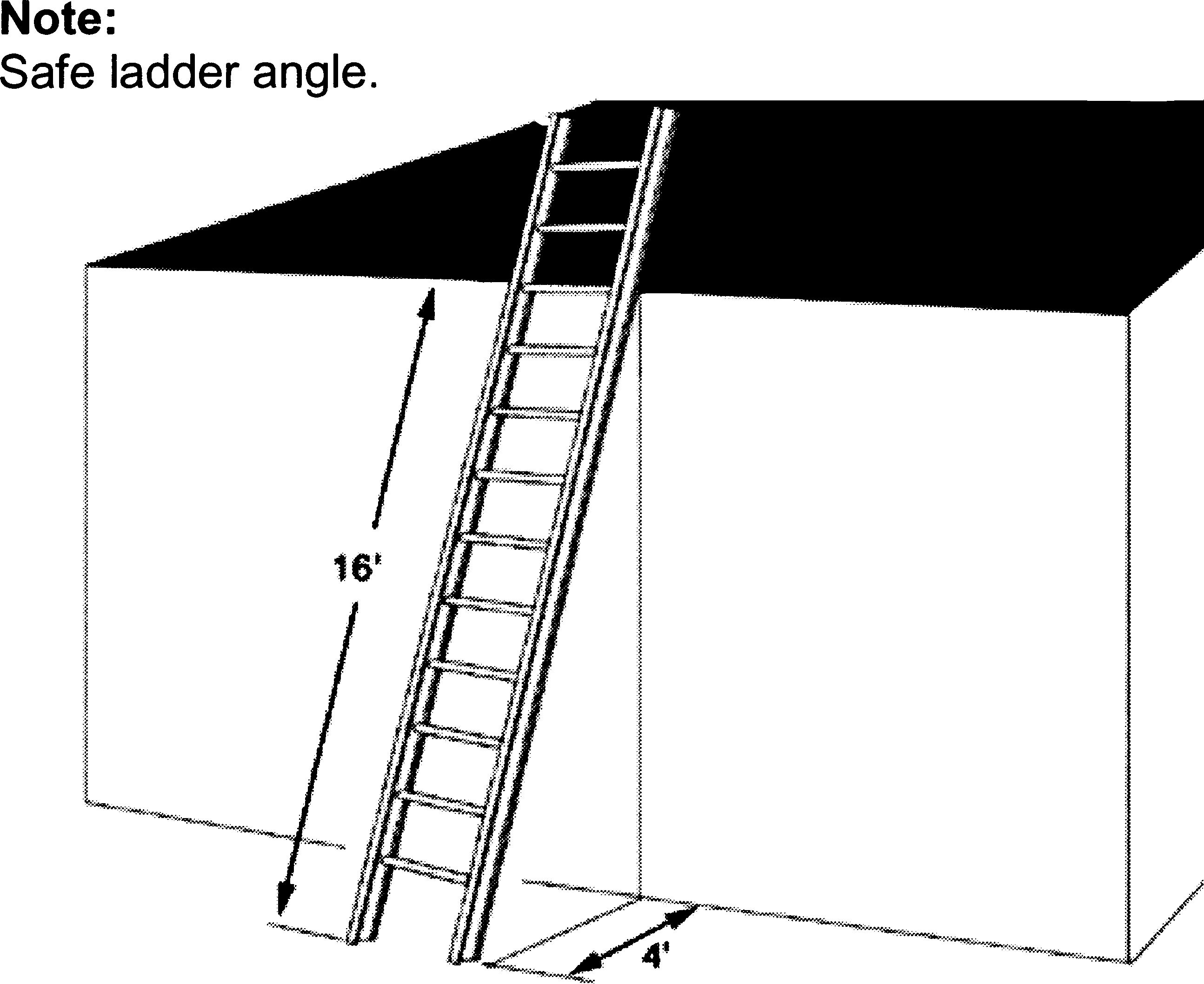

WAC 296-876-40020 Set-up.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed. Move "Working length" definition to WAC 296-876-099 Definitions. Remove redundant "Safe Ladder Angle" notation from above the graphic.

WAC 296-876-40025 Climbing and descending.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed. Move "Single-rail ladder" definition to 296-876-099 Definitions.

WAC 296-876-40030 Getting on and off ladders at upper levels.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed. Make the word "Exemption" all caps.

WAC 296-876-40035 Exposed electrical hazards.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-876-40040 Persons on ladders.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-876-40045 Multisection ladders.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-876-40050 Self-supporting ladders.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed. Make the word "Exemption" all caps.

WAC 296-876-500 Fixed ladder design and construction installed on or after December 1, 2006.

Add "installed on or after December 1, 2006" to section name. Create summary table with link to subsection.

WAC 296-876-50010 Design and construction—Fixed ladders installed on or after December 1, 2006.

Consolidate requirement into a single sentence. Remove colon from Note to make text a continuous sentence.

WAC 296-876-600 Fixed ladder design and construction installed before December 1, 2006.

Add "installed before December 1, 2006" to section name. Create summary table with links to subsections.

WAC 296-876-60005 Design and construction—Fixed ladders installed before December 1, 2006.

Consolidate requirement into a single sentence. Remove colon from Note to make text a continuous sentence.

WAC 296-876-60010 Design loads.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-876-60015 Pitch.

Consolidate requirement into a single sentence. Number Notes items.

WAC 296-876-60020 Welding.

Consolidate requirement into a single sentence.

WAC 296-876-60025 Ladder surfaces.

Consolidate requirement into a single sentence.

WAC 296-876-60030 Rungs, cleats and steps.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-876-60035 Side rails.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-876-60040 Clearances.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed. Make the word "Exemption" all caps.

WAC 296-876-60045 Step-across distance.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-876-60050 Extensions and grab bars.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed. Number Note items. Make the word "Exemption" all caps.

WAC 296-876-60055 Hatches.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-876-60060 Platforms.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed. Make the word "Exemption" all caps.

WAC 296-876-60065 Protective structures and equipment.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed. Make the word "Exemption" all caps.

WAC 296-876-60070 Cages.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed. In subsection (4)(a), change "is" to "are."

WAC 296-876-60075 Wells.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-876-60080 Ladder safety devices.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed. In subsection (1)(a), hyphenate "five-hundred-pound weight."

WAC 296-876-700 Fixed ladders inspection and maintenance.

Delete "-- Section contents" from section title. Create summary table with links to subsections.

WAC 296-876-70005 Protection against corrosion and deterioration.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-876-70010 Inspection and repair.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed. Number and lettered Note items and subitems.

WAC 296-876-800 Fixed ladder use.

Delete "-- Section contents" from section title. Create summary table with links to subsections.

WAC 296-876-80005 Designed load.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed. Delete redundant "Maximum intended load" definition restatement already added to WAC 296-876-099 Definitions.

WAC 296-876-80010 Climbing and descending.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-878-10005 Summary.

Change "IMPORTANT" to upper and lowercase. Remove list of subsections, as each following three-digit WAC section was changed to have its own summary table, with link(s) to any subsections within that three-digit WAC section.

WAC 296-878-110 Training.

Create summary table with links to subsections.

WAC 296-878-11005 Train workers to use window-cleaning equipment.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed. Number Note items.

WAC 296-878-120 Building surfaces and fixtures.

Create summary table with link to subsection.

WAC 296-878-12005 Make sure building surfaces and fixtures are safe to use.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-878-130 Inspection procedures.

Create summary table with links to subsections.

WAC 296-878-13005 Inspect the area to be cleaned.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-878-13010 Inspect window-cleaning equipment before use.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-878-140 Develop site-specific service and emergency plans.

Create summary table with links to subsections.

WAC 296-878-14005 Develop a site-specific service and emergency recovery plan for window-cleaning operations.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed. Number Note items.

WAC 296-878-150 Equipment.

Create summary table with links to subsections.

WAC 296-878-15005 Select and use appropriate equipment.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-878-15015 Select appropriate rope for suspended equipment.

Consolidate requirement into a single sentence.

WAC 296-878-15020 Select appropriate carabiners.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-878-15025 Use fall protection equipment.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-878-160 Warning signs and barricades.

Create summary table with link to subsection.

WAC 296-878-16005 Provide warning signs and barricades when suspended equipment is used.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-878-170 Power line clearances.

Create summary table with links to subsections.

WAC 296-878-17005 Maintain clearance between window cleaners and power lines.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-878-180 Window-cleaners' belts and anchors.

Create summary table with links to subsections.

WAC 296-878-18005 Select appropriate window-cleaners' belts and anchors.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-878-18010 Inspect the anchors you plan to use for window cleaning.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-878-18015 Use window-cleaners' belts safely.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-878-18020 Move safely on the outside of buildings.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed. Number Note items.

WAC 296-878-190 Boatswains' chairs.

Create summary table with links to subsections.

WAC 296-878-19005 Select appropriate boatswains' chairs.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-878-19010 Safely use boatswains' chairs rigged with a block and tackle.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed. Make "Exemption" all caps. Number exemption items.

WAC 296-878-200 Rope descent systems.

Create summary table with links to subsections.

WAC 296-878-20005 Select appropriate rope descent systems.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-878-20010 Safely use rope descent systems.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed. Number Note items.

WAC 296-878-20015 Safely use rope descent devices.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

WAC 296-878-210 Equipment prohibited.

Create summary table with links to subsections.

WAC 296-878-21005 Prohibit equipment from use.

Apply numbers (or numbers and letters) to content items, and repeated "You must" as needed.

REPEALED SECTIONS:

WAC 296-829-500 Definitions, 296-876-900 Definitions, and 296-878-220 Definitions, are being proposed to be repealed.

Hearing Location(s): Department of Labor and Industries, 7273 Linderson Way S.W., Rooms S118 and S119, Tumwater, WA 98501, on January 23, 2014, at 1:00 p.m.

Date of Intended Adoption: April 22, 2014.

Submit Written Comments to: Catherine Julian, P.O. Box 44620, Olympia, WA 98504, e-mail catherine.julian@lni.wa.gov, fax (360) 902-5619, by January 30, 2014.

Assistance for Persons with Disabilities: Contact Catherine Julian by January 9, 2014, (360) 902-5401 or catherine.julian@lni.wa.gov.

Purpose of the Proposal and Its Anticipated Effects, Including Any Changes in Existing Rules:

• | No requirements are changing because of this rule making. |

• | Consistent format for all DOSH safety and health rules. |

• | Easy to access rules for smart phone and table [tablet] users. |

• | Bookmarks in the rules allow easy navigation in PDF files. |

• | Bullets and dashes are removed and replaced with numbers and letters for easier referencing. |

• | Enhances rule update efficiency for customers through electronic postings. |

Reasons Supporting Proposal: Stakeholders have complained that our rules on the web are confusing and difficult to access in real time. When the agency updated its website, template DOSH rules in HTML were broken and DOSH began forwarding rule users to the office of the code reviser web site, which caused more confusion. This rule package will resolve stakeholder issues that have caused confusion for rule users by bringing one clear and consistent format to all of our rules.

Statutory Authority for Adoption: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060.

Statute Being Implemented: Chapter 49.17 RCW.

Rule is not necessitated by federal law, federal or state court decision.

Name of Proponent: Department of labor and industries, governmental.

Name of Agency Personnel Responsible for Drafting: Jeff Killip, Tumwater, Washington, (360) 902-5530; Implementation and Enforcement: Anne Soiza, Tumwater, Washington, (360) 902-5090.

No small business economic impact statement has been prepared under chapter 19.85 RCW. No change in requirements, so no economic impact.

A cost-benefit analysis is not required under RCW 34.05.328. No change in requirements, so no change in costs or benefits.

December 17, 2013

Joel Sacks

Director

NEW SECTION

WAC 296-829-099 Definitions.

Aviation gasoline. Gasoline fuel for reciprocating piston engine helicopters, also known as avgas.

Cargo hook. A device attached to a helicopter that is used to hold suspended loads.

Competent person. One who is capable of identifying existing and predictable hazards in the surroundings, or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them.

Deadman controls. A control, switch or device that will automatically shut off whenever the operator releases it.

Deposit area. An area that is designated for dropping off and picking up suspended loads.

Downwash. The wind created by the rotating blades of a helicopter.

Ground device. A device used to dissipate the static electricity charge that has built up on a suspended load.

Helicopter crane. A helicopter that carries cargo or equipment suspended underneath it.

Jet A type fuel. A kerosene grade fuel suitable for helicopters with turbine engines.

Jet B type fuel. A blend of gasoline and kerosene fuel.

Powered hoist. A powered device designed to lift and lower equipment and cargo.

Tag line. A line or rope used to control suspended loads that can swing freely.

AMENDATORY SECTION (Amending WSR 04-09-099, filed 4/20/04, effective 9/1/04)

WAC 296-829-100 Scope.

Chapter 296-829 WAC applies to helicopters when used to carry loads, suspended with a cargo sling, powered hoist, or other attaching methods.

((Exemption)) EXEMPTION: | This chapter does not apply to the use of helicopters: |

((•)) 1. In the logging industry. | |

((•)) 2. For rescue operations when a winch or hoist is used. |

AMENDATORY SECTION (Amending WSR 04-09-099, filed 4/20/04, effective 9/1/04)

WAC 296-829-200 Design and installation requirements for helicopters.

Summary:

Your responsibility: To make sure your helicopters meet design specifications and are equipped properly.

((You must:

Follow Federal Aviation Administration (FAA) requirements

WAC 296-829-20005.

Install and test hooks on helicopters correctly

WAC 296-829-20010.))

You must meet the requirements... | in this section: |

Follow Federal Aviation Administration (FAA) requirements | WAC 296-829-20005 |

Install and test hooks on helicopters correctly | WAC 296-829-20010 |

AMENDATORY SECTION (Amending WSR 04-09-099, filed 4/20/04, effective 9/1/04)

WAC 296-829-20005 Follow Federal Aviation Administration (FAA) requirements.

You must((:

•)) make sure helicopter cranes and their use meet the applicable requirements of the Federal Aviation Administration (FAA).

AMENDATORY SECTION (Amending WSR 04-09-099, filed 4/20/04, effective 9/1/04)

WAC 296-829-20010 Install and test hooks on helicopters correctly.

((You must:

• Make sure electrically operated cargo hooks are:

– Designed and installed to prevent accidental operation.

– Equipped with an emergency mechanical control to release the load.

• Make sure a competent person tests all hooks before each day's operation to make sure both the electrical and mechanical releases work properly.)) (1) You must make sure electrically operated cargo hooks are:

(a) Designed and installed to prevent accidental operation.

(b) Equipped with an emergency mechanical control to release the load.

(2) You must make sure a competent person tests all hooks before each day's operation to make sure both the electrical and mechanical releases work properly.

AMENDATORY SECTION (Amending WSR 04-09-099, filed 4/20/04, effective 9/1/04)

WAC 296-829-300 Maintenance.

Summary:

Your responsibility: To keep helicopters in safe operating condition.

((You must:

Keep landing and deposit areas safe

WAC 296-829-30005.

Follow safe refueling procedures

WAC 296-829-30010.))

You must meet the requirements... | in this section: |

Keep landing and deposit areas safe | WAC 296-829-30005 |

Follow safe refueling procedures | WAC 296-829-30010 |

AMENDATORY SECTION (Amending WSR 04-09-099, filed 4/20/04, effective 9/1/04)

WAC 296-829-30005 Keep landing and deposit areas safe.

((You must:

(1) Make sure precautions are taken to prevent loose objects from being caught in the downwash and flying around.

• Secure or remove all loose gear:

– Within one hundred feet of lift and deposit areas.

– In all other areas affected by rotor downwash.

(2) Make sure employees do not work under hovering craft, except where necessary to hook or unhook loads.

(3) Make sure safe access and exit, including an emergency escape route, is provided for employees who hook or unhook loads.

(4) Prohibit open fires in any area that could be affected by the rotor downwash.

(5) Make sure unauthorized people do not go within fifty feet of the helicopter when the rotor blades are turning.

(6) Make sure all employees:

• Stay in full view of the pilot, in a crouched position, when approaching or leaving a helicopter with rotating blades.

• Stay away from the area behind the cockpit or cabin unless the operator authorizes them to work there.

(7) Take precautions to eliminate reduced visibility.

(8) Make sure ground personnel take special care to stay clear of rotors when visibility is reduced by dust or other conditions.)) (1) You must make sure precautions are taken to prevent loose objects from being caught in the downwash and flying around. Secure or remove all loose gear:

(a) Within one hundred feet of lift and deposit areas.

(b) In all other areas affected by rotor downwash.

(2) You must make sure employees do not work under hovering craft, except where necessary to hook or unhook loads.

(3) You must make sure safe access and exit, including an emergency escape route, is provided for employees who hook or unhook loads.

(4) You must prohibit open fires in any area that could be affected by the rotor downwash.

(5) You must make sure unauthorized people do not go within fifty feet of the helicopter when the rotor blades are turning.

(6) You must make sure all employees:

(a) Stay in full view of the pilot, in a crouched position, when approaching or leaving a helicopter with rotating blades.

(b) Stay away from the area behind the cockpit or cabin unless the operator authorizes them to work there.

(7) You must take precautions to eliminate reduced visibility.

(8) You must make sure ground personnel take special care to stay clear of rotors when visibility is reduced by dust or other conditions.

AMENDATORY SECTION (Amending WSR 04-09-099, filed 4/20/04, effective 9/1/04)

WAC 296-829-30010 Follow safe refueling procedures.

((You must:

• Make sure refueling areas are safe.

– Post "NO SMOKING" signs at all entrances to the refueling area.

– Provide at least one thirty-pound fire extinguisher, or a combination totaling thirty pounds, good for class A, B, and C fires, within one hundred feet on the upwind side of the refueling operation.

Reference: | For additional requirements relating to portable fire extinguishers, see WAC 296-800-300 in the safety and health core rules. |

You must:

• Make sure workers involved in refueling are trained in both:

– The refueling operation;

AND

– The use of fire extinguishing equipment they may need.

• Make sure the following precautions are taken before and during refueling:

– Keep unauthorized people at least fifty feet away from the refueling operation or equipment.

– Prohibit smoking and open flames within fifty feet of the refueling area or fueling equipment.

– Make sure helicopter engines are shut down before refueling, if using aviation gasoline or jet B type fuel.

– Pump fuel, either by hand or power.

– Use self-closing nozzles or deadman controls:

■ Do not allow these to be blocked open.

– Make sure nozzles are not dragged along the ground.

– Make sure the helicopter and the fueling equipment are grounded.

– Electrically bond the fueling nozzle to the helicopter:

■ Do not use conductive hose for this bonding.

– Make sure all grounding and bonding connections are:

■ Electrically and mechanically firm.

■ On clean unpainted metal parts.

• Stop fueling immediately if there is a spill:

– Do not continue operation until the person in charge has determined it is safe.)) (1) You must make sure refueling areas are safe.

(a) Post "NO SMOKING" signs at all entrances to the refueling area.

(b) Provide at least one thirty-pound fire extinguisher, or a combination totaling thirty pounds, good for class A, B, and C fires, within one hundred feet on the upwind side of the refueling operation.

Reference: | For additional requirements relating to portable fire extinguishers, see WAC 296-800-300 in the safety and health core rules. |

(2) You must make sure workers involved in refueling are trained in both:

(a) The refueling operation; and

(b) The use of fire extinguishing equipment they may need.

(3) You must make sure the following precautions are taken before and during refueling:

(a) Keep unauthorized people at least fifty feet away from the refueling operation or equipment.

(b) Prohibit smoking and open flames within fifty feet of the refueling area or fueling equipment.

(c) Make sure helicopter engines are shut down before refueling, if using aviation gasoline or jet B type fuel.

(d) Pump fuel, either by hand or power.

(e) Use self-closing nozzles or deadman controls:

(i) Do not allow these to be blocked open.

(ii) Make sure nozzles are not dragged along the ground.

(iii) Make sure the helicopter and the fueling equipment are grounded.

(iv) Electrically bond the fueling nozzle to the helicopter.

(v) Do not use conductive hose for this bonding.

(f) Make sure all grounding and bonding connections are:

(i) Electrically and mechanically firm.

(ii) On clean unpainted metal parts.

(4) Stop fueling immediately if there is a spill. Do not continue operation until the person in charge has determined it is safe.

AMENDATORY SECTION (Amending WSR 04-09-099, filed 4/20/04, effective 9/1/04)

WAC 296-829-400 Operating the helicopter.

Summary:

Your responsibility: To make sure helicopters are operated safely.

((You must:

Hold daily briefings

WAC 296-829-40005.

Make sure employees are dressed correctly

WAC 296-829-40010.

Make sure loads are attached correctly

WAC 296-829-40015.

Make sure the load is handled correctly

WAC 296-829-40020.))

You must meet the requirements... | in this section: |

Hold daily briefings | WAC 296-829-40005 |

Make sure employees are dressed correctly | WAC 296-829-40010 |

Make sure loads are attached correctly | WAC 296-829-40015 |

Make sure the load is handled correctly | WAC 296-829-40020 |

AMENDATORY SECTION (Amending WSR 04-09-099, filed 4/20/04, effective 9/1/04)

WAC 296-829-40005 Hold daily briefings.

You must((:

•)) make sure the helicopter pilot and ground personnel hold a briefing before each day's operation to discuss cargo-handling plans.

AMENDATORY SECTION (Amending WSR 04-09-099, filed 4/20/04, effective 9/1/04)

WAC 296-829-40010 Make sure employees are dressed correctly.

((You must:

• Make sure employees receiving the load:

– Do NOT wear loose-fitting clothes that could snag on the hoist line.

– Wear personal protective equipment (PPE), including complete eye protection and hard hats that are secured by chin straps.)) You must make sure employees receiving the load:

(1) Do not wear loose-fitting clothes that could snag on the hoist line.

(2) Wear personal protective equipment (PPE), including complete eye protection and hard hats that are secured by chin straps.

Reference: | For other requirements relating to PPE, see WAC 296-800-160 in the safety and health core rules. |

AMENDATORY SECTION (Amending WSR 04-09-099, filed 4/20/04, effective 9/1/04)

WAC 296-829-40015 Make sure loads are attached correctly.

((You must:

• Make sure loads are properly slung so tag lines cannot be drawn up into rotors.

• Make sure precautions are taken on all freely suspended loads to keep hand splices from spinning open or cable clamps from loosening, such as using pressed sleeves or swedged eyes.

• Make sure the weight of the load does not exceed the manufacturer's load ratings.

• Make sure hoist wires and other gear are not attached to or allowed to catch on any fixed structure.)) (1) You must make sure loads are properly slung so tag lines cannot be drawn up into rotors.

(2) You must make sure precautions are taken on all freely suspended loads to keep hand splices from spinning open or cable clamps from loosening, such as using pressed sleeves or swedged eyes.

(3) You must make sure the weight of the load does not exceed the manufacturer's load ratings.

(4) You must make sure hoist wires and other gear are not attached to or allowed to catch on any fixed structure.

((Exemption)) EXEMPTION: | This requirement does not apply to pulling lines or conductors that "pay out" from a container or reel. |

AMENDATORY SECTION (Amending WSR 04-09-099, filed 4/20/04, effective 9/1/04)

WAC 296-829-40020 Make sure the load is handled correctly.

((You must:

• Make sure signal systems, whether radio or hand signals, are checked before hoisting the load:

– When using hand signals, use those shown in Figure 1.

• Make sure workers on the ground do either of the following before touching the suspended load:

– Use a ground device to safely discharge any static charge;

or

– Put on and wear rubber gloves.

• Make sure there are enough employees for safe loading and unloading operations.

• Make sure constant communications are maintained between the pilot and signal person:

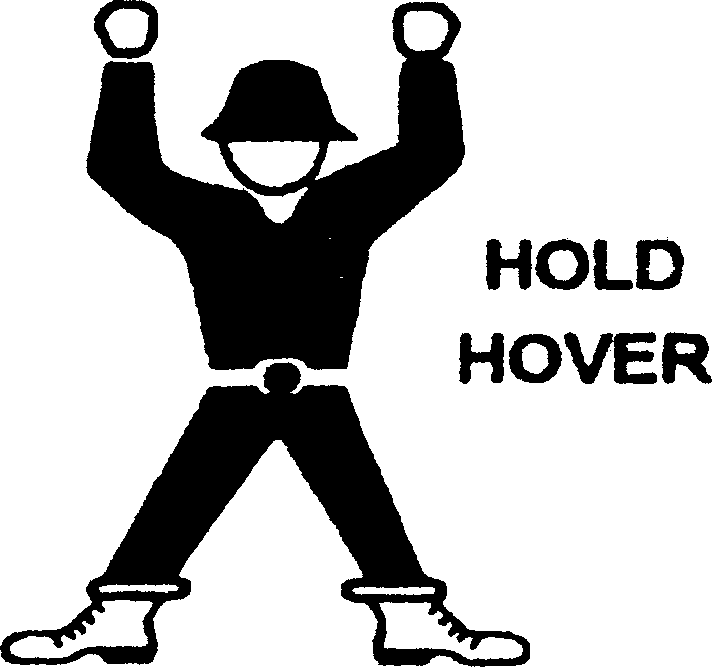

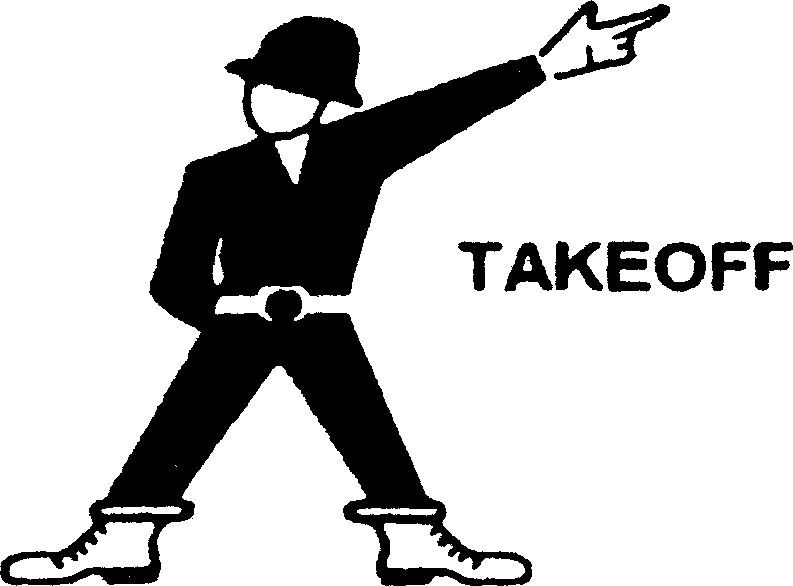

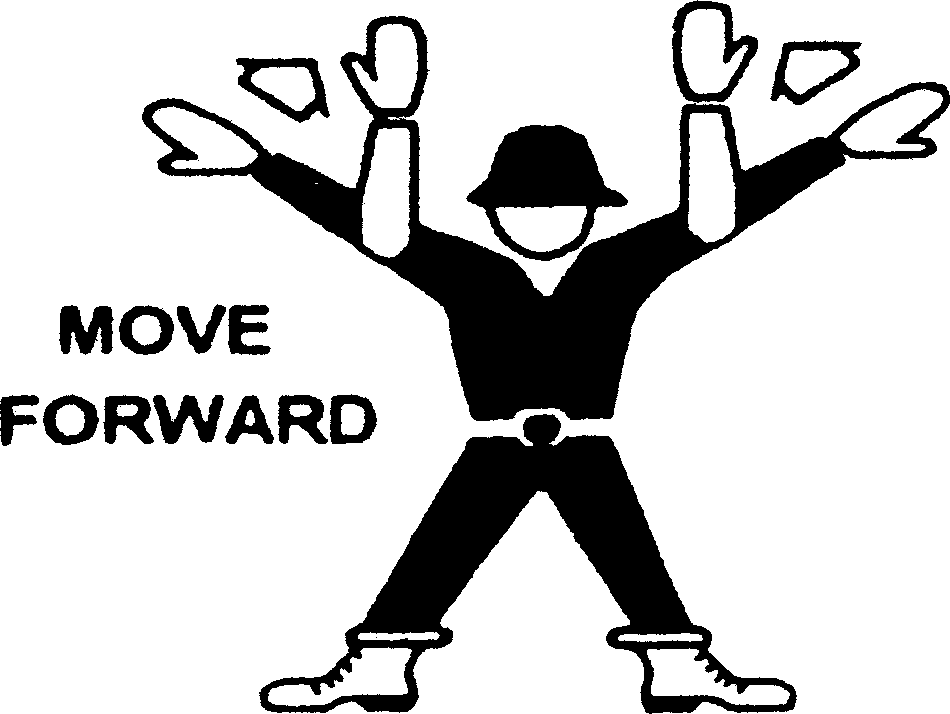

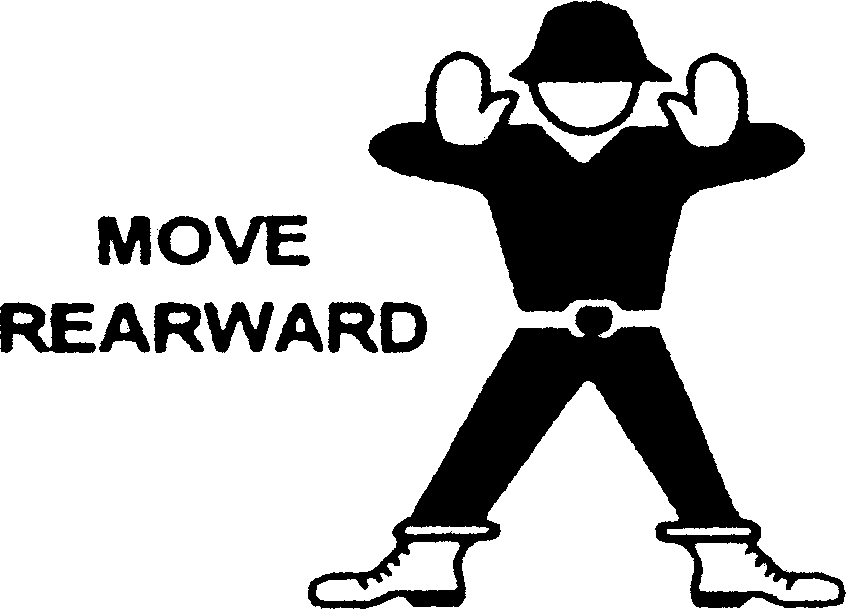

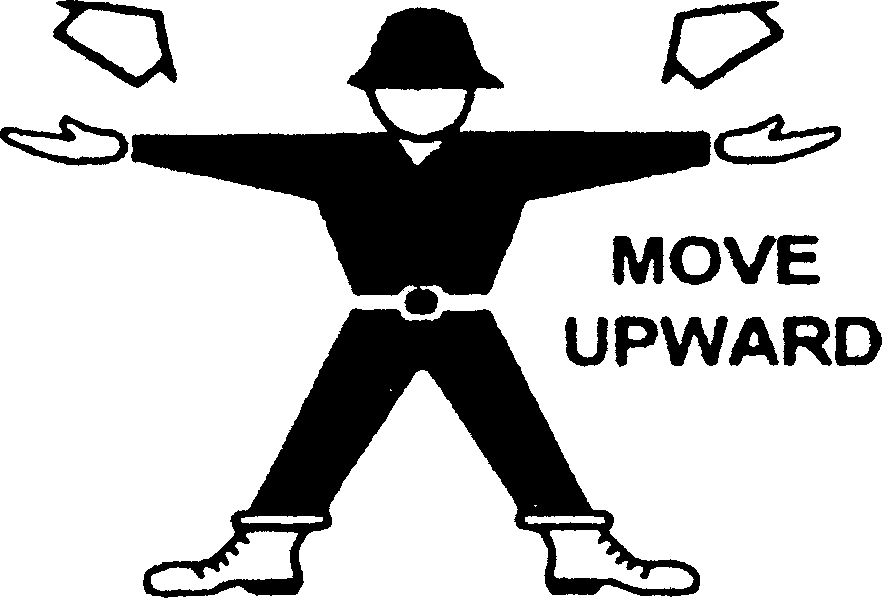

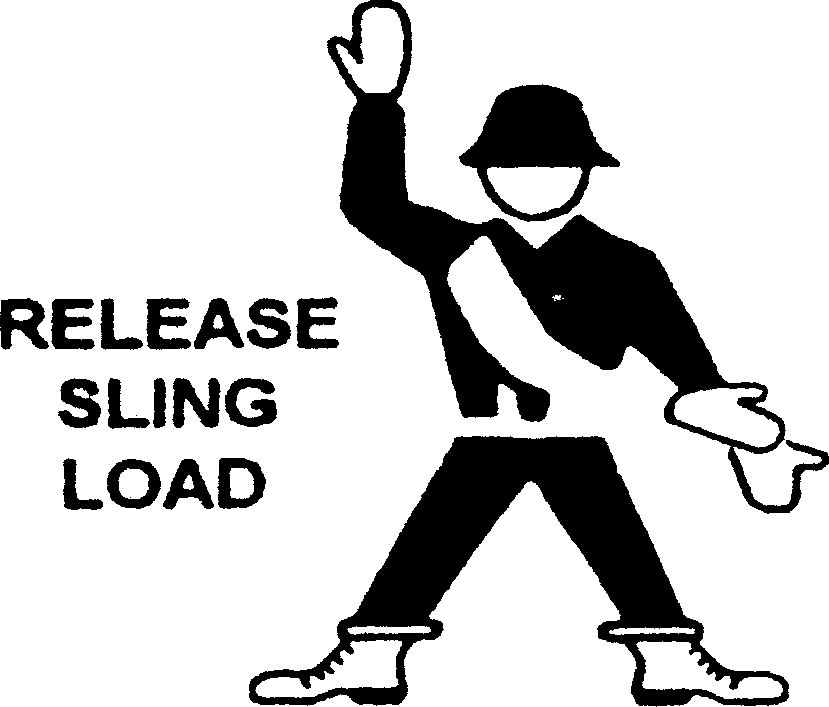

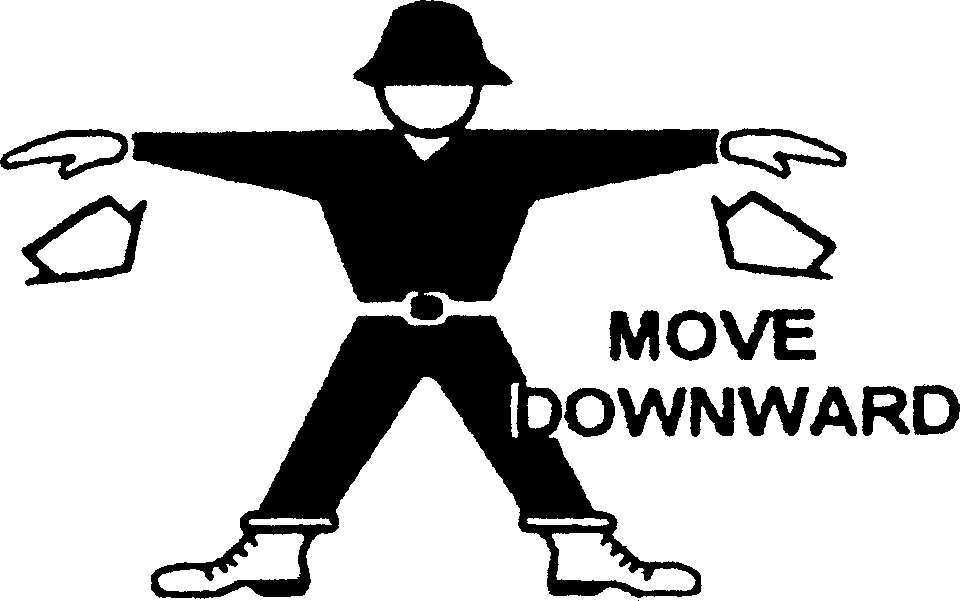

The signal person must be distinctly recognizable from other ground personnel.)) (1) You must make sure signal systems, whether radio or hand signals, are checked before hoisting the load. When using hand signals, use those shown in Figure 1.

(2) You must make sure workers on the ground do either of the following before touching the suspended load:

(a) Use a ground device to safely discharge any static charge; or

(b) Put on and wear rubber gloves.

(3) You must make sure there are enough employees for safe loading and unloading operations.

(4) You must make sure constant communications are maintained between the pilot and signal person.

(5) You must make sure the signal person is distinctly recognizable from other ground personnel.

helicopter hand signals

|  | |

Left arm extended horizontally; right arm sweeps upward to position over. | The signal "Hold" is executed by placing arms over head with clenched fists. | |

|  | |

Right arm extended horizontally; left sweeps upward to position over head. | Right hand behind back; left hand pointing up. | |

|  | |

Combination of arm and hand movement in a collecting motion pulling toward head. | Arms crossed in front of body and pointing downward. | |

|  | |

Hands above arm, palms out using a noticeable showing motion. | Arms extended, palms up; arms sweeping up. | |

|  | |

Left arm held down away from body. Right arm cuts across left arm in a slashing movement from above. | Arms extended, palms down; arms sweeping down. |

REPEALER

The following section of the Washington Administrative Code is repealed:

WAC 296-829-500 |

Definitions. |

AMENDATORY SECTION (Amending WSR 02-16-087, filed 8/7/02, effective 10/1/02)

WAC 296-832-200 Training.

summary

Your responsibility: To make sure all employees receive crime prevention training as part of your accident prevention program.

((You must:

Provide crime prevention training to your employees

WAC 296-832-20005

Provide crime prevention retraining to your employees annually

WAC 296-832-20010.))

You must meet the requirements… | in this section: |

Provide crime prevention training to your employees | WAC 296-832-20005 |

Provide crime prevention retraining to your employees annually | WAC 296-832-20010 |

AMENDATORY SECTION (Amending WSR 02-16-087, filed 8/7/02, effective 10/1/02)

WAC 296-832-20005 Provide crime prevention training to your employees.

Note: | These training requirements apply only to employees working any time during the hours of 11:00 p.m. to 6:00 a.m. This training must be conducted prior to the employee working this time period. |

((You must:

• Provide crime prevention training as part of your accident prevention program.

– Make sure you have instructed your employees on the purpose and function of robbery and violence prevention to provide them with the knowledge and skills required to maintain their personal safety.

• Provide training and training materials that outline your company's:

– Security policies

– Safety and security procedures

– Personal safety and crime prevention techniques.

• Provide formal instruction about crime prevention through a training seminar or training video presentation that includes these topics:

– How keeping the store clean, neat and uncluttered discourages potential robbers

– Why the cash register should be kept in plain view from outside the store, if your store layout allows

– Reasons for operating your business with only a minimum number of cash registers at night

– Reasons for keeping cash register funds to a minimum

– How to take extra precautions after dark such as ways to keep alert, making sure appropriate lights are on, inspecting dark corners, and identifying possible hiding places for robbers

– Violence prevention procedures in case of a robbery.

• Have employees sign a statement indicating the date, time, and place they received their crime prevention training.

• Keep a record of this information readily available for review when requested by the department of labor and industries.)) (1) You must provide crime prevention training as part of your accident prevention program. Make sure you have instructed your employees on the purpose and function of robbery and violence prevention to provide them with the knowledge and skills required to maintain their personal safety.

(2) You must provide training and training materials that outline your company's:

(a) Security policies;

(b) Safety and security procedures;

(c) Personal safety and crime prevention techniques.

(3) You must provide formal instruction about crime prevention through a training seminar or training video presentation that includes these topics:

(a) How keeping the store clean, neat, and uncluttered discourages potential robbers;

(b) Why the cash register should be kept in plain view from outside the store, if your store layout allows;

(c) Reasons for operating your business with only a minimum number of cash registers at night;

(d) Reasons for keeping cash register funds to a minimum;

(e) How to take extra precautions after dark such as ways to keep alert, making sure appropriate lights are on, inspecting dark corners, and identifying possible hiding places for robbers;

(f) Violence prevention procedures in case of a robbery.

(4) You must have employees sign a statement indicating the date, time, and place they received their crime prevention training.

(5) You must keep a record of this information readily available for review when requested by the department of labor and industries.

Note: | Employers may keep electronic records of employee training and verification. |

((• Have a videotape or other materials about crime prevention available to all employees at their request.)) (6) You must have a videotape or other materials about crime prevention available to all employees at their request.

AMENDATORY SECTION (Amending WSR 02-16-087, filed 8/7/02, effective 10/1/02)

WAC 296-832-20010 Provide crime prevention retraining to your employees annually.

You must((:

•)) provide a refresher course in crime prevention training annually.

AMENDATORY SECTION (Amending WSR 02-16-087, filed 8/7/02, effective 10/1/02)

WAC 296-832-300 Store safety.

summary

Your responsibility: To take certain safety measures to discourage crime in your store.

((You must:

Have a safe in your store

WAC 296-832-30005

Post a notice about your store's safe and cash register

WAC 296-832-30010

Provide outside lighting

WAC 296-832-30015.))

You must meet the requirements… | in this section: |

Have a safe in your store | WAC 296-832-30005 |

Post a notice about your store's safe and cash register | WAC 296-832-30010 |

Provide outside lighting | WAC 296-832-30015 |

AMENDATORY SECTION (Amending WSR 02-16-087, filed 8/7/02, effective 10/1/02)

WAC 296-832-30005 Have a safe in your store.

You must((:

•)) have a drop-safe, limited access safe, or comparable device in your store.

AMENDATORY SECTION (Amending WSR 02-16-087, filed 8/7/02, effective 10/1/02)

WAC 296-832-30010 Post a notice about your store's safe and cash register.

((You must:

• Post a notice in an obvious place on a window or door stating:

– There is a safe in the store

– Employees have no access to the safe

– The cash register contains only enough cash to do business.)) You must post a notice in an obvious place on a window or door stating:

(1) There is a safe in the store.

(2) Employees have no access to the safe.

(3) The cash register contains only enough cash to do business.

Notes: | ((•)) 1. You will not be cited by ((WISHA)) DOSH for having money in the cash register over the minimal amount needed to do business. |

((•)) 2. All displays and other materials posted in the window(s) or door(s) should be arranged to provide an unobstructed view of the cash register if it is visible from the street. |

AMENDATORY SECTION (Amending WSR 02-16-087, filed 8/7/02, effective 10/1/02)

WAC 296-832-30015 Provide outside lighting.

You must((:

•)) light the store's approach area and parking lot during all night hours your business is open.

Note: | You can do this by: |

((–)) 1. Providing surveillance lighting to observe pedestrian and vehicle entrances. | |

((–)) 2. Providing lighting of a minimum of one foot candle to comply with ANSI/IES RP7-1983. Lighting levels can be measured with a light meter; for comparison purposes 1 foot-candle = 1 lumen incident per square foot = 10.76 lux. |

NEW SECTION

WAC 296-876-099 Definitions.

Cage. An enclosure that encircles the climbing space of a fixed ladder. It is fastened to the ladder side rails or to the structure and may also be called a cage or basket guard.

Cleat. A ladder crosspiece used in climbing or descending. Also called a step or rung.

Equivalent. Alternative design, material, or method to protect against a hazard. You have to demonstrate it provides an equal or greater degree of safety for employees than the method, material, or design specified in the rule.

Extension ladder. A nonself-supporting portable ladder consisting of two or more sections. The sections travel in guides or brackets that allow the length of the ladder to be changed. The size is designated by the sum of the lengths of each section, measured along the side rails.

Failure. The ladder or ladder component loses the ability to carry the load, breaks, or separates into component parts.

Fastenings. Devices to attach a ladder to a structure, building, or equipment.

Fixed ladder. A ladder permanently attached to a structure, building, or equipment.

Grab bars. Handholds placed adjacent to or as an extension above ladders for the purpose of providing access beyond the limits of the ladder.

Job-made ladder. A ladder that is made, not commercially manufactured, to fit a specific job situation. They are for temporary use until a particular phase of construction is completed or until permanent stairways or fixed ladders are ready to use.

Individual-rung/step ladder. A fixed ladder consisting of individual steps or rungs mounted directly to the side or wall of the structure, building, or equipment.

Ladder. A device having steps, rungs, or cleats that can be used to climb or descend.

Ladder safety device. Any device, other than a cage or well, designed to arrest the fall of a person using a fixed ladder.

Ladder type. The designation that identifies the maximum intended load (working load) of the ladder. Ladder types are as follows:

Duty Rating | Ladder Type | Use | Maximum Intended Load (pounds) |

Extra Heavy-Duty | IA | Industry, utilities, contractors | 300 |

Heavy-Duty | I | Industry, utilities, contractors | 250 |

Medium-Duty | II | Painters, offices, light maintenance | 225 |

Light-Duty | III | General household use | 200 |

Landing. Any area such as the ground, roof, or platform that provides access or egress to a ladder.

Maximum intended load. The total load of all persons, equipment, tools, materials, transmitted loads, and other loads reasonably anticipated to be applied to a ladder or ladder component at any one time. Sometimes referred to as working load.

Pitch. The included angle between the horizontal and the ladder, measured on the opposite side of the ladder from the climbing side.

Portable ladder. A ladder that can be readily moved or carried.

Reinforced plastic. A plastic that has high-strength fillers embedded in the base resin to increase strength.

Reinforced plastic ladder. A ladder whose side rails are reinforced plastic. The crosspieces, hardware, and fasteners may be made of metal or other suitable material.

Rung. A ladder crosspiece used in climbing or descending. Also called a cleat or step.

Side-step ladder. A fixed ladder that requires a person to step to the side of the ladder side rails to reach the landing.

Single ladder. A nonself-supporting portable ladder, nonadjustable in length, consisting of one section. The size is designated by the overall length of the side rail.

Single-rail ladder. A portable ladder with crosspieces mounted on a single rail. Single-rail ladders are prohibited from use.

Special-purpose ladder. A portable ladder that is made by modifying or combining design or construction features of the general-purpose types of ladders in order to adapt the ladder to special or specific uses.

Step. A ladder crosspiece used in climbing or descending. Also called a cleat or rung.

Stepladder. A self-supporting portable ladder, nonadjustable in length, with flat steps and hinged at the top. The size is designated by the overall length of the ladder measured along the front edge of the side rails.

Through ladder. A fixed ladder that requires a person to step between the side rails of the ladder to reach the landing.

Trestle ladder. A self-supporting portable ladder, nonadjustable in length, consisting of two sections hinged at the top to form equal angles with the base. The size is designated by the length of the side rails measured along the front edge.

Well. A walled enclosure around a fixed ladder that provides a person climbing the ladder with the same protection as a cage.

Working length. The length of a nonself-supporting ladder, measured along the rails, from the base support point of the ladder to the point of bearing at the top.

AMENDATORY SECTION (Amending WSR 06-16-020, filed 7/24/06, effective 12/1/06)

WAC 296-876-100 Scope.

This chapter applies to portable and fixed ladders, including job-made wooden ladders.

((Exemption:)) EXEMPTION: | This chapter does not apply to: |

((•)) 1. Portable ladders used by the fire services for fire combat that are covered by safety standards for firefighters, chapter 296-305 WAC; | |

((•)) 2. Agriculture activities covered by safety standards for agriculture, chapter 296-307 WAC. |

AMENDATORY SECTION (Amending WSR 06-22-024, filed 10/24/06, effective 12/1/06)

WAC 296-876-150 Training((—Section contents)).

Your responsibility: To train employees who use ladders.

((Training.

WAC 296-876-15005.))

You must meet the requirements... | in this section: |

Training | WAC 296-876-15005 |

AMENDATORY SECTION (Amending WSR 06-22-024, filed 10/24/06, effective 12/1/06)

WAC 296-876-15005 Training.

(1) You must((:

•)) train employees to recognize ladder hazards and the procedures to minimize these hazards.

((•)) (2) You must have a competent person train employees that use ladders in at least the following topics:

((–)) (a) The proper construction, use, placement, and care in handling ladders.

((–)) (b) The maximum intended load capacities of ladders that are used.

((–)) (c) The requirements of this chapter.

((•)) (3) You must retrain employees as necessary to make sure they know and understand the content of the original training.

AMENDATORY SECTION (Amending WSR 05-20-068, filed 10/4/05, effective 1/1/06)

WAC 296-876-200 Design and construction((—Section contents)).

Summary

Your responsibility: To make sure portable ladders meet design and construction requirements.

((Design and construction

WAC 296-876-20005.))

You must meet the requirements... | in this section: |

Design and construction | WAC 296-876-20005 |

AMENDATORY SECTION (Amending WSR 05-20-068, filed 10/4/05, effective 1/1/06)

WAC 296-876-20005 Design and construction.

((IMPORTANT:)) Important:

Design and construction requirements of this section do not apply to special purpose ladders.

((Definition:

A special purpose ladder is a portable ladder that is made by modifying or combining design or construction features of the general-purpose types of ladders in order to adapt the ladder to special or specific uses.))

(1) You must((:

•)) make sure portable ladders and job-made wooden ladders manufactured on or after January 1, 2006, meet the design and construction requirements and specifications of the appropriate American National Standards Institute (ANSI) standard:

((–)) (a) ANSI A14.1-2000, American National Standard for Ladders-Portable Wood-Safety Requirements.

((–)) (b) ANSI A14.2-2000, American National Standard for Ladders-Portable Metal-Safety Requirements.

((–)) (c) ANSI A14.5-2000, American National Standard for Ladders-Portable Reinforced Plastic-Safety Requirements.

((–)) (d) ANSI A14.4-2002, American National Standard Safety Requirements for Job-Made Wooden Ladders.

((•)) (2) You must make sure portable ladders manufactured before January 1, 2006, meet the design and construction requirements and specifications of the appropriate ANSI standard in effect on the date of manufacture:

((–)) (a) ANSI A14.1, American National Standard for Ladders-Portable Wood-Safety Requirements.

((–)) (b) ANSI A14.2, American National Standard for Ladders-Portable Metal-Safety Requirements.

((–)) (c) ANSI A14.5, American National Standard for Ladders-Portable Reinforced Plastic-Safety Requirements.

Note: | A commercially manufactured portable ladder should have a label indicating it meets the requirements of the ANSI standard. If in doubt, check with the manufacturer. |

AMENDATORY SECTION (Amending WSR 05-20-068, filed 10/4/05, effective 1/1/06)

WAC 296-876-300 Ladder care((—Section contents)).

Summary

Your responsibility: To make sure portable ladders are inspected, maintained, stored, and transported properly.

((Condition and inspection

WAC 296-876-30005.

Repair

WAC 296-876-30010.

Storage

WAC 296-876-30015.

Transport

WAC 296-876-30020.))

You must meet the requirements... | in this section: |

Condition and inspection | WAC 296-876-30005 |

Repair | WAC 296-876-30010 |

Storage | WAC 296-876-30015 |

Transport | WAC 296-876-30020 |

AMENDATORY SECTION (Amending WSR 05-20-068, filed 10/4/05, effective 1/1/06)

WAC 296-876-30005 Condition and inspection.

(1) You must((:

•)) keep portable ladders in good, usable condition. Good, usable condition includes, but is not limited to:

((–)) (a) Joints between the steps or rungs and the side rails are tight.

((–)) (b) Rungs, cleats, or steps are not bent, broken, or missing.

((–)) (c) Side rails are not bent, broken, or split.

((–)) (d) All bolts and rivets are in place and secure.

((–)) (e) Hardware, fittings, and accessories are securely attached and working properly.

((–)) (f) Ropes are not frayed or badly worn.

((–)) (g) Moveable parts operate freely without binding or excessive play.

((–)) (h) Safety feet and other auxiliary equipment are not excessively worn.

((–)) (i) Metal components are not corroded.

((–)) (j) There are no other faulty or defective components.

((•)) (2) You must make sure wood ladders are not coated with an opaque covering except for the minimum amount necessary for identification and warning information which may be placed on one face only of a side rail.

((•)) (3) You must have a competent person inspect a ladder:

((–)) (a) When required by Table 1, Ladder Inspection Criteria; ((AND)) and

((–)) (b) After any other occurrence that could affect safe use.

((•)) (4) You must make sure any ladder with structural damage or other hazardous defect is:

((–)) (a) Marked to identify it as defective or tagged with "do not use" or similar language; ((AND)) and

((–)) (b) Removed from service.

Note: | Ladders subjected to certain acids or alkali materials may experience chemical corrosion and a reduction in strength. Consult the manufacturer or a qualified person prior to use. |

Table 1

Ladder Inspection Criteria

When the ladder is: | Do the following: | |

First placed into service and periodically while in service | ((•)) | Inspect the ladder for visible defects, including, but not limited to: |

((–)) 1. | Working parts; ((AND)) and | |

((–)) 2. | Rung or step connections to the side rails. | |

Damaged by impact or tips over | ((•)) 1. | Visually inspect the ladder for((: |

–)) | dents, bends, cracks or splits | |

((•)) 2. | Check: | |

((–)) a. | Rung or step connections to the side rails. | |

((–)) b. | Hardware connections. | |

((–)) c. | Rivets for shear damage. | |

((–)) d. | All other components. | |

Exposed to excessive heat such as a fire | ((•)) 1. | Visually inspect the ladder for damage. |

((•)) 2. | Test for deflection and strength characteristics using the "in-service use tests” contained in the appropriate ANSI. | |

((Exemption)) EXEMPTION: Job-made wooden ladders are not to be subjected to load or impact tests. Those tests may weaken lumber components or fasteners, causing hidden damage that could result in sudden failure during use. | ||

AMENDATORY SECTION (Amending WSR 05-20-068, filed 10/4/05, effective 1/1/06)

WAC 296-876-30010 Repair.

(1) You must((:

•)) make sure repairs restore the ladder to a condition meeting its original design criteria.

((•)) (2) You must prohibit repairs to a defective side rail.

Note: | A commercially manufactured ladder with a defective side rail cannot be repaired by the user. Side rail repair can only be done by the manufacturer. |

AMENDATORY SECTION (Amending WSR 05-20-068, filed 10/4/05, effective 1/1/06)

WAC 296-876-30015 Storage.

You must((:

•)) make sure material is not put on ladders in storage.

Note: | ((•)) Store portable ladders on racks designed to protect them when not in use. The racks should have enough supporting points to prevent the ladder from sagging. ((•)) Do not store wood ladders near sources of heat, moisture, or dampness. |

AMENDATORY SECTION (Amending WSR 05-20-068, filed 10/4/05, effective 1/1/06)

WAC 296-876-30020 Transport.

(1) You must((:

•)) properly support ladders while transporting them on vehicles.

((•)) (2) You must make sure ladders transported in a truck rack are positively secured in a fixed position that prevents chafing or abrasion.

Note: | Securing the ladder to each support point will greatly reduce damage due to road shock. |

AMENDATORY SECTION (Amending WSR 05-20-068, filed 10/4/05, effective 1/1/06)

WAC 296-876-400 ((Use—Section contents)) Portable ladder use.

Summary

Your responsibility: To use portable ladders safely.

((Designed use

WAC 296-876-40005.

Workplace activities or traffic

WAC 296-876-40010.

Support

WAC 296-876-40015.

Set-up

WAC 296-876-40020.

Climbing and descending

WAC 296-876-40025.

Getting on and off ladders at upper levels

WAC 296-876-40030.

Exposed electrical hazards

WAC 296-876-40035.

Persons on ladders

WAC 296-876-40040.

Multisection ladders

WAC 296-876-40045.

Self-supporting ladders

WAC 296-876-40050.))

You must meet the requirements... | in this section: |

Designed use | WAC 296-876-40005 |

Workplace activities or traffic | WAC 296-876-40010 |

Support | WAC 296-876-40015 |

Set-up | WAC 296-876-40020 |

Climbing and descending | WAC 296-876-40025 |

Getting on and off ladders at upper levels | WAC 296-876-40030 |

Exposed electrical hazards | WAC 296-876-40035 |

Persons on ladders | WAC 296-876-40040 |

Multisection ladders | WAC 296-876-40045 |

Self-supporting ladders | WAC 296-876-40050 |

AMENDATORY SECTION (Amending WSR 05-20-068, filed 10/4/05, effective 1/1/06)

WAC 296-876-40005 Designed use.

(1) You must((:

•)) use ladders only for their intended purpose.

Note: | Unless specifically recommended by the manufacturer, do not use a ladder as a: |

((•)) 1. Brace. | |

((•)) 2. Skid. | |

((•)) 3. Lever. | |

((•)) 4. Guy or gin pole. | |

((•)) 5. Gangway. | |

((•)) 6. Platform. | |

((•)) 7. Scaffold plank. | |

((•)) 8. Material hoist. |

(2) You must((:

•)) make sure not to overload ladders. Do not exceed either the:

((–)) (a) Maximum intended load; ((OR)) or

((–)) (b) Manufacturer's rated capacity.

((Definitions:

– The maximum intended load is the total load of all persons, equipment, tools, materials, transmitted loads, and other loads reasonably anticipated to be applied to a ladder or ladder component at any one time.

– Ladder type. The designation that identifies the maximum intended load (working load) of the ladder. Ladder types are as follows:

Duty Rating | Ladder Type | Use | Maximum Intended Load (Pounds) |

Extra Heavy-Duty | IA | Industry, utilities, contractors | 300 |

Heavy-Duty | I | Industry, utilities, contractors | 250 |

Medium-Duty | II | Painters, offices, light maintenance | 225 |

Light-Duty | III | General household use | 200)) |

AMENDATORY SECTION (Amending WSR 05-20-068, filed 10/4/05, effective 1/1/06)

WAC 296-876-40010 Workplace activities or traffic.

(1) You must((:

•)) protect ladders that are ((set-up)) set up in a location where they could be displaced by workplace activities or traffic by either:

((–)) (a) Securing the ladder to prevent accidental displacement; ((OR)) or

((–)) (b) Using a barricade to keep the activities or traffic away from the ladder.

((•)) (2) You must protect ladders that are set-up in front of doors that open towards the ladder by doing at least one of the following:

((–)) (a) Block the door open.

((–)) (b) Lock the door.

((–)) (c) Guard the door to keep it from opening into the ladder.

AMENDATORY SECTION (Amending WSR 05-20-068, filed 10/4/05, effective 1/1/06)

WAC 296-876-40015 Support.

(1) You must((:

•)) place the ladder either:

((–)) (a) With a secure footing on a firm, level support surface; ((OR)) or

((–)) (b) Secure the ladder to prevent accidental displacement.

((•)) (2) You must make sure a ladder is not placed on ice, snow, or other slippery surface unless the ladder is prevented from accidental displacement by either:

((–)) (a) Securing it; ((OR)) or

((–)) (b) Providing the ladder with slip-resistant feet.

Note: | Slip-resistant feet are not a substitute for care in placing, lashing, or holding a ladder that is used on a slippery surface. |

(3) You must((:

•)) make sure ladders are not placed on boxes, barrels, or other unstable bases to obtain additional height.

((•)) (4) You must place a straight ladder so the side rails are equally supported by the top support, unless the ladder is equipped with a single support attachment.

((•)) (5) You must make sure the top support of the ladder is reasonably rigid and able to support the load.

AMENDATORY SECTION (Amending WSR 05-20-068, filed 10/4/05, effective 1/1/06)

WAC 296-876-40020 Set-up.

(1) You must((:

•)) set up nonself-supporting ladders at a safe angle. The ladder is set at the proper angle when the horizontal distance from the top support to the foot of the ladder is approximately one-quarter the working length of the ladder.

((•)) (2) You must set up job-made ladders with spliced side rails so that the horizontal distance from the top support to the foot of the ladder is not greater than one-eighth the working length of the ladder.

((Definition:

The working length of a nonself-supporting ladder is the length, measured along the rails, from the base support point of the ladder to the point of bearing at the top.

Safe Ladder Angle))

|

AMENDATORY SECTION (Amending WSR 05-20-068, filed 10/4/05, effective 1/1/06)

WAC 296-876-40025 Climbing and descending.

(1) You must((:

•)) have both hands free to hold on to the ladder.

((•)) (2) You must face the ladder when climbing or descending.

((•)) (3) You must keep ladders free of oil, grease, or other slippery materials.

((•)) (4) You must keep the area around the top and bottom of ladders clear.

((•)) (5) You must make sure single-rail ladders are not used.

((Definition:

A single-rail ladder is a portable ladder with crosspieces mounted on a single rail.))

AMENDATORY SECTION (Amending WSR 05-20-068, filed 10/4/05, effective 1/1/06)

WAC 296-876-40030 Getting on and off ladders at upper levels.

(1) You must((:

•)) make sure a ladder used to access an upper level has the side rails extended at least three feet (((.9)) 0.9 m) above the landing surface if the ladder length permits.

((•)) (2) You must do the following if a ladder used to access an upper level is not long enough to obtain a three-foot side rail extension above the landing surface:

((–)) (a) Secure the ladder at the top to a rigid support that will not deflect.

((–)) (b) Provide a grasping device, such as a grabrail, to assist in mounting and dismounting the ladder.

((–)) (c) Make sure the ladder deflection under a load would not, by itself, cause it to slip off its support.

((•)) (3) You must make sure, if two or more separate ladders are used to reach an elevated work area, that the ladders are offset with a platform or landing between them.

((Exemption:)) EXEMPTION: | A platform or landing is not required when a portable ladder is used to reach a fixed ladder on structures such as utility towers and billboards where the bottom of the fixed ladder is elevated to limit access. |

AMENDATORY SECTION (Amending WSR 05-20-068, filed 10/4/05, effective 1/1/06)

WAC 296-876-40035 Exposed electrical hazards.

You must((:

•)) use ladders with nonconductive side rails where the ladder could contact uninsulated, energized electric lines or equipment. ((–)) Metal ladders or other ladders specifically designed to permit grounding or dissipation of static electricity may be used around high-static electrical fields if all of the following are met:

((•)) (1) Using nonconductive ladders would present a greater hazard than using conductive ladders.

((•)) (2) Ladders are prominently marked and identified as being conductive.

((•)) (3) Ladders are grounded when used near energized lines or equipment.

Note: | Examples of ladders with conductive side rails are metal ladders, and wood or reinforced plastic ladders with metal side rail reinforcement. |

AMENDATORY SECTION (Amending WSR 05-20-068, filed 10/4/05, effective 1/1/06)

WAC 296-876-40040 Persons on ladders.

(1) You must((:

•)) make sure a ladder is not moved, shifted, or adjusted while anyone is on it.

((•)) (2) You must secure the ladder at the top and bottom when working from it.

((•)) (3) You must use a safety belt with a lanyard that is secured to the ladder when doing any work that:

((–)) (a) Requires the use of both hands; ((AND)) and

((–)) (b) Is done from a ladder more than twenty-five feet above the ground or floor.

((•)) (4) You must prohibit work being done from a ladder more than twenty-five feet above the ground or floor if the work requires wearing eye protection or a respirator.

AMENDATORY SECTION (Amending WSR 05-20-068, filed 10/4/05, effective 1/1/06)

WAC 296-876-40045 Multisection ladders.

(1) You must((:

•)) make sure not to tie or fasten ladder sections together to make longer ladders unless:

((–)) (a) The ladder manufacturer endorses this type of use; ((AND)) and

((–)) (b) You have hardware fittings specifically designed for this purpose.

((•)) (2) You must make sure each section of a multisection ladder, when fully extended and locked in position to be used, overlaps the adjacent section as indicated in Table 2, Minimum Required Overlap for Extension Ladders.

Table 2

Minimum Required Overlap for Extension Ladders

If the ladder size (feet) is: | Minimum required overlap (feet) for a two-section ladder is (((feet))): |

Up to and including 36 | 3 |

Over 36 up to and including 48 | 4 |

Over 48 up to and including 60 | 5 |

AMENDATORY SECTION (Amending WSR 05-20-068, filed 10/4/05, effective 1/1/06)

WAC 296-876-40050 Self-supporting ladders.

(1) You must((:

•)) make sure self-supporting ladders are not used as single ladders or in the partially closed position.

((•)) (2) You must make sure stepladders are fully opened with the spreaders locked.

((•)) (3) You must make sure not to climb on the rear braces of a self-supporting ladder unless they are designed and recommended for that purpose by the manufacturer.

((•)) (4) You must prohibit standing or stepping on the:

((–)) (a) Top cap and top step of a step or trestle ladder.

((–)) (b) Bucket or pail shelf of a self-supporting ladder.

((Exemption:)) EXEMPTION: | The restriction against using the top step is not applicable if it is eighteen inches or more below the top cap. |

AMENDATORY SECTION (Amending WSR 06-16-020, filed 7/24/06, effective 12/1/06)

WAC 296-876-500 Fixed ladder design and construction((—Section contents)) installed on or after December 1, 2006.

Summary

Your responsibility: To make sure fixed ladders installed on or after December 1, 2006, meet design and construction requirements.

((Design and construction—Fixed ladders installed on or after December 1, 2006.

WAC 296-876-50010))

You must meet the requirements... | in this section: |

Design and construction—Fixed ladders installed on or after December 1, 2006 | WAC 296-876-50010 |

AMENDATORY SECTION (Amending WSR 06-16-020, filed 7/24/06, effective 12/1/06)

WAC 296-876-50010 Design and construction—Fixed ladders installed on or after December 1, 2006.

You must((:

•)) make sure fixed ladders installed on or after December 1, 2006, meet the design and construction requirements of ANSI A14.3-2002, American National Standard for Ladders-Fixed-Safety Requirements.

Note: | Ladders will be considered to have met the requirements of this section if they meet the design and construction requirements of ANSI A14.3, American National Standard for Ladders-Fixed-Safety Requirements, in effect at the time they are installed. |

AMENDATORY SECTION (Amending WSR 06-16-020, filed 7/24/06, effective 12/1/06)

WAC 296-876-600 Fixed ladder design and construction((—Section contents)) installed before December 1, 2006.

Summary

Your responsibility: To make sure fixed ladders installed before December 1, 2006, meet design and construction requirements.

((Design and construction—Fixed ladders installed before December 1, 2006.

WAC 296-876-60005

Design loads.

WAC 296-876-60010

Pitch.

WAC 296-876-60015

Welding.

WAC 296-876-60020

Ladder surfaces.

WAC 296-876-60025

Rungs, cleats and steps.

WAC 296-876-60030

Side rails.

WAC 296-876-60035

Clearances.

WAC 296-876-60040

Step-across distance.

WAC 296-876-60045

Extensions and grab bars.

WAC 296-876-60050

Hatches.

WAC 296-876-60055

Platforms.

WAC 296-876-60060

Protective structures and equipment.

WAC 296-876-60065

Cages.

WAC 296-876-60070

Wells.

WAC 296-876-60075

Ladder safety devices.

WAC 296-876-60080))

You must meet the requirements... | in this section: |

Design and construction—Fixed ladders installed before December 1, 2006. | WAC 296-876-60005 |

Design loads | WAC 296-876-60010 |

Pitch | WAC 296-876-60015 |

Welding | WAC 296-876-60020 |

Ladder surfaces | WAC 296-876-60025 |

Rungs, cleats and steps | WAC 296-876-60030 |

Side rails | WAC 296-876-60035 |

Clearances | WAC 296-876-60040 |

Step-across distance | WAC 296-876-60045 |

Extensions and grab bars | WAC 296-876-60050 |

Hatches | WAC 296-876-60055 |

Platforms | WAC 296-876-60060 |

Protective structures and equipment | WAC 296-876-60065 |

Cages | WAC 296-876-60070 |

Wells | WAC 296-876-60075 |

Ladder safety devices | WAC 296-876-60080 |

AMENDATORY SECTION (Amending WSR 06-16-020, filed 7/24/06, effective 12/1/06)

WAC 296-876-60005 Design and construction—Fixed ladders installed before December 1, 2006.

You must((:

•)) make sure fixed ladders installed before December 1, 2006, meet the requirements of WAC 296-876-60010 through 296-876-60080.

Note: | Ladders will be considered to have met the requirements of this section if they meet the design and construction requirements of ANSI A14.3, American National Standard for Ladders-Fixed-Safety Requirements, in effect at the time they are installed. |

AMENDATORY SECTION (Amending WSR 06-16-020, filed 7/24/06, effective 12/1/06)

WAC 296-876-60010 Design loads.

(1) You must((:

•)) make sure each ladder is able to support, without failure, the total of the following loads:

((–)) (a) At least two loads of two hundred and fifty pounds each, concentrated between any two consecutive attachments.

((–)) (b) Any additional concentrated loads of two hundred and fifty pounds each determined from the anticipated use of the ladder.

((–)) (c) Anticipated loads caused by all of the following that apply:

((■)) (i) Ice buildup.

((■)) (ii) Winds.

((■)) (iii) Rigging attached to the ladder, including the load to be lifted.

((■)) (iv) Impact loads resulting from the use of ladder safety devices.

((•)) (2) You must make sure the design of rails, supports, and fastenings includes:

((–)) (a) Live loads to be supported by the ladder; and

((–)) (b) The weight of the ladder and everything attached to it.

((•)) (3) You must consider all live loads to be concentrated at the point or points that will cause the maximum stress on the ladder or structural member.

((•)) (4) You must make sure each step or rung is capable of supporting a single concentrated load of at least two hundred fifty pounds applied in the middle of the step or rung.

((•)) (5) You must make sure the design stresses for wood components of ladders meet the requirements and specifications of ANSI A14.1, American National Standard for Ladders-Portable Wood-Safety Requirements, in effect when the ladder was installed.

((•)) (6) You must make sure fastenings are designed to meet the ladder load requirements.

AMENDATORY SECTION (Amending WSR 06-16-020, filed 7/24/06, effective 12/1/06)

WAC 296-876-60015 Pitch.

You must((:

•)) make sure the pitch of the ladder is no greater than ninety degrees from the horizontal.

Notes: | ((•)) 1. The preferred pitch of fixed ladders is within the range of seventy-five to ninety degrees from the horizontal. Ladders with a pitch range of sixty to seventy-five degrees from the horizontal are considered substandard and are only permitted if necessary to meet the installation requirements. |

((•)) 2. Fixed stairs are an alternative for installations where a pitch angle of less than sixty degrees is necessary. See Fixed industrial stairs, WAC 296-24-765, in the General Safety and Health Standards, chapter 296-24 WAC. |

AMENDATORY SECTION (Amending WSR 06-16-020, filed 7/24/06, effective 12/1/06)

WAC 296-876-60020 Welding.

You must((:

•)) make sure welding meets the requirements of the ANSI A14.3, American National Standard for Ladders-Fixed-Safety Requirements, in effect at the time the ladder was installed.

AMENDATORY SECTION (Amending WSR 06-16-020, filed 7/24/06, effective 12/1/06)

WAC 296-876-60025 Ladder surfaces.

You must((:

•)) make sure all parts and surfaces of the ladder are free of splinters, sharp edges, burrs, or projections that may be hazardous to persons using the ladder.

AMENDATORY SECTION (Amending WSR 06-16-020, filed 7/24/06, effective 12/1/06)

WAC 296-876-60030 Rungs, cleats and steps.

(1) You must((:

•)) make sure rungs have a minimum diameter as follows:

((–)) (a) Rungs of wood ladders are at least one and one-eighth inches.

((–)) (b) Rungs of metal ladders subject to unusually corrosive exposures, such as individual metal rungs imbedded in concrete which serve as access to pits and to other areas under floors, are at least one inch.

((–)) (c) Rungs of all other metal ladders are at least three-quarters inch.

((•)) (2) You must make sure rungs, cleats, and steps are all of the following:

((–)) (a) Parallel.

((–)) (b) Level.

((–)) (c) Uniformly spaced throughout the length of the ladder.

((–)) (d) Spaced so the distance from the centerline of one rung to the centerline of the next rung does not exceed twelve inches.

Exception: | The vertical distance from the ground, floor, or roof at the access level to the first rung may be adjusted within a range of fourteen inches. |

(3) You must((:

•)) make sure the minimum inside clear width of the stepping surface of rungs, steps, or cleats is sixteen inches.

((•)) (4) You must make sure individual rung or step-type ladders have rungs or steps that are shaped so that a person's foot cannot slide off the end.

AMENDATORY SECTION (Amending WSR 06-16-020, filed 7/24/06, effective 12/1/06)

WAC 296-876-60035 Side rails.

(1) You must((:

•)) make sure the shape of the side rail:

((–)) (a) Provides an adequate gripping surface; and

((–)) (b) Is uniform throughout the length of climb.

((•)) (2) You must make sure a side rail that has been spliced to obtain a longer length is at least equivalent in strength to a one-piece side rail made of the same material.

AMENDATORY SECTION (Amending WSR 06-16-020, filed 7/24/06, effective 12/1/06)

WAC 296-876-60040 Clearances.

(1) You must((:

•)) make sure ladders without wells or cages are at least thirty inches from the nearest permanent object on the climbing side, measured perpendicular to the ladder from the centerline of the rungs, cleats, or steps.

((Exemption:)) EXEMPTION: | When unavoidable obstructions are encountered, the minimum perpendicular clearance between the centerline of the rungs, cleats, or steps and an obstruction on the climbing side may be reduced to twenty-four inches if a deflection device is installed to guide persons around the obstruction. |

(2) You must((:

•)) make sure ladders without wells or cages have a clear width from the nearest permanent object on each side of the ladder of at least fifteen inches, measured from the center of the rungs, cleats, or steps.

((•)) (3) You must make sure the distance from the centerline of the rungs, cleats, or steps to the nearest permanent object in back of the ladder is at least seven inches.

((Exemption:)) EXEMPTION: | Fixed ladders in elevator pits may reduce the minimum clearance from the ladder to the nearest permanent object in back of the ladder to four and one-half inches. |

AMENDATORY SECTION (Amending WSR 06-16-020, filed 7/24/06, effective 12/1/06)

WAC 296-876-60045 Step-across distance.

(1) You must((:

•)) make sure a through ladder at the point of access or egress has a step-across distance, measured from the centerline of the steps or rungs to the nearest edge of the landing area, that is:

((–)) (a) Not less than seven inches; or

((–)) (b) Greater than twelve inches.

((•)) (2) You must make sure a side-step ladder at the point of access or egress has a step-across distance, measured from the side rail of the ladder to the nearest edge of the landing area, that is:

((–)) (a) Not less than seven inches; or

((–)) (b) Greater than twelve inches.

AMENDATORY SECTION (Amending WSR 06-16-020, filed 7/24/06, effective 12/1/06)

WAC 296-876-60050 Extensions and grab bars.

(1) You must((:

•)) make sure the side rails of through or side-step ladders extend forty-two inches above the top of the access level or landing platform.

Note: | For a parapet ladder, the access level is: |

((–)) 1. The roof if the parapet is cut to permit passage through it; or | |

((–)) 2. The top of the parapet if it is continuous and uncut. |

(2) You must((:

•)) make sure the extension of a through ladder above the access level or landing platform has:

((–)) (a) Steps or rungs omitted from the extension; and

((–)) (b) Clearance between the side rails that is:

((■)) (i) Not less than twenty-four inches; or

((■)) (ii) Greater than thirty inches.

((Exemption:)) EXEMPTION: | The maximum clearance between side rails of the extension may be increased to thirty-six inches if the ladder has a ladder safety device. |

(3) You must((:

•)) make sure the side rails of through or side-step ladders extend forty-two inches above the top of the access level or landing platform.

((•)) (4) You must make sure side-step ladders have the steps or rungs and the side rails continuous in the extension.

((•)) (5) You must make sure individual rung-step ladders are extended at least forty-two inches above the access level or landing platform by:

((–)) (a) Continuing the rung spacings as horizontal grab bars; or

((–)) (b) Providing vertical grab bars that have the same lateral spacing as the vertical legs of the rungs.

((Exemption:)) EXEMPTION: | Extensions are not required for individual rung-step ladders with access openings through a manhole or hatch. |

(6) You must((:

•)) make sure grab bars:

((–)) (a) Are at least four inches from the nearest permanent object in back of the grab bar, measured from the centerline of the grab bar; and

((–)) (b) Do not extend beyond the rungs on the climbing side of the ladder.

AMENDATORY SECTION (Amending WSR 06-16-020, filed 7/24/06, effective 12/1/06)

WAC 296-876-60055 Hatches.

(1) You must((:

•)) make sure counterbalanced hatch covers open at least seventy degrees from the horizontal.

((•)) (2) You must make sure the inside clear width of the hatch is a nominal thirty inches.