WSR 15-15-150

PROPOSED RULES

DEPARTMENT OF

LABOR AND INDUSTRIES

[Filed July 21, 2015, 7:55 a.m.]

Original Notice.

Preproposal statement of inquiry was filed as WSR 14-17-089.

Title of Rule and Other Identifying Information: eRules phase III; chapter 296-56 WAC, Safety standards for longshore, stevedore, and waterfront operations; chapter 296-809 WAC, Confined spaces; chapter 296-806 WAC, Machine safety; chapter 296-828 WAC, Hazardous chemicals in laboratories; chapter 296-860 WAC, Railroad clearances and walkways in private rail yards and plants; and chapter 296-864 WAC, Split (multipiece) rim and single-piece rim wheels.

Hearing Location(s): Department of Labor and Industries, 7273 Linderson Way S.W., Tumwater, WA 98501, on September 14, 2015, at 1:00 p.m.

Date of Intended Adoption: October 27, 2015.

Submit Written Comments to: Tari Enos, P.O. Box 44620, Olympia, WA 98504, e-mail tari.enos@lni.wa.gov, fax (360) 902-5619, by September 21, 2015.

Assistance for Persons with Disabilities: Contact Tari Enos by September 8, 2015, at (360) 902-5541.

Purpose of the Proposal and Its Anticipated Effects, Including Any Changes in Existing Rules:

• | No changes in requirements as a result of this rule making. |

• | Consistent format for all DOSH safety and health rules. |

• | Easy to access rules for smart phone and table [tablet] users. |

• | Easy navigation in PDF files provided through bookmarks in the rules. |

• | Easier referencing by replacing bullets and dashes with numbers and letters. |

• | Enhanced rule update efficiency for customers through electronic postings. |

Reasons Supporting Proposal: When the agency updated its web site, template DOSH rules in HTML were broken and DOSH began forwarding rule users to the office of the code reviser web site, causing more confusion among customers. This rule package will resolve stakeholder issues that have caused confusion for rule users by bringing one clear and consistent format to all of our rules.

Statutory Authority for Adoption: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060.

Statute Being Implemented: Chapter 49.17 RCW.

Rule is not necessitated by federal law, federal or state court decision.

Name of Proponent: Department of labor and industries, governmental.

Name of Agency Personnel Responsible for Drafting: Chris Miller, Tumwater, (360) 902-5516; Implementation and Enforcement: Anne Soiza, Tumwater, (360) 902-5090.

No small business economic impact statement has been prepared under chapter 19.85 RCW. No change in requirements, so no economic impact.

A cost-benefit analysis is not required under RCW 34.05.328. No change in requirements, so no change in costs or benefits.

July 22 [21], 2015

Joel Sacks

Director

NEW SECTION

WAC 296-56-099 Definitions.

Approved. The equipment has been approved for the specified use by a nationally recognized testing laboratory.

Approved power-operated industrial truck. One listed or approved for the intended use by a nationally recognized testing laboratory.

Apron. That open portion of a marine terminal immediately adjacent to a vessel berth and used in the direct transfer of cargo between the terminal and vessel.

Assistant director for DOSH. The assistant director of DOSH services, department of labor and industries or their authorized representative.

Authorized. In reference to an employee's assignment, means selected by the employer for that purpose.

Cage (basket guard). A barrier enclosing or nearly enclosing a ladder's climbing space and fastened to one or both of the ladder's side rails or to another structure.

Cargo board. The typical wing or lip-type stevedore board hoisted to or from vessels by means of a bar bridle. Other pallet boards include all other platforms used to hold cargo for the purpose of transporting it from place to place.

Cargo door (transit shed door). A door designed to permit transfer of cargo to and from a marine terminal structure.

Cargo packaging. Any method of containment for shipment, including cases, cartons, crates, and sacks, but excluding large units such as intermodal containers, vans, or similar devices.

Confined space. A space that:

(a) Is large enough and so configured that an employee can bodily enter and perform assigned work; and

(b) Has limited or restricted means for entry or exit (for example, tanks, vessels, silos, storage bins, hoppers, vaults, and pits are spaces that may have limited means of entry); and

(c) Is not designed for continuous employee occupancy.

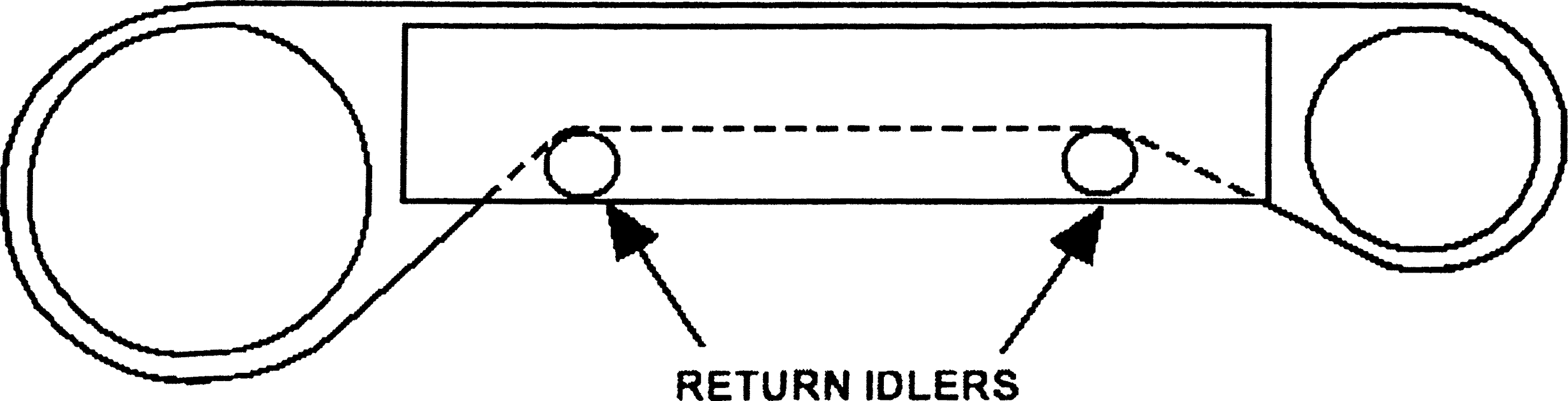

Conveyor. A device designed exclusively for transporting bulk materials, packages or objects in a predetermined path and having fixed or selective points of loading or discharge.

Danger zone. Any place in or about a machine or piece of equipment where an employee may be struck by or caught between moving parts, caught between moving and stationary objects or parts of the machine, caught between the material and a moving part of the machine, burned by hot surfaces or exposed to electric shock. Examples of danger zones are nip and shear points, shear lines, drive mechanisms, and areas beneath counterweights.

Designated person. A person who possesses specialized abilities in a specific area and is assigned by the employer to perform a specific task in that area.

Dock. A wharf or pier forming all or part of a waterfront facility, including marginal or quayside berthing facilities; not to be confused with "loading dock" as at a transit shed or container freight station, or with the body of water between piers or wharves.

Dock facilities. Includes all piers, wharves, sheds, aprons, dolphins, cranes, or other gear or equipment owned or controlled by the dock or facility owner, where cargo or materials are loaded, moved or handled to or from a vessel.

Dockboards (car and bridge plates). Devices for spanning short distances between rail cars or highway vehicles and loading platforms that do not expose employees to falls greater than 4 feet (1.22 m).

DOSH. Division of Occupational Safety and Health.

Elevator. A permanent hoisting and lowering mechanism with a car or platform moving vertically in guides and serving two or more floors of a structure. The term excludes such devices as conveyors, tiering or piling machines, material hoists, skip or furnace hoists, wharf ramps, lift bridges, car lifts, and dumpers.

Enclosed space. An indoor space, other than a confined space, that may contain or accumulate a hazardous atmosphere due to inadequate natural ventilation. Examples of enclosed spaces are trailers, railcars, and storage rooms.

Escalator. A power-driven continuous moving stairway principally intended for the use of persons.

Examination. As applied to material handling devices required to be certified by this chapter, means a comprehensive survey consisting of the criteria outlined in WAC 296-56-60093 through 296-56-60097. The examination is supplemented by a unit proof test in the case of annual survey.

Fixed ladder. A ladder, including individual rung ladders, permanently attached to a structure, building, or piece of equipment.

Fixed stairway. Interior or exterior stairs serving machinery, tanks, or equipment, and stairs to or from floors, platforms, or pits. The term does not apply to stairs intended only for fire exit purposes, to articulated stairs (the angle of which changes with the rise and fall of the base support) or to stairs forming an integral part of machinery.

Flammable atmosphere. An atmosphere containing more than ten percent of the lower flammable limit (LFL) of a flammable or combustible vapor or dust mixed with air. Such atmospheres are usually toxic as well as flammable.

Front-end attachments.

(a) As applied to power-operated industrial trucks, means the various devices, such as roll clamps, rotating and sideshifting carriages, magnets, rams, crane arms or booms, load stabilizers, scoops, buckets, and dumping bins, attached to the load end for handling lifts as single or multiple units.

(b) As applied to cranes, means various attachments applied to the basic machine for the performance of functions such as lifting, clamshell, or magnet services.

Fumigant. Is a substance or mixture of substances, used to kill pests or prevent infestation, which is a gas or is rapidly or progressively transformed to the gaseous state even though some nongaseous or particulate matter may remain and be dispersed in the treatment space.

Guarded. Shielded, fenced, or enclosed by covers, casings, shields, troughs, spillways or railings, or guarded by position or location. Examples of guarding methods are guarding by location (positioning hazards so they are inaccessible to employees) and point of operation guarding (using barrier guards, two-hand tripping devices, electronic safety devices, or other such devices).

Hazardous cargo, material, substance or atmosphere.

(a) Any substance listed in chapters 296-62 and 296-841 WAC;

(b) Any material in the hazardous materials table and hazardous materials communications regulations of the Department of Transportation, 49 C.F.R. Part 172;

(c) Any article not properly described by a name in the hazardous materials table and hazardous materials communications regulations of the Department of Transportation, 49 C.F.R. Part 172, but which is properly classified under the definition of those categories of dangerous articles given in 49 C.F.R. Part 173;

(d) Atmospheres having concentrations of airborne chemicals in excess of permissible exposure limits as defined in chapter 296-62 WAC; or

(e) Any atmosphere with an oxygen content of less than nineteen and one-half percent by volume.

Hot work. Riveting, welding, flame cutting or other fire or spark-producing operation.

House falls. Spans and supporting members, winches, blocks, and standing and running rigging forming part of a marine terminal and used with a vessel's cargo gear to load or unload by means of married falls.

Inspection. As applied to material handling devices required to be certified by this chapter, includes a complete visual examination of all visible parts of the device.

Intermodal container. A reusable cargo container of rigid construction and rectangular configuration intended to contain one or more articles of cargo or bulk commodities for transportation by water and one or more other transport modes without intermediate cargo handling. The term includes completely enclosed units, open top units, fractional height units, units incorporating liquid or gas tanks and other variations fitting into the container system, demountable or with attached wheels. It does not include cylinders, drums, crates, cases, cartons, packages, sacks, unitized loads or any other form of packaging.

Ladder safety device. A support system limiting an employee's drop or fall from the ladder, and which may incorporate friction brakes, lifelines and lanyards, or sliding attachments.

Loose gear. Removable or replaceable components of equipment or devices which may be used with or as a part of assembled material handling units for purposes such as making connections, changing line direction and multiplying mechanical advantage. Examples include shackles and snatch blocks.

Marina. A small harbor or boat basin providing dockage, supplies, and services for small craft.

Marine terminal. Wharves, bulkheads, quays, piers, docks, and other berthing locations and adjacent storage or contiguous areas and structures associated with the primary movement of cargo or materials from vessel to shore or shore to vessel. It includes structures which are devoted to receiving, handling, holding, consolidation, loading or delivery of waterborne shipments and passengers, and areas devoted to the maintenance of the terminal or equipment. The term does not include production or manufacturing areas having their own docking facilities and located at a marine terminal nor storage facilities directly associated with those production or manufacturing areas.

Other pallet boards. All other platforms used to hold cargo for the purpose of transporting it from place to place.

Permit-required confined space (permit space). A confined space that has one or more of the following characteristics:

(a) Contains or has a potential to contain a hazardous atmosphere;

(b) Contains a material that has the potential for engulfing an entrant;

(c) Has an internal configuration such that an entrant could be trapped or asphyxiated by inwardly converging walls or by a floor which slopes downward and tapers to a smaller cross-section; or

(d) Contains any other recognized serious safety or health hazard.

Ramps. Other flat-surface devices for passage between levels and across openings not covered under "dockboards."

Ship's stores. Materials that are aboard a vessel for the upkeep, maintenance, safety, operation, or navigation of the vessel, or for the safety or comfort of the vessel's passengers or crew.

Spiral stairway. One with closed circular form, uniform sector-shaped treads and a supporting column.

Spray booth. An enclosure containing a flammable or combustible spraying operation and confining and limiting the escape of paint, vapor and residue by means of a powered exhaust system.

Spraying area. Any area where flammable vapors, mists or combustible residues, dusts or deposits may be present due to paint spraying operations.

Well. A permanent complete enclosure around a fixed ladder, which is attached to the walls of the well.

((PART A—GENERAL))

AMENDATORY SECTION (Amending WSR 85-01-022, filed 12/11/84)

WAC 296-56-600 Marine terminals.

Summary

Your responsibility: To protect employees from hazards associated with marine terminals.

You must meet the requirements … |

in this section: |

Scope and applicability |

WAC 296-56-60001 |

Variance and procedure |

WAC 296-56-60003 |

Definitions |

WAC 296-56-60005 |

Personnel |

WAC 296-56-60006 |

Housekeeping |

WAC 296-56-60007 |

Accident prevention program |

WAC 296-56-60009 |

Emergency action plans |

WAC 296-56-60010 |

AMENDATORY SECTION (Amending WSR 99-02-024, filed 12/30/98, effective 3/30/99)

WAC 296-56-60006 Personnel.

(1) ((Qualifications of)) You must make sure machinery operators((.)) meet qualifications:

(a) Only those employees determined by the employer to be competent by reason of training or experience, who understand the signs, notices, and operating instructions and are familiar with the signal code in use ((shall)) must be permitted to operate a crane, winch, or other power-operated cargo handling apparatus, or any power-operated vehicle, or give signals to the operator of any hoisting apparatus. Employees being trained and supervised by a designated individual may operate such machinery and give signals to operators during training.

(b) No employee known to have defective uncorrected eyesight or hearing, or to be suffering from heart disease, epilepsy, or similar ailments which may suddenly incapacitate the employee ((shall)) must be permitted to operate a crane, winch, other power-operated cargo handling apparatus, or a power-operated vehicle.

(c) Persons who have recovered from a heart attack ((shall)) must be exempted from the provisions of (b) of this subsection, as it pertains to their heart condition, provided:

(i) A medical release is obtained from their attending medical doctor.

(ii) The release ((shall)) must state that the operation of a crane, winch, power-operated cargo handling apparatus, or power-operated vehicle, will not present a hazard to themselves or others.

(iii) An examination by a medical doctor, and renewal of the work release certification is required annually.

(2) You must meet the following requirements for supervisory accident prevention proficiency((.)):

(a) Immediate supervisors of cargo-handling operations of more than five persons ((shall)) must satisfactorily complete a course in accident prevention. Employees newly assigned to supervisory duties ((shall)) must be required to meet the provisions of this subsection (2)(a) within ninety days of such assignment.

(b) The course ((shall)) must consist of instruction suited to the particular operations involved.

(c) No minor under eighteen years of age ((shall)) must be employed in occupations involving the operation of any power-operated hoisting apparatus or assisting in such operations by performing work such as hooking on or landing drafts, rigging gear, etc.

AMENDATORY SECTION (Amending WSR 92-22-067, filed 10/30/92, effective 12/8/92)

WAC 296-56-60007 Housekeeping.

(1) You must keep active work areas ((shall be kept)) free of equipment and materials not in use, and clear of debris, projecting nails, strapping and other sharp objects not necessary for the work in progress.

(2) You must make sure hatch beams, covers, and pontoons placed in terminal working areas ((shall be)) are stowed in stable piles with beams secured against tipping or falling. Alternatively, beams may be laid on their sides. When beams and pontoons are stowed in tiers more than one high, dunnage or other suitable material ((shall)) must be used under and between tiers.

(3) ((Cargo and material shall)) You must not obstruct access to vessels, cranes, vehicles, or buildings with cargo and materials. Means of access and egress within buildings ((shall)) must be unobstructed.

(4) ((The employer shall)) You must eliminate, to the extent possible, conditions causing slippery working or walking surfaces in immediate work areas used by employees.

AMENDATORY SECTION (Amending WSR 07-03-163, filed 1/24/07, effective 4/1/07)

WAC 296-56-60009 Accident prevention program.

(1) You must establish an accident prevention program, which provides equitable management-employee participation, ((shall be established)) in all establishments, industrial plants, or operations.

(2) ((It shall be the responsibility of the employer to)) You must initiate and maintain the accident prevention program necessary to comply with this section. ((The division of WISHA services)) DOSH may be contacted for assistance in initiating and maintaining an effective accident prevention program.

(3) You must tailor all accident prevention programs ((shall be tailored)) to the needs of the particular operation.

(4) You must have employer and employee representatives, as elected, delegated or appointed, ((shall)) to attend and actively take part in frequent and regular safety committee meetings.

(5) You must provide in the accident prevention programs ((shall provide)) for employer-employee safety meetings and frequent and regular safety inspections of job sites, materials, equipment, and operating procedures.

(6) You must maintain a record of safety activities, such as inspections and meetings, ((shall be maintained by the employer)) for a period covering the previous twelve months and ((shall)) must be made available, upon request, to noncompliance personnel of the department of labor and industries.

(7) You must ensure employees ((shall)) individually comply with all safety rules and cooperate with management in carrying out the accident prevention program.

(8) You must establish committees in each port to make effective the preceding statement and promote on-the-job accident prevention((, committees shall be established in each port)). These committees ((shall)) must consist of an equal number of port or stevedore company and longshoremen representatives at the job level with the industry or company safety supervisor serving as secretary and coordinator. Some functions of the committee are to maintain the interest of the workers in accident prevention by providing for their actual participation in the program, to direct their attention to the real causes of accidents, and to provide a means for making practical use of their intimate knowledge of working conditions and practices.

(9) It is intended that this program will produce mutually practical and effective recommendations regarding correction of accident-producing circumstances and conditions.

Note: | For first-aid requirements, see WAC 296-800-150. |

AMENDATORY SECTION (Amending WSR 07-03-163, filed 1/24/07, effective 4/1/07)

WAC 296-56-60010 Emergency action plans.

(1) ((Scope and application. This section requires all employers to)) You must develop and implement an emergency action plan. The emergency action plan ((shall)) must be in writing (except as provided in subsection (5)(d) of this section) and ((shall)) must cover those designated actions employers and employees must take to ensure employee safety from fire and other emergencies.

Note: | When an employer directs ((his or her)) their employees to respond to an emergency that is beyond the scope of the emergency action plan developed in accordance with this section, then chapter 296-824 WAC ((shall)) must apply. |

(2) ((Elements.)) You must include the following elements, at a minimum, ((shall be included)) in the plan:

(a) Emergency escape procedures and emergency escape route assignments;

(b) Procedures to be followed by employees who remain to operate critical plant operations before they evacuate;

(c) Procedures to account for all employees after emergency evacuation has been completed;

(d) Rescue and medical duties for those employees who are to perform them;

(e) The preferred means of reporting fires and other emergencies; and

(f) Names or regular job titles of persons or departments that can be contacted for further information or explanation of duties under the plan.

(3) ((Alarm system. The employer shall)) You must establish an employee alarm system that provides warning for necessary emergency action and for reaction time for safe escape of employees from the workplace or the immediate work area.

(4) ((Evacuation. The employer shall)) You must establish the types of evacuation to be used in emergency circumstances.

(5) ((Training.)) You must meet the following requirements for training:

(a) Before implementing the emergency action plan, ((the employer shall)) you must designate and train a sufficient number of persons to assist in the safe and orderly emergency evacuation of employees.

(b) ((The employer shall)) You must review the plan with each employee covered by the plan at the following times:

(i) Initially when the plan is developed;

(ii) Whenever the employee's responsibilities or designated actions under the plan change; and

(iii) Whenever the plan is changed.

(c) ((The employer shall)) You must review with each employee upon initial assignment those parts of the plan that the employee must know to protect the employee in the event of an emergency. The written plan ((shall)) must be kept at the workplace and be made available for employee review.

(d) ((Employers with ten or fewer employees)) You may communicate the plan orally to employees and need not maintain a written plan if you have ten or fewer employees.

((PART B—WATERFRONT OPERATIONS))

NEW SECTION

WAC 296-56-60010A Waterfront operations.

Summary

This section applies to all waterfront operations in your workplace.

Your responsibility: To protect employees from waterfront operation hazards in your workplace.

You must meet the requirements … |

in this section: |

Slinging |

WAC 296-56-60011 |

Stacking of cargo and pallets |

WAC 296-56-60013 |

Coopering |

WAC 296-56-60015 |

Line handling |

WAC 296-56-60017 |

Standard gauge railroad operations |

WAC 296-56-60019 |

Signals displayed by each maintenance crew |

WAC 296-56-60021 |

Warning flags or lights |

WAC 296-56-60023 |

Signals unobscured |

WAC 296-56-60025 |

Audible warning system |

WAC 296-56-60027 |

Safety observer on railroad switching |

WAC 296-56-60029 |

Warning at road crossing |

WAC 296-56-60031 |

Flying switches |

WAC 296-56-60033 |

Clearance from railroad tracks |

WAC 296-56-60035 |

Car plates |

WAC 296-56-60037 |

Dockboards (bridge plates) |

WAC 296-56-60039 |

Log handling |

WAC 296-56-60041 |

Movement of barges and railcars |

WAC 296-56-60043 |

Communication |

WAC 296-56-60045 |

Open fires |

WAC 296-56-60047 |

AMENDATORY SECTION (Amending WSR 99-02-024, filed 12/30/98, effective 3/30/99)

WAC 296-56-60011 Slinging.

(1) ((Drafts shall be safely slung)) You must safely sling drafts before being hoisted. Loose dunnage or debris hanging or protruding from loads ((shall)) must be removed.

(2) You must hoist bales of cotton, wool, cork, wood pulp, gunny bags, or similar articles ((shall be hoisted)) only by straps strong enough to support the weight of the bale. At least two hooks, each in a separate strap, ((shall)) must be used.

(3) You must only hoist unitized loads bound by bands or straps ((shall only be hoisted)) by the banding or strapping if the banding or strapping is suitable for hoisting and is strong enough to support the weight of the load.

(4) You must use additional means of hoisting ((shall be employed)) to ensure safe lifting of unitized loads having damaged banding or strapping.

(5) You must use case hooks ((shall be used)) only with cases designed to be hoisted by these hooks.

(6) You must guide loads requiring continuous manual guidance during handling ((shall be guided)) by guide ropes (tag lines) that are long enough to control the load.

(7) You must handle intermodal containers ((shall be handled)) in accordance with WAC 296-56-60103.

(8) ((The employer shall)) You must require employees to stay clear of the area beneath overhead drafts or descending lifting gear.

(9) ((Employees shall not be permitted)) You must not permit employees to ride the hook or the load.

(10) You must attach cargo handling bridles, such as pallet bridles, which are to remain attached to the hoisting gear while hoisting successive drafts, ((shall be attached)) by shackles, or other positive means ((shall)) must be taken to prevent them from becoming accidentally disengaged from the cargo hook.

(11) You must sling drafts of lumber, pipe, dunnage and other pieces, the top layer of which is not bound by the sling, ((shall be slung)) in such a manner as to prevent sliders. Double slings ((shall)) must be used on unstrapped dunnage, except, when due to the size of hatch or deep tank openings, it is impractical to use them.

(12) You must not load hand loaded buckets, tubs, bins and baskets used in handling bulk cargo ((shall not be loaded)) above their rim.

AMENDATORY SECTION (Amending WSR 85-01-022, filed 12/11/84)

WAC 296-56-60013 Stacking of cargo and pallets.

You must stack cargo, pallets, and other material stored in tiers ((shall be stacked)) in such a manner as to provide stability against sliding and collapse.

AMENDATORY SECTION (Amending WSR 85-01-022, filed 12/11/84)

WAC 296-56-60015 Coopering.

You must perform repair and reconditioning of damaged or leaking cargo packaging (coopering) ((shall be performed)) so as not to endanger employees.

AMENDATORY SECTION (Amending WSR 09-15-144, filed 7/21/09, effective 9/1/09)

WAC 296-56-60017 Line handling.

(1) ((In order to provide safe access for handling lines while mooring and unmooring vessels,)) You must not stow cargo or material ((shall not be stowed or vehicles placed)) or place vehicles where they obstruct the work surface, in order to provide safe access for handling lines while mooring and unmooring vessels.

(2) You must install grab lines or rails on the sides of permanent structures when stringpiece or apron width is insufficient for safe footing((, grab lines or rails shall be installed on the sides of permanent structures)). ("Stringpiece" means a narrow walkway between the water edge of a berth and a shed or other structure.)

(3) You must light areas around bitts or cleats where workers perform their duties as line handlers ((shall be lighted)) as required by this chapter. There ((shall)) must be a nonslip surface around each bitt or cleat.

(4) You must ensure a six inch by six inch toeboard is installed if the handrail is omitted on the line handling side for walkways on which the mooring hawsers must be moved ((may have the handrail omitted on the line handling side provided a six inch by six inch toeboard is installed)).

AMENDATORY SECTION (Amending WSR 86-03-064, filed 1/17/86)

WAC 296-56-60019 Standard gauge railroad operations.

WAC 296-56-60019 through 296-56-60041 apply to standard gauge railroad operations.

(1) ((Work shall be)) You must make sure work is performed in railcars only if floors of the railcars are in visibly safe condition for the work activity being conducted and the equipment being used.

(2) You must establish a route ((shall be established)) to allow employees to pass to and from places of employment without passing under, over or through railcars, or between cars less than ten feet (3 m) apart on the same track.

(3) ((The employer shall)) You must direct that no employees remain in railcars after work is concluded. No employee ((shall)) may remain in a railcar after work is concluded.

(4) ((Railcars shall be)) You must make sure railcars are chocked or otherwise prevented from moving:

(a) While dockboards or carplates are in position; or

(b) While employees are working within, on or under the railcars or near the tracks at the ends of the cars.

(5) You must take positive means to protect employees from exposure to impact from moving railcars when employees are working in, on, or under a railcar((, positive means shall be taken to protect them from exposure to impact from moving railcars)).

(6) You must protect employees by flags and derails set a minimum of fifty feet from one or both ends of the worksite when there is work being carried on, in, or under cars which subjects employees to the hazard of moving railroad equipment ((shall be protected by flags and derails set a minimum of fifty feet from one or both ends of the worksite)). Where the spur track switch is less than fifty feet from the work location, the switch padlocked in the open position may take the place of the derail. The blue flag ((shall)) must be placed at that point.

(7) You must remove or place unsecured and over-hanging stakes, wire straps, banding, and similar objects so as not to create hazards before cars are moved((, unsecured and over-hanging stakes, wire straps, banding, and similar objects shall be removed or placed so as not to create hazards)).

(8) ((The employer shall)) You must institute all necessary controls during railcar movement to safeguard personnel. If winches or capstans are employed for movement, employees ((shall)) must stand clear of the hauling rope and ((shall)) must not stand between the rope and the cars.

(9) You must open doors slightly before being opened fully((, doors shall be opened slightly)) to ensure that the load has not shifted during transit. Special precautions ((shall)) must be taken if the doors being opened are visibly damaged.

(10) You must equip trucks or railcar doors with door opening attachments if power industrial trucks are used to open freight car doors((, the trucks or the railcar doors shall be equipped with door opening attachments)). Employees ((shall)) must stand clear of the railcar doors while they are being opened and closed.

(11) ((Only)) You must only use railcar door openers or power trucks equipped with door opening attachments ((shall be used)) to open jammed doors.

(12) ((Employees shall)) You must make sure employees do not remain in or on gondolas or flat cars when drafts that create overhead, caught-in, caught-between or struck-by hazards are being landed in or on the railcar. End gates, if raised, ((shall)) must be secured.

(13) You must make sure operators of railcar dumps ((shall)) have an unrestricted view of dumping operations and ((shall)) must have an emergency means of stopping movement.

(14) You must enclose recessed railroad switches ((shall be enclosed)) to provide a level surface.

(15) You must post warning signs ((shall be posted)) where doorways open onto tracks, at blind corners and at similar places where vision may be restricted.

(16) You must post warning signs ((shall be posted)) if insufficient clearance for personnel exists between railcars and structures.

AMENDATORY SECTION (Amending WSR 85-01-022, filed 12/11/84)

WAC 296-56-60021 Signals displayed by each maintenance crew.

You must have each maintenance crew ((shall)) display and remove its own set of blue signals.

AMENDATORY SECTION (Amending WSR 86-03-064, filed 1/17/86)

WAC 296-56-60023 Warning flags or lights.

You must display a blue flag, bright colored flag or blue light ((shall be displayed)) at one or both ends of an engine, car or train to indicate that workers are under or about the railway equipment. When such warning devices are displayed, the equipment ((shall)) must not be coupled to or moved. On a dead end spur, a blue light or flag may be displayed adjacent to the switch opening while cars are being loaded or unloaded.

AMENDATORY SECTION (Amending WSR 86-03-064, filed 1/17/86)

WAC 296-56-60025 Signals unobscured.

You must not place equipment which could obscure signals ((shall not be placed)) on the track.

AMENDATORY SECTION (Amending WSR 86-03-064, filed 1/17/86)

WAC 296-56-60027 Audible warning system.

You must employ a clearly audible warning system ((shall be employed)) when cars are being moved in areas where workers may be in the vicinity of the tracks. When the audible warning signal might not be heard above the surrounding noises, a person ((shall)) must be delegated and stationed close enough to the track crew to warn them, by contact, of the oncoming equipment.

AMENDATORY SECTION (Amending WSR 86-03-064, filed 1/17/86)

WAC 296-56-60029 Safety observer on railroad switching.

You must have a person charged with the responsibility to warn of an approaching switch of the railway car or cars when persons are required to work between railway cars, underneath railway cars or in areas where switching is done, ((there shall be a person charged with the responsibility to warn of an approaching switch of the railway car or cars,)) unless other reasonable and practical safeguards are provided.

AMENDATORY SECTION (Amending WSR 86-03-064, filed 1/17/86)

WAC 296-56-60031 Warning at road crossing.

You must have the locomotive engineer sound an audible whistle, horn or bell ((shall be sounded by the locomotive engineer)) to give adequate warning prior to switching across any road crossing. Whenever cars are pushed with a locomotive, a signalman ((shall)) must be located at the crossing to give signals in conjunction with other warnings by the engineer.

AMENDATORY SECTION (Amending WSR 85-01-022, filed 12/11/84)

WAC 296-56-60033 Flying switches.

You must not use flying switches ((shall not be used)) when switching railroad equipment in congested areas or across roadways or walkways.

AMENDATORY SECTION (Amending WSR 85-01-022, filed 12/11/84)

WAC 296-56-60035 Clearance from railroad tracks.

You must not stack or pile materials ((shall not be stacked or piled)) closer than eight and one-half feet from the center line of the railroad tracks.

AMENDATORY SECTION (Amending WSR 86-03-064, filed 1/17/86)

WAC 296-56-60037 Car plates.

You must use a railway car plate whenever workers are required to move cargo into or out of a railway car((, a railway car plate shall be used which shall)) that meets the following specifications:

(1) All car plates ((shall)) must be strong enough to carry maximum loads with a safety factor of three.

(2) All car plates ((shall)) must be provided with positive stops to prevent shifting of plates. One set of these stops ((shall)) must be adjustable to allow for different spaces between car door and platform.

(3) Car plates ((shall)) must be so shaped that edges will always bear on the floor of car and platform to prevent "teetering" or rocking.

(4) All car plates ((shall)) must have skid resistant surfaces.

(5) All car plates ((shall)) must be provided with toe or guard plates at the sides with a minimum height of four inches.

(6) All car plates must bear no less than six inches back from edge of platform.

(7) Maximum capacity of car plates ((shall)) must be marked in a conspicuous place.

(8) Car plates ((shall)) must be provided with an appropriate fixture to enable the plates to be lifted and moved by fork trucks.

AMENDATORY SECTION (Amending WSR 86-03-064, filed 1/17/86)

WAC 296-56-60039 Dockboards (bridge plates).

(1) You must use portable and powered dockboards ((shall be)) strong enough to carry the load imposed.

(2) You must secure portable dockboards ((shall be secured)) in position, either by being anchored or equipped with devices which will prevent slipping.

(3) You must design and construct powered dockboards ((shall be designed and constructed)) in accordance with commercial standards CS202-56 (1956) Industrial Lifts and Hinged Loading Ramps published by the United States Department of Commerce.

(4) You must provide handholds or other effective means((, shall be provided)) on portable dockboards to permit safe handling.

(5) You must provide positive protection ((shall be provided)) to prevent railroad cars from being moved while dockboards or bridge plates are in position.

AMENDATORY SECTION (Amending WSR 92-22-067, filed 10/30/92, effective 12/8/92)

WAC 296-56-60041 Log handling.

(1) ((The employer shall)) You must ensure that structures (bunks) used to contain logs have rounded corners and rounded structural parts to avoid sling damage.

(2) You must have two or more binders or equivalently safe means of containment ((shall remain)) on logging trucks and railcars to secure logs during movement of the truck or car within the terminal. During unloading, logs ((shall)) must be prevented from moving while binders are being removed.

(3) ((Logs shall be hoisted)) You must hoist logs by two slings or by other gear designed for safe hoisting.

(4) You must not stack logs placed adjacent to vehicle curbs on the dock ((shall not be)) over one tier high unless placed in bunks or so stacked as not to roll or otherwise creating a hazard to employees.

(5) You must make sure before logs are slung up from the dock, they ((shall be)) are stably supported to prevent spreading and to allow passage of slings beneath the load. When bunks or similar retaining devices are used, no log shall be higher than the stanchions or retaining members of the device.

(6) You must make sure a draft of logs for hoisting aboard ship ((shall)) will not vary in length more than twenty percent.

(7) You must make sure audible alarms((.)) meet the following requirements:

(a) All bidirectional machines, ((shall)) must be equipped with a horn, distinguishable from the surrounding noise level, which ((shall)) must be operated as needed when the machine is moving in either direction. The horn ((shall)) must be maintained in operable condition.

(b) Automatic back-up alarms ((shall)) must be installed on bidirectional equipment used to handle logs or containers and ((shall)) must be maintained in operable condition.

AMENDATORY SECTION (Amending WSR 92-22-067, filed 10/30/92, effective 12/8/92)

WAC 296-56-60043 Movement of barges and railcars.

You must not move barges and railcars ((shall not be moved)) by cargo runners (running rigging) from vessel cargo booms, cranes or other equipment not suitable for the purpose.

AMENDATORY SECTION (Amending WSR 85-10-004, filed 4/19/85)

WAC 296-56-60045 Communication.

(1) ((Radio.)) You must provide crane operators, when practical and safe, ((crane operators shall be provided)) with a radio or telephone to be in contact with the signalman or crane chaser in those cases where a signalman or crane chaser is required.

(2) ((Interference.)) You must make sure cargo handling operations ((shall not be)) are not carried on when noise-producing maintenance, construction or repair work interferes with communication of warnings or instructions.

AMENDATORY SECTION (Amending WSR 85-01-022, filed 12/11/84)

WAC 296-56-60047 Open fires.

You must prohibit open fires and fires in drums or similar containers ((are prohibited)).

((PART C—HAZARDOUS ATMOSPHERES AND MATERIALS))

NEW SECTION

WAC 296-56-60048 Hazardous atmospheres and materials.

Summary

This section applies to all machines in your workplace.

Your responsibility: To protect employees from hazardous atmospheres and materials in the workplace.

You must meet the requirements … |

in this section: |

Hazardous cargo |

WAC 296-56-60049 |

Handling explosives or hazardous materials |

WAC 296-56-60051 |

Hazardous atmospheres and substances |

WAC 296-56-60053 |

Carbon monoxide |

WAC 296-56-60055 |

Fumigants, pesticides, insecticides and hazardous preservatives (see also WAC 296-56-60049, 296-56-60051 and 296-56-60053) |

WAC 296-56-60057 |

AMENDATORY SECTION (Amending WSR 86-03-064, filed 1/17/86)

WAC 296-56-60049 Hazardous cargo.

(1) You must ascertain whether any hazardous cargo is to be handled and must determine the nature of the hazard before cargo handling operations begin((, the employer shall ascertain whether any hazardous cargo is to be handled and shall determine the nature of the hazard. The employer shall)). You must inform employees of the nature of any hazard and any special precautions to be taken to prevent employee exposure, and ((shall)) must instruct employees to notify the employer of any leaks or spills.

(2) You must sling and secure all hazardous cargo ((shall be slung and secured)) so that neither the draft nor individual packages can fall as a result of tipping the draft or slackening of the supporting gear.

(3) You must remove employees from the affected area if hazardous cargo is spilled or if its packaging leaks((, employees shall be removed from the affected area)) until the employer has ascertained the specific hazards, provided any equipment, clothing, ventilation and fire protection equipment necessary to eliminate or protect against the hazard. Cleanup employees ((shall)) must be instructed as to the safe method of cleaning up and disposing of the spill, and handling and disposing of leaking containers. Actual cleanup or disposal work ((shall)) must be conducted under the supervision of a designated person.

(4) The Department of Transportation and the United States Coast Guard impose requirements related to handling, storing and transportation of hazardous cargo (see 33 C.F.R. Part 126, 46 C.F.R., 49 C.F.R.).

AMENDATORY SECTION (Amending WSR 86-03-064, filed 1/17/86)

WAC 296-56-60051 Handling explosives or hazardous materials.

(1) You must thoroughly inform all workers handling explosive or other hazardous material which is properly labeled pursuant to the Washington State Labeling Code, chapters 296-62 and 296-64 WAC, promulgated by the department of labor and industries; or the Explosive Act, chapter 70.74 RCW and chapter 296-52 WAC; or the Federal and Washington State Food, Drug and Cosmetic Acts; the Federal Insecticide, Fungicide and Rodenticide Act, the Washington Pesticide Act, chapter 17.21 RCW; the Federal Hazardous Substances Labeling Act; or the Interstate Commerce Commission and Foreign Commerce regulations; or explosives or other dangerous cargo which is reasonably known by the employers to be mislabeled or to be lacking a required label, ((shall be thoroughly informed by the employer)) of the explosive or hazardous nature of the cargo.

(2) ((In)) You must ensure that all shipping operations including, but not limited to, handling, storage, and preparation, compliance with the standards of the Interstate Commerce Commission, the United States Coast Guard, or the safety rules developed by the Institute of Makers of Explosives ((shall be)) are deemed proper and safe methods of operation.

(3) ((Handling of breakage.)) You must require the foreman to order the work in the immediate area to cease, if breakage should occur while handling explosives or other hazardous materials, ((the foreman shall order the work in the immediate area to cease)) until the hazard has been removed. ((It shall be the responsibility of the employer to)) You must use a safe method of handling such breakage and placing it in a remote, safe location.

(4) ((No smoking.)) You must prohibit all workers supervising or engaged in the handling, hoisting, stowing of explosives, combustible oxidizing materials or flammable materials ((shall smoke only)) from smoking, except in designated areas. No person shall smoke within one hundred feet of any location where such materials are handled or stored.

(5) ((Loading chute.)) You must take care in chuting packaged explosives((, care must be exercised)) to ensure that one package is taken from the mat before starting another. Each package ((shall)) must be completely removed from the mat before another is placed on the chute.

(6) ((Specifications for chutes.)) You must construct chutes only of wood in the loading of explosive merchandise in package form where chutes are used((, the chutes shall be constructed only of wood)). All fastenings shall be of wooden pins, dowelings, or pegs. Metal fastenings may be used, provided they are countersunk.

(7) ((Mattress landing buffer. The bottoms of the chutes shall be provided with)) You must provide a stuffed mattress not less than four inches thick and of sufficient width and length to allow for safe landing of packages at the bottoms of the chutes.

(8) You must sling and secure drafts of hazardous or explosive cargo shall be so slung and secured that neither the draft nor individual packages can fall as a result of tipping the draft or slackening the supporting gear.

AMENDATORY SECTION (Amending WSR 05-03-093, filed 1/18/05, effective 3/1/05)

WAC 296-56-60053 Hazardous atmospheres and substances.

(1) Purpose and scope. ((This section covers areas where a hazardous atmosphere or substance may exist, except where one or more of the following sections apply: WAC 296-56-60049 Hazardous cargo; WAC 296-56-60051 Handling explosives or hazardous materials; WAC 296-56-60055 Carbon monoxide; WAC 296-56-60057 Fumigants, pesticides, insecticides and hazardous preservatives; WAC 296-56-60107 Terminal facilities handling menhaden and similar species of fish; WAC 296-56-60235 Welding, cutting and heating (hot work); and WAC 296-56-60237 Spray painting.))

Important: |

|

This section covers areas where a hazardous atmosphere or substance may exist, except where one or more of the following sections apply: |

|

1. |

WAC 296-56-60049 Hazardous cargo |

2. |

WAC 296-56-60051 Handling explosives or hazardous materials |

3. |

WAC 296-56-60055 Carbon monoxide |

4. |

WAC 296-56-60057 Fumigants, pesticides, insecticides and hazardous preservatives |

5. |

WAC 296-56-60107 Terminal facilities handling menhaden and similar species of fish |

6. |

WAC 296-56-60235 Welding, cutting and heating (hot work) |

7. |

WAC 296-56-60237 Spray painting |

(2) You must make a determination of hazard((.)):

(a) Whenever a room, building, vehicle, railcar or other space contains or has contained a hazardous atmosphere, a designated and appropriately equipped person ((shall)) must test the atmosphere before entry to determine whether a hazardous atmosphere exists.

(b) Records of results of any tests required by this section ((shall)) must be maintained for at least thirty days.

(3) ((Testing during ventilation. When mechanical ventilation is used to maintain a safe atmosphere, tests shall be)) You must make sure tests are made by a designated person to ensure that the atmosphere is not hazardous when mechanical ventilation is used to maintain a safe atmosphere.

(4) ((Entry into hazardous atmospheres.)) You must make sure only designated persons ((shall)) enter hazardous atmospheres. The following provisions ((shall)) apply:

(a) Persons entering a space containing a hazardous atmosphere ((shall)) must be protected by respiratory and emergency protective equipment meeting the requirements of chapter 296-842 WAC;

(b) Persons entering a space containing a hazardous atmosphere ((shall)) must be instructed in the nature of the hazard, precautions to be taken, and the use of protective and emergency equipment. Standby observers, similarly equipped and instructed, ((shall)) must continuously monitor the activity of employees within such space; and

(c) Except for emergency or rescue operations, employees ((shall)) must not enter into any atmosphere which has been identified as flammable or oxygen deficient (less than nineteen and one-half percent oxygen). Persons who may be required to enter flammable or oxygen deficient atmospheres in emergency operations ((shall)) must be instructed in the dangers attendant to those atmospheres and instructed in the use of self-contained breathing apparatus, which ((shall)) must be utilized.

(d) To prevent inadvertent employee entry into spaces that have been identified as having hazardous, flammable or oxygen deficient atmospheres, appropriate warning signs or equivalent means ((shall)) must be posted at all means of access to those spaces.

(5) ((When the packaging of asbestos cargo leaks, spillage shall be cleaned up by)) You must make sure only designated employees protected from the harmful effects of asbestos as required by WAC 296-62-07517 and chapter 296-65 WAC, clean up spills when the packaging of asbestos cargo leaks.

AMENDATORY SECTION (Amending WSR 86-03-064, filed 1/17/86)

WAC 296-56-60055 Carbon monoxide.

(1) ((Exposure limits.)) You must maintain the carbon monoxide content of the atmosphere in a room, building, vehicle, railcar or any enclosed space shall be maintained below fifty parts per million (0.005%) as an eight-hour time-weighted average. Employees ((shall)) must be removed from the enclosed space if the carbon monoxide concentration exceeds one hundred parts per million (0.01%).

(2) ((Testing.)) You must conduct tests to determine carbon monoxide concentration ((shall be made)) whenever necessary to ensure that employee exposure does not exceed the limits specified in subsection (1) of this section.

(3) ((Instrumentation.)) You must make sure tests for carbon monoxide concentration ((shall be)) are made by designated persons using gas detector tube units certified by NIOSH under 30 C.F.R. Part 11 or other measuring instruments whose accuracy is as great or greater.

(4) ((Records.)) You must make available a record of the date, time, location and result of carbon monoxide tests ((shall be available)) for at least thirty days.

AMENDATORY SECTION (Amending WSR 05-03-093, filed 1/18/05, effective 3/1/05)

WAC 296-56-60057 Fumigants, pesticides, insecticides and hazardous preservatives (see also WAC 296-56-60049, 296-56-60051 and 296-56-60053).

(1) You must make a determination as to whether a hazardous atmosphere is present whenever cargo in a space is or has been stowed, handled, or treated with a fumigant, pesticide, insecticide, or hazardous preservative((, a determination shall be made as to whether a hazardous atmosphere is present in the space)). Only employees protected as required in subsection (5) of this section shall enter the space if it is hazardous.

(2) You must make sure tests to determine the atmospheric concentration of chemicals used to treat cargo ((shall be)) are:

(a) Appropriate for the hazard involved;

(b) Conducted by designated persons; and

(c) Performed at the intervals necessary to ensure that employee exposure does not exceed the permissible exposure limit for the chemical involved, see chapters 296-62 and 296-841 WAC.

(3) ((Results of any tests shall be available)) You must make available any test results for at least thirty days.

(4) ((Chemicals shall only be)) You must make sure chemicals are only applied to cargoes by designated persons.

(5) You must make sure only designated persons ((shall)) enter hazardous atmospheres. Whenever a hazardous atmosphere is entered the following provisions apply((.)):

(a) Persons entering a space containing a hazardous atmosphere ((shall)) must be protected by respiratory and emergency protective equipment meeting the requirements of part G of this standard; and

(b) Persons entering a space containing a hazardous atmosphere ((shall)) must be instructed in the nature of the hazard, precautions to be taken, and the use of protective and emergency equipment. Standby observers, similarly equipped and instructed, ((shall)) must continuously monitor the activity of employees within such a space.

(6) ((Signs shall be clearly posted)) You must clearly post signs where fumigants, pesticides or hazardous preservatives have created a hazardous atmosphere. These signs ((shall)) must note the danger, identify specific chemical hazards, and give appropriate information and precautions, including instructions for the emergency treatment of employees affected by any chemical in use.

(7) ((In the case of containerized shipments of fumigated tobacco,)) You must aerate the contents of ((the)) a container ((shall be aerated)) by opening the container doors for a period of forty-eight hours after the completion of fumigation and prior to loading in the case of containerized shipments of fumigated tobacco. When tobacco is within shipping cases having polyethylene or similar bag liners, the aeration period ((shall)) must be seventy-two hours. ((The employer shall)) You must obtain a written warranty from the fumigation facility stating that the appropriate aeration period has been met.

((PART E—CARGO HANDLING GEAR AND EQUIPMENT))

NEW SECTION

WAC 296-56-60070 Cargo handling gear and equipment.

Summary

This section applies to all cargo handling gear and equipment in your workplace.

Your responsibility: To protect employees from cargo handling gear and equipment hazards in your workplace.

You must meet the requirement … |

in this section: |

House falls |

WAC 296-56-60071 |

Miscellaneous auxiliary gear |

WAC 296-56-60073 |

Cargo boards and other type pallet boards |

WAC 296-56-60075 |

Powered industrial trucks |

WAC 296-56-60077 |

General rules applicable to vehicles |

WAC 296-56-60079 |

Multipiece and single-piece rim wheels |

WAC 296-56-60081 |

Cranes and derricks |

WAC 296-56-60083 |

Crane load and limit devices |

WAC 296-56-60085 |

Winches |

WAC 296-56-60087 |

Conveyors |

WAC 296-56-60089 |

Spouts, chutes, hoppers, bins, and associated equipment |

WAC 296-56-60091 |

Certification of marine terminal material handling devices |

WAC 296-56-60093 |

Advisory crane certification panel |

WAC 296-56-60095 |

Unit proof load test and inspection |

WAC 296-56-60097 |

Examination and inspection of cranes and derricks |

WAC 296-56-60098 |

Hand tools |

WAC 296-56-60099 |

AMENDATORY SECTION (Amending WSR 85-01-022, filed 12/11/84)

WAC 296-56-60071 House falls.

(1) You must secure span beams ((shall be secured)) to prevent accidental dislodgement.

(2) You must provide a safe means of access ((shall be provided)) for employees working with house fall blocks.

(3) You must have designated employees ((shall)) inspect chains, links, shackles, swivels, blocks and other loose gear used in house fall operations before each day's use. Defective gear ((shall)) must not be used.

AMENDATORY SECTION (Amending WSR 00-21-103, filed 10/18/00, effective 2/1/01)

WAC 296-56-60073 Miscellaneous auxiliary gear.

(1) You must meet the following requirements for routine inspections((.)):

(a) At the completion of each use, loose gear such as slings, chains, bridles, blocks, and hooks ((shall)) must be so placed as to avoid damage to the gear. Loose gear ((shall)) must be inspected and any defects corrected before reuse.

(b) All loose gear ((shall)) must be inspected by the employer or ((his/her)) their authorized representative before each use and, when necessary, at intervals during its use, to ensure that it is safe. Any gear which is found upon inspection to be unsafe ((shall)) must not be used until it is made safe.

(c) Defective gear ((shall)) must not be used. Distorted hooks, shackles, or similar gear ((shall)) must be discarded.

(d) Chains or other gear which have been lengthened, altered, or repaired by welding ((shall)) must be properly heat treated, and before again being put into use, ((shall)) must be tested and reexamined in the manner set forth in WAC 296-56-60097 and 296-56-60098.

(2) ((The employer shall)) You must maintain a record of the dates and results of the tests with each unit of gear concerned clearly identified. The records ((shall)) must be available for examination by division of consultation and compliance personnel and the employee safety committee.

(3) You must meet the following requirements for wire rope and wire rope slings((.)):

(a) ((The employer shall)) You must ascertain and adhere to the manufacturer's recommended ratings for wire rope and wire rope slings and ((shall)) must have such ratings available at the terminal. When the manufacturer is unable to supply such ratings, ((the employer shall)) you must use the tables for wire rope and wire rope slings found in American National Safety Standard for Slings, ANSI/ASME B30.9-1984. A design safety factor of at least five ((shall)) must be maintained for the common sizes of running wire used as falls, in purchases or in such uses as light load slings. Wire rope with a safety factor of less than five may be used only:

(i) In specialized equipment, such as cranes designed to be used with lesser wire rope safety factors;

(ii) In accordance with design factors in standing rigging applications; or

(iii) For heavy lifts or other purposes for which a safety factor of five is impractical and for which the employer can demonstrate that equivalent safety is ensured.

(b) Wire rope or wire rope slings exhibiting any of the following conditions ((shall)) must not be used:

(i) Ten randomly distributed broken wires in one rope lay or three or more broken wires in one strand in one rope lay;

(ii) Kinking, crushing, bird caging, or other damage resulting in distortion of the wire rope structure;

(iii) Evidence of heat damage;

(iv) Excessive wear, corrosion, deformation or other defect in the wire or attachments, including cracks in attachments;

(v) Any indication of strand or wire slippage in end attachments; or

(vi) More than one broken wire in the close vicinity of a socket or swaged fitting.

(c) Four by twenty-nine (4 x 29) wire rope ((shall)) must not be used in any running rigging.

(d) Protruding ends of strands in splices on slings and bridles ((shall)) must be covered or blunted. Coverings ((shall)) must be removable so that splices can be examined. Means used to cover or blunt ends ((shall)) must not damage the wire.

(e) Where wire rope clips are used to form eyes, ((the employer shall)) you must adhere to the manufacturer's recommendations, which ((shall)) must be available at the terminal. If "U" bolt clips are used and the manufacturer's recommendations are not available, Table C-1 ((shall)) must be used to determine the number and spacing of clips. "U" bolts ((shall)) must be applied with the "U" section in contact with the dead end of the rope.

Table C-1 ((—))

Number and Spacing of U-Bolt Wire Rope Clips

Improved plow steel, rope diameter |

Minimum number of clips |

Minimum spacing |

|

inches/(cm) |

Drop forged |

Other material |

inches/(cm) |

1/2 or less (1.3) |

3 |

4 |

3 (7.6) |

5/8 (1.6) |

3 |

4 |

3 3/4 (9.5) |

3/4 (1.9) |

4 |

5 |

4 1/2 (11.4) |

7/8 (2.2) |

4 |

5 |

5 1/4 (13.3) |

1 (2.5) |

5 |

7 |

6 (15.2) |

1 1/8 (2.9) |

6 |

7 |

6 3/4 (17.1) |

1 1/4 (3.2) |

6 |

8 |

7 1/2 (19.1) |

1 3/8 (3.5) |

7 |

8 |

8 1/4 (21.0) |

1 1/2 (3.8) |

7 |

9 |

9 (22.9) |

(f) Wire rope ((shall)) must not be secured by knots.

(g) Eyes in wire rope bridles, slings, bull wires, or in single parts used for hoisting ((shall)) must not be formed by wire rope clips or knots.

(h) Eye splices in wire ropes ((shall)) must have at least three tucks with a whole strand of the rope and two tucks with one-half of the wire cut from each strand. Other forms of splices or connections which are demonstrated to be equally safe may be used.

(i) Except for eye splices in the ends of wires and for endless rope slings, each wire rope used in hoisting or lowering, or in bulling cargo, ((shall)) must consist of one continuous piece without knot or splice.

(4) You must meet the following requirements for natural fiber rope.

(a) ((The employer shall)) You must ascertain the manufacturer's ratings for the specific natural fiber rope used and have such ratings available at the terminal. The manufacturer's ratings ((shall)) must be adhered to and a minimum design safety factor of five maintained.

(b) Eye splices ((shall)) must consist of at least three full tucks. Short splices ((shall)) must consist of at least six full tucks, three on each side of the center line.

(5) You must meet the following requirements for synthetic rope((.)):

(a) ((The employer shall)) You must adhere to the manufacturer's ratings and use recommendations for the specific synthetic fiber rope used and ((shall)) must have such ratings available at the terminal.

(b) Unless otherwise recommended by the manufacturer, when synthetic fiber ropes are substituted for manila ropes of less than three inches (7.62 cm) circumference, the substitute ((shall)) must be of equal size. Where substituted for manila rope of three inches or more in circumference, the size of the synthetic rope ((shall)) must be determined from the formula:

C = √.6(Cs2) + .4(Cm2) |

Where C = the required circumference of the synthetic rope in inches, Cs = the circumference to the nearest one-quarter inch of a synthetic rope having a breaking strength not less than that of the size manila rope that would be required by subsection (4) of this section, and Cm = the circumference of manila rope in inches which would be required by subsection (4) of this section.

(c) In making such substitution, it ((shall)) must be ascertained that the inherent characteristics of the synthetic fiber are suitable for hoisting.

(6) ((Removal of natural and synthetic rope from service.)) You must remove natural or synthetic rope having any of the following defects ((shall be removed)) from service:

(a) Abnormal wear;

(b) Powdered fiber between strands;

(c) Sufficient cut or broken fibers to affect the capacity of the rope;

(d) Variations in the size or roundness of strands;

(e) Discolorations other than stains not associated with rope damage;

(f) Rotting; or

(g) Distortion or other damage to attached hardware.

(7) ((Thimbles.)) You must use properly fitting thimbles ((shall be used)) where any rope is secured permanently to a ring, shackle or attachment, where practical.

(8) You must meet the following requirements for synthetic web slings((.)):

(a) Slings and nets or other combinations of more than one piece of synthetic webbing assembled and used as a single unit (synthetic web slings) ((shall)) must not be used to hoist loads in excess of the sling's rated capacity.

(b) Synthetic web slings ((shall)) must be removed from service if they exhibit any of the following defects:

(i) Acid or caustic burns;

(ii) Melting or charring of any part of the sling surface;

(iii) Snags, punctures, tears or cuts;

(iv) Broken or worn stitches;

(v) Distortion or damage to fittings; or

(vi) Display of visible warning threads or markers designed to indicate excessive wear or damage.

(c) Defective synthetic web slings removed from service ((shall)) must not be returned to service unless repaired by a sling manufacturer or similar entity. Each repaired sling ((shall)) must be proof tested by the repairer to twice the slings' rated capacity prior to its return to service. ((The employer shall)) You must retain a certificate of the proof test and make it available for examination.

(d) Synthetic web slings provided by ((the employer shall)) you must only be used in accordance with the manufacturer's recommendations, which ((shall)) must be made available upon request.

(e) Fittings ((shall)) must have a breaking strength at least equal to that of the sling to which they are attached and ((shall)) must be free of sharp edges.

(9) You must meet the following requirements for chains and chain slings used for hoisting.

(a) ((The employer shall)) You must adhere to the manufacturer's recommended ratings for safe working loads for the sizes of the wrought iron and alloy steel chains and chain slings used and ((shall)) must have such ratings available. When the manufacturer is unable to provide such ratings, ((the employer shall)) you must use the tables for chains and chain slings found in American National Safety Standard for Slings, ANSI B30.9-1971.

(b) Proof coil steel chain, also known as common or hardware chain, and other chain not recommended by the manufacturer for slinging or hoisting ((shall)) must not be used for slinging or hoisting.

(c)(((i))) Sling chains, including end fastenings, ((shall)) must be inspected for visible defects before each day's use and as often as necessary during use to ensure integrity of the sling.

(((ii))) (i) Thorough inspections of chains in use ((shall)) must be made quarterly to detect wear, defective welds, deformation, increase in length or stretch. The month of inspection ((shall)) must be indicated on each chain by color of paint on a link or by other effective means.

(((iii))) (ii) Chains ((shall)) must be removed from service when maximum allowable wear, as indicated in Table C-2, is reached at any point of link.

(((iv))) (iii) Chain slings ((shall)) must be removed from service when stretch has increased the length of a measured section by more than five percent; when a link is bent, twisted or otherwise damaged; or when a link has a raised scarf or defective weld.

(((v))) (iv) Only designated persons shall inspect chains used for slinging and hoisting.

Table C-2 ((—))

Maximum Allowable Wear at Any Point of Link

Chain Size |

Maximum Allowable Wear |

|||

Inches |

(cm) |

Inches |

(cm) |

|

1/4 (9/32) |

(0.6) |

3/64 |

(0.1) |

|

3/8 |

(1.0) |

5/64 |

(0.2) |

|

1/2 |

(1.3) |

7/64 |

(0.3) |

|

5/8 |

(1.6) |

9/64 |

(0.4) |

|

3/4 |

(1.9) |

5/32 |

(0.4) |

|

7/8 |

(2.2) |

11/64 |

(0.4) |

|

1 |

(2.5) |

3/16 |

(0.5) |

|

1 1/8 |

(2.9) |

7/32 |

(0.6) |

|

1 1/4 |

(3.2) |

1/4 |

(0.6) |

|

1 3/8 |

(3.5) |

9/32 |

(0.7) |

|

1 1/2 |

(3.8) |

5/16 |

(0.8) |

|

1 3/4 |

(4.4) |

((1 1/32)) 11/32 |

(0.9) |

|

(d) Chains ((shall)) must only be repaired under qualified supervision. Links or portions of chain defective under any of the criteria ((of WAC 296-56-60073 (9)(c) shall)) under (c) of this subsection must be replaced with properly dimensioned links or connections of material similar to that of the original chain. Before repaired chains are returned to service, they ((shall)) must be tested to the proof test load recommended by the manufacturer for the original chain. Tests ((shall)) must be performed by the manufacturer or ((shall)) must be certified by an agency accredited for the purpose under WAC 296-56-60093. Test certificates ((shall)) must be available at the terminal.

(e) Wrought iron chains in constant use ((shall)) must be annealed or normalized at intervals not exceeding six months. Heat treatment certificates ((shall)) must be available at the terminal. Alloy chains ((shall)) must not be annealed.

(f) Kinked or knotted chains ((shall)) must not be used for lifting. Chains ((shall)) must not be shortened by bolting, wiring or knotting. Makeshift links or fasteners such as wire, bolts or rods ((shall)) must not be used.

(g) Hooks, rings, links and attachments affixed to sling chains ((shall)) must have rated capacities at least equal to that of the chains to which they are attached.

(h) Chain slings ((shall)) must bear identification of size, grade and rated capacity.

(10) You must meet the following requirements for shackles((.)):

(a) If available, the manufacturer's recommended safe working loads for shackles ((shall)) must not be exceeded. In the absence of manufacturer's recommendations, Table C-3 ((shall)) must apply.

(b) Screw pin shackles used aloft in house fall or other gear, except in cargo hook assemblies, ((shall)) must have their pins moused or otherwise effectively secured.

Table C-3 ((—))

Safe Working Loads for Shackles

Material Size |

Pin Diameter |

Safe Working Load in 2,000 lb Tons |

||

Inches |

(cm) |

Inches |

(cm) |

|

1/2 |

(1.3) |

5/8 |

(1.6) |

1.4 |

5/8 |

(1.6) |

3/4 |

(1.9) |

2.2 |

3/4 |

(1.9) |

7/8 |

(2.2) |

3.2 |

7/8 |

(2.2) |

1 |

(2.5) |

4.3 |

1 |

(2.5) |

1 1/8 |

(2.9) |

5.6 |

1 1/8 |

(2.9) |

1 1/4 |

(3.2) |

6.7 |

1 1/4 |

(3.2) |

1 3/8 |

(3.5) |

8.2 |

1 3/8 |

(3.5) |

1 1/2 |

(3.8) |

10.0 |

1 1/2 |

(3.8) |

1 5/8 |

(4.1) |

11.9 |

1 3/4 |

(4.4) |

2 |

(5.1) |

16.2 |

2 |

(5.1) |

2 1/4 |

(5.7) |

21.2 |

(c) Tables G-2 through G-5 ((shall)) must be used to determine the safe working loads of various sizes and classifications of improved plow steel wire rope slings with various types of terminals. For sizes, classifications and grades not included in these tables the safe working load recommended by the manufacturer for specific, identifiable products ((shall)) must be followed, however, a safety factor of not less than five ((shall)) must be maintained.

TABLE G-1

MANILA ROPE

In Pounds or Tons of 2,000 Pounds

((Circum- ference |

Diameter in Inches |

Single Leg |

60 Degree |

45 Degree |

30 Degree |

|

|

|

|

||

Lbs. |

Lbs. |

Lbs. |

Lbs.)) |

||

Circum- ference |

Diameter in Inches |

Single Leg |

60 Degree |

45 Degree |

30 Degree |

|

|

|

|

||

Lbs. |

Lbs. |

Lbs. |

Lbs. |

||

3/4 |

1/4 |

120 |

204 |

170 |

120 |

1 |

5/16 |

200 |

346 |

282 |

200 |

1 1/8 |

3/8 |

270 |

467 |

380 |

270 |

1 1/4 |

7/16 |

350 |

605 |

493 |

350 |

1 3/8 |

15/32 |

450 |

775 |

635 |

450 |

1 1/2 |

1/2 |

530 |

915 |

798 |

530 |

1 3/4 |

9/16 |

690 |

1190 |

973 |

690 |

2 |

5/8 |

880 |

1520 |

1240 |

880 |

2 1/4 |

3/4 |

1080 |

1870 |

1520 |

1080 |

2 1/2 |

13/16 |

1300 |

2250 |

1830 |

1300 |

2 3/4 |

7/8 |

1540 |

2660 |

2170 |

1540 |

3 |

1 |

1800 |

3120 |

2540 |

1800 |

Tons |

Tons |

Tons |

Tons |

||

3 1/4 |

1 1/16 |

1.0 |

1.7 |

1.4 |

1.0 |

3 1/2 |

1 1/8 |

1.2 |

2.1 |

1.7 |

1.2 |

3 3/4 |

1 1/4 |

1.35 |

2.3 |

1.9 |

1.35 |

4 |

1 5/16 |

1.5 |

2.6 |

2.1 |

1.5 |

4 1/2 |

1 1/2 |

1.8 |

3.1 |

2.5 |

1.8 |

5 |

1 5/8 |

2.25 |

3.9 |

3.2 |

2.25 |

5 1/2 |

1 3/4 |

2.6 |

4.5 |

3.7 |

2.6 |

6 |

2 |

3.1 |

5.4 |

4.4 |

3.1 |

6 1/2 |

2 1/8 |

3.6 |

6.2 |

5.1 |

3.6 |

TABLE G-2

RATED CAPACITIES FOR IMPROVED PLOW STEEL, INDEPENDENT WIRE ROPE CORE, WIRE ROPE AND WIRE SLINGS

(In Tons of 2,000 Pounds)

Rope Diameter Inches |

Single Leg |

|||||

Vertical |

Choker |

|||||

A |

B |

C |

A |

B |

C |

|

6 x 19 Classification |

||||||

1/4" |

.59 |

.56 |

.53 |

.44 |

.42 |

.40 |

3/8" |

1.3 |

1.2 |

1.1 |

.98 |

.93 |

.86 |

1/2" |

2.3 |

2.2 |

2.0 |

1.7 |

1.6 |

1.5 |

5/8" |

3.6 |

3.4 |

3.0 |

2.7 |

2.5 |

2.2 |

3/4" |

5.1 |

4.9 |

4.2 |

3.8 |

3.6 |

3.1 |

7/8" |

6.9 |

6.6 |

5.5 |

5.2 |

4.9 |

4.1 |

1" |

9.0 |

8.5 |

7.2 |

6.7 |

6.4 |

5.4 |

((1-1/8")) 1 1/8" |

11 |

10 |

9.0 |

8.5 |

7.8 |

6.8 |

6 x 37 Classification |

||||||

((1-1/4")) 1 1/4" |

13 |

12 |

10 |

9.9 |

9.2 |

7.9 |

((1-3/8")) 1 3/8" |

16 |

15 |

13 |

12 |

11 |

9.6 |

((1-1/2")) 1 1/2" |

19 |

17 |

15 |

14 |

13 |

11 |

((1-3/4")) 1 3/4" |

26 |

24 |

20 |

19 |

18 |

15 |

2" |

33 |

30 |

26 |

25 |

23 |

20 |

((2-1/4")) 2 1/4" |

41 |

38 |

33 |

31 |

29 |

25 |

(A) — Socket or Swaged Terminal Attachment. (B) — Mechanical Sleeve Attachment. (C) — Hand Tucked Splice Attachment. |

||||||

TABLE G-3

RATED CAPACITIES FOR IMPROVED PLOW STEEL, INDEPENDENT WIRE ROPE CORE, WIRE ROPE SLING (IN TONS OF 2,000 POUNDS)

((Two-leg bridle or basket hitch |

||||||||||||

Vertical |

60 Degree |

45 Degree |

30 Degree |

|||||||||

Rope dia. inches |

|

|

)) )) |

|||||||||

Two-leg bridle or basket hitch |

||||||||||||

Vertical |

60 Degree |

45 Degree |

30 Degree |

|||||||||

Rope dia. inches |

|

|

|

|||||||||

A |

B |

C |

A |

B |

C |

A |

B |

C |

A |

B |

C |

|

6 x 19 Classification |

||||||||||||

1/4" |

1.2 |

1.1 |

1.0 |

1.0 |

.97 |

.92 |

.83 |

.79 |

.75 |

.59 |

.56 |

.53 |

3/8" |

2.6 |

2.5 |

2.3 |

2.3 |

2.1 |

2.0 |

1.8 |

1.8 |

1.6 |

1.3 |

1.2 |

1.1 |

1/2" |

4.6 |

4.4 |

3.9 |

4.0 |

3.8 |

3.4 |

3.2 |

3.1 |

2.8 |

2.3 |

2.2 |

2.0 |

5/8" |

7.2 |

6.8 |

6.0 |

6.2 |

5.9 |

5.2 |

5.1 |

4.8 |

4.2 |

3.6 |

3.4 |

3.0 |

3/4" |

10 |

9.7 |

8.4 |

8.9 |

8.4 |

7.3 |

7.2 |

6.9 |

5.9 |

5.1 |

4.9 |

4.2 |

7/8" |

14 |

13 |

11 |

12 |

11 |

9.6 |

9.8 |

9.3 |

7.8 |

6.9 |

6.6 |

5.5 |

1" |

18 |

17 |

14 |

15 |

15 |

12 |

13 |

12 |

10 |

9.0 |

8.5 |

7.2 |

1 1/8" |

23 |

21 |

18 |

19 |

18 |

16 |

16 |

15 |

13 |

11 |

10 |

9.0 |

6 x 37 Classification |

||||||||||||

1 1/4" |

26 |

24 |

21 |

23 |

21 |

18 |

19 |

17 |

15 |

13 |

12 |

10 |

1 3/8" |

32 |

29 |

25 |

28 |

25 |

22 |

22 |

21 |

18 |

16 |

15 |

13 |

1 1/2" |

38 |

35 |

30 |

33 |

30 |

26 |

27 |

25 |

21 |

19 |

17 |

15 |

1 3/4" |

51 |

47 |

41 |

44 |

41 |

35 |

36 |

33 |

29 |

26 |

24 |

20 |

2" |

66 |

61 |

53 |

57 |

53 |

46 |

47 |

43 |

37 |

33 |

30 |

26 |

2 1/4" |

83 |

76 |

66 |

72 |

66 |

57 |

58 |

54 |

47 |

41 |

38 |

33 |