WSR 16-09-085

PERMANENT RULES

DEPARTMENT OF

LABOR AND INDUSTRIES

[Filed April 19, 2016, 10:44 a.m., effective May 20, 2016]

Effective Date of Rule: Thirty-one days after filing.

Purpose: eRules Phase V, the purpose of adopting this rule is to have a consistent format across all department of occupational safety and health (DOSH) rules. The updated format would provide easy access to rules from smart phones and tablet users. It will also provide easy navigation in PDF documents, as well as easier referencing by replacing bullets and dashes with numbers and letters. "Plain talk" writing principles have also been implemented throughout for greater clarity and comprehension. No rule requirements were changed as a result of this rule-making adoption. References, formatting and minor housekeeping changes were made throughout the chapters in this rule making.

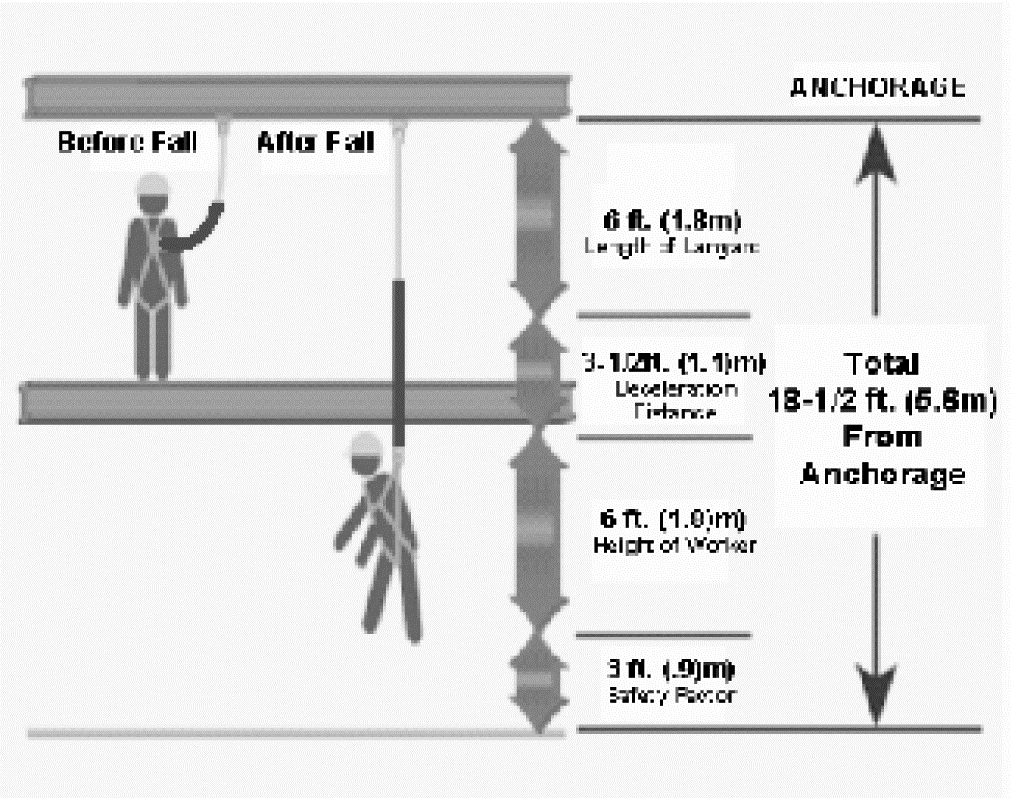

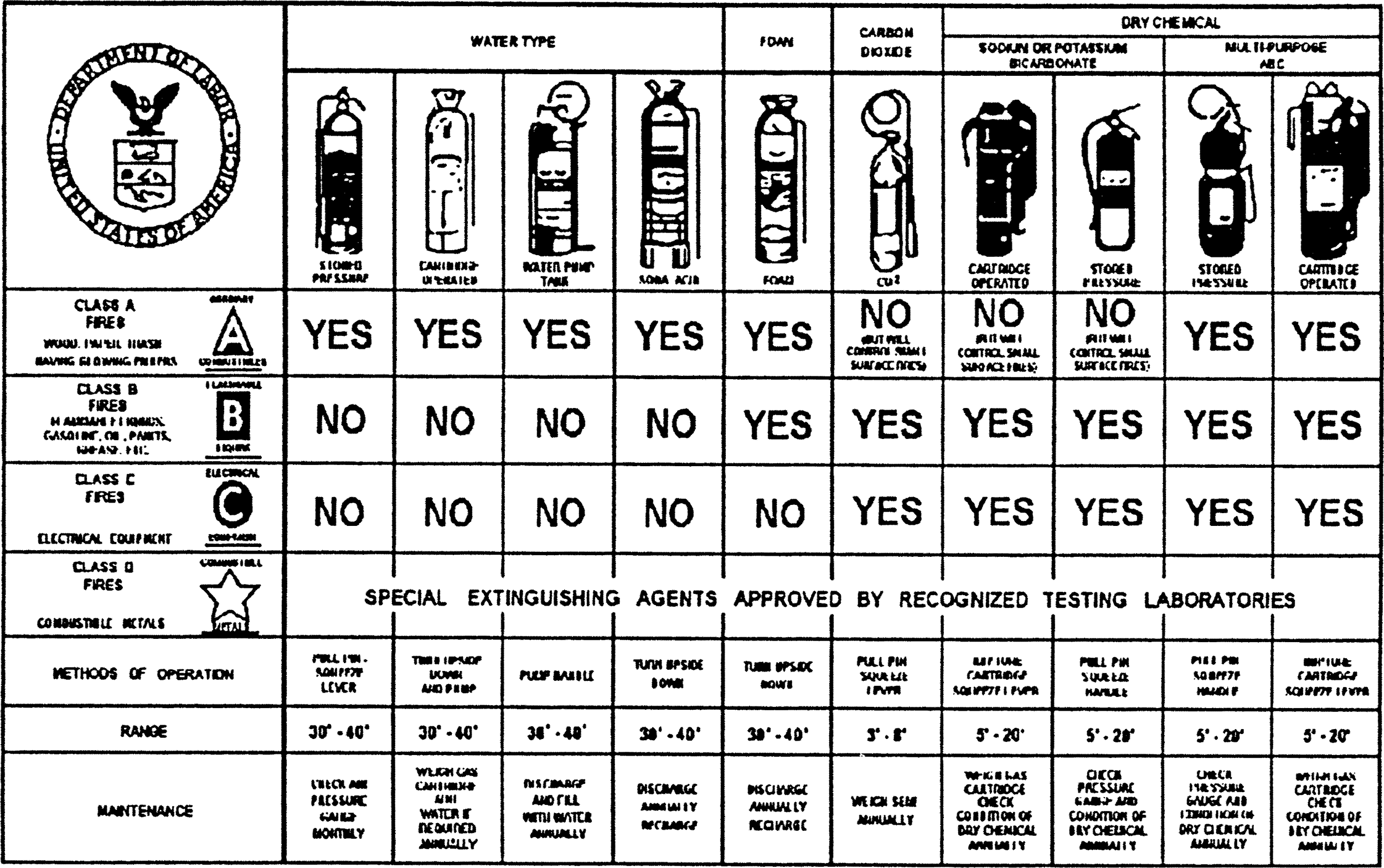

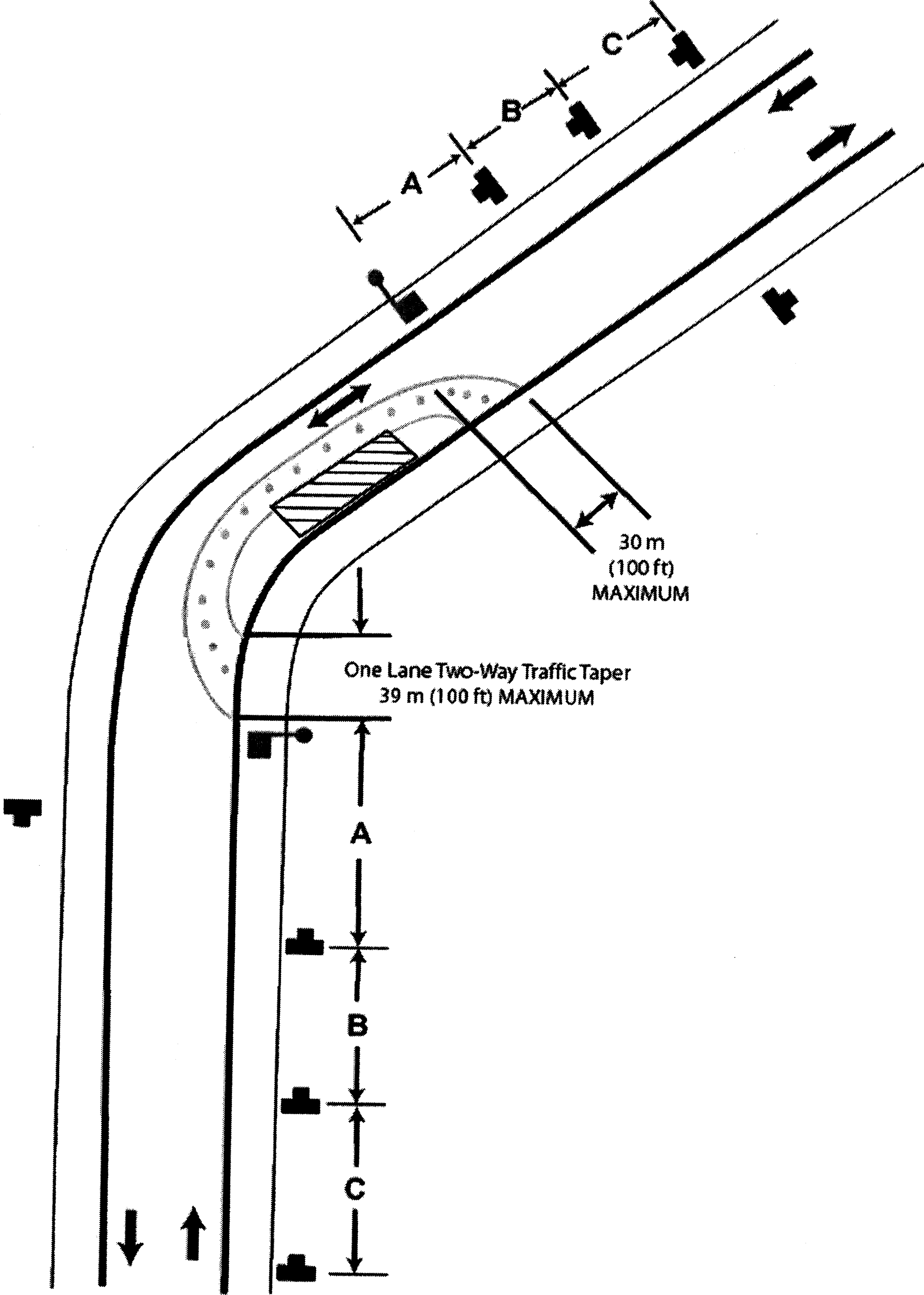

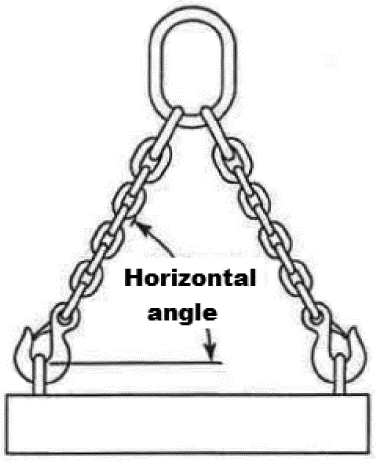

Citation of Existing Rules Affected by this Order: Amending WAC 296-155-005 Purpose and scope, 296-155-006 Equipment approval by nonstate agency or organization, 296-155-008 Incorporation of standards of federal agency, 296-155-009 Equipment whether or not owned by, or under control of the employer, 296-155-010 Variance and procedure, 296-155-012 Definitions applicable to all sections of this chapter, 296-155-015 Education and first-aid standards, 296-155-020 Housekeeping, 296-155-030 Acceptable certifications, 296-155-035 General requirements, 296-155-040 Safe place standards, 296-155-100 Management's responsibility, 296-155-105 Employee's responsibility, 296-155-110 Accident prevention program, 296-155-115 Safety bulletin board, 296-155-120 First-aid training and certification, 296-155-130 First-aid station, 296-155-140 Sanitation, 296-155-150 Ionizing radiation, 296-155-155 Nonionizing radiation, 296-155-160 Gases, vapors, fumes, dusts, and mists, 296-155-17301 Scope and application, 296-155-17303 Definitions, 296-155-17305 Permissible exposure limits, 296-155-17307 Communication among employers, 296-155-17309 Emergency situations, 296-155-17311 Exposure monitoring, 296-155-17313 Regulated areas, 296-155-17315 Methods of compliance, 296-155-17317 Respiratory protection, 296-155-17319 Protective work clothing and equipment, 296-155-17321 Hygiene facilities and practices, 296-155-17323 Communication of hazards, 296-155-17325 Housekeeping, 296-155-17327 Medical surveillance, 296-155-17329 Medical removal, 296-155-17331 Recordkeeping, 296-155-17333 Observation of monitoring, 296-155-17339 Startup dates, 296-155-17341 Appendix A to WAC 296-155-173—Substance data sheet, for 4-4'-methylenedianiline, 296-155-17343 Appendix B to WAC 296-155-173—Substance technical guidelines, MDA, 296-155-17345 Appendix C to WAC 296-155-173—Medical surveillance guidelines for MDA, 296-155-17347 Appendix D to WAC 296-155-173—Sampling and analytical methods for MDA monitoring and measurement procedures, 296-155-174 Cadmium, 296-155-176 Lead, 296-155-17605 Definitions, 296-155-17607 Permissible exposure limit, 296-155-17609 Exposure assessment, 296-155-17611 Methods of compliance, 296-155-17613 Respiratory protection, 296-155-17615 Protective work clothing and equipment, 296-155-17617 Housekeeping, 296-155-17619 Hygiene facilities and practices, 296-155-17621 Medical surveillance, 296-155-17623 Medical removal protection, 296-155-17625 Communication of hazards, 296-155-17627 Signs, 296-155-17629 Recordkeeping, 296-155-17631 Observation of monitoring, 296-155-17650 Appendix A to WAC 296-155-176—Substance data sheet for occupational exposure to lead, 296-155-17652 Appendix B to WAC 296-155-176—Employee standard summary, 296-155-17654 Appendix C to WAC 296-155-176—Medical surveillance guidelines, 296-155-180 Hazard communication, 296-155-200 General requirements for personal protective equipment (PPE), 296-155-201 Definitions applicable to this chapter, 296-155-203 Confined spaces, 296-155-20301 Definitions, 296-155-20307 Confined space work on sewer systems under construction, 296-155-205 Head protection, 296-155-211 Leg protection, 296-155-212 Foot protection, 296-155-215 Eye and face protection, 296-155-235 Working over or adjacent to water, 296-155-240 Sterilization of protective equipment, 296-155-24603 Definitions, 296-155-24605 General requirements, 296-155-24607 Fall protection required regardless of height, 296-155-24609 Fall protection required at four feet or more, 296-155-24611 Fall protection required at ten feet or more, 296-155-24613 Fall arrest specifications, 296-155-24615 Fall restraint specifications, 296-155-24617 Positioning device system specifications, 296-155-24619 Other specifications, 296-155-24621 Training, 296-155-24623 Appendix A—Determining roof widths—Nonmandatory guidelines for complying with WAC 296-155-24615, 296-155-24624 Appendix B—Calculating fall clearance distance using a shock-absorbing lanyard and D-ring anchorage connector—Nonmandatory guidelines for complying with WAC 296-155-24613 (1)(d), 296-155-250 Definitions applicable to this part, 296-155-260 Fire protection, 296-155-265 Fire prevention, 296-155-270 Flammable liquids, 296-155-275 Liquefied petroleum gas (LP-gas), 296-155-280 Temporary heating devices, 296-155-305 Signaling and flaggers, 296-155-310 Barricades, 296-155-315 Definitions applicable to this part, 296-155-325 General requirements for storage, 296-155-335 Disposal of waste materials, 296-155-33605 Definitions, 296-155-33705 General requirements, 296-155-33800 Chain slings, 296-155-33805 Wire rope slings, 296-155-33810 Metal mesh slings, 296-155-33815 Synthetic rope slings, 296-155-33820 Synthetic webbing slings, 296-155-33825 Synthetic roundslings, 296-155-33900 General requirements, 296-155-33905 Shackles, 296-155-33910 Adjustable hardware, 296-155-33915 Compression hardware, 296-155-33920 Links, rings, and swivels, 296-155-34005 Structural and mechanical lifters, 296-155-34010 Vacuum lifters, 296-155-34015 Close proximity lifting magnets, 296-155-34020 Remotely operated lifting magnets, 296-155-34025 Scrap and material handling grapples, 296-155-350 General requirements, 296-155-355 Hand tools, 296-155-360 Power-operated hand tools, 296-155-36305 Definitions applicable to this section, 296-155-36307 Requirements, 296-155-36309 Power loads, 296-155-36311 Fasteners, 296-155-36313 Operation, 296-155-36315 Limitations of use, 296-155-36317 Maintenance and storage, 296-155-36319 Authorized instructor, 296-155-36321 Qualified operator, 296-155-365 Abrasive wheels and tools, 296-155-367 Masonry saws, 296-155-370 Woodworking tools, 296-155-375 Jacks—Lever and ratchet, screw, and hydraulic, 296-155-380 Air receivers, 296-155-400 Gas welding and cutting, 296-155-405 Arc welding and cutting, 296-155-407 Protective clothing, 296-155-410 Fire prevention, 296-155-415 Ventilation and protection in welding, cutting, and heating, 296-155-420 Welding, cutting, and heating in way of preservative coatings, 296-155-426 Introduction, 296-155-428 General requirements, 296-155-429 Lockout and tagging of circuits, 296-155-432 Maintenance of equipment, 296-155-434 Environmental deterioration of equipment, 296-155-437 Batteries and battery charging, 296-155-441 Applicability, 296-155-444 General requirements, 296-155-447 Wiring design and protection, 296-155-449 Wiring methods, components, and equipment for general use, 296-155-452 Specific purpose equipment and installations, 296-155-456 Hazardous (classified) locations, 296-155-459 Special systems, 296-155-462 Definitions applicable to this part, 296-155-47501 Definitions applicable to this part, 296-155-476 General requirements, 296-155-477 Stairways, 296-155-52900 Scope, 296-155-52902 Definitions, 296-155-53102 Accreditation—Application form and applicant qualifications, 296-155-53106 Accreditation application—Processing time, 296-155-53108 Duration and renewal of an accreditation, 296-155-53110 Revocation or suspension of an accreditation, 296-155-53114 Issuance of temporary and annual certificates of operation, 296-155-53200 General inspection criteria, wire rope inspection and removal criteria, and preproof load test requirements for all cranes, 296-155-53202 Additional inspection criteria and proof load testing—Mobile cranes, 296-155-53204 Additional inspection criteria and proof load testing—Articulating boom cranes, 296-155-53206 Additional inspection criteria and proof load testing—Tower cranes, 296-155-53208 Additional inspection criteria and proof load testing—Self-erecting tower cranes, 296-155-53210 Additional inspection criteria and proof load testing—Overhead/bridge and gantry bridge cranes, 296-155-53212 Additional inspection criteria and proof load testing—Derricks, 296-155-53214 Crane decertification and reinstatement, 296-155-53300 Operator qualifications and certification, 296-155-53302 Signal person qualifications, 296-155-53306 Rigger qualifications, 296-155-53400 General requirements, 296-155-53401 Duties of assigned personnel, 296-155-53402 Assembly/disassembly, 296-155-53403 Fall protection, 296-155-53404 Wire rope, 296-155-53405 Inspections, 296-155-53406 Signals, 296-155-53408 Power line safety, 296-155-53409 Training, 296-155-53410 Safety devices, 296-155-53412 Operational aids, 296-155-53414 Cranes/derricks with a rated hoisting/lifting capacity of two thousand pounds or less, 296-155-53700 Mobile cranes—General, 296-155-53715 Mobile cranes—Operations, 296-155-53815 Articulating boom cranes—Operations, 296-155-53900 Tower cranes—General, 296-155-53915 Tower cranes—Operations, 296-155-54100 Self-erecting tower cranes—General, 296-155-54115 Self-erecting tower cranes—Operations, 296-155-54200 Overhead/bridge and gantry cranes—General, 296-155-54215 Overhead/bridge and gantry cranes—Operations, 296-155-54300 Derricks—General, 296-155-54305 Derricks—Construction, 296-155-54320 Derricks—Operations, 296-155-54400 Floating cranes/derricks and land cranes/derricks on barges, 296-155-54800 Design of platforms and suspension systems, 296-155-54900 Crane or derrick requirements for personnel lifting, 296-155-55100 Inspections on cranes and personnel platforms, 296-155-55105 Adjustments and repairs on personnel platforms, 296-155-55110 Proof load test platforms and rigging, 296-155-55115 Trial lift, 296-155-55200 Employer responsibilities for lifting personnel, 296-155-55205 Responsibilities of the personnel lift supervisor, 296-155-55210 Crane or derrick operation requirements for personnel lifting, 296-155-553 Lifting personnel, 296-155-55300 Personnel lifting requirements, 296-155-55305 Lifting personnel near electrical power lines, 296-155-55400 Use boatswain's chairs as a last resort, 296-155-55405 Lifting personnel using a boatswain's chair, 296-155-55600 General requirements, 296-155-55800 Chain slings, 296-155-55805 Wire rope slings, 296-155-55810 Metal mesh slings, 296-155-55815 Synthetic rope slings, 296-155-55820 Synthetic webbing slings, 296-155-55825 Synthetic roundslings, 296-155-56100 General requirements, 296-155-56105 Shackles, 296-155-56110 Adjustable hardware, 296-155-56115 Compression hardware, 296-155-56120 Links, rings, and swivels, 296-155-56200 Structural and mechanical lifters, 296-155-56205 Vacuum lifters, 296-155-56210 Close proximity lifting magnets, 296-155-56215 Remotely operated lifting magnets, 296-155-56220 Scrap and material handling grapples, 296-155-600 Definitions applicable to this part, 296-155-605 Equipment, 296-155-610 Motor vehicles on construction sites, 296-155-615 Material handling equipment, 296-155-620 Pile driving equipment, 296-155-625 Site clearing, 296-155-630 Marine operations and equipment, 296-155-650 Scope, application, and definitions applicable to this part, 296-155-655 General protection requirements, 296-155-657 Requirements for protective systems, 296-155-66401 Appendix A—Soil classification, 296-155-66403 Appendix B—Sloping and benching, 296-155-66405 Appendix C—Timber shoring for trenches, 296-155-66407 Appendix D—Aluminum hydraulic shoring for trenches, 296-155-675 Scope, application, and definitions applicable to this part, 296-155-680 General provisions, 296-155-681 Safe walking surfaces on concrete structural members, 296-155-682 Requirements for equipment and tools, 296-155-683 Concrete finishing, 296-155-684 Requirements for cast in place concrete, 296-155-685 Tubular welded frame shoring, 296-155-686 Tube and coupler shoring, 296-155-687 Single post shores, 296-155-688 Vertical slip forms, 296-155-689 Placing and removal of forms, 296-155-690 Appendix to WAC 296-155-684 cast in place concrete, 296-155-691 Precast concrete and tilt-up operations, 296-155-694 Requirements for lift-slab construction operations, 296-155-695 Miscellaneous concrete construction, 296-155-697 Requirements for masonry construction, 296-155-699 Appendix A to Part O—References to Part O of chapter 296-155 WAC, 296-155-702 Definitions, 296-155-703 Site layout, site-specific erection plan and construction sequence, 296-155-704 Hoisting and rigging, 296-155-706 Structural steel assembly, 296-155-707 Column anchorage, 296-155-708 Beams and columns, 296-155-709 Open web steel joists, 296-155-711 Systems-engineered metal buildings, 296-155-714 Falling object protection, 296-155-716 Fall protection, 296-155-717 Training, 296-155-725 Definitions applicable to this part, 296-155-730 Tunnels and shafts, 296-155-735 Caissons, 296-155-740 Cofferdams, 296-155-745 Compressed air, 296-155-74501 Appendix A—Decompression tables, 296-155-755 Roofing, insulating and waterproofing, 296-155-765 Rock crushing, gravel washing, and hot mix plants, 296-155-770 Moving of structures, 296-155-77100 Hoists, elevators, excavators, and conveyors, 296-155-77105 Material hoists, personnel hoists, and elevators, 296-155-77110 Base-mounted drum hoists, 296-155-77115 Overhead hoists, 296-155-77120 Conveyors, 296-155-77125 Aerial cableways, 296-155-77130 Concrete bucket towers, 296-155-77135 Hoisting engines, 296-155-775 Preparatory operations, 296-155-780 Stairs, passageways, and ladders, 296-155-785 Chutes, 296-155-790 Removal of materials through floor openings, 296-155-795 Removal of walls, masonry sections, and chimneys, 296-155-800 Manual removal of floors, 296-155-805 Removal of walls, floors, and material with equipment, 296-155-810 Catch platforms, 296-155-815 Storage, 296-155-820 Removal of steel construction, 296-155-825 Mechanical demolition, 296-155-830 Selective demolition by explosives, 296-155-950 Rollover protective structures (ROPS) for material handling equipment, 296-155-955 Minimum performance criteria for rollover protective structures for designated scrapers, loaders, dozers, graders, and crawler tractors, 296-155-960 Protective frame (ROPS) test procedures and performance requirements for wheel-type agricultural and industrial tractors used in construction, and 296-155-965 Overhead protection for operators of agricultural and industrial tractors.

Adopted under notice filed as WSR 16-02-094 on January 5, 2016.

Changes Other than Editing from Proposed to Adopted Version: The differences between the proposed rule and the rule as adopted are the following housekeeping corrections:

WAC 296-155-020(10), replaced the word "their" with the word "your" to remain consistent with change from "The employer shall …" to "You must …"

During the course of construction, alteration, repair or demolition of buildings and structures, you must ensure continuous clean-up of their your work area, including removal of all rubble, scrap, boxes, crates and excess material to trash disposal areas.

Number of Sections Adopted in Order to Comply with Federal Statute: New 0, Amended 0, Repealed 0; Federal Rules or Standards: New 0, Amended 0, Repealed 0; or Recently Enacted State Statutes: New 0, Amended 0, Repealed 0.

Number of Sections Adopted at Request of a Nongovernmental Entity: New 0, Amended 304, Repealed 0.

Number of Sections Adopted on the Agency's Own Initiative: New 0, Amended 304, Repealed 0.

Number of Sections Adopted in Order to Clarify, Streamline, or Reform Agency Procedures: New 0, Amended 304, Repealed 0.

Number of Sections Adopted Using Negotiated Rule Making: New 0, Amended 0, Repealed 0; Pilot Rule Making: New 0, Amended 0, Repealed 0; or Other Alternative Rule Making: New 0, Amended 304, Repealed 0.

Date Adopted: April 19, 2016.

Joel Sacks

Director

AMENDATORY SECTION (Amending WSR 01-11-038, filed 5/9/01, effective 9/1/01)

WAC 296-155-005 Purpose and scope.

(1) The standards included in this chapter apply throughout the state of Washington, to any and all work places subject to the Washington Industrial Safety and Health Act (chapter 49.17 RCW), where construction, alteration, demolition, related inspection, and/or maintenance and repair work, including painting and decorating, is performed. These standards are minimum safety requirements with which all industries must comply when engaged in the above listed types of work.

(2) If a provision of this chapter conflicts with a provision of the general safety and health standard (chapter 296-24 WAC), the general occupational health standard (chapter 296-62 WAC), or the safety and health core rules (chapter 296-800 WAC), the provision of this chapter ((shall)) will prevail. When a provision of this chapter conflicts with a provision of another vertical safety standard applying to the place of work, the provisions of the vertical standard of specific application ((shall)) will prevail.

AMENDATORY SECTION (Amending WSR 94-15-096, filed 7/20/94, effective 9/20/94)

WAC 296-155-006 Equipment approval by nonstate agency or organization.

Whenever a provision of this chapter states that only that equipment or those processes approved by an agency or organization other than the department of labor and industries, such as the Underwriters Laboratories or the Mine Safety and Health Administration (MSHA) and the National Institute for Occupational Safety and Health (NIOSH), ((shall)) must be utilized, that provision ((shall)) must be construed to mean that approval of such equipment or process by the designated agency or group ((shall)) must be prima facie evidence of compliance with the provisions of this chapter.

AMENDATORY SECTION (Amending Order 76-29, filed 9/30/76)

WAC 296-155-008 Incorporation of standards of federal agency.

(1) Whenever a provision of this chapter incorporates therein provisions of the Code of Federal Regulations (C.F.R.) and changes thereto, or any other regulations adopted by an agency of the federal government, that provision of this chapter ((shall)) must be construed to mean that compliance with such regulations ((shall)) must be prima facie evidence of compliance with the provisions of this chapter.

(2) Whenever a provision of this chapter incorporates therein provisions of the Code of Federal Regulations, the provisions so incorporated ((shall)) must be those in effect on the date of effectiveness of this chapter, unless the content of the incorporating section specifies otherwise.

AMENDATORY SECTION (Amending WSR 86-03-074, filed 1/21/86)

WAC 296-155-009 Equipment whether or not owned by, or under control of the employer.

(1) It is the employer's responsibility to ensure that any defective equipment or tools are not used.

(2) When any tool or piece of equipment fails to meet the requirements of any safety standard or recognized safe practice, you must not use the tool or equipment ((shall not be used)).

AMENDATORY SECTION (Amending WSR 94-15-096, filed 7/20/94, effective 9/20/94)

WAC 296-155-010 Variance and procedure.

Realizing that conditions may exist in operations under which certain state standards will not have practical application, the director of the department of labor and industries or ((his/her)) authorized representative may, pursuant to this section, sections ((eight)) 8 or ((nine)) 9 of the Washington Industrial Safety and Health Act (chapter 80, Laws of 1973, RCW 49.17.080 and 49.17.090) and appropriate administrative rules of this state and the department of labor and industries and upon receipt of application and after adequate investigation by the department, permit a variation from these requirements when other means of providing an equivalent measure of protection are afforded. Such variation granted ((shall)) must be limited to the particular case or cases covered in the application for variance and may be revoked for cause. The order granting a variance ((shall)) must be conspicuously posted on the premises and ((shall)) must remain posted during the time it is in effect. A copy of the variance ((shall)) must be available at the work site. All requests for variances from safety and health standards included in this chapter, ((shall)) must be made in writing to the director of the department of labor and industries at Olympia, Washington, or ((his/her)) duly authorized representative, Department of Labor and Industries, P.O. Box 44600, Olympia, Washington 98504-4600.

AMENDATORY SECTION (Amending WSR 95-04-007, filed 1/18/95, effective 3/1/95)

WAC 296-155-012 Definitions applicable to all sections of this chapter.

Note: | Unless the context indicates otherwise, words used in this chapter ((shall)) must have the meaning given in this section. Certain parts of this chapter contain definitions as they apply to that particular part. |

(("))Approved((" means)). Approved by the director of the department of labor and industries or ((his/her)) authorized representative: Provided, however, That should a provision of this chapter state that approval by an agency or organization other than the department of labor and industries is required, such as Underwriters' Laboratories or the bureau of mines, the provisions of WAC 296-155-006 ((shall)) must apply.

(("))Assistant director((" means)). The individual in charge of the division of consultation and compliance, department of labor and industries, or an authorized representative.

(("))Authorized person((" means)). A person approved or assigned by the employer to perform a specific type of duty or duties or be at a specific location or locations at the workplace.

(("))Competent person((" means)). One who is capable of identifying existing and predictable hazards in the surroundings or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has authorization to take prompt corrective action to eliminate them.

(("))Confined space((" means)). A space that:

(1) Is large enough and so configured that an employee can bodily enter and perform assigned work; and

(2) Has limited or restricted means for entry or exit (for example, tanks, vessels, silos, storage bins, hoppers, vaults, and pits are spaces that may have limited means of entry); and

(3) Is not designed for continuous employee occupancy.

(("))Construction work((" shall mean and include)). All or any part of excavation, construction, erection, alteration, repair, demolition, and dismantling, of buildings and other structures and all operations in connection therewith; the excavation, construction, alteration and repair of sewers, trenches, caissons, conduits, pipe lines, roads and all operations pertaining thereto; the moving of buildings and other structures, and to the construction, alteration, repair, or removal of wharfs, docks, bridges, culverts, trestles, piers, abutments or any other construction, alteration, repair or removal work related thereto.

(("))Defect((" means)). Any characteristic or condition which tends to weaken or reduce the strength of the tool, object, or structure of which it is a part.

(("))Department((" means)). The department of labor and industries.

(("))Designated person((" means)). "Authorized person" as defined in this section.

(("))Director((" means)). The director of the department of labor and industries, or his/her designated representative.

(("))Division((" means)). The division of consultation and compliance of the department.

(("))Employer((" means)). Any person, firm, corporation, partnership, business trust, legal representative, or other business entity which engages in any business, industry, profession, or activity in this state and employs one or more employees or who contracts with one or more persons, the essence of which is the personal labor of such person or persons and includes the state, counties, cities, and all municipal corporations, public corporations, political subdivisions of the state, and charitable organizations: Provided, that any person, partnership, or business entity not having employees, and who is covered by the industrial insurance act ((shall)) must be considered both an employer and an employee.

(("))Equipment((" means)). All machinery, devices, tools, facilities, safeguards, and protective construction used in connection with construction operations.

(("))Ground fault circuit interrupter((" means)). A fast acting circuit breaker that is sensitive to very low levels of current leakage to ground. The device is designed to limit the electric shock to a current and time duration below that which can cause serious injury.

(("))Hazard((" means that)). A condition, potential or inherent, which is likely to cause injury, death, or occupational disease.

(("))Hazardous substance((" means)). A substance which, by reason of being explosive, flammable, poisonous, corrosive, oxidizing, irritating, or otherwise harmful, is likely to cause death or injury.

(("))Maintenance((" means)). The work of keeping a building, machine, roadway, etc., in a state of good repair.

Must. The provision(s) of the standard are mandatory.

(("))Part((" means)). A major division, of this chapter, relating to a specific topic or topics and containing various sections, subsections, etc.

(("))Permit-required confined space (permit space)((" means)). A confined space that has one or more of the following characteristics:

(1) Contains or has a potential to contain a hazardous atmosphere;

(2) Contains a material that has the potential for engulfing an entrant;

(3) Has an internal configuration such that an entrant could be trapped or asphyxiated by inwardly converging walls or by a floor which slopes downward and tapers to a smaller cross-section; or

(4) Contains any other recognized serious safety or health hazard.

(("))Qualified((" means)). One who, by possession of a recognized degree, certificate, or professional standing, or who by extensive knowledge, training, and experience, has successfully demonstrated their ability to solve or resolve problems relating to the subject matter, the work, or the project.

(("))Repair((" means)). To restore a building, machine, roadway, etc., to an original state after damage or decay.

(("))Safety factor((" means)). The ratio of the ultimate breaking strength of a member or piece of material or equipment to the actual working stress or safe load when in use.

(("))Safety and health standard((" means)). A standard which requires the adoption or use of one or more practices, means, methods, operations, or processes reasonably necessary or appropriate to provide safe or healthful employment and places of employment.

(("Shall" means that the provision(s) of the standard are mandatory.

"))Substantial((" means)). Constructed of such strength, of such material, and of such workmanship, that the object referred to will withstand all normal wear, shock and usage.

(("))Standard safeguard((" means)). A device designed and constructed with the object of removing the hazard of accident incidental to the machine, appliance, tool, building, or equipment to which it is attached.

Standard safeguards ((shall)) must be constructed of either metal or wood or other suitable material or a combination of these. The final determination of the sufficiency of any safeguard rests with the director of the department of labor and industries through the division of consultation and compliance.

(("))Suitable((" means)). That which fits, or has the qualities or qualifications to meet a given purpose, occasion, condition, function, or circumstance.

(("))Working day((" means)). A calendar day, except Saturdays, Sundays, and legal holidays as set forth in RCW 1.16.050, as now or hereafter amended, and for the purposes of the computation of time within which an act is to be done under the provisions of this chapter, ((shall)) must be computed by excluding the first working day and including the last working day.

(("Worker," "personnel," "man," "person," "employee,")) Worker, personnel, man, person, employee, and other terms of like meaning, unless the context of the provision containing such term indicates otherwise((, mean)). An employee of an employer who is employed in the business of their employer whether by way of manual labor or otherwise and every person in this state who is engaged in the employment of or who is working under an independent contract the essence of which is their personal labor for an employer whether by manual labor or otherwise.

(("))Work place((" means)). Any plant, yard, premises, room, or other place where an employee or employees are employed for the performance of labor or service over which the employer has the right of access or control, and includes, but is not limited to, all work places covered by industrial insurance under Title 51 RCW, as now or hereafter amended.

Abbreviations used in this chapter:

(("))ANSI((" means)). American National Standards Institute.

(("))API((" means)). American Petroleum Institute.

(("))ASA((" means)). American Standards Association.

(("))ASAE((" means)). American Society of Agricultural Engineers.

(("))ASHRE((" means)). American Society of Heating and Refrigeration Engineers.

(("))ASME((" means)). American Society of Mechanical Engineers.

(("))ASTM((" means)). American Society of Testing and Materials.

(("))AWS((" means)). American Welding Society.

(("))BTU((" means)). British thermal unit.

(("))BTUH((" means)). British thermal unit per hour.

(("))CFM((" means)). Cubic feet per minute.

(("))C.F.R.((" means)). Code of Federal Register.

(("))CGA((" means)). Compressed Gas Association.

(("))CIE((" means)). Commission Internationale de l' Eclairage.

(("))DOT((" means)). Department of transportation.

DOSH. Division of Occupational Safety and Health.

(("))FRP((" means)). Fiberglass reinforced plastic.

(("))GPM((" means)). Gallons per minute.

(("))ICC((" means)). Interstate Commerce Commission.

(("))ID((" means)). Inside diameter.

(("))LPG((" means)). Liquefied petroleum gas.

(("))MCA((" means)). Manufacturing Chemist Association.

(("))MSHA((" means)). United States Department of Labor, Mine Safety and Health Administration.

(("))NBFU((" means)). National Board of Fire Underwriters.

(("))NEMA((" means)). National Electrical Manufacturing Association.

(("))NFPA((" means)). National Fire Protection Association.

(("))NTP((" means)). Normal temperature and pressure.

(("))OD((" means)). Outside diameter.

(("))PSI((" means)). Pounds per square inch.

(("))PSIA((" means)). Pounds per square inch absolute.

(("))PSIG((" means)). Pounds per square inch gauge.

(("))RMA((" means)). Rubber Manufacturers Association.

(("))SAE((" means)). Society of Automotive Engineers.

(("))TFI((" means)). The Fertilizer Institute.

(("))TSC((" means)). Trailer Standard Code.

(("))UL((" means)). Underwriters' Laboratories, Inc.

(("))USASI((" means)). United States of America Standards Institute.

(("))U.S.C.((" means)). United States Code.

(("))USCG((" means)). United States Coast Guard.

(("))WAC((" means)). Washington Administrative Code.

(("))WISHA((" means)). Washington Industrial Safety and Health Act of 1973.

AMENDATORY SECTION (Amending WSR 94-15-096, filed 7/20/94, effective 9/20/94)

WAC 296-155-015 Education and first-aid standards.

((It shall be the duty of every employer to)) You must comply with such standards and systems of education for safety as ((shall be)) is, from time to time, prescribed for such employer by the director of labor and industries or by statute. Refer to WAC 296-155-100 through 296-155-135 for additional requirements.

AMENDATORY SECTION (Amending WSR 86-03-074, filed 1/21/86)

WAC 296-155-020 Housekeeping.

(1) You must keep all places of employment ((shall be kept)) clean to the extent that the nature of the work allows.

(2) To facilitate cleaning, you must keep every floor, working surface, and passageway ((shall be kept)) free from protruding nails, splinters, loose boards or openings.

(3) You must perform cleaning and sweeping ((shall be performed)) in such a manner as to minimize the contamination of the air with dust.

(4) In areas where workers may pass or perform duties, you must remove all debris and accumulations of material ((shall be removed)). You must cover hoses and electrical conductors across aisles or passageways ((shall be covered or suspended)) or suspend them overhead so that there is no tripping hazard.

(5) Where mechanical handling equipment is used, you must allow sufficient safe clearances ((shall be allowed)) for aisles, at loading docks, through doorways and wherever turns or passages must be made. You must mark such aisles and passageways ((shall be marked)).

(6) Storage of material ((shall)) must not create a hazard. You must store bags, containers, bundles, construction materials and other equipment ((shall be stored)) in tiers, stacked, blocked or interlocked. They ((shall)) must be limited in height so that they are stable and secure against falling, sliding, or collapse.

(7) You must maintain free access ((shall be maintained)) at all times to all exits, fire alarm boxes, fire extinguishing equipment, and any other emergency equipment. Free access means clear of all obstructions.

(8) You must keep working and storage areas ((shall be kept)) free from accumulation of materials that pose hazards of tripping, fire, explosion, or pest harborage. You must exercise vegetation control ((shall be exercised)).

(9) You must keep all lunchrooms, washrooms and restrooms ((shall be kept)) in a clean and sanitary condition. Garbage cans in lunchrooms and restrooms ((shall)) must be equipped with fitted covers and the contents disposed of daily.

(10) During the course of construction, alteration, repair or demolition of buildings and structures, ((employers shall)) you must ensure continuous clean-up of ((their)) your work area, including removal of all rubble, scrap, boxes, crates and excess material to trash disposal areas.

(11) You must provide containers ((shall be provided)) for the collection and separation of waste, trash, oily or used rags, and other refuse. Containers used for garbage and other oily, flammable or hazardous wastes, such as caustics, acids, harmful dusts or similar materials ((shall)) must be equipped with covers. You must dispose of common garbage and other waste ((shall be disposed of)) at frequent and regular intervals. You must store and dispose of chemical agents or substances which might react to create a hazardous condition ((shall be stored and disposed of)) separately. You must handle, accumulate and dispose of all hazardous wastes which are subject to the requirements of chapter 173-303 WAC ((shall be handled, accumulated and disposed of)) in accordance with that chapter.

(12) You must maintain all floors and walkways ((shall be maintained)) in good condition. You must repair or replace loose or broken components ((shall be repaired or replaced)). You must ensure secure footing ((shall be ensured)) on all floors and walkways.

AMENDATORY SECTION (Amending Order 74-26, filed 5/7/74, effective 6/6/74)

WAC 296-155-030 Acceptable certifications.

(1) Pressure vessels. You must deem current and valid certification by an insurance company or regulatory authority ((shall be deemed)) as acceptable evidence of safe installation, inspection, testing of pressure vessels provided by the employer.

(2) Boilers. You must deem boilers provided by the employer ((shall be deemed)) to be in compliance with the requirements of this section when evidence of current and valid certification by an insurance company or regulatory authority attesting to the safe installation, inspection, and testing is presented.

(3) Other requirements. Regulations prescribing specific requirements for other types of pressure vessels and similar equipment are contained in Parts D and M of this chapter.

AMENDATORY SECTION (Amending WSR 86-03-074, filed 1/21/86)

WAC 296-155-035 General requirements.

(1) The use of any machinery, tool, material, or equipment which is not in compliance with any applicable requirements of this chapter is prohibited. You must either identify such machine, tool, material, or equipment ((shall either be identified)) as unsafe by tagging or locking the controls to render them inoperable or ((shall be)) you must physically ((removed)) remove it from its place of operation.

(2) ((The employer shall)) You must permit only those employees qualified by training or experience to operate equipment and machinery.

(3) ((Employees shall)) You must use safeguards provided for ((their)) employee protection.

(4) You must wear suitable clothing ((shall be worn)) for the job. You must wear sufficient and proper clothing ((shall be worn)) to assist in preventing scratches, abrasions, slivers, sunburn, hot liquid burns, or similar hazards. You must not wear loose or ragged clothing, scarfs or ties ((shall not be worn)) while working around moving machinery.

(5) Where work is in progress above workers, you must provide a catch platform or other means ((shall be provided)) to protect those working below. You must notify all workers ((shall be notified)). You must maintain one completed floor ((shall be maintained)) between workers and steel or concrete work above.

(6) Employees ((shall)) must report to their employers the existence of any unsafe equipment or method or any other hazard which, to their knowledge is unsafe and where such unsafe equipment or method or other hazard exists in violation of this chapter ((it shall be corrected)) you must correct it.

(7) Nothing herein contained ((shall)) prevents the use of existing equipment during its lifetime provided it ((shall be)) is properly safeguarded, maintained in good condition, ((be)) in conformity with applicable safety and health standards, and ((shall)) conforms to safety factors for the material used, as herein provided.

(8) As construction progresses, you must secure or brace the component parts of structures ((shall be secured or braced)) to prevent collapse or failure.

(9) You must ensure prompt and safe removal of injured employees from elevated work locations, trenches and excavations ((shall be ensured)) prior to commencement of work.

AMENDATORY SECTION (Amending WSR 94-15-096, filed 7/20/94, effective 9/20/94)

WAC 296-155-040 Safe place standards.

(1) ((Each employer shall)) You must furnish to each employee a place of employment free from recognized hazards that are causing or likely to cause serious injury or death to employees.

(2) ((Every employer shall)) You must require safety devices, furnish safeguards, and ((shall)) you must adopt and use practices, methods, operations, and processes which are reasonably adequate to render such employment and place of employment safe. ((Every employer shall)) You must do everything reasonably necessary to protect the life and safety of employees.

(3) ((No employer shall)) You must not require any employee to go or be in any employment or place of employment which is hazardous to the employee.

(4) ((No employer shall)) You must not fail or neglect:

(a) To provide and use safety devices and safeguards.

(b) To adopt and use methods and processes reasonably adequate to render the employment and place of employment safe.

(c) To do everything reasonably necessary to protect the life and safety of employees.

(5) No employer, owner, or lessee of any real property ((shall)) is permitted to construct or cause to be constructed any place of employment that is hazardous to the employee.

(6) ((No person shall)) You must not do any of the following:

(a) Remove, displace, damage, destroy or carry off any safety device, safeguard, notice, or warning, furnished for use in any employment or place of employment.

(b) Interfere in any way with the use thereof by any other person.

(c) Interfere with the use of any method or process adopted for the protection of any employee, including themselves, in such employment, or place of employment.

(d) Fail or neglect to do everything reasonably necessary to protect the life and safety of employees.

(7) The use of intoxicants or debilitating drugs while on duty is prohibited. Employees under the influence of intoxicants or drugs ((shall)) must not be permitted in or around worksites. This subsection (7) ((shall)) does not apply to employees taking prescription drugs or narcotics as directed and prescribed by a physician, provided such use does not endanger the employee or others.

AMENDATORY SECTION (Amending WSR 06-05-027, filed 2/7/06, effective 4/1/06)

WAC 296-155-100 Management's responsibility.

(1) It ((shall be)) is the responsibility of management to establish, supervise, and enforce, in a manner which is effective in practice:

(a) A safe and healthful working environment.

(b) An accident prevention program as required by these standards.

(c) Training programs to improve the skill and competency of all employees in the field of occupational safety and health.

(2) You must instruct employees required to handle or use poisons, caustics, and other harmful substances ((shall be instructed)) regarding the safe handling and use, and be made aware of the potential hazards, personal hygiene, and personal protective measures required.

(3) In job site areas where harmful plants or animals are present, you must instruct employees who may be exposed ((shall be instructed)) regarding the potential hazards, and how to avoid injury, and the first-aid procedures to be used in the event of injury.

(4) You must instruct employees required to handle or use flammable liquids, gases, or toxic materials ((shall be instructed)) in the safe handling and use of these materials and made aware of the specific requirements contained in Parts B, D, and other applicable parts of this standard.

(5) Permit-required confined spaces. The requirements of chapters 296-24, 296-62 and 296-155 WAC apply.

(6) ((The employer shall)) You must ensure that work assignments place no employee in a position or location not within ordinary calling distance of another employee able to render assistance in case of emergency.

Note: | This subsection does not apply to operators of motor vehicles, watchpersons or other jobs which, by their nature, are single employee assignments. However, a definite procedure for checking the welfare of all employees during working hours should be instituted and all employees so advised. |

(7) ((Each employer shall)) You must post and keep posted a notice or notices (Job Safety and Health Protection - Form F416-081-909) to be furnished by the department of labor and industries, informing employees of the protections and obligations provided for in the act and that for assistance and information, including copies of the act, and of specific safety and health standards employees should contact the employer or the nearest office of the department of labor and industries. You must post such notice or notices ((shall be posted by the employer)) at each establishment in a conspicuous place or places where notices to employees are customarily posted. ((Each employer shall)) You must take steps to ((assure)) ensure that such notices are not altered, defaced, or covered by other material.

AMENDATORY SECTION (Amending Order 74-26, filed 5/7/74, effective 6/6/74)

WAC 296-155-105 Employee's responsibility.

(1) Employees ((shall)) must coordinate and cooperate with all other employees in an attempt to eliminate accidents.

(2) Employees ((shall)) must study and observe all safety standards governing their work.

(3) Employees ((shall)) must apply the principles of accident prevention in their daily work and ((shall)) must use proper safety devices and protective equipment as required by their employment or employer.

(4) Employees ((shall)) must properly care for all personal protective equipment.

(5) Employees ((shall)) must make a report, on the day of the incident, to their immediate supervisor, of each industrial injury or occupational illness, regardless of the degree of severity.

AMENDATORY SECTION (Amending WSR 01-11-038, filed 5/9/01, effective 9/1/01)

WAC 296-155-110 Accident prevention program.

(1) Exemptions. Workers of employers whose primary business is other than construction, who are engaged solely in maintenance and repair work, including painting and decorating, are exempt from the requirement of this section provided:

(a) The maintenance and repair work, including painting and decorating, is being performed on the employer's premises, or facility.

(b) The length of the project does not exceed one week.

(c) The employer is in compliance with the requirements of WAC 296-800-140 Accident prevention program, and WAC 296-800-130, Safety committees and safety meetings.

(2) ((Each employer shall)) You must develop a formal accident-prevention program, tailored to the needs of the particular plant or operation and to the type of hazard involved. The department may be contacted for assistance in developing appropriate programs.

(3) The following are the minimal program elements for all employers:

A safety orientation program describing the employer's safety program and including:

(a) How, where, and when to report injuries, including instruction as to the location of first-aid facilities.

(b) How to report unsafe conditions and practices.

(c) The use and care of required personal protective equipment.

(d) The proper actions to take in event of emergencies including the routes of exiting from areas during emergencies.

(e) Identification of the hazardous gases, chemicals, or materials involved along with the instructions on the safe use and emergency action following accidental exposure.

(f) A description of the employer's total safety program.

(g) An on-the-job review of the practices necessary to perform the initial job assignments in a safe manner.

(4) You must outline each accident-prevention program ((shall be outlined)) in written format.

(5) ((Every employer shall)) You must conduct crew leader-crew safety meetings as follows:

(a) You must hold crew leader-crew safety meetings ((shall be held)) at the beginning of each job, and at least weekly thereafter.

(b) You must tailor crew leader-crew meetings ((shall be tailored)) to the particular operation.

(6) Crew leader-crew safety meetings ((shall)) must address the following:

(a) A review of any walk-around safety inspection conducted since the last safety meeting.

(b) A review of any citation to assist in correction of hazards.

(c) An evaluation of any accident investigations conducted since the last meeting to determine if the cause of the unsafe acts or unsafe conditions involved were properly identified and corrected.

(d) You must document attendance ((shall be documented)).

(e) You must document subjects discussed ((shall be documented)).

Note: | Subcontractors and their employees may, with the permission of the general contractor, elect to fulfill the requirements of subsection (5)(a) and (b) of this section by attending the prime contractors crew leader-crew safety meeting. Any of the requirements of subsections (6)(a), (b), (c), and (7) of this section not satisfied by the prime contractors safety meetings ((shall)) must be the responsibility of the individual employers. |

(7) You must prepare minutes of each crew leader-crew meeting ((shall be prepared)) and you must maintain a copy ((shall be maintained)) at the location where the majority of the employees of each construction site report for work each day.

(8) You must retain minutes of crew leader-crew safety meetings ((shall be retained)) by the employer for at least one year and ((shall be made)) you must make them available for review by personnel of the department, upon request.

(9) ((Every employer shall)) You must conduct walk-around safety inspections as follows:

(a) At the beginning of each job, and at least weekly thereafter, you must conduct a walk-around safety inspection ((shall be conducted)) jointly by one member of management and one employee, elected by the employees, as their authorized representative.

(b) ((The employer shall)) You must document walk-around safety inspections and such documentation ((shall)) must be available for inspection by personnel of the department.

(c) You must maintain records of walk-around inspections ((shall be maintained by the employer)) until the completion of the job.

AMENDATORY SECTION (Amending Order 74-26, filed 5/7/74, effective 6/6/74)

WAC 296-155-115 Safety bulletin board.

((There shall be installed and maintained)) You must install and maintain in every fixed establishment (the place where employees regularly report to work) employing ((eight)) 8 or more persons, a safety bulletin board sufficient in size to display and post safety bulletins, newsletters, posters, accident statistics and other safety educational material.

AMENDATORY SECTION (Amending WSR 04-07-160, filed 3/23/04, effective 5/1/04)

WAC 296-155-120 First-aid training and certification.

This section is designed to ((assure)) ensure that all employees in this state are afforded quick and effective first-aid attention in the event of an on the job injury. To achieve this purpose the presence of personnel trained in first-aid procedures at or near those places where employees are working is required. Compliance with the provisions of this section may require the presence of more than one first-aid trained person.

(1) ((Each employer)) You must have available at all worksites, where a crew is present, a person or persons holding a valid first-aid certificate.

(2) All crew leaders, supervisors or persons in direct charge of one or more employees must have a valid first-aid certificate.

(3) For the purposes of this section, a crew means a group of two or more employees working at any worksite.

Note: | The requirement that all crew leaders, supervisors or person in direct charge of one or more employees (subsection (3) of this section) applies even if other first-aid trained person(s) are available. In emergencies, crew leaders will be permitted to work up to thirty days without having the required certificate, providing an employee in the crew or another crew leaders in the immediate work area has the necessary certificate. |

AMENDATORY SECTION (Amending WSR 01-11-038, filed 5/9/01, effective 9/1/01)

WAC 296-155-130 First-aid station.

Employers with ((fifty)) 50 or more employees per shift at one location must establish a first-aid station in accordance with the requirements in chapter 296-800 WAC.

AMENDATORY SECTION (Amending WSR 12-24-071, filed 12/4/12, effective 1/4/13)

WAC 296-155-140 Sanitation.

(1) Potable water.

(a) You must provide an adequate supply of potable water ((shall be provided)) in all places of employment.

(b) Portable containers used to dispense drinking water ((shall)) must be capable of being tightly closed and equipped with a tap. Water ((shall)) must not be dipped from containers.

(c) You must clearly mark any container used to distribute drinking water ((shall be clearly marked)) as to the nature of its contents and not used for any other purpose.

(d) The common drinking cup is prohibited.

(e) Where single service cups (to be used but once) are supplied, you must provide both a sanitary container for the unused cups and a receptacle for disposing of the used cups ((shall be provided)).

(f) You must thoroughly clean all water containers used to furnish drinking water ((shall be thoroughly cleaned)) at least once each week or more often as conditions require.

(g) The requirements of this subsection do not apply to mobile crews or to normally unattended work locations as long as employees working at these locations have transportation immediately available, within the normal course of their duties, to nearby facilities otherwise meeting the requirements of this section.

(h) The following definitions apply:

(i) Mobile crew((:)). A work crew that routinely moves to a different work location periodically. Normally a mobile crew is not at the same location all day.

(ii) Normally unattended work location((:)). An unattended site that is visited occasionally by one or more employees.

(iii) Nearby facility((:)). A sanitary facility that is within three minutes travel by the transportation provided.

(iv) (("))Potable water((" means)). Water that is suitable for drinking by the public and meets the requirements of chapter 246-290 or 246-291 WAC.

(2) Wash water.

(a) You must provide clean, tepid wash water, between 70 and 100 degrees Fahrenheit, ((shall be provided)) at all construction sites.

(b) You must provide individual hand towels ((shall be provided)). You must provide both a sanitary container for the unused towels and a receptacle for disposal of used towels ((shall be provided)).

(c) You must provide hand soap, industrial hand cleaner or similar cleansing agents ((shall be provided)). Cleansing agents ((shall)) must be adequate to remove any paints, coatings, herbicides, insecticides or other contaminants.

(d) The requirements of this subsection do not apply to mobile crews or to normally unattended work locations as long as employees working at these locations have transportation immediately available, within the normal course of their duties, to nearby facilities otherwise meeting the requirements of this section.

(e) You must not use gasoline or solvents ((shall not be used)) for personal cleaning.

(f) Wash water areas will be maintained in a dry condition. You must eliminate slipping or other hazards ((shall be eliminated)) from the wash water area before it is acceptable for use.

(3) Nonpotable water.

(a) You must identify outlets for nonpotable water, such as water for industrial or firefighting purposes only, ((shall be identified)) by signs meeting the requirements of Part E of this chapter, to indicate clearly that the water is unsafe and is not to be used for drinking, washing or cooking purposes.

(b) ((There shall be)) You must ensure that there is no cross-connection, open or potential, between a system furnishing potable water, a system furnishing nonpotable water or a system furnishing wash water.

(4) Toilets.

(a) The provisions of this section apply to both portable chemical toilets and to flush toilets, except where flush toilets are used the requirements of WAC 296-800-230 ((shall)) apply instead of (b) of this subsection.

(b) You must provide accessible toilets ((shall be provided)) for employees according to the following table:

TABLE B-1 |

||||

Number of Employees |

Toilets Required |

|||

1 - 10 |

1 |

|||

11 - 25 |

2 |

|||

26 - 40 |

3 |

|||

41 - 60 |

4 |

|||

61 - 80 |

5 |

|||

Over 80 |

one additional toilet for each additional ((twenty)) 20 employees or any fraction thereof. |

|||

(c) When the employer provides both flush and portable chemical toilets, the number of employees allowed to be served by the flush toilets, per WAC 296-800-230 will be calculated. That number will be subtracted from the total number of employees and the employer will be required to provide an adequate number of portable chemical toilets for the number of remaining employees, as required by (b) of this subsection.

(d) You must maintain toilets ((shall be maintained)) in clean, sanitary and functional condition. You must provide internal latches ((shall be provided)) to secure the units from inadvertent entry. Where there are ((twenty)) 20 or more employees consisting of both sexes, you must provide facilities ((shall be provided)) for each sex.

(i) You must properly clean each unit ((shall be properly cleaned)) on a routine basis.

(ii) You must maintain chemicals, toilet tissue and sanitary seat covers ((shall be maintained)) in a supply sufficient for use during the entire shift.

(iii) You must immediately remove any defective or inadequate unit ((shall be immediately removed)) from service.

(e) Specifications. The following specifications apply:

(i) A noncaustic chemical toilet (portable chemical toilet is) a self-contained unit equipped with a waste receiving chemical holding container.

(ii) Portable chemical toilets consisting of only a holding tank, commonly referred to as "elevator units" or "elevator toilets" are not acceptable. "Elevator units" may be used if they are individually located in a lockable room which affords privacy. When this type unit is used in a private individual lockable room the entire room will be considered a toilet facility, as such the room will meet all requirements of toilet facilities and be inspected in accordance with subsection (5)(b)(iii) of this section.

(iii) Rooms, buildings or shelters housing toilets ((shall)) must be of sound construction, easy to clean, provide shelter and provide privacy. The toilet rooms ((shall)) must be ventilated to the outside and adequately lighted. All openings into the toilet room ((shall)) must be covered with 16-mesh screen.

(iv) You must service toilets ((shall be serviced)) on a regular schedule. Servicing ((shall)) must include the use of a disinfectant for cleaning urinals and seats, removing waste from containers, recharging containers with an odor controlling chemical and installing an adequate supply of toilet tissue and seat covers.

(v) You must perform service ((shall be performed)) in accordance with local codes by approved servicing organizations. You must dispose of or discharge waste ((shall be disposed of or discharged)) in accordance with requirements of local health department regulations.

(vi) Waste containers ((shall)) must be fabricated from impervious materials, e.g. plastic, steel, fiberglass or their equivalent. Containers ((shall)) must be water tight and capable of containing the chemical waste in a sanitary manner. The container ((shall)) must be fitted to the building in a manner so as to prevent insects from entering from the exterior of the building. Containers ((shall)) must be adequate in size to be used by the number of persons, according to the schedule for minimum requirements, without filling the container to more than half of its volume before regularly scheduled servicing.

(vii) Removal of waste ((shall)) must be handled in a clean and sanitary manner by means of a vacuum hose and received by a leak-proof tank truck. All valves on the tank ((shall)) must be leak-proof.

(viii) You must make provisions ((shall be made)) so service trucks have a clear approach and convenient access to the toilets to be serviced.

(ix) Disposal of waste from tank trucks ((shall)) must be in accordance with local health department requirements. In the absence of provisions by local health departments, waste must be disposed of through municipal or district sanitary sewage systems. Municipal or area sanitary sewage districts ((shall)) must provide sewage disposal locations and facilities which are adequate and convenient for duly authorized toilet service organizations.

(f) The requirements of this subsection do not apply to mobile crews or to normally unattended work locations as long as employees working at these locations have transportation immediately available, within the normal course of their duties, to nearby facilities otherwise meeting the requirements of this section.

(5) Employer responsibilities.

(a) On multiemployer worksites, the prime contractor ((shall)) must ensure that the requirements of this section are met. Each employer is responsible for seeing that facilities for their own employees are provided.

(b) ((Each employer shall)) You must ensure, at the beginning of each shift, that the sanitation facilities required by this section are inspected. If any facility or unit fails to meet the following requirements, you must take immediate corrective action ((shall be taken)). You must document and maintain such action ((shall be documented and maintained)) at the site for at least 72 hours. Inspection ((shall)) must establish:

(i) Potable water: Sufficient supply of water, sufficient supply of cups, container integrity, cleanliness of unit and area, capacity of trash receptacle (empty).

(ii) Wash water: Sufficient supply of clean water, proper temperature, sufficient supply of towels, sufficient supply of cleansing agents, container integrity, cleanliness of unit and area without the presence of physical hazards, capacity of trash receptacle (empty).

(iii) Toilets: Sufficient supply of toilet tissue and sanitary seat covers, capacity and condition of chemical agent, capacity and condition of holding tank, cleanliness of unit and area without the presence of physical hazards, physical and structural condition of unit, condition of lock, condition of toilet seat and tissue holder, absence of all foreign debris.

(c) The location of the facilities required by subsections (1), (2) and (4) of this section ((shall)) must be as close as practical to the highest concentration of employees.

(i) On multistory structures they ((shall)) must be furnished on every third floor.

(ii) At all sites they ((shall)) must be located within 200 feet horizontally of all employees.

(iii) The requirements of subsection (5)(c)(i) and (ii) do not apply to mobile crews or to normally unattended work locations as long as employees working at these locations have transportation immediately available, within the normal course of their duties, to nearby facilities otherwise meeting the requirements of this section.

(6) Food handling. All employees' food service facilities and operations ((shall)) must meet the applicable laws, ordinances and regulations of the jurisdictions in which they are located.

(7) Temporary sleeping quarters. When temporary sleeping quarters are provided, they ((shall)) must be heated, ventilated and lighted.

AMENDATORY SECTION (Amending WSR 94-15-096, filed 7/20/94, effective 9/20/94)

WAC 296-155-150 Ionizing radiation.

(1) In construction and related activities involving the use of sources of ionizing radiation, the pertinent provisions of the Nuclear Regulatory Commission's Standards for Protection Against Radiation, relating to protection against occupational radiation exposure, ((shall)) apply.

(2) Any activity which involves the use of radioactive material or X ray, whether or not under license from the Nuclear Regulatory Commission, ((shall)) must be performed by competent persons specially trained in the proper and safe operation of such equipment. In the case of materials used under commission license, only persons actually licensed, or competent persons under direction and supervision of the licensee ((shall)) are permitted to perform such work.

AMENDATORY SECTION (Amending WSR 86-03-074, filed 1/21/86)

WAC 296-155-155 Nonionizing radiation.

(1) Only qualified and trained employees ((shall)) must be assigned to install, adjust, and operate laser equipment.

(2) Proof of qualification of the laser equipment operator ((shall)) must be available and in possession of operator at all times.

(3) You must provide employees, when working in areas in which a potentially hazardous exposure (see WAC 296-62-09005(4)) to direct or reflected laser radiation exists, ((shall be provided)) with antilaser eye protection devices specified in Part C of this chapter.

(4) Areas in which Class II and III lasers are used ((shall)) must be posted with standard laser warning placards.

(5) You must utilize beam shutters or caps ((shall be utilized)), or the laser turned off, when laser transmission is not actually required. When the laser is left unattended for a substantial period of time, such as during lunch hour, overnight, or at change of shifts, the laser ((shall)) must be turned off.

(6) You must use only mechanical or electronic means ((shall be used)) as a detector for guiding the internal alignment of the laser.

(7) The laser beam ((shall)) must not be directed at employees.

(8) When it is raining or snowing, or when there is dust or fog in the air, and it is impracticable to cease laser system operation, you must keep employees ((shall be kept)) out of range of the area of source and target during such weather conditions.

(9) Laser equipment ((shall)) must bear a conspicuously displayed label to indicate hazard classification. This label ((shall)) must be prepared in accordance with 21 C.F.R. 1040.10.

(10) You must use only Class I, II, or III laser equipment ((shall be used)). You must not use Class IV laser equipment ((shall not be used)).

(11) You must set up laser unit in operation ((shall be set up)) above the heads of the employees, when possible.

(12) You must not expose employees ((shall not be exposed)) to radiofrequency/microwave radiation in excess of the permissible exposure limits specified in WAC 296-62-09005.

AMENDATORY SECTION (Amending WSR 07-03-163, filed 1/24/07, effective 4/1/07)

WAC 296-155-160 Gases, vapors, fumes, dusts, and mists.

(1) You must avoid exposure of employees to inhalation, ingestion, skin absorption, or contact with any material or substance at a concentration above those specified in chapter 296-841 WAC ((shall be avoided)).

(2) To achieve compliance with subsection (1) of this section, administrative or engineering controls must first be implemented whenever feasible. When such controls are not feasible to achieve full compliance, you must use protective equipment or other protective measures ((shall be used)) to keep the exposure of employees to air contaminants within the limits prescribed in WAC 296-62-07515 [296-841-20025]. Any equipment and technical measures used for this purpose must first be approved for each particular use by a competent industrial hygienist or other technically qualified person. Whenever respirators are used, ((their use shall)) you must comply with WAC 296-155-220.

(3) Whenever internal combustion equipment exhausts in enclosed spaces, you must make and record tests ((shall be made and recorded)) to ensure that employees are not exposed to unsafe concentrations of toxic gases or oxygen deficient atmospheres. See chapter 296-62 WAC, the general occupational health standards and chapter 296-841 WAC, identifying and controlling respiratory hazards.

(4) Whenever any employee is exposed to asbestos, the provisions of the general occupational health standards, chapter 296-62 WAC ((shall)) apply.

(5) Subsections (1) and (2) of this section do not apply to the exposure of employees to formaldehyde. Whenever any employee is exposed to formaldehyde, the requirements of chapter 296-856 WAC ((shall)) apply.

AMENDATORY SECTION (Amending WSR 93-04-111, filed 2/3/93, effective 3/15/93)

WAC 296-155-17301 Scope and application.

(1) This section applies to all construction work as defined in WAC 296-155-005, in which there is exposure to MDA, including but not limited to the following:

(a) Construction, alteration, repair, maintenance, or renovation of structures, substrates, or portions thereof, that contain MDA;

(b) Installation or the finishing of surfaces with products containing MDA;

(c) MDA spill/emergency cleanup at construction sites; and

(d) Transportation, disposal, storage, or containment of MDA or products containing MDA on the site or location at which construction activities are performed.

(2) Except as provided in subsection (7) of this section and WAC 296-155-17311(5), this standard does not apply to the processing, use, and handling of products containing MDA where initial monitoring indicates that the product is not capable of releasing MDA in excess of the action level under the expected conditions of processing, use, and handling which will cause the greatest possible release; and where no "dermal exposure to MDA" can occur.

(3) Except as provided in subsection (7) of this section, this standard does not apply to the processing, use, and handling of products containing MDA where objective data are reasonably relied upon which demonstrate the product is not capable of releasing MDA under the expected conditions of processing, use, and handling which will cause the greatest possible release; and where no "dermal exposure to MDA" can occur.

(4) Except as provided in subsection (7) of this section, this standard does not apply to the storage, transportation, distribution, or sale of MDA in intact containers sealed in such a manner as to contain the MDA dusts, vapors, or liquids, except for the provisions of WAC 296-62-054 and 296-155-17309.

(5) Except as provided in subsection (7) of this section, this standard does not apply to materials in any form which contain less than 0.1% MDA by weight or volume.

(6) Except as provided in subsection (7) of this section, this standard does not apply to "finished articles containing MDA."

(7) Where products containing MDA are exempted under subsections (2) and (6) of this section, ((the employer shall)) you must maintain records of the initial monitoring results or objective data supporting that exemption and the basis for the employer's reliance on the data, as provided in the recordkeeping provision of WAC 296-155-17331.

AMENDATORY SECTION (Amending WSR 93-04-111, filed 2/3/93, effective 3/15/93)

WAC 296-155-17303 Definitions.

For the purpose of this standard, the following definitions ((shall)) apply:

(((1) "))Action level((" means)). A concentration of airborne MDA of 5 ppb as an 8-hour time-weighted average.

(((2) "))Authorized person((" means)). Any person specifically authorized by the employer whose duties require the person to enter a regulated area, or any person entering such an area as a designated representative of employees for the purpose of exercising the right to observe monitoring and measuring procedures under WAC 296-155-17333, or any other person authorized by the act or regulations issued under the act.

(((3) "))Container((" means)). Any barrel, bottle, can, cylinder, drum, reaction vessel, storage tank, commercial packaging, or the like, but does not include piping systems.

(((4) "))Decontamination area((" means)). An area outside of, but as near as practical to, the regulated area, consisting of an equipment storage area, wash area, and clean change area, which is used for the decontamination of workers, materials, and equipment contaminated with MDA.

(((5) "))Dermal exposure to MDA((")). Occurs where employees are engaged in the handling, application, or use of mixtures or materials containing MDA, with any of the following nonairborne forms of MDA:

(a) Liquid, powdered, granular, or flaked mixtures containing MDA in concentrations greater than 0.1% by weight or volume; and

(b) Materials other than "finished articles" containing MDA in concentrations greater than 0.1% by weight or volume.

(((6) "))Director((" means)). The director of the department of labor and industries.

(((7) "))Emergency((" means)). Any occurrence such as, but not limited to, equipment failure, rupture of containers, or failure of control equipment which results in an unexpected and potentially hazardous release of MDA.

(((8) "))Employee exposure((" means)). Exposure to MDA which would occur if the employee were not using respirators or protective work clothing and equipment.

(((9) "))Finished article containing MDA((" is defined as)). A manufactured item:

(a) Which is formed to a specific shape or design during manufacture;

(b) Which has end use function(s) dependent in whole or part upon its shape or design during end use; and

(c) Where applicable, is an item which is fully cured by virtue of having been subjected to the conditions (temperature, time) necessary to complete the desired chemical reaction.

(((10) "))Historical monitoring data((" means)). Monitoring data for construction jobs that meet the following conditions:

(a) The data upon which judgments are based are scientifically sound and were collected using methods that are sufficiently accurate and precise;

(b) The processes and work practices that were in use when the historical monitoring data were obtained are essentially the same as those to be used during the job for which initial monitoring will not be performed;

(c) The characteristics of the MDA-containing material being handled when the historical monitoring data were obtained are the same as those on the job for which initial monitoring will not be performed;

(d) Environmental conditions prevailing when the historical monitoring data were obtained are the same as those on the job for which initial monitoring will not be performed; and

(e) Other data relevant to the operations, materials, processing, or employee exposures covered by the exception are substantially similar. The data must be scientifically sound, the characteristics of the MDA containing material must be similar, and the environmental conditions comparable.

(((11) "))4,4' methylenedianiline((")) or (("))MDA((" means)). The chemical 4,4'-diaminodiphenylmethane, Chemical Abstract Service Registry Number 101-77-9, in the form of a vapor, liquid, or solid. The definition also includes the salts of MDA.

(((12) "))Regulated areas((" means)). Areas where airborne concentrations of MDA exceed or can reasonably be expected to exceed, the permissible exposure limits, or where "dermal exposure to MDA" can occur.

(((13) "))STEL((" means)). Short-term exposure limit as determined by any 15-minute sample period.

AMENDATORY SECTION (Amending WSR 93-04-111, filed 2/3/93, effective 3/15/93)

WAC 296-155-17305 Permissible exposure limits.

((The employer shall assure)) You must ensure that no employee is exposed to an airborne concentration of MDA in excess of ((ten)) 10 parts per billion (10 ppb) as an 8-hour time-weighted average and a STEL of ((one hundred)) 100 parts per billion (100 ppb).

AMENDATORY SECTION (Amending WSR 93-04-111, filed 2/3/93, effective 3/15/93)

WAC 296-155-17307 Communication among employers.

On multiemployer worksites, an employer performing work involving the application of MDA or materials containing MDA for which establishment of one or more regulated areas ((is required shall)) must inform other employers on the site of the nature of the employer's work with MDA and of the existence of, and requirements pertaining to, regulated areas.

AMENDATORY SECTION (Amending WSR 93-04-111, filed 2/3/93, effective 3/15/93)

WAC 296-155-17309 Emergency situations.

(1) Written plan.

(a) You must develop a written plan for emergency situations ((shall be developed)) for each construction operation where there is a possibility of an emergency. The plan ((shall)) must include procedures where the employer identifies emergency escape routes for her or his employees at each construction site before the construction operation begins. You must implement appropriate portions of the plan ((shall be implemented)) in the event of an emergency.

(b) The plan ((shall)) must specifically provide that employees engaged in correcting emergency conditions ((shall be)) are equipped with the appropriate personal protective equipment and clothing as required in WAC 296-155-17317 and 296-155-17319 until the emergency is abated.

(c) The plan ((shall)) must specifically include provisions for alerting and evacuating affected employees as well as the applicable elements prescribed in WAC 296-24-567, "Employee emergency plans and fire prevention plans."

(2) Alerting employees. Where there is the possibility of employee exposure to MDA due to an emergency, ((means shall be developed)) you must develop means to promptly alert employees who have the potential to be directly exposed. You must immediately evacuate affected employees not engaged in correcting emergency conditions ((shall be evacuated immediately)) in the event that an emergency occurs. You must also develop means ((shall also be developed)) for alerting other employees who may be exposed as a result of the emergency.

AMENDATORY SECTION (Amending WSR 06-05-027, filed 2/7/06, effective 4/1/06)

WAC 296-155-17311 Exposure monitoring.

(1) General.

(a) You must make a determination((s)) of employee exposure ((shall be made)) from breathing zone air samples that are representative of each employee's exposure to airborne MDA over an eight-hour period. You must make a determination of employee exposure to the STEL ((shall be made)) from breathing zone air samples collected over a ((fifteen)) 15 minute sampling period.

(b) You must determine representative employee exposure ((shall be determined)) on the basis of one or more samples representing full shift exposure for each shift for each job classification in each work area where exposure to MDA may occur.

(c) Where the employer can document that exposure levels are equivalent for similar operations in different work shifts, ((the employer shall)) you must only be required to determine representative employee exposure for that operation during one shift.

(2) Initial monitoring. Each employer who has a workplace or work operation covered by this standard ((shall)) must perform initial monitoring to determine accurately the airborne concentrations of MDA to which employees may be exposed unless:

(a) The employer can demonstrate, on the basis of objective data, that the MDA-containing product or material being handled cannot cause exposures above the standard's action level, even under worst-case release conditions; or

(b) The employer has historical monitoring or other data demonstrating that exposures on a particular job will be below the action level.

(3) Periodic monitoring and monitoring frequency.