WSR 24-05-085

PERMANENT RULES

DEPARTMENT OF

LABOR AND INDUSTRIES

[Filed February 21, 2024, 11:09 a.m., effective April 1, 2024]

Effective Date of Rule: April 1, 2024.

Purpose: The purpose of this rule making is to adopt the 2023 edition of the National Fire Protection Agency (NFPA) 70, the National Electrical Code (NEC), and other related codes for electrical. The 2023 NEC (NFPA 70-2023) replaces the 2020 NEC (NFPA 70-2020) adopted standards.

The department of labor and industries' (L&I) electrical program reviewed chapter 296-46B WAC, Electrical safety standards, administration, and installation, and adopting the 2023 NEC (NFPA 70-2023) updates the rules for consistency with the latest national safety standards and industry practice. The 2023 edition of the code presents the latest comprehensive regulations for electrical wiring, overcurrent protection, grounding and installation of equipment.

The review process included an opportunity for electrical stakeholders and other interested parties to participate in the review of existing rules, submit proposals, and provide recommendations for possible rule amendments. A technical advisory committee (TAC) of industry experts and the electrical board reviewed the proposals and provided advice on adoption of the rules. This rule making adopts the latest safety codes and other amendments to the rules identified during the formal review process and recommended by stakeholders to improve public safety.

A summary of the adopted updates to chapter 296-46B WAC are as follows:

New Sections:

WAC 296-46B-235 Branch circuits, feeders, and services over 1,000 volts ac, 1,500 volts dc nominal.

| |

| • | Creates a new section for an exception to not restrict wiring methods when proper overcurrent protection is provided. |

WAC 296-46B-692 Fuel cell systems.

| |

| • | Creates a new section requiring installers to provide a system design review defined under WAC 296-46B-100 that will likely improve conformance to code requirements intended to protect life and property. |

WAC 296-46B-710 Standalone systems.

| |

| • | Creates a new section to implement a design review requirement for standalone systems. |

Amended Sections:

WAC 296-46B-010 General.

| |

| • | Amends references to adopt the 2023 NEC (NFPA 70-2023), which is the latest version of the code published in September 2022. |

| • | Amends language to automatically adopt the latest published versions of the American National Standards Institute and Telecommunications Industry Association (ANSI/TIA) and National Electrical Safety Code (NESC). |

| • | Removes references to the Electronic Industries Alliance (EIA), as this organization no longer exists. |

| • | Amends language for general housekeeping, such as updating references, clarifying language, removing obsolete language, renumbering subsections, etc. |

WAC 296-46B-100 General definitions.

| |

| • | Adds a new definition to define the meaning of "equivalent apprenticeship program," due to the passage of SSB 6126, chapter 249, Laws of 2018. |

| • | Amends the definitions of "WAC" and "RCW" to clarify that only electronic copies of the electrical laws and rules are available from L&I and the office of the code reviser. |

| • | Amends NEC reference 725.121(A) to 725.60(A) to reflect updated references made by the NEC. |

WAC 296-46B-110 General—Requirements for electrical installations.

| |

| • | Amends language for general housekeeping, such as punctuation and updating the section title. |

WAC 296-46B-210 Wiring and protection—Branch circuits.

| |

| • | Adds language that does not require future provisions for receptacle outlets installed on islands or peninsular countertops or work surfaces. |

| • | Adds language that clarifies "accessible" locations for equipment that requires servicing outdoors, as the code is unclear. |

| • | Amends the section title for consistency with the 2023 NEC and to narrow content. |

WAC 296-46B-215 Wiring and protection—Feeders.

| |

| • | Amends the section title to narrow focus of content. |

WAC 296-46B-220 Wiring and protection—Branch circuit, feeder, and service calculations.

| |

| • | Amends the section title, header, and references for consistency with the 2023 NEC. |

WAC 296-46B-225 Wiring and protection—Outside branch circuits and feeders.

| |

| • | Amends references related to feeder disconnecting means for uniformity with the 2023 NEC. |

| • | Amends language for general housekeeping, such as updating the section title and headers, clarifying language, and relocating and restructuring existing language. |

WAC 296-46B-230 Wiring and protection—Services.

| |

| • | Adds exceptions to wiring methods for service conductors within a building or structure when protected by customer-owned supply side overcurrent protection. |

| • | Adds language that clarifies when an emergency disconnecting means must be installed if replacing existing equipment. |

| • | Amends language for general housekeeping, such as the section title, renumbering subsections, relocating language, and removing obsolete language. |

WAC 296-46B-240 Overcurrent protection.

| |

| • | Includes roofs in the requirement that overcurrent protection equipment enclosures be installed 24 inches above the surface. |

| • | Creates new subsections requiring documentation to assure [ensure] that testing required by the NEC 240.67 and NEC 240.87 is performed. |

WAC 296-46B-250 Wiring and protection—Grounding and bonding.

| |

| • | Adds new language to clarify when concrete electrode requirements apply where additions are made to existing foundations. |

| • | Amends the section title to narrow focus of content. |

WAC 296-46B-300 Wiring methods and materials—Wiring methods.

| |

| • | Amends language for general housekeeping, such as updating section title, header, and reference. |

WAC 296-46B-314 Wiring methods and materials—Outlet, device, pull, and junction boxes.

| |

| • | Adds a new subsection to clarify the locations acceptable for installing ceiling-suspended (paddle) fans for consistency with L&I's existing practice. |

| • | Adds clarifying language to include device accessibility for consistency with the 2023 NEC. |

| • | Amends the section title and header for consistency with the 2023 NEC and to narrow content. |

WAC 296-46B-334 Wiring methods and materials—Nonmetallic-sheathed cable.

| |

| • | Adds new language that clarifies wet or damp locations and conditions for installing nonmetallic sheath (NM) cables for consistency with L&I's existing practice. |

| • | Amends the title for consistency with the 2023 NEC. |

WAC 296-46B-358 Wiring methods and materials—Electrical metallic tubing.

| |

| • | Amends the title to narrow focus of content. |

WAC 296-46B-394 Wiring methods and materials—Concealed knob-and-tube wiring.

| |

| • | Updates table references for consistency with the 2023 NEC table. |

| • | Amends the title to narrow focus of content. |

WAC 296-46B-408 Equipment for general use—Switchboards, switchgear, and panelboards.

| |

| • | Amends the title to narrow focus of content. |

WAC 296-46B-410 Equipment for general use—Luminaires.

| |

| • | Amends language for general housekeeping, such as updating section title, header, and term for use in the 2023 NEC. |

WAC 296-46B-422 Equipment for general use—Appliances.

| |

| • | Amends the title to narrow focus of content. |

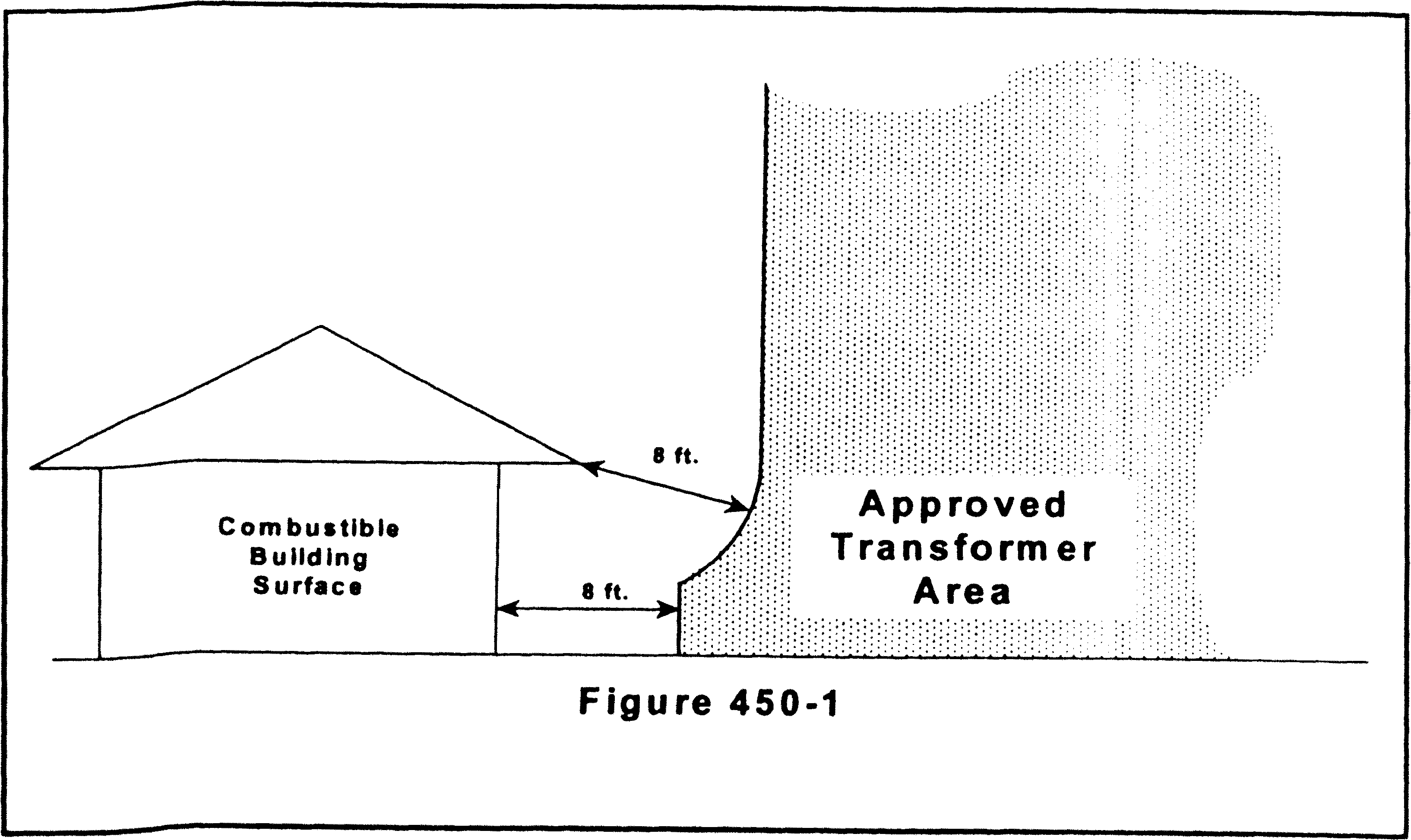

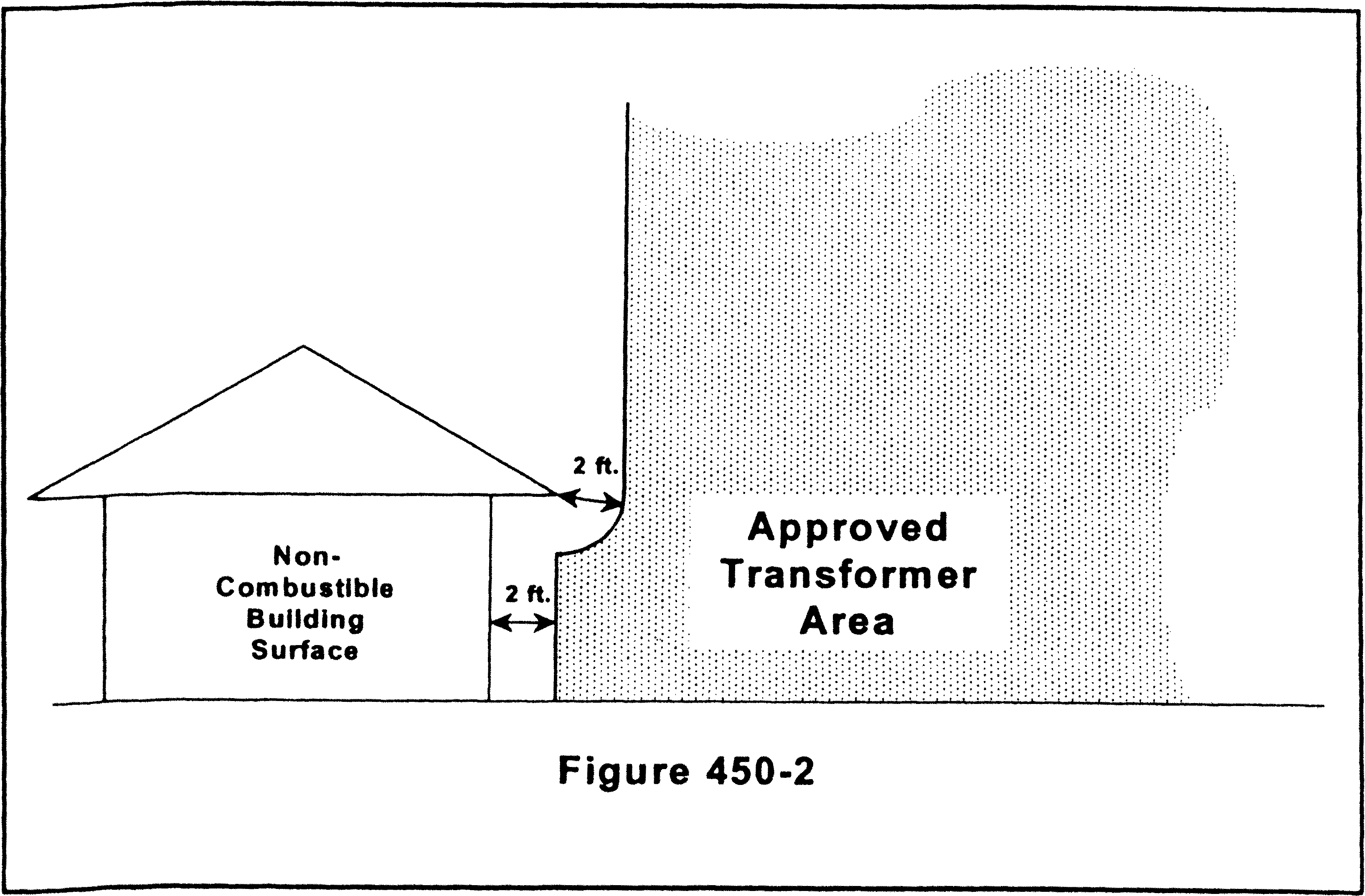

WAC 296-46B-450 Equipment for general use—Transformers and transformer vaults.

| |

| • | Amends the title and header for consistency with the 2023 NEC and to narrow focus of content. |

WAC 296-46B-501 Special occupancies NEC Class I locations.

| |

| • | Amends the title to narrow focus of content. |

WAC 296-46B-505 Class I, Zone 0, 1, and 2 locations.

| |

| • | Amends the title for consistency with the 2023 NEC. |

WAC 296-46B-513 Special occupancies—Aircraft hangars.

| |

| • | Amends the title to narrow focus of content. |

WAC 296-46B-514 Special occupancies—Motor fuel dispensing facilities.

| |

| • | Updated reference to align with the 2023 NEC. |

| • | Amends the title to narrow focus of content. |

WAC 296-46B-517 Special occupancies—Health care facilities.

| |

| • | Amends the title and header for consistency with the NEC and to narrow focus of content. |

WAC 296-46B-547 Special occupancies—Agricultural buildings.

| |

| • | Amends the title to narrow focus of content. |

WAC 296-46B-550 Special occupancies—Mobile homes, manufactured homes and mobile home parks.

| |

| • | Adds new language to allow for mounting of service equipment on mobile/manufactured homes if approved by the manufacturer. |

| • | Amends the title to narrow focus of content. |

WAC 296-46B-555 Special occupancies—Marinas, boatyards, floating buildings, and commercial and noncommercial docking facilities.

| |

| • | Amends language to clarify the meaning of corrosion resistant and provide information for what is acceptable. |

| • | Amends the title to narrow focus of content. |

WAC 296-46B-590 Special occupancies—Temporary installations.

| |

| • | Amends the title to narrow focus of content. |

WAC 296-46B-600 Special equipment—Electric signs and outline lighting.

| |

| • | Amends the title to narrow focus of content. |

WAC 296-46B-620 Special equipment—Elevators.

| |

| • | Amends the title for consistency with the 2023 NEC and to narrow focus of content. |

WAC 296-46B-680 Special equipment—Swimming pools, fountains, and similar installations.

| |

| • | Amends language for general housekeeping, such as updating the title, removing a header, and renumbering subsections. |

WAC 296-46B-690 Solar photovoltaic systems.

| |

| • | Adds new language to clarify availability of the design review defined under WAC 296-46B-100. |

WAC 296-46B-694 Wind electric systems.

| |

| • | Adds new language that clarifies the availability of the design review defined under WAC 296-46B-100. |

WAC 296-46B-700 Emergency systems.

| |

| • | Adds new requirements for selective coordination when overcurrent devices are replaced for consistency with the 2023 NEC. |

| • | Amends header for consistency with the 2023 NEC. |

WAC 296-46B-701 Legally required standby systems.

| |

| • | Adds new requirements for selective coordination when overcurrent devices are replaced for consistency with the 2023 NEC. |

| • | Amends header for consistency with the 2023 NEC. |

WAC 296-46B-702 Optional standby systems.

| |

| • | Amends the requirements pertaining to placing signs for consistency with the 2023 NEC. |

WAC 296-46B-705 Interconnected electric power production sources.

| |

| • | Adds new subsection requiring installers to provide a system design review for interconnected electric power production sources. |

WAC 296-46B-800 Communications systems—Communications circuits.

| |

| • | Amends the title and header for consistency with the 2023 NEC and to narrow focus of content. |

WAC 296-46B-908 Class B permits. Class B electrical work permit—Use.

| |

| • | Amends language to extend the validity of Class B permits to 120 days to allow more time for installations. |

WAC 296-46B-920 Electrical/telecommunications license/certificate types and scope of work.

| |

| • | Amends language for general housekeeping, such as relocating and restructuring requirements for the (06A) and (06B) scopes of work, clarifying language, updating references, renumbering subsections, etc. |

WAC 296-46B-925 Electrical/telecommunications contractor's license. General.

| |

| • | Amends subsection numbers for consistency with SB 6170, chapter 153, Laws of 2020. |

WAC 296-46B-942 Training certificate required. General.

| |

| • | Amends language to clarify the submittal requirements for affidavits to streamline the process. |

| • | Removes obsolete language. |

WAC 296-46B-960 Administrator and electrician certificate of competency examinations. General.

| |

| • | Amends language that allows special accommodations for candidates with language barriers when taking the electrician certificate of competency examination. This also includes: |

| |

| o | Removing the requirement for a notarized release to discuss matters, written opinion from a physician or other appropriate specialist is adequate. |

| |

| o | Amending the order of actions necessary for approval of a special accommodations request. |

| |

| o | Streamlines requirements [for] an applicant with limited English proficiency to request an accommodation. |

Repealed Sections:

WAC 296-46B-406R Equipment for general use—Receptacles.

| |

| • | Repeals the rule, as these requirements are obsolete and now addressed in 2023 NEC 406.12. |

WAC 296-46B-440 Air conditioning and refrigerating equipment.

| |

| • | Repeals the rule to align with NEC 440.8 that may consider split systems a "single machine" under certain conditions. |

Citation of Rules Affected by this Order: New WAC 296-46B-235, 296-46B-692 and 296-46B-710; repealing WAC 296-46B-406R and 296-46B-440; and amending WAC 296-46B-010, 296-46B-100, 296-46B-110, 296-46B-210, 296-46B-215, 296-46B-220, 296-46B-225, 296-46B-230, 296-46B-240, 296-46B-250, 296-46B-300, 296-46B-314, 296-46B-334, 296-46B-358, 296-46B-394, 296-46B-408, 296-46B-410, 296-46B-422, 296-46B-450, 296-46B-501, 296-46B-505, 296-46B-513, 296-46B-514, 296-46B-517, 296-46B-547, 296-46B-550, 296-46B-555, 296-46B-590, 296-46B-600, 296-46B-620, 296-46B-680, 296-46B-690, 296-46B-694, 296-46B-700, 296-46B-701, 296-46B-702, 296-46B-705, 296-46B-800, 296-46B-908, 296-46B-920, 296-46B-925, 296-46B-942, and 296-46B-960.

Statutory Authority for Adoption: Chapter

19.28 RCW, Electricians and electrical installations, including RCW

19.28.031 and

19.28.251.

Adopted under notice filed as WSR 23-24-084 on December 5, 2023.

Changes Other than Editing from Proposed to Adopted Version: WAC 296-46B-100 General definitions.

| |

| • | Subsections (c) and (d) were amended under the definition of "low voltage." The references to NEC 725.121(A) were updated to NEC 725.60(A) for consistency with the NEC. |

WAC 296-46B-920 Electrical/telecommunications license/certificate types and scope of work. The following subsections that allow an increase in the scope of work for (06A) HVAC/refrigeration specialty electricians were removed from the adopted rule to allow more time for conversations with stakeholders and consideration in possible future rule making:

| |

| • | WAC 296-46B-920 (2)(f)(iii)(A)(IX) allowing certain wiring of mini-split HVAC systems. |

| • | WAC 296-46B-920 (2)(f)(iii)(A)(X) allowing installation of external overcurrent protection devices for replacement gas or oil furnaces. |

| • | WAC 296-46B-920 (2)(f)(iii)(A)(XI) allowing installation of surge protection devices for HVAC equipment. |

| |

| o | In WAC 296-46B-920 (2)(f)(iii)(A), removed the exception referring to WAC 296-46B-920 (2)(f)(iii)(A)(IX) and (X) that was removed from the rule. |

| |

| o | In WAC 296-46B-920 (2)(f)(iii)(B)(I), removed the exception referring to WAC 296-46B-920 (2)(f)(iii)(A)(IX) that was removed from the rule. |

| |

| o | In WAC 296-46B-920 (2)(f)(iii)(B)(II), removed the exception referring to WAC 296-46B-920 (2)(f)(iii)(A)(IX) and (X) that were removed from the rule. |

A final cost-benefit analysis is available by contacting Meagan Edwards, L&I, Field Services and Public Safety, P.O. Box 44400, Olympia, WA 98504-4400, phone 360-522-0125, fax 360-902-6210, email Meagan.Edwards@Lni.wa.gov, website www.Lni.wa.gov.

Number of Sections Adopted in Order to Comply with Federal Statute: New 0, Amended 0, Repealed 0; Federal Rules or Standards: New 0, Amended 0, Repealed 0; or Recently Enacted State Statutes: New 0, Amended 0, Repealed 0.

Number of Sections Adopted at the Request of a Nongovernmental Entity: New 0, Amended 0, Repealed 0.

Number of Sections Adopted on the Agency's own Initiative: New 3, Amended 43, Repealed 2.

Number of Sections Adopted in Order to Clarify, Streamline, or Reform Agency Procedures: New 0, Amended 0, Repealed 0.

Number of Sections Adopted using Negotiated Rule Making: New 0, Amended 0, Repealed 0; Pilot Rule Making: New 0, Amended 0, Repealed 0; or Other Alternative Rule Making: New 3, Amended 43, Repealed 2.

Date Adopted: February 21, 2024.

Joel Sacks

Director

OTS-4900.12

AMENDATORY SECTION(Amending WSR 20-11-053 and 20-14-083, filed 5/19/20 and 6/30/20, effective 10/29/20)

WAC 296-46B-010General.

Adopted standards.

(1) The ((2020))2023 edition of the National Electrical Code (NFPA 70 - ((2020))2023) published ((August, 2019))September, 2023 including Annex A, B, C, and subsequent Errata and Tentative Interim Amendments issued by the National Fire Protection Association; the latest published versions of Commercial Building Telecommunications Cabling Standard (((ANSI/TIA-568-C series, February 2009)))(ANSI/TIA-568); Commercial Building Standard for Telecommunications Pathway and Spaces (((TIA-569-B, October 2004)))(ANSI/TIA-569); Commercial Building Grounding and Bonding Requirements for Telecommunications (((ANSI-TIA-607-B, August 2011)))(ANSI/TIA-607); Residential Telecommunications Cable Standard (((ANSI/TIA/EIA 570-B-2004)))(ANSI/TIA-570); and the latest published version of the National Electrical Safety Code (NESC ((C2-2017)) excluding Appendixes A and B) are hereby adopted by reference as part of this chapter.

This chapter will be followed where there is any conflict between this chapter and the above adopted standards.

The National Electrical Code will be followed where there is any conflict between the National Electrical Code and, ((ANSI/TIA/EIA 568-C, ANSI/TIA/EIA 569-B, ANSI/TIA/EIA 607-B, ANSI/TIA/EIA 570-B))ANSI/TIA 568, ANSI/TIA 569, ANSI/TIA 607, ANSI/TIA/570, or the NESC ((C2)).

Adopted standards apply to installations when issue dates of electrical permits are on and after adoption dates of standards except for:

(a) New one- and two-family dwellings, or multifamily dwellings where the issue date of building permits for the premises is before the adoption date of standards; or

(b) New installations where plan review is required by WAC 296-46B-900 when plans are received and accepted for review before the adoption date of standards.

Inspections - General.

(2) Electrical inspectors will give information as to the interpretation or application of the standards in this chapter, but will not lay out work or act as consultants for contractors, owners, or users.

(3) A variance from the electrical installation requirements of chapter

19.28 RCW or this chapter may be granted by the department or the city that has electrical inspection jurisdiction when it is assured that equivalent objectives can be achieved by establishing and maintaining effective safety.

(a) Any electrical permit holder may request a variance.

(b) The permit holder must make the request in writing, using a form provided by the department, to the chief electrical inspector or to the city that has electrical inspection jurisdiction. The request must include:

(i) A description of the installation as installed or proposed;

(ii) A detailed list of the applicable code violations;

(iii) A detailed list of safety violations;

(iv) A description of the proposal for meeting equivalent objectives for code and/or safety violations; and

(v) Appropriate variance application fee as listed in chapter 296-46B WAC, Part C.

(4) Electrical wiring or equipment subject to this chapter must be sufficiently accessible, at the time of inspection, to allow the inspector to visually inspect the installation to verify conformance with the NEC and any other electrical requirements of this chapter with the exception of not more than ((8))eight feet of electrical conduit in a foundation of a one- or two-family dwelling or residential outbuilding for use as service entrance raceway.

(5) All required equipment grounding conductors installed in concealed cable or flexible conduit systems must be completely installed and made up at the time of the rough-in cover inspection.

(6) The installation of all structural elements and mechanical systems (e.g., framing, plumbing, ducting, etc.) must be complete in the area(s) where electrical inspection is requested. Prior to completion of an exterior wall cover inspection, either:

(a) The exterior shear panel/sheathing nail inspection must be completed by the building code inspector and, where siding nails or fasteners which penetrate into the wall cavity are to be used, all siding must be installed; or

(b) All wiring and device boxes must be a minimum of 2 1/2 inches from the exterior surface of the framing member; or

(c) All wiring and device boxes must be protected by a steel plate a minimum of 1/16 inch thick and of appropriate width and height installed to cover the area of the wiring or box.

(7) In order to meet the minimum electrical safety standards for installations, all materials, devices, appliances, and equipment, not exempted in chapter

19.28 RCW, must conform to applicable electrical product standards recognized by the department, be listed, or field evaluated. For any equipment that requires an amusement operating permit under chapter

67.42 RCW, the operating permit is prima facie evidence of an appropriate standard. Other than as authorized by the chief electrical inspector or a city authorized to do electrical inspection, equipment must not be energized until such standards are met.

(8) The state department of transportation is recognized as the inspection authority for telecommunications systems installations within the rights of way of state highways provided the department of transportation maintains and enforces an equal, higher or better standard of construction, and of materials, devices, appliances, and equipment than is required for telecommunications systems installations by chapter

19.28 RCW and this chapter.

Inspection move on buildings and structures.

(9) All buildings or structures relocated into or within the state:

(a) Other than residential, wired inside the United States (U.S.) must be inspected to ensure compliance with current requirements of chapter

19.28 RCW and the rules developed by the department.

(b) Wired outside the U.S. or Canada must be inspected to ensure compliance with all current requirements of chapter

19.28 RCW and the rules developed by the department.

(10) Residential buildings or structures wired in the U.S., to NEC requirements, and moved into or within a county, city, or town must be inspected to ensure compliance with the NEC requirements in effect at the time and place the original wiring was made. The building or structure must be inspected to ensure compliance with all current requirements of chapter

19.28 RCW and the rules developed by the department if:

(a) The original occupancy classification of the building or structure is changed as a result of the move; or

(b) The building or structure has been substantially remodeled or rehabilitated as a result of the move.

(11) Residential buildings or structures wired in Canada to Canadian Electrical Code (CEC) standards and moved into or within a county, city, or town, must be inspected to ensure compliance with the following minimum safety requirements:

(a) Service, service grounding, and service bonding must comply with the current chapter

19.28 RCW and rules adopted by the department.

(b) Canadian Standards Association (CSA) listed Type NMD cable is allowed with the following qualifications:

(i) CSA listed Type NMD cable, American Wire Gauge #10 and smaller installed after 1964 utilizing an equipment grounding conductor smaller than the phase conductors, must be:

(A) Replaced with a cable utilizing a full-size equipment grounding conductor; or

(B) Protected by a ground fault circuit interrupter protection device.

(ii) CSA listed Type NMD cable, #8 AWG and larger, must:

(A) Utilize an equipment grounding conductor sized according to the requirements of the NEC in effect at the time of the installation;

(B) Be protected by a ground fault circuit interrupter protection device; or

(C) Be replaced.

(c) Other types of wiring and cable must be:

(i) Replaced with wiring listed or field evaluated in accordance with U.S. standards by a laboratory approved by the department; or

(ii) Protected by a ground fault circuit interrupter protection device and arc fault circuit protection device.

(d) Equipment, other than wiring or panelboards, manufactured and installed prior to 1997 must be listed and identified by laboratory labels approved by the department or CSA labels.

(e) All panelboards must be listed and identified by testing laboratory labels approved by the department with the following qualifications:

(i) CSA listed panelboards labeled "suitable for use as service equipment" will be considered to be approved as "suitable for use only as service equipment."

(ii) CSA listed panelboards used as panelboards as described in the NEC, must meet all current requirements of the NEC and this chapter.

(f) Any wiring or panelboards replaced or changed as a result of the move must meet current requirements of chapter

19.28 RCW and this chapter.

(g) The location, type, and ground fault circuit interrupter protection of receptacles and equipment in a bathroom, kitchen, basement, garage, or outdoor area must meet the Washington requirements in effect at the time the wiring was installed.

(h) 4, 15-ampere, kitchen small appliance circuits will be accepted in lieu of ((2))two, 20-ampere, kitchen small appliance circuits. Receptacles will not be required to be added on kitchen peninsular or island counters.

(i) Spacing requirements for all other receptacles must meet the Washington requirements in effect at the time the wiring was installed.

(j) Receptacles installed above baseboard or fixed wall space heaters must be removed and the outlet box covered with a blank cover. The receptacle is required to be relocated as closely as possible to the existing location.

(k) Lighting outlet and switch locations must meet the Washington requirements in effect at the time the wiring was installed.

(l) Dedicated 20-ampere small appliance circuits are not required in dining rooms.

(m) Electric water heater branch circuits must be adequate for the load.

(n) The location, type, and circuit protection of feeders must meet the Washington requirements in effect at the time the wiring was installed.

Wiring methods for designated building occupancies.

(12) Wiring methods in educational or institutional facilities as defined in this chapter must be metallic or nonmetallic raceways, MI, MC, or AC cable. Places of assembly located within these facilities must comply with NEC 518.4(A) and (B).

(13) Assisted living facility generator systems may be wired and installed per NEC 517.

(14) Lawfully installed existing electrical installations that do not comply with the provisions of this chapter and remain in compliance with the code at the time of the installation, will be permitted to be continued without change (i.e., without circuitry or occupancy change). Additions, alterations, modifications, or repairs to the electrical system must conform to the current requirements of this chapter.

(((15) See WAC 296-46B-406R for tamper-resistant receptacle requirements in psychiatric patient care facilities.))

Traffic management systems.

(((16)))(15) The department or city authorized to do electrical inspections will perform the electrical inspection and acceptance of traffic management systems within its jurisdiction. A traffic management system includes:

(a) Traffic illumination systems;

(b) Traffic signal systems;

(c) Traffic monitoring systems;

(d) The electrical service cabinet and all related components and equipment installed on the load side of the service cabinet supplying electrical power to the traffic management system; and

(e) Signalization system(s) necessary for the operation of a light rail system.

A traffic management system can provide signalization for controlling vehicular traffic, pedestrian traffic, or rolling stock.

((

(17)))

(16) The department or city authorized to do electrical inspections recognizes that traffic signal conductors, pole and bracket cables, signal displays, traffic signal controllers/cabinets and associated components used in traffic management systems are acceptable for the purpose of meeting the requirements of chapter

19.28 RCW provided they conform with the following standards or are listed on the Washington state department of transportation (WSDOT) qualified products list.

(a) WSDOT/APWA standard specifications and plans;

(b) WSDOT Design Manual;

(c) International Municipal Signal Association (IMSA);

(d) National Electrical Manufacturer's Association (NEMA);

(e) Federal Standards 170/Controller Cabinets;

(f) Manual for Uniform Road, Bridge, and Municipal Construction;

(g) Institute of Transportation Engineers (ITE); or

(h) Manual of Uniform Traffic Control Devices (MUTCD).

(((18)))(17) Associated induction detection loop or similar circuits will be accepted by the department or city authorized to do electrical inspections without inspection.

((

(19)))

(18) For the licensing requirements of chapter

19.28 RCW, jurisdictions will be considered owners of traffic management systems when doing electrical work for another jurisdiction(s) under a valid interlocal agreement, as permitted by chapter

39.34 RCW. Interlocal agreements for traffic management systems must be filed with the department or city authorized to do electrical inspections prior to work being performed for this provision to apply.

((

(20)))

(19) Jurisdictions, with an established electrical inspection authority, and WSDOT may perform electrical inspection on their rights of way for each other by interlocal agreement. They may not perform electrical inspection on other rights of way except as allowed in chapter

19.28 or

39.34 RCW.

(((21)))(20) Underground installations.

(a) In other than open trenching, raceways will be considered "fished" according to the NEC and do not require visual inspection.

(b) The department or city authorized to do electrical inspections will conduct inspections in open trenching within its jurisdiction. The electrical work permit purchaser must coordinate the electrical inspection. A written request (e.g., letter, email, fax, etc.) for inspection, made to the department or city authorized to do electrical inspections office having the responsibility to perform the inspection, must be made a minimum of two working days prior to the day inspection is needed (e.g., two working days 10:00 a.m. Tuesday request for a 10:00 a.m. Thursday inspection, excluding holidays and weekends).

If, after proper written request, the department or city authorized to do electrical inspections fails to make an electrical inspection at the time requested, underground conduit may be covered after inspection by the local government jurisdiction's project inspector/designee. Written documentation of a local government jurisdiction inspection must be provided to the department or city authorized to do electrical inspections when requested. Written documentation will include:

(i) Date and time of inspection;

(ii) Location;

(iii) Installing firm;

(iv) Owner;

(v) Type of conduit;

(vi) Size of conduit;

(vii) Depth of conduit; and

(viii) Project inspector/designee name and contact information.

(((22)))(21) Identification of traffic management system components. Local government jurisdictions or WSDOT may act as the certifying authority for the safety evaluation of all components.

(a) An electrical service cabinet must contain only listed components. The electrical service cabinet enclosure is not required to be listed but will conform to the standards in subsection (((17)))(16) of this section.

(b) The local government jurisdiction must identify, as acceptable, the controller cabinet or system component(s) with an identification plate. The identification plate must be located inside the cabinet and may be attached with adhesive.

(((23)))(22) Conductors of different circuits in same cable, enclosure, or raceway. All traffic management system circuits will be permitted to occupy the same cable, enclosure, or raceway without regard to voltage characteristics, provided all conductors are insulated for the maximum voltage of any conductor in the cable, enclosure, or raceway.

AMENDATORY SECTION(Amending WSR 20-11-053 and 20-14-083, filed 5/19/20 and 6/30/20, effective 10/29/20)

WAC 296-46B-100General definitions.

All definitions listed in the National Electrical Code and chapter

19.28 RCW are recognized in this chapter unless other specific definitions are given in this chapter and chapter

19.28 RCW. The definitions in this section apply to all parts of this chapter. Some sections may have definitions specific to that section.

"Accreditation" is a determination by the department that a laboratory meets the requirements of this chapter and is therefore authorized to evaluate electrical products that are for sale in the state of Washington.

"Administrative law judge" means an administrative law judge (ALJ) appointed pursuant to chapter

34.12 RCW and serving in board proceedings pursuant to chapter

19.28 RCW and this chapter.

"ANSI" means American National Standards Institute. Copies of ANSI standards are available from the National Conference of States on Building Codes and Standards, Inc.

"Appeal" is a request for review of a department action by the board as authorized by chapter

19.28 RCW.

"Appellant" means any person, firm, partnership, corporation, or other entity that has filed an appeal or request for board review.

"Appliance" means household appliance.

"ASTM" means the American Society for Testing and Materials. Copies of ASTM documents are available from ASTM International.

"AWG" means American Wire Gauge.

"Basement" means that portion of a building that is partly or completely below grade plane. A basement will be considered as a story above grade plane and not a basement where the finished surface of the floor above the basement is:

(a) More than ((6))six feet above grade plane;

(b) More than ((6))six feet above the finished ground level for more than 50((%))percent of the total building perimeter; or

(c) More than 12 feet above the finished ground level at any point. Also see "mezzanine" and "story."

"Board" means the electrical board established and authorized under chapter

19.28 RCW.

"Category list" is a list of manufacturing safety standards or product types determined by the department.

A "certified electrical product" is an electrical product to which a laboratory, accredited by the state of Washington, has the laboratory's certification mark attached.

A "certification mark" is a specified laboratory label, symbol, or other identifying mark that indicates the manufacturer produced the product in compliance with appropriate standards or that the product has been tested for specific end uses.

"Certificate of competency" includes the certificates of competency for master journey level electrician, master specialty electrician, journey level, and specialty electrician.

A laboratory "certification program" is a specified set of testing, inspection, and quality assurance procedures, including appropriate implementing authority, regulating the evaluation of electrical products for certification marking by an electrical products certification laboratory.

A "complete application" includes the submission of all appropriate fees, documentation, and forms.

"Chapter" means chapter 296-46B WAC unless expressly used for separate reference.

"Construction," for the purposes of chapter

19.28 RCW, means electrical construction.

"Coordination (selective)" as defined in NEC 100 must be determined and documented by a professional engineer registered under chapter

18.43 RCW.

"Department" means the department of labor and industries of the state of Washington.

"Director" means the director of the department, or the director's designee.

"Egress - Unobstructed (as applied to NEC 110.26 (C)(2)(a))" means an egress path that allows a worker to travel to the exit from any other area in the room containing the equipment described in NEC 110.26 (C)(2) without having to pass through that equipment's required working space.

"Electrical equipment" includes electrical conductors, conduit, raceway, apparatus, materials, components, and other electrical equipment not exempted by RCW

19.28.006(9). Any conduit/raceway of a type listed for electrical use is considered to be electrical equipment even if no wiring is installed in the conduit/raceway at the time of the conduit/raceway installation.

An "electrical products certification laboratory" is a laboratory or firm accredited by the state of Washington to perform certification of electrical products.

An "electrical products evaluation laboratory" is a laboratory or firm accredited by the state of Washington to perform on-site field evaluation of electrical products for safety.

An "equivalent apprenticeship program" for the purposes of RCW 19.28.161 (2)(a)(i), means one that is party to a reciprocal agreement recognized by the Washington state apprenticeship and training council (WSATC) under WAC 296-05-011(3). "Field evaluated" means an electrical product to which a field evaluation mark is attached. Field evaluation must include job site inspection unless waived by the department, and may include component sampling and/or laboratory testing.

"Field evaluation mark" is a specified laboratory label, symbol, or other identifying mark indicating the manufacturer produced the product in essential compliance with appropriate standards or that the product has been evaluated for specific end uses.

A "field evaluation program" is a specified set of testing, inspection, and quality assurance procedures, including appropriate implementing authority regulating the testing and evaluation of electrical products for field evaluation marking.

The "filing" is the date the document is actually received in the office of the chief electrical inspector.

"Final judgment" means any money that is owed to the department under this chapter, including fees and penalties, or any money that is owed to the department as a result of an individual's or contractor's unsuccessful appeal of a citation.

"Fished wiring" is when cable or conduit is installed within the finished surfaces of an existing building or building structure (e.g., wall, floor or ceiling cavity).

"Household appliance" means utilization equipment installed in a dwelling unit that is built in standardized sizes or types and is installed or connected as a unit to perform one or more household functions such as food preparation, cooking, and cleaning. Includes appliances typically installed in a dwelling unit kitchen, clothes washing, drying, and water heating appliances, portable room air conditioning units and portable heaters, etc. Fixed electric space-heating equipment covered in NEC 424 (furnaces, baseboard and wall heaters, electric heat cable, etc.) and fixed air-conditioning/heat pump equipment (NEC 440) are not household appliances. Household appliance does not mean any utilization equipment that:

(a) Supplies electrical power, other than Class 2, to other utilization equipment; or

(b) Receives electrical power, other than Class 2, through other utilization equipment.

HVAC/refrigeration specific definitions:

(a) "HVAC/refrigeration" means heating, ventilation, air conditioning, and refrigeration.

(b) "HVAC/refrigeration component" means electrical power and limited energy components within the "HVAC/refrigeration system," including, but not limited to: Pumps, compressors, motors, heating coils, controls, switches, thermostats, humidistats, low-voltage damper controls, outdoor sensing controls, outside air dampers, stand-alone duct smoke detectors, air monitoring devices, zone control valves and equipment for monitoring of HVAC/refrigeration control panels and low-voltage connections. This definition excludes equipment and components of non-"HVAC/refrigeration control systems."

(c) "HVAC/refrigeration control panel" means an enclosed, manufactured assembly of electrical components designed specifically for the control of a HVAC/refrigeration system. Line voltage equipment that has low voltage, NEC Class 2 control or monitoring components incidental to the designed purpose of the equipment is not an HVAC/refrigeration control panel (e.g., combination starters).

(d) "HVAC/refrigeration control system" means a network system regulating and/or monitoring a HVAC/refrigeration system. Equipment of a HVAC/refrigeration control system includes, but is not limited to: Control panels, data centers, relays, contactors, sensors, and cables related to the monitoring and control of a HVAC/refrigeration system(s).

(e) "HVAC/refrigeration equipment" means the central unit primary to the function of the "HVAC/refrigeration system." HVAC/refrigeration includes, but is not limited to: Heat pumps, swamp coolers, furnaces, compressor packages, and boilers.

(f) "HVAC/refrigeration system" means a system of HVAC/refrigeration: Wiring, equipment, and components integrated to generate, deliver, or control heated, cooled, filtered, refrigerated, or conditioned air. This definition excludes non-HVAC/refrigeration control systems (e.g., fire alarm systems, intercom systems, building energy management systems, and similar non-HVAC/refrigeration systems).

"IBC" means the International Building Code. Copies of the IBC are available from the International Code Council.

An "individual" or "party" or "person" means an individual, firm, partnership, corporation, association, government subdivision or unit thereof, or other entity.

An "installation" includes the act of installing, connecting, repairing, modifying, or otherwise performing work on an electrical system, component, equipment, or wire except as exempted by WAC 296-46B-925. An installation is not the passive testing or operational programming of an electrical system, component, equipment, or wire. See "passive testing."

An "identification plate" is suitable for the environment and is a printed or etched adhesive label approved by the department or a phenolic or metallic plate or other similar material engraved in block letters at least 1/4 inch high unless specifically required to be larger by this chapter, suitable for the environment and application. The letters and the background must be in contrasting colors. Screws, rivets, permanent adhesive, or methods specifically described in this chapter must be used to affix an identification plate to the equipment or enclosure.

"Job site" means a specific worksite having a single address or specific physical location (e.g., a single-family residence, a building, a structure, a marina, an individual apartment building with a specific address, etc.).

"Journey level electrician" means a person who has been issued a journey level electrician certificate of competency by the department. The terms "journey level" and "journeyperson" in chapter

19.28 RCW are synonymous.

"Labeled" means an electrical product that bears a certification mark issued by a laboratory accredited by the state of Washington.

A "laboratory" may be either an electrical product(s) certification laboratory or an electrical product(s) evaluation laboratory.

A "laboratory operations control manual" is a document to establish laboratory operation procedures and may include a laboratory quality control manual.

"License" means a license required under chapter

19.28 RCW.

"Like-in-kind" means having the same overcurrent protection requirements and similar characteristics such as voltage requirement, current draw, short circuit characteristics, and function within the system and being in the same location. Like-in-kind also includes any equipment component authorized by the manufacturer as a suitable component replacement part.

For the purpose of WAC 296-46B-940, a "lineworker" is a person employed by a serving electrical utility or employed by a licensed general electrical contractor who carries, on their person, evidence that they:

(a) Have graduated from a department-approved lineworker's apprenticeship course; or

(b) Are currently registered in a department-approved lineworker's apprenticeship course and are working under the direct ((one hundred))100 percent supervision of a journey level electrician or a graduate of a lineworker's apprenticeship course approved by the department. The training received in the lineworker's apprenticeship program must include training in applicable articles of the currently adopted National Electrical Code.

"Listed" means equipment has been listed and identified by a laboratory approved by the state of Washington for the appropriate equipment standard per this chapter.

"Low voltage" means:

(a) NEC, Class 1 power limited circuits at 30 volts maximum.

(b) NEC, Class 2 circuits powered by a Class 2 power supply as defined in NEC ((725.121))725.60(A).

(c) NEC, Class 3 circuits powered by a Class 3 power supply as defined in NEC ((725.121))725.60(A).

(d) Circuits of telecommunications systems as defined in chapter

19.28 RCW.

"Member of the firm" means the member(s) on file with the department of licensing for sole proprietorships/partnerships or with the secretary of state for corporations.

"Mezzanine" is the intermediate level or levels between the floor and ceiling of any story with an aggregate floor area of not more than one-third of the area of the room or space in which the level or levels are located. Also see "basement" and "story."

"NEC" means National Electrical Code. Copies of the NEC are available from the National Fire Protection Association.

"NEMA" means National Electrical Manufacturer's Association. Copies of NEMA standards are available from the National Electrical Manufacturer's Association.

"NESC" means National Electrical Safety Code. Copies of the NESC are available from the Institute of Electrical and Electronics Engineers, Inc.

"NETA" means International Electrical Testing Association, Inc. Copies of the NETA standards and information are available from the International Electrical Testing Association, Inc.

"NFPA" means the National Fire Protection Association. Copies of NFPA documents are available from the National Fire Protection Association.

"NRTL" means Nationally Recognized Testing Laboratory accredited by the federal Occupational Safety and Health Administration (OSHA) after meeting the requirements of 29 C.F.R. 1910.7.

A "new building" for the purposes of RCW

19.28.261 includes the setting of a manufactured, mobile, or modular building.

"Passive testing" (e.g., pressing of test buttons, use of testing equipment like voltage testers, clamp-on meters, removal of a device head where the wiring is terminated on a separate base plate, etc.) means testing that does not require any:

(a) Physical modification to the electrical system wiring; or

(b) Wiring to be disconnected or terminated, except as necessary for an approved electrical testing laboratory or approved engineer performing an equipment evaluation.

"Point of contact" or "point of connection" means the service point.

"Proceeding" means any matter regarding an appeal before the board including hearings before an administrative law judge.

"Public area or square" is an area where the public has general, clear, and unrestricted access.

A "quality control manual" is a document to maintain the quality control of the laboratory's method of operation. It consists of specified procedures and information for each test method responding to the requirements of the product standard. Specific information must be provided for portions of individual test methods when needed to comply with the standard's criteria or otherwise support the laboratory's operation.

"RCW" means the Revised Code of Washington. Electronic copies of electrical RCW are available from the department and the office of the code reviser (https://leg.wa.gov/codereviser).

"Readily accessible" means the definition as defined in NEC 100. In addition, it means that, except for keys, no tools or other devices are necessary to gain access (e.g., covers secured with screws, etc.).

"Service" or "served" means that as defined in RCW

34.05.010(19) when used in relation to department actions or proceedings.

A "sign," when required by the NEC, for use as an identification method (e.g., legibly marked, legible warning notice, marked, field marked, permanent plaque/directory, etc.) means "identification plate."

A "stand-alone amplified sound or public address system" is a system that has distinct wiring and equipment for audio signal generation, recording, processing, amplification, and reproduction. This definition does not apply to telecommunications installations.

"Story" is that portion of a building included between the upper surface of a floor and the upper surface of the floor or roof next above. Next above means vertically and not necessarily directly above. Also see "basement" and "mezzanine."

"Structure," for the purposes of this chapter and in addition to the definition in the NEC, means something constructed either in the field or factory that is used or intended for supporting or sheltering any use or occupancy as defined by the IBC.

"Supervision" for the purpose of supervising electrical trainees, means that the appropriately certified supervising electrician is on the same job site as the trainee being supervised. The trainee is not considered to be on the same job site if the supervising electrician and the trainee are working:

(a) In separate buildings at a single address (e.g., a campus, multibuilding industrial complex, multibuilding apartment complex, etc.) except for a single-family residence; or

(b) On an outdoor project (e.g., irrigation system, farm, street lighting, traffic signalization, etc.) where the trainee is more than 1,000 feet from the supervising electrician or where the trainee is more than 200 feet from the supervising electrician and out of sight.

"System design review" means a set of design documents that include the manufacturer's installation information, a legible one-line diagram of the system design, and calculations used to determine voltage and current within the system. The one-line diagram must show the system equipment, devices, overcurrent protection, conductor sizing, grounding, ground fault protection if required, and any system interconnection points. The review must be available to the inspector during all inspections.

A "telecommunications local service provider" is a regulated or unregulated (e.g., by the Federal Communications Commission or the utilities and transportation commission as a telephone or telecommunications provider) firm providing telecommunications service ahead of the telecommunications network demarcation point to an end-user's facilities.

"TIA/EIA" means the Telecommunications Industries Association/Electronic Industries Association which publishes the TIA/EIA Telecommunications Building Wiring Standards. Standards and publications are adopted by TIA/EIA in accordance with the American National Standards Institute (ANSI) patent policy.

A "training school" is a Washington public community or technical college or not-for-profit nationally accredited technical or trade school licensed by the work force training and education coordinating board under chapter

28C.10 RCW.

"Under the control of a utility" for the purposes of RCW

19.28.091 and

19.28.101 is when electrical equipment is not owned by a utility and:

(a) Is located in a vault, room, closet, or similar enclosure that is secured by a lock or seal so that access is restricted to the utility's personnel; or

(b) The utility is obligated by contract to maintain the equipment and the contract provides that access to the equipment is restricted to the utility's personnel or other qualified personnel.

"UL" means Underwriters Laboratory.

"Utility" means an electrical utility.

"Utility system" means electrical equipment owned by or under the control of a serving utility that is used for the transmission or distribution of electricity from the source of supply to the point of contact and is defined in section 90.2 (b)(5) of the National Electrical Code, 1981 edition (see RCW

19.28.010(1)).

"Utilization voltage" means the voltage level employed by the utility's customer for connection to lighting fixtures, motors, heaters, or other electrically operated equipment other than power transformers.

"Variance" is a modification of the electrical requirements as adopted in chapter

19.28 RCW or any other requirements of this chapter that may be approved by the chief electrical inspector if assured that equivalent objectives can be achieved by establishing and maintaining effective safety.

"WAC" means the Washington Administrative Code. Electronic copies of this chapter of the WAC are available from the department and the office of the code reviser (https://leg.wa.gov/codereviser).

AMENDATORY SECTION(Amending WSR 20-11-053 and 20-14-083, filed 5/19/20 and 6/30/20, effective 10/29/20)

WAC 296-46B-110General((—))requirements for electrical installations.

003 Examination, identification, installation, ((and)) use, and listing (product certification) of equipment.

(1) Listed electrical conduit can only be installed and used in accordance with its listing (i.e., as an electrical raceway for electrical conductors). If used as a sleeve for electrical conductors or other listed electrical conduits, the installation of a listed electrical conduit will be assumed to be for use as an electrical raceway and must be installed as allowed by chapter

19.28 RCW and this chapter (e.g., owner exemption, electrical contractor, etc.).

EXCEPTION: | Electrical nonmetallic elbow fittings may be connected to piping other than electrical conduit for the purposes of enclosing mechanical piping systems provided the elbows are distinctively marked to indicate their use as nonelectrical fittings prior to installation. For underground installations outside of buildings, elbows used for purposes other than electrical must be substantially painted to match the color of piping to which they are connected. |

011 Deteriorating agents.

(2) Electrical equipment and wiring that has been submerged or exposed to water must comply with the following:

(a) All breakers, fuses, controllers, receptacles, lighting switches/dimmers, electric heaters, and any sealed device/equipment (e.g., relays, contactors, etc.) must be replaced.

(b) All other electrical equipment (e.g., wiring, breaker panelboards, disconnect switches, switchgear, motor control centers, boiler controls, HVAC/R equipment, electric motors, transformers, appliances, water heaters, and similar appliances) must be replaced or reconditioned by the original manufacturer or by its approved representative.

022 Identification of disconnecting means.

(3) For the purposes of legibly marking a disconnecting means, as required in NEC 110.22, an identification plate is required unless the disconnect is a circuit breaker/fused switch installed within a panelboard and the circuit breaker/fused switch is identified by a panelboard schedule. In other than dwelling units, the identification plate must include the identification designation of the circuit source panelboard that supplies the disconnecting means.

030 Over 1,000 volts - General.

(4) Each cable operating at over 1,000 volts and installed on customer-owned systems must be legibly marked in a permanent manner at each termination point and at each point the cable is accessible. The required marking must use phase designation, operating voltage, and circuit number if applicable.

AMENDATORY SECTION(Amending WSR 20-11-053 and 20-14-083, filed 5/19/20 and 6/30/20, effective 10/29/20)

WAC 296-46B-210((Wiring and protection—))Branch circuits not over 1,000 volts ac, 1,500 volts dc nominal.

008(A) Dwelling units GFCI requirements.

(1) In a garage or unfinished basement, a red receptacle, with a red cover plate, supplying a fire alarm system is not required to have ground-fault circuit-interrupter protection. The receptacle must be identified for use only with the fire alarm system by an identification plate or engraved cover with letters at least 1/4 inch high.

(2) All fixed electrical equipment with exposed grounded metal parts within an enclosed shower area or within ((5))five feet of the top inside edge of a bathtub must have ground fault circuit interrupter protection.

008(B) Other than dwelling units - GFCI requirements.

(3) GFCI requirements. GFCI protection for personnel will not be required for:

(a) Three-phase receptacles unless specifically required elsewhere in the NEC; or

(b) Receptacles other than 125-volt, single phase, 15- or 20-ampere used for: Recreational vehicle supply equipment or for attachment of a mobile home supply cord.

For the purposes of NEC 210.8(B), kitchen means any area where utensils, dishes, etc., are cleaned or where food or beverages are prepared or cooked.

011 Branch circuits.

(4) A raceway system or one dedicated 15-ampere minimum, 120 volt circuit must be taken to all unfinished space areas adaptable to future dwelling unit living areas that are not readily accessible to the service or branch circuit panelboard. One circuit or raceway is required for each 480 square feet or less of unfinished space area. If the total adjacent unfinished space area is less than 480 square feet, the circuit can be an extension of an existing circuit. The circuits must terminate in a suitable box(es). The box must contain an identification of the intended purpose of the circuit(s). The branch circuit panelboard must have adequate space and capacity for the intended load(s).

013 Ground fault protection of equipment.

(5) Equipment ground fault protection systems required by the NEC must be tested prior to being placed into service to verify proper installation and operation of the system as determined by the manufacturer's published instructions. A firm having qualified personnel and proper equipment must perform the tests required. A copy of the manufacturer's performance testing instructions and a written performance acceptance test record signed by the person performing the test must be available at the time of inspection. The performance acceptance test record must include test details including, but not limited to, all trip settings and measurements taken during the test.

025 Common area branch circuits.

(6) For the purpose of NEC 210.25, loads for septic or water well systems that are shared by no more than two dwelling units may be supplied from either of the two dwelling units if approved by the local building official and local health department.

052 (A)(2) Dwelling unit receptacle outlets.

(7) For the purpose of NEC 210.52 (A)(2)(1), "similar openings" include the following configurations that are a permanent part of the dwelling configuration or finish:

(a) Window seating; and

(b) Bookcases or cabinets that extend from the floor to a level at least ((5))five feet ((6))six inches above the floor.

Any outlets eliminated by such window seating, bookcases, or cabinets must be installed elsewhere within the room.

052 (C)(2) Island and peninsular countertop and work surfaces.

(8) If receptacle outlets are not installed to serve an island or peninsular countertop or work surface, no future provisions to do so are required.

063 Equipment requiring servicing.

(9) For the purposes of NEC 210.63, when equipment requiring servicing is located outdoors, accessible locations for receptacle outlets do not include locations accessed through doors or windows.

AMENDATORY SECTION(Amending WSR 19-15-117, filed 7/23/19, effective 8/23/19)

WAC 296-46B-215((Wiring and protection—))Feeders.

002 Minimum rating and size.

(1) For other than one- or two-family dwelling feeders rated up to 400 amperes, if the feeder conductors have a lesser ampacity than the equipment rating that they terminate in or on, an identification plate showing conductor ampacity stating: "Feeder conductor ampacity: _____ " must be installed on the equipment at the load end of the feeder conductors.

005 Diagrams of feeders.

(2) Other than plan review projects, the installer must provide a one-line diagram showing the service and feeder details for the project before the initial inspection can be approved for all nondwelling services or feeders:

(a) Larger than 400 amperes; or

(b) Over 600 volts.

The diagram must be signed and dated by the project owner if the owner is doing the work, the assigned administrator or master electrician if an electrical contractor is doing the work, or stamped with an engineer's mark and signature who is registered under chapter

18.43 RCW. The diagram must show:

(c) All services including: Wire size(s), wire type(s), service size(s) (e.g., voltage, phase, ampacity), overcurrent protection, available symmetrical fault current at the service point, equipment short-circuit rating, total load before and after demand factors have been applied including any demand factors used, and a panel schedule where multiple disconnecting devices are present; and

(d) All feeders including: Wire size(s), wire type(s), feeder size(s) (e.g., voltage, phase, ampacity), overcurrent protection, total calculated load before and after demand factors have been applied including any demand factors used, and a panel schedule(s) where multiple disconnecting devices are present.

If the installer deviates, in any way, from the service/feeder design shown on the diagram, a supplemental diagram must be supplied to the inspector showing the most recent design before inspection can proceed. Load reductions and moving branch circuit locations within a panelboard do not require a supplemental diagram. Written documentation must also be provided to the inspector that the supplemental diagram was provided to the project owner at the time of submission to the inspector.

The diagram must be available on the job site during the inspection process.

010 Ground fault protection testing.

(3) Equipment ground fault protection systems required by the NEC must be tested prior to being placed into service to verify proper installation and operation of the system as determined by the manufacturer's published instructions. This test or a subsequent test must include all system feeders unless the installer can demonstrate, in a manner acceptable to the inspector, that there are no grounded conductor connections to the feeder(s). A firm having qualified personnel and proper equipment must perform the tests required. A copy of the manufacturer's performance testing instructions and a written performance acceptance test record signed by the person performing the test must be available at the time of inspection. The performance acceptance test record must include test details including, but not limited to, all trip settings and measurements taken during the test.

AMENDATORY SECTION(Amending WSR 20-11-053 and 20-14-083, filed 5/19/20 and 6/30/20, effective 10/29/20)

WAC 296-46B-220((Wiring and protection—))Branch circuit, feeder, and service calculations.

((012))042 Lighting load calculations.

In determining feeder and service entrance conductor sizes and equipment ratings, a building that is designed and constructed to comply with the currently adopted Washington state energy code unit lighting power allowance table and footnotes may be used in lieu of NEC ((220.12))220.42. The requirements of NEC ((220.12(B)))220.42(B), items 1, 2, and 3 do not apply.

AMENDATORY SECTION(Amending WSR 20-11-053 and 20-14-083, filed 5/19/20 and 6/30/20, effective 10/29/20)

WAC 296-46B-225((Wiring and protection—))Outside branch circuits and feeders.

019 Clearances from buildings for conductors of not over 1,000 volts, nominal.

(1) Add the following exception to NEC 225.19(A): Where the voltage between conductors does not exceed 300 and the roof area is guarded or isolated, a reduction in clearance to ((3))three feet shall be permitted.

((032))031(B) Location of outside feeder disconnecting means.

(2) The disconnecting means required by NEC ((225.32))225.31(B) must be provided to disconnect all ungrounded conductors that supply or pass through a building/structure in accordance with the requirements of NEC ((225.32))225.31(B) with the following exceptions.

(a) Outside location: A feeder disconnecting means, including that required by NEC 700, 701, or 702 for a generator, is considered in the building if installed on the outside of the building/structure or within sight and within ((fifteen))15 feet of the building/structure. The building disconnecting means may supply only one building/structure unless the secondary building(s)/structure(s) has a separate building disconnecting means meeting the requirements of the NEC and this subsection. The disconnecting means must have an identification plate with at least one-half-inch high letters identifying:

(i) The building/structure served; and

(ii) Its function as the building/structure main disconnect(s).

(b) Inside location: The feeder disconnecting means ((may be installed anywhere inside a building or structure when there is a feeder disconnecting means, located elsewhere on the premises, with overcurrent protection sized for the feeder conductors))must comply with NEC 225.31(B).

036 Suitable for use as service equipment.

(3) A generator disconnecting means installed per subsection (2)(a) ((or (b))) of this section, is not required to be suitable for use as service equipment.

(4) A generator disconnecting means installed per subsection (2)(b) of this section, is not required to be suitable for use as service equipment when there is a feeder disconnecting means, located elsewhere on the premises, with overcurrent protection sized for feeder conductors.

AMENDATORY SECTION(Amending WSR 19-15-117, filed 7/23/19, effective 8/23/19)

WAC 296-46B-230((Wiring and protection—))Services.

001 General service requirements.

(1) The owner, the owner's agent, or the electrical contractor making the installation must consult the serving utility regarding the utility's service entrance requirements for equipment location and meter equipment requirements before installing the service and equipment. Provisions for a meter and related equipment, an attachment of a service drop, or an underground service lateral must be made at a location acceptable to the serving utility. The point of contact for a service drop must permit the clearances required by the NEC.

(2) A firewall must have a minimum two-hour rating as defined by the local building official to be considered a building separation in accordance with Article 100 NEC.

(3) The height of the center of the service meter must be as required by the serving utility. Secondary instrument transformer metering conductor(s) are not permitted in the service raceway.

028 Service or other masts.

(4) Conduit extended through the roof to provide means of attaching:

(a) All overhead drops for service, feeder, or branch circuits exceeding #1 AWG aluminum or #3 AWG copper must be rigid steel galvanized conduit no smaller than ((2))two inches.

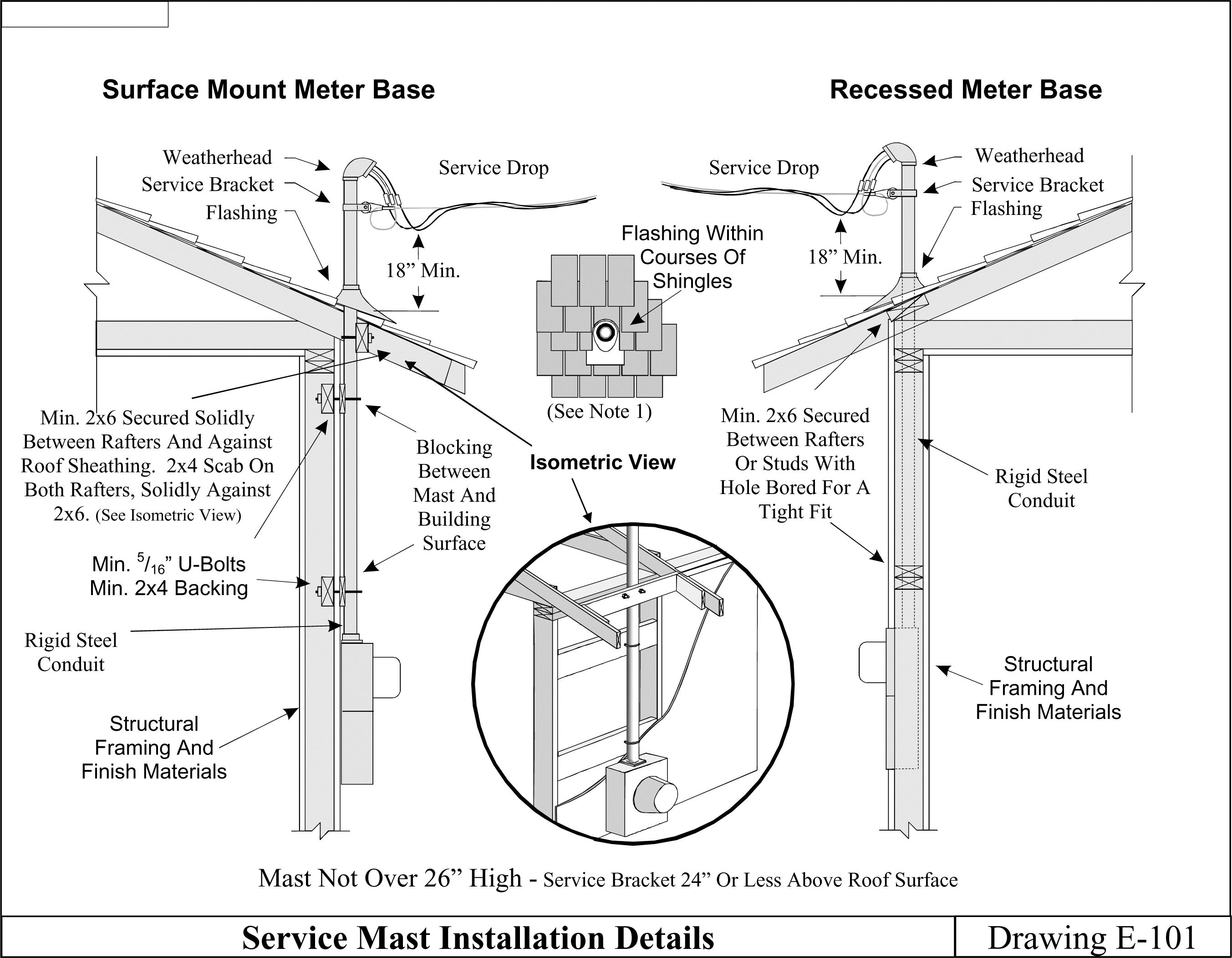

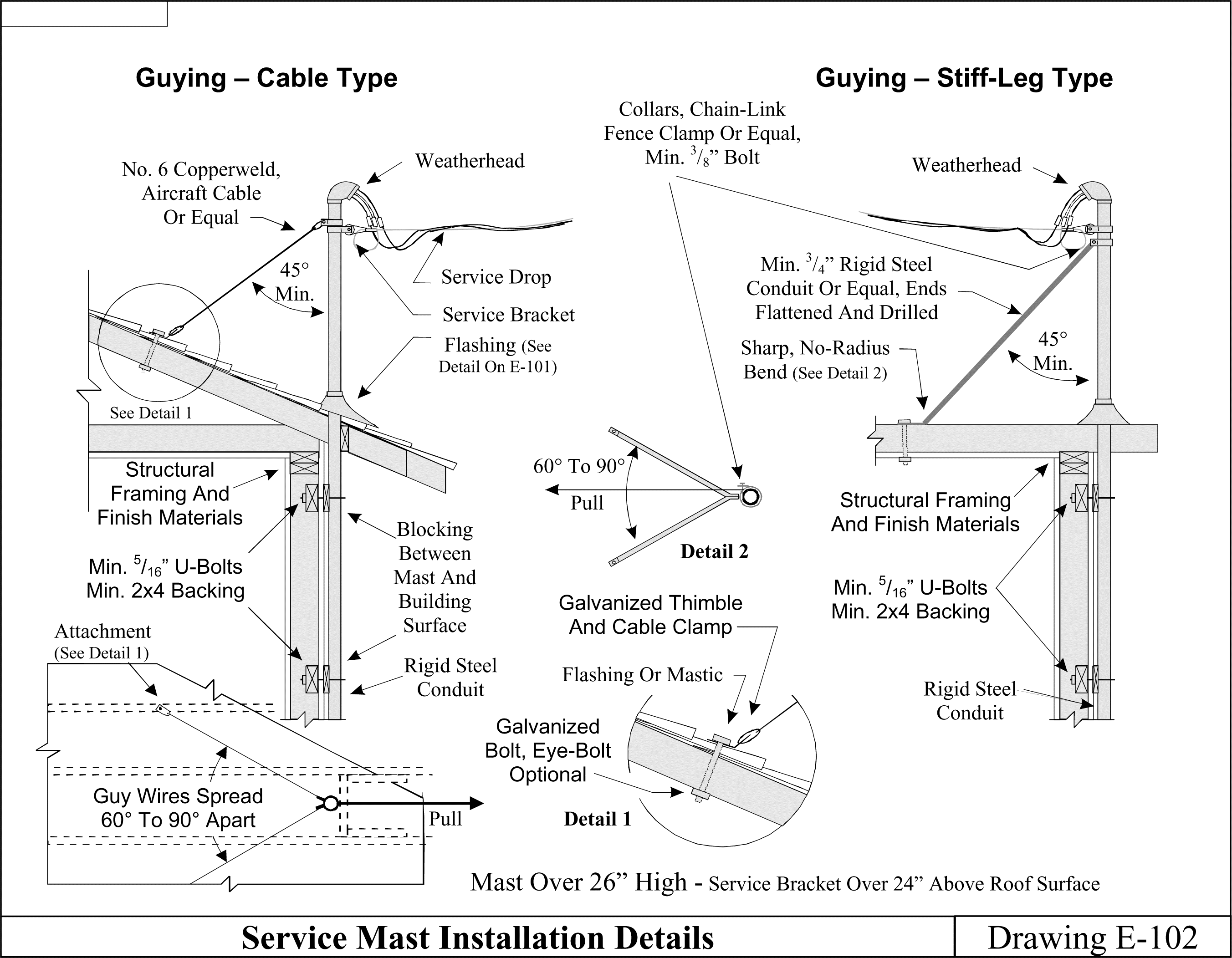

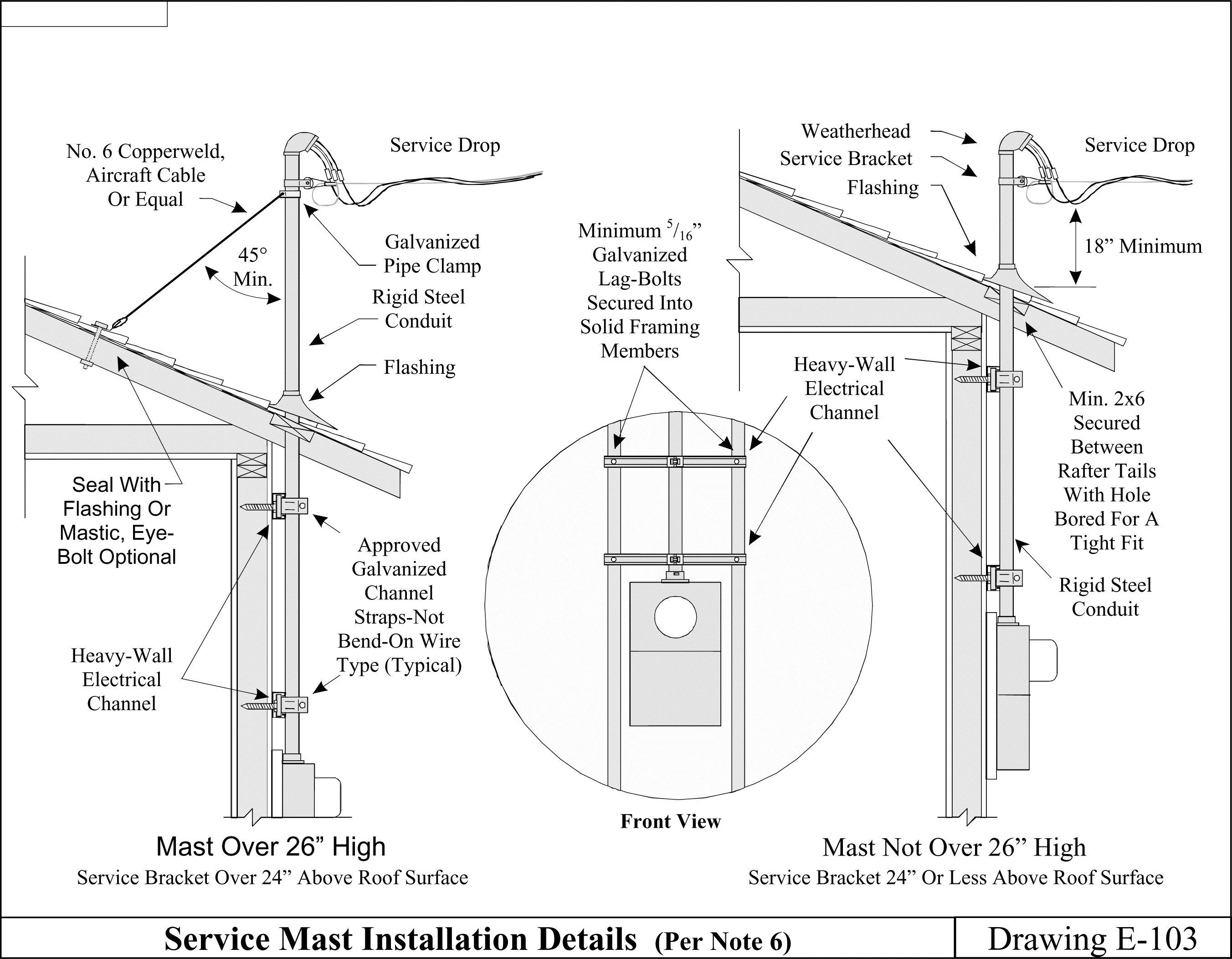

(b) All overhead drops for service, feeder or branch circuits not exceeding #1 AWG aluminum or #3 AWG copper must be rigid steel galvanized conduit no smaller than 1 1/4 inches. The installation must comply with drawings E-101 and/or E-102, or must provide equivalent strength by other approved means. Masts for altered or relocated installations will be permitted to comply with drawing E-103.

Notes to drawings E-101, E-102, and E-103

| |

| (1) | An approved roof flashing must be installed on each mast where it passes through a roof. Plastic, nonhardening mastic must be placed between lead-type flashings and the conduit. Neoprene type flashings will also be permitted to be used. |

| (2) | Masts must be braced, secured, and supported in such a manner that no pressure from the attached conductors will be exerted on a roof flashing, meter base, or other enclosures. |

| (3) | Utilization of couplings for a mast is permitted only below the point the mast is braced, secured, or supported. There must be a minimum of two means of support above any couplings used. A properly installed cable or stiff leg type support qualifies as one of the two required means of support. |

| (4) | Except as otherwise required by the serving utility, service mast support guys must be installed if the service drop attaches to the mast more than 24 inches above the roof line or if the service drop is greater than 100 feet in length from the pole or support. Masts for support of other than service drops must comply with this requirement as well. |

| (5) | Intermediate support masts must be installed in an approved manner with methods identical or equal to those required for service masts. |

| (6) | For altered services, where it is impractical to install U bolt mast supports due to interior walls remaining closed, it will be permissible to use other alternate mast support methods such as heavy gauge, galvanized, electrical channel material that is secured to two or more wooden studs with 5/16 inch diameter or larger galvanized lag bolts. |

| (7) | Conductors must extend at least 18 inches from all mastheads to permit connection to the connecting overhead wiring. |

040 Service conductors - Two-family and multiple-occupancy buildings.

(5) Two-family and multiple-occupancy buildings. A second or additional service drop or lateral to a building having more than one occupancy will be permitted to be installed at a location separate from other service drops or laterals to the building provided that all the following conditions are complied with:

(a) Each service drop or lateral must be sized in accordance with the NEC for the calculated load to be served by the conductors;

(b) Each service drop or lateral must terminate in listed metering/service equipment;

(c) Each occupant must have access to the occupant's service disconnecting means;

(d) No more than six service disconnects may be supplied from a single transformer;

(e) All service drops or laterals supplying a building must originate at the same transformer or power supply;

(f) A permanent identification plate must be placed at each service disconnect location that identifies all other service disconnect locations in or on the building, the area or units served by each, the total number of service disconnecting means on the building/structure and the area or units served. If a structure consists of multiple buildings (i.e., by virtue of fire separation), all service disconnects in or on the entire structure must be labeled to identify all service disconnects in or on the structure; and

(g) A permanent identification plate must be placed at each feeder disconnecting means identifying the area or units served if the feeder disconnecting means is remote from the area or unit served.

042 Service conductor - Size and rating.

(6) For other than one- or two-family dwelling services rated up to 400 amperes, if the service conductors have a lesser ampacity than the overcurrent protection, permitted by NEC 230.90 or NEC 310.15, or the equipment rating that they terminate in or on, an identification plate showing the ampacity of the conductors stating: "Service conductor ampacity: _____" must be installed on the service equipment.

043 Wiring methods for 1,000 volts, nominal or less.

(7) The installation of service conductors not exceeding 1,000 volts, nominal, within a building or structure is limited to the following methods: Galvanized or aluminum rigid metal conduit; galvanized intermediate metal conduit; wireways; busways; auxiliary gutters; minimum schedule 40 rigid polyvinyl chloride conduit; cablebus; or mineral-insulated, metal-sheathed cable (type MI). Exception: Wiring methods per NEC 230.43 shall be permitted for service conductors within a building or structure when those conductors are protected by customer owned supply side overcurrent protection sized per NEC 240.4.

(8) ((Electrical metallic tubing must not be installed as the wiring method for service entrance conductors inside a building.)) Existing electrical metallic tubing, installed prior to October 1984, which is properly grounded and used for service entrance conductors may be permitted to remain if the conduit is installed in a nonaccessible location and is the proper size for the installed conductors.

(9) In addition to methods allowed in the NEC, the grounded service conductor is permitted to be identified with a yellow jacket or with one or more yellow stripes.

070 Service equipment - Disconnecting means.

(10) The service disconnecting means must be installed at a readily accessible location in accordance with (a) or (b) of this subsection.

(a) Outside location: Service disconnecting means will be permitted on the building or structure or within sight and within ((fifteen))15 feet of the building or structure served. The building disconnecting means may supply only one building/structure. The service disconnecting means must have an identification plate with one-half-inch high letters identifying:

(i) The building/structure served; and

(ii) Its function as the building/structure main service disconnect(s).

(b) Inside location: When the service disconnecting means is installed inside the building or structure, it must be located so that the service raceway extends no more than ((fifteen))15 feet inside the building/structure. Exception: There is no limit to the length of service raceway when conductors are protected by customer owned supply side overcurrent protection sized per NEC 240.4.

085(C) Replacements.

(11) This subsection replaces NEC 230.85(C). When service equipment suppling one- and two-family dwellings is replaced, an emergency disconnecting means must be installed whenever the service ampacity is increased or decreased, or when any of the following are relocated: Service disconnects, meter bases, overhead service masts, or underground service risers.

095 Ground-fault protection of equipment.

(((11)))(12) Equipment ground-fault protection systems required by the NEC must be tested prior to being placed into service to verify proper installation and operation of the system as determined by the manufacturer's published instructions. This test or a subsequent test must include all service voltage feeders unless the installer can demonstrate, in a manner acceptable to the department, that there are no grounded conductor connections to the feeder(s). A firm having qualified personnel and proper equipment must perform the tests required. A copy of the manufacturer's performance testing instructions and a written performance acceptance test record signed by the person performing the test must be available for the inspector at the time of inspection. The performance acceptance test record must include test details including, but not limited to, all trip settings and measurements taken during the test.

((200 Wiring methods exceeding 1000 volts.

(12) The installation of service conductors exceeding 1000 volts, nominal, within a building or structure must be limited to the following methods: Galvanized rigid metal conduit, galvanized intermediate metal conduit, schedule 80 polyvinyl chloride conduit, metal-clad cable that is exposed for its entire length, cablebus, or busways.

(13) In addition to methods allowed in the NEC, the grounded service conductor is permitted to be identified with a yellow jacket or with one or more yellow stripes.))

NEW SECTION

WAC 296-46B-235Branch circuits, feeders, and services over 1,000 volts ac, 1,500 volts dc nominal.

402(B) Wiring methods.

The installation of service entrance conductors exceeding 1,000 volts ac, 1,500 volts dc, nominal, within a building or structure must be limited to the following methods: Galvanized rigid metal conduit, galvanized intermediate metal conduit, schedule 80 polyvinyl chloride conduit, metal-clad cable that is exposed for its entire length, cablebus, or busways. Exception: Wiring methods per NEC 235.402(B) shall be permitted for service conductors within a building or structure when customer owned overcurrent protection in accordance with NEC requirements is provided outside the building.

AMENDATORY SECTION(Amending WSR 17-12-021, filed 5/30/17, effective 7/1/17)

WAC 296-46B-240Overcurrent protection.

024(C) Not exposed to physical damage.