(1) All resource protection wells constructed shall have a continuous seal, which seals the annular space between the bore hole and the permanent casing. The seal shall be constructed to prevent interconnection of separate aquifers penetrated by the well, and shall provide casing stability. Except for environmental investigation wells, the seal shall have a minimum diameter of four inches larger than the nominal size of the permanent casing, and shall extend from land surface to the top of the filter pack. The filter pack shall be no less than one foot or greater than five feet above the screen interval. See Figure 7. Wells that are installed using direct push technology will follow the sealing guidelines of WAC 173-160-451.

(2) After the permanent casing has been set in final position, the filter pack (optional) and sealing material shall be placed in the open bore hole annular space that must be a minimum of four inches greater in diameter than the nominal size of the permanent casing. After installing the filter pack (optional) a layer of bentonite shall be placed on top of the filter pack to maintain separation between the seal material and the screened interval. Insure that placement will not disturb the filter pack. The remaining annular space shall be filled to land surface in a continuous operation with bentonite, neat cement, or neat cement grout. If neat cement, neat cement grout or bentonite slurry is used as the sealant, it shall be installed with a tremie tube and pumped from the top of the bentonite plug (above the filter pack) to land surface. Use only potable water to hydrate the mixture.

(3) The completed annular seal shall fully surround the permanent casing, be evenly distributed, free of voids, and extend from the permanent casing to undisturbed or recompacted soil.

(4) All sealing materials used shall conform to one of the following minimum requirements:

(a) Bentonite sealants:

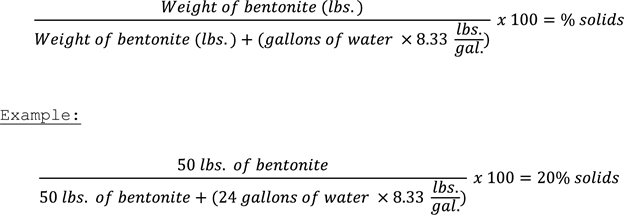

(i) Bentonite used to prepare slurries for sealing or decommissioning shall be specifically designed for this purpose. All bentonite slurries shall be prepared and installed according to the manufacturer's instructions. Active solids content (bentonite) shall be twenty percent by weight or greater in all bentonite slurries. The active solids shall be checked by using the following formula:

|

(ii) Unhydrated bentonite—pelletized, granulated, powder, or chip bentonite may be used in the construction of seals or in decommissioning of wells. The bentonite material shall be specifically designed for sealing or decommissioning and be within the industry tolerances for dry western sodium bentonite. Placement of bentonite shall conform to the manufacturer's specifications and result in a seal free of voids or bridges.

(iii) All bentonite used in any well shall be certified by NSF/ANSI approval standards for use in potable water supply wells, or equivalent standards as approved by the department. The product shall be clearly labeled as meeting these standards.

(b) Cement sealants:

(i) Neat cement consists of either portland cement types I, II, III, or high-alumina cement mixed with not more than six gallons of potable water per sack of cement (ninety-four pounds per sack).

(ii) Neat cement grout consists of neat cement with up to five percent bentonite clay added, by dry weight of the bentonite. Bentonite is to be added to improve flow qualities and compensate for shrinkage.

(iii) Expanding agents, such as aluminum powder, may be used at a rate not exceeding 0.075 ounce (1 level teaspoon) per sack (ninety-four pounds per sack) of dry cement. The powder may not contain polishing agents. High-alumina cement and portland cement of any type must not be mixed together.

(5) This section may not preclude the use of new sealant materials which have been approved by the technical advisory group.