"Chain Shot" Awareness and Prevention Training

Employee _____ | Trainer _____ | Date _____ |

All employees who operate or work around or perform maintenance and/or repair of any kind of machinery equipped with a hydraulic powered bar saw must receive "chain shot" awareness training appropriate to their job.

Note: Employers who have employees who are potentially exposed to the chain shot but do not operate, inspect, or maintain the equipment can limit training to the information in Section 1.

□ Indicates that the employee has received training.

□ Section 1 General information

• Chain shot is the high velocity separation and ejection of a piece or pieces of cutting chain from the end of a broken chain in mechanized timber harvesting/processing. Chain shot exposes both machine operators and bystanders to a risk of serious injury or death. Chain shot typically occurs near the drive end of the cutting system but can also come from the bar tip area.

• A chain shot consists of two breaks in a chain. First, the loop of chain breaks and forms two ends. One end moves past the drive sprocket or bar nose and is rapidly accelerated due to a whip-like motion of the chain end. The "whip action" causes the second break releasing small parts at extremely high speed.

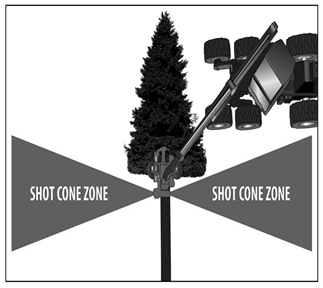

• The "shot cone zone" is the area along the plane of the guide bar where pieces of a broken chain usually travel unless pieces are deflected. The SCZ angles out approximately at a 15 degree angle on both sides of the guide bar and a distance that possibly exceeds 250 feet.

• Employees should stay clear of the shot cone zone.

|

□ Section 2 Cutting system inspection

The cutting system must be inspected before initial use during each work shift. Defective parts that would make the cutting system unsafe to operate, must be replaced or repaired before the cutting system is placed in service. Report unsafe conditions to your supervisor.

Inspections must include:

• The lubrication system for leaks or damage.

• The chain for cracks or worn/damaged parts.

• The bar for wear and straightness and ensure the tip is properly secured.

• The sprocket.

• The chain catcher if equipped.

• The chain shot guard if equipped.

□ Section 3 Cutting system maintenance

• Sharpen, assemble and repair chains in accordance with the manufacturer's specifications.

• Maintain proper bar and chain lubrication, making sure to use the right type and amount of lubricant.

• Replace the drive sprocket when it has excessivewear.

• Clean guide bar grooves and oil port holes regularly.

• Guidebars should be flipped regularly to ensure even wear.

□ Section 4 Cutting system operation

• The operator and other persons should be kept clear of the shot cone zone.

• Follow chain manufacturer's recommendations for chain speed. "Boosting" or exceeding the recommended chain speed is prohibited.

• Maintain proper chain tension.