(1) The accredited crane certifier must review the following documents as part of the crane certification process:

(a) Crane maintenance records of critical components to ensure maintenance of these components has been performed in accordance with the manufacturer's recommendations.

(b) Crane monthly and annual inspection documentation.

(2) Safety devices. Make sure all safety devices are installed on equipment in accordance with the requirements located in WAC 296-155-53410.

(3) Operational aids. Operations must not begin unless operational aids are in proper working order, except where the owner or lessee meets the specified temporary alternative measures. See WAC 296-155-53412 for the list of operational aids.

Note: | All accredited crane certifiers must meet and follow the requirements relating to fall protection, located in chapter 296-880 WAC, Unified safety standards for fall protection. |

(4) General.

(a) The accredited crane certifier must determine that the configurations of the crane are in accordance with the manufacturer's equipment criteria.

(b) Where the manufacturer equipment criteria are unavailable, a registered professional engineer (RPE), familiar with the type of equipment involved, must ensure criteria are developed for the equipment configuration.

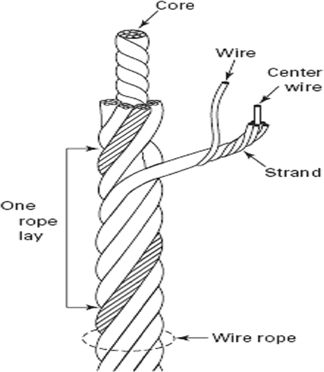

(5) Wire rope.

(a) Wire ropes must meet the crane or wire rope manufacturer's specifications for size, type and inspection requirements. In the absence of the manufacturer's specifications, follow the requirements for removal criteria located in this section, including Table 1.

Table 1 - Wire Rope Inspection/Removal Criteria

(See also Figure 1 - Wire Rope)

Category of Crane Types | Running Ropes* # of broken wires in | Rotation Resistant* # of broken wires in | Standing Ropes* # of broken wires | |||

1 rope lay | 1 strand in 1 lay | Specified diameters | In 1 lay beyond end connection | At end connection | ||

Mobile | 6 | 3 | 2 (in 6xd) | 4 (in 30xd) | 3 | 2 |

Articulating | 6 | 3 | Consult rope mfg. | Consult rope mfg. | 3 | 2 |

Tower | 12 | 4 | 2 (in 6xd) | 4 (in 30xd) | 3 | 3 |

Self-Erector | 6 | 3 | 2 (in 6xd) | 4 (in 30xd) | 3 | 2 |

Overhead & Bridge | 12 | 4 | 2 (in 6xd) | 4 (in 30xd) | — | — |

Derricks | 6 | 3 | Consult rope mfg. | Consult rope mfg. | 3 | 2 |

* | Also remove if you detect 1 wire broken at the contact point with the core or adjacent strand; so called valley breaks or evidence from any heat damage from any cause. |

Note: | xd means times the "diameter." |

(b) The accredited crane certifier must perform a complete and thorough inspection covering the surface of the working range plus 3 additional wraps on the drum of the wire ropes.

(c) If a deficiency is identified, an immediate determination must be made by the accredited crane certifier as to whether the deficiency constitutes a safety hazard. If the deficiency is determined to constitute a safety hazard, the crane must not be certified until:

(i) The wire rope is replaced and verified by the accredited crane certifier; or

(ii) If the deficiency is localized, the problem is corrected by severing the wire rope; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited.

(d) Remove wire rope from service if reduction from nominal diameter is greater than 5%.

(e) Replacement rope must be of a compatible size and have a strength rating at least as great as the original rope furnished or recommended by the crane manufacturer.

|

Figure 1 - Wire Rope |

(6) Sheaves.

(a) Sheave grooves must be free from surface defects that could damage the rope. The cross-sectional radius at the bottom of the groove should be such as to form a close fitting saddle for the size of rope used. The sides of the groove must be tapered outward and rounded at the rim to facilitate entrance of the rope into the groove. Flange rims must run true about the axis of rotation.

(b) Sheave guards must be in place to:

(i) Guide the rope back into the sheave groove, when using ropes that can be momentarily unloaded.

(ii) Prevent ropes from becoming fouled when the block is lying on the ground with loose ropes.

(c) Sheave bearings, except for permanently lubricated ones, must have a means of lubrication.

(7) Prior to performing a proof load test:

(a) A safe test area must be selected and all traffic and unauthorized personnel and equipment must be cleared from test area. This test area must be roped off or otherwise secured to prevent entry of unauthorized personnel and equipment;

(b) Rigging gear must be inspected by a qualified person prior to using for load test of crane;

(c) You must ensure all load test personnel understand the safety procedures of the test;

(d) Proof load tests, with the exception of tower cranes, are overload tests and extreme caution must be observed at all times. Personnel must remain clear of suspended loads and areas where they could be struck in the event of boom failure. The test load must be raised only to a height sufficient to perform the test;

(e) During tests, safe operating speeds must be employed. Rated speeds in accordance with manufacturer's specifications need not be attained. Emphasis must be placed on the ability to safely control loads through all motions at normal speeds;

(f) Proof load tests require the use of freely suspended certified weights, or scaled weights using a certified scale with a current certificate of calibration; however, line pull test can be accomplished using a static test and a certified scale with a current certificate of calibration;

(g) Proof load tests must not exceed the manufacturer's specifications. Where these specifications are unavailable, a registered professional engineer familiar with the type of equipment involved must develop written specifications.