Persons subject to the requirements of this chapter must submit GHG reports to ecology, as specified in this section. Every metric ton of CO2e emitted by a reporter required to report under this chapter and covered under any applicable source category listed in WAC 173-441-120, 173-441-122, or 173-441-124 must be included in the report.

(1) General. Follow the procedures for emission calculation, monitoring, quality assurance, missing data, recordkeeping, and reporting that are specified in each relevant section of this chapter.

(2) Schedule. The annual GHG report must be submitted as follows:

(a) Report submission due date:

(i) A person required to report or voluntarily reporting GHG emissions under WAC 173-441-030 must submit the report required under this chapter to ecology no later than March 31st of each calendar year for GHG emissions in the previous calendar year. Electric power entities reporting under WAC 173-441-124 must submit a report based on best available information by March 31st. Electric power entities reporting under WAC 173-441-124 must submit a final revised report by June 1st of each calendar year for GHG emissions in the previous calendar year consistent with deadlines for electric power entities in external GHG emissions trading programs.

(ii)

Unless otherwise stated, if the final day of any time period falls on a weekend or a state holiday, the time period shall be extended to the next business day.

(b) Reporting requirements begin:

(i) For an existing reporter that began operation before January 1, 2012, report emissions for calendar year 2012 and each subsequent calendar year.

(ii) For a new reporter that begins operation on or after January 1, 2012, and becomes subject to the rule in the year that it becomes operational, report emissions beginning with the first operating month and ending on December 31st of that year. Each subsequent annual report must cover emissions for the calendar year, beginning on January 1st and ending on December 31st.

(iii) For any reporter that becomes subject to this rule because of a physical or operational change that is made after January 1, 2012, report emissions for the first calendar year in which the change occurs.

(A) Reporters begin reporting with the first month of the change and ending on December 31st of that year. For a reporter that becomes subject to this rule solely because of an increase in hours of operation or level of production, the first month of the change is the month in which the increased hours of operation or level of production, if maintained for the remainder of the year, would cause the reporter to exceed the applicable threshold.

(B) Suppliers and electric power entities begin reporting January 1st and ending on December 31st the year of the change.

(C) For all reporters, each subsequent annual report must cover emissions for the calendar year, beginning on January 1st and ending on December 31st.

(3) Content of the annual report. Each annual GHG report must contain the following information. All reported information is subject to verification by ecology as described in subsection (5) of this section.

(a) Reporter name, reporter ID number, and physical street address of the reporter, including the city, state, and zip code. If the facility does not have a physical street address, then the facility must provide the latitude and longitude representing the geographic centroid or center point of facility operations in decimal degree format. This must be provided in a comma-delimited "latitude, longitude" coordinate pair reported in decimal degrees to at least four digits to the right of the decimal point.

(b) Year and months covered by the report.

(c) Date of submittal.

(d) For facilities, report annual emissions of each GHG (as defined in WAC 173-441-020) and each fluorinated heat transfer fluid, as follows:

(i) Annual emissions (including biogenic CO2) aggregated for all GHGs from all applicable source categories in WAC 173-441-120 and expressed in metric tons of CO2e calculated using Equation A-1 of WAC 173-441-030 (1)(b)(iii).

(ii) Annual emissions of biogenic CO2 aggregated for all applicable source categories in WAC 173-441-120, expressed in metric tons.

(iii) Annual emissions from each applicable source category in WAC 173-441-120, expressed in metric tons of each applicable GHG listed in (d)(iii)(A) through (F) of this subsection.

(A) Biogenic CO2.

(B) CO2 (including biogenic CO2).

(C) CH4.

(D) N2O.

(E) Each fluorinated GHG.

(F) For electronics manufacturing each fluorinated heat transfer fluid that is not also a fluorinated GHG as specified under WAC 173-441-040.

(iv) Emissions and other data for individual units, processes, activities, and operations as specified in the "data reporting requirements" section of each applicable source category referenced in WAC 173-441-120.

(v) Indicate (yes or no) whether reported emissions include emissions from a cogeneration unit located at the facility.

(vi) When applying (d)(i) of this subsection to fluorinated GHGs and fluorinated heat transfer fluids, calculate and report CO2e for only those fluorinated GHGs and fluorinated heat transfer fluids listed in WAC 173-441-040.

(vii) For reporting year 2014 and thereafter, you must enter into verification software specified by the director the data specified in the verification software records provision in each applicable recordkeeping section. For each data element entered into the verification software, if the software produces a warning message for the data value and you elect not to revise the data value, you may provide an explanation in the verification software of why the data value is not being revised. Whenever the use of verification software is required or voluntarily used, the file generated by the verification software must be submitted with the facility's annual GHG report.

(e) For suppliers and electric power entities, report annual emissions of each GHG (as defined in WAC 173-441-020) as follows:

(i) Annual emissions (including biogenic CO2) aggregated for all GHGs from all applicable source categories in WAC 173-441-122 and 173-441-124 and expressed in metric tons of CO2e calculated using Equation A-1 of WAC 173-441-030 (1)(b)(iii).

(ii) Annual emissions of biogenic CO2 aggregated for all applicable source categories in WAC 173-441-122 and 173-441-124, expressed in metric tons.

(iii) Annual emissions from each applicable source category in WAC 173-441-122 and 173-441-124, expressed in metric tons of each applicable GHG listed in subsection (3)(d)(iii)(A) through (E) of this section.

(A) Biogenic CO2.

(B) CO2 (including biogenic CO2).

(C) CH4.

(D) N2O.

(E) Each fluorinated GHG.

(iv) Emissions and other data for individual units, processes, activities, and operations as specified in the "data reporting requirements" section of each applicable source category referenced in WAC 173-441-122 and 173-441-124.

(f) A written explanation, as required under subsection (4) of this section, if you change emission or product data calculation methodologies during the reporting period or since the previous reporting period.

(g) Each data element for which a missing data procedure was used according to the procedures of an applicable subpart referenced in WAC 173-441-120, 173-441-122, or 173-441-124 and the total number of hours in the year that a missing data procedure was used for each data element.

(h) A signed and dated certification statement provided by the designated representative of the owner or operator, according to the requirements of WAC 173-441-060 (5)(a).

(i) NAICS code(s) that apply to the reporter. NAICS codes are subject to approval by ecology.

(i) Primary NAICS code. Report the NAICS code that most accurately describes the reporter's primary product/activity/service. The primary product/activity/service is the principal source of revenue for the reporter. A reporter that has two distinct products/activities/services providing comparable revenue may report a second primary NAICS code.

(ii) Additional NAICS code(s). Report all additional NAICS codes that describe all product(s)/activity(s)/service(s) at the reporter that are not related to the principal source of revenue.

(j) Legal name(s) and physical address(es) of the highest-level United States parent company(s) of the owners (or operators) of the reporter and the percentage of ownership interest for each listed parent company as of December 31st of the year for which data are being reported according to the following instructions.

(i) If the reporter is entirely owned by a single United States company that is not owned by another company, provide that company's legal name and physical address as the United States parent company and report 100 percent ownership.

(ii) If the reporter is entirely owned by a single United States company that is, itself, owned by another company (e.g., it is a division or subsidiary of a higher-level company), provide the legal name and physical address of the highest-level company in the ownership hierarchy as the United States parent company and report 100 percent ownership.

(iii) If the reporter is owned by more than one United States company (e.g., company A owns 40 percent, company B owns 35 percent, and company C owns 25 percent), provide the legal names and physical addresses of all the highest-level companies with an ownership interest as the United States parent companies and report the percent ownership of each company.

(iv) If the reporter is owned by a joint venture or a cooperative, the joint venture or cooperative is its own United States parent company. Provide the legal name and physical address of the joint venture or cooperative as the United States parent company, and report 100 percent ownership by the joint venture or cooperative.

(v) If the reporter is entirely owned by a foreign company, provide the legal name and physical address of the foreign company's highest-level company based in the United States as the United States parent company, and report 100 percent ownership.

(vi) If the reporter is partially owned by a foreign company and partially owned by one or more United States companies, provide the legal name and physical address of the foreign company's highest-level company based in the United States, along with the legal names and physical addresses of the other United States parent companies, and report the percent ownership of each of these companies.

(vii) If the reporter is a federally owned facility, report "U.S. Government" and do not report physical address or percent ownership.

(k) An indication of whether the facility includes one or more plant sites that have been assigned a "plant code" by either the Department of Energy's Energy Information Administration or by the Environmental Protection Agency's (EPA) Clean Air Markets Division.

(l) Facilities must report electricity information including:

(i) Total annual electricity purchased in megawatt hours (MWh), itemized by the supplying utility or, if not obtained from a utility, from the supplying electric power entity for each different source of electricity. Total annual purchases must be reported separately for each supplying utility or electric power entity.

(ii) Self-generated electricity should be itemized separately if a facility includes an electricity generating unit as follows:

(A) Total facility nameplate generating capacity in megawatts (MW).

(B) Generated electricity in MWh provided or sold to each retail provider, electricity marketer, or other reportable end-user that is not a part of the facility, itemized by end-user.

(C) Generated electricity for on-site industrial applications not related to electricity generation in MWh.

(m) Report fuel use or supplied as follows:

(i) Facilities, report each fuel combusted separately by type, quantity, and units of measurement.

(ii) Fuel suppliers, report:

(A) Each fuel supplied separately by type, quantity, and units of measurement; and

(B) Separately report the quantity of each fuel type by purpose if the fuel supplier reports that the fuel is used for one of the purposes described in WAC 173-441-122 (5)(d)(xi).

(n) Facilities, report total annual facility product data, units of production, and specific product based on their first primary NAICS code.

(i) Facilities with a primary NAICS code listed in Table 050-1 of this section must report total annual facility product data as described in Table 050-1. Facilities may additionally report total annual facility product data as described in Table 050-1 for any reported secondary NAICS code. Use six digit NAICS codes when available, otherwise use the shorter NAICS codes listed below substituting the values in the full reported six digit NAICS code for "X".

Table 050-1: Total Annual Facility Product Data Requirements by Primary NAICS Code.

Primary NAICS Code and Sector Definition | Activity | Production Metric |

112112: Cattle Feedlots | Cattle feedlots | Cattle head days |

211130: Natural Gas Extraction | Natural gas extraction | Million standard cubic feet of natural gas extracted |

212399: All Other Nonmetallic Mineral Mining | Freshwater diatomite filter aids manufacturing | Metric tons of mineral product produced |

2211XX: Electric Power Generation, Transmission and Distribution | Electric power generation, transmission and distribution | Net megawatt hours |

221210: Natural Gas Distribution | Natural gas distribution | Million standard cubic feet of natural gas distributed |

221330: Steam and Air-conditioning Supply | Steam supply | Kilograms steam produced |

311213: Malt Manufacturing | Malt manufacturing | Metric tons of malt produced |

3114XX: Fruit and Vegetable Preserving and Specialty Food Manufacturing | Fruit and vegetable preserving and specialty food manufacturing | Metric tons of food product produced |

3115XX: Dairy Product Manufacturing | Dairy product manufacturing | Metric tons of dairy product produced |

311611: Animal (except poultry) Slaughtering | Animal (except poultry) slaughtering | Metric tons of meat product processed |

311613: Rendering and Meat By-product Processing | Rendering and meat by-product processing | Metric tons of meat by-product processed |

311919: Other Snack Food Manufacturing | Other snack food manufacturing | Metric tons of snack food produced |

311920: Coffee and Tea Manufacturing | Coffee and tea manufacturing | Metric tons of coffee and tea produced |

321XXX: Wood Product Manufacturing | Wood product manufacturing | Air dried (10 percent moisture) metric tons of wood product produced |

3221XX: Pulp, Paper, and Paperboard Mills | Pulp, paper, and paperboard mills | Air dried (10 percent moisture) metric tons of produced: • Pulp product; or • Paper; or • Paperboard |

322299: All Other Converted Paper Product Manufacturing | All other converted paper product manufacturing | Air dried (10 percent moisture) metric tons of converted paper product produced |

324110: Petroleum Refineries | Petroleum refineries | Report all of the following: • Facility level Subpart MM report as reported under 40 C.F.R. Part 98; • Barrels of crude oil and intermediate products received from off-site that are processed at the facility; and • Beginning with the first emissions year after a refinery's first turnaround after 2022, the refinery must also submit complexity weighted barrel (CWB) as described in CARB MRR section 95113(l)(3) as adopted by 7/1/2021. CWB supporting data must also be submitted to Ecology as described in CARB MRR section 95113(l)(3). |

324121: Asphalt Paving Mixture and Block Manufacturing | Asphalt paving mixture and block manufacturing | Metric tons of asphalt paving mixture and block produced |

3251XX: Basic Chemical Manufacturing | Basic chemical manufacturing | Metric tons of chemical produced |

325311: Nitrogenous Fertilizer Manufacturing | Nitric acid production | Metric tons of nitric acid produced |

32721X: Glass and Glass Product Manufacturing | Glass and glass product manufacturing | Metric tons of glass produced |

327310: Cement Manufacturing | Cement manufacturing | Metric tons of adjusted clinker and mineral additives produced |

327390: Other Concrete Product Manufacturing | Other concrete product manufacturing | Metric tons of concrete product produced |

327410: Lime Manufacturing | Lime manufacturing | Metric tons of lime produced |

327420: Gypsum Product Manufacturing | Gypsum product manufacturing | Metric tons of gypsum product produced |

331110: Iron and Steel Mills and Ferroalloy Manufacturing | Steel production using an electric arc furnace (EAF) | Metric tons of steel produced |

33131X: Alumina and Aluminum Production and Processing | Alumina and aluminum production and processing | Metric tons of aluminum produced |

331410: Nonferrous Metal (except aluminum) Smelting and Refining | Granular polysilicon production | Metric tons of granular polysilicon produced |

332111: Iron and Steel Forging | Iron forging | Metric tons of iron produced |

334413: Semiconductor and Related Device Manufacturing | Semiconductor and related device manufacturing | Square meters of mask layer produced |

335991: Carbon and Graphite Product Manufacturing | Carbon and graphite product manufacturing | Metric tons of carbon and graphite product produced |

3364XX: Aerospace Product and Parts Manufacturing | Aerospace product and parts manufacturing | • Metric tons of aircraft product and parts produced; or • Square meters of external surface area of aircraft |

486210: Pipeline Transportation of Natural Gas | Pipeline transportation of natural gas | Million standard cubic feet of natural gas transported |

488119: Other Airport Operations | Other airport operations | Passenger kilometers serviced |

562111: Solid Waste Collection | Solid waste collection | Metric tons of total solid waste collected |

562212: Solid Waste Landfill | Solid waste landfill | Metric tons of total waste entered into landfill |

562213: Solid Waste Combustors and Incinerators | Solid waste combustors and incinerators | Net megawatt hours |

611310: Colleges, Universities, and Professional Schools | Colleges, universities, and professional schools | Students serviced |

928110: National Security | Military bases | Troops stationed |

(ii) Facilities without a primary NAICS code listed in Table 050-1 of this section must contact ecology no later than 45 calendar days prior to the emissions report deadline established in subsection (2) of this section and report total annual facility product data as instructed by the department. If ecology does not identify product data for a facility, a facility must use the energy-based calculation method described in Equation 050-1 of this section. Report product data and inputs to the equation. Product data calculated using the energy-based method shall use the following equation:

Product data | = | Sconsumed + Fconsumed – esold | (Eq. 050-1) |

Where: | ||

"SConsumed" is the annual amount of steam consumed, measured in MMBtu, at the facility for any process, including heating or cooling applications. This value shall exclude any steam used to produce electricity. This value shall exclude steam produced from an on-site cogeneration unit; | ||

"FConsumed" is the annual amount of energy produced due to fuel combustion at the facility, measured in MMBtu. This value shall be calculated based on measured higher heating values or the default higher heating value of the applicable fuel in Table C-1 of 40 C.F.R. Part 98. This value shall include any energy from fuel combusted in an on-site electricity generation or cogeneration unit. This value shall exclude energy to generate the steam accounted for in the "SConsumed" term; | ||

"eSold" is the annual amount of electricity sold or provided for off-site use, measured in MWh and converted to MMBtu using the reporting year U.S. Energy Information Administration conversion factor; | ||

(iii) Facilities with a change in operation that alters either their primary NAICS code, units of production, or product data measurement method must contact ecology no later than 45 calendar days prior to the emissions report deadline established in subsection (2) of this section and report total annual facility product data as instructed by the department. If ecology does not identify product data for a facility, a facility must use the energy-based calculation method described in Equation 050-1 of this section. Report product data and inputs to the equation.

(iv) For a primary NAICS code in Table 050-1 that has multiple production metrics, a facility that wishes to change their reported production metric must contact ecology no later than 45 calendar days prior to the emissions report deadline established in subsection (2) of this section and report total annual facility production data as instructed by the department.

(o) Reporters that cease operation, other than routine maintenance or seasonal shutdowns, for more than 90 calendar days must provide the following information:

(i) The anticipated type of cessation: Closure or curtailment;

(ii) Date cessation began;

(iii) Date cessation ended (if applicable); and

(iv) Reason for cessation and/or resumption of operation.

(p) If there is an increase or decrease of more than five percent in emissions of greenhouse gases in relation to the previous year, the reporter must provide a brief narrative description of what caused the increase or decrease in emissions.

(4) Emission calculations. In preparing the GHG report, you must use the calculation methodologies specified in the relevant sections of this chapter. For each source category, you must use the same calculation methodology as previous reports. This includes throughout a reporting period, and between reporting years. An owner or operator intending to change methodologies must provide a written explanation at least 60 calendar days before the report submission due date in subsection (2)(a) of this section of why a change in methodology was required. Ecology has 45 calendar days to approve or reject the change in method. The reporter must continue to use existing methods until the change is approved by ecology.

(5) Verification. To verify the completeness and accuracy of reported GHG emissions, ecology may review the certification statements described in subsection (3)(h) of this section and any other credible evidence, in conjunction with a comprehensive review of the GHG reports and periodic audits of selected reporting facilities. Nothing in this section prohibits ecology from using additional information to verify the completeness and accuracy of the reports. Reporters must cooperate with ecology's efforts to verify GHG reports.

(6) Recordkeeping. A person that is required to report GHGs under this chapter must keep records as specified in this subsection. Retain all required records for at least 10 years from the date of submission of the annual GHG report for the reporting year in which the record was generated. Upon request by ecology, the person must submit the records required under this section within 15 business days of receipt of the notification, unless a different schedule is agreed to by ecology. Records may be retained off-site if the records are readily available for expeditious inspection and review. For records that are electronically generated or maintained, the equipment or software necessary to read the records must be made available, or, if requested by ecology, electronic records must be converted to paper documents. You must retain the following records, in addition to those records prescribed in each applicable section of this chapter:

(a) A list of all units, operations, processes, and activities for which GHG emissions were calculated.

(b) The data used to calculate the GHG emissions for each unit, operation, process, and activity, categorized by fuel or material type. These data include, but are not limited to, the following information:

(i) The GHG emissions calculations and methods used.

(ii) Analytical results for the development of site-specific emissions factors.

(iii) The results of all required analyses for high heat value, carbon content, and other required fuel or feedstock parameters.

(iv) Any facility operating data or process information used for the GHG emission calculations.

(c) The annual GHG reports.

(d) Missing data computations. For each missing data event, also retain a record of the cause of the event and the corrective actions taken to restore malfunctioning monitoring equipment.

(e) Owners or operators required to report under WAC 173-441-030 must keep a written GHG monitoring plan (monitoring plan, plan).

(i) At a minimum, the GHG monitoring plan must include the following elements:

(A) Identification of positions of responsibility (i.e., job titles) for collection of the emissions data.

(B) Explanation of the processes and methods used to collect the necessary data for the GHG calculations.

(C) Description of the procedures and methods that are used for quality assurance, maintenance, and repair of all continuous monitoring systems, flow meters, and other instrumentation used to provide data for the GHGs reported under this chapter.

(D) Facilities must reference to one or more simplified block diagrams that provide a clear visual representation of the relative locations and positions of measurement devices and sampling locations, as applicable, required for calculating covered emissions and covered product data (e.g., temperature, total pressure, HHV, fuel consumption). The diagram(s) must include fuel sources, combustion units, and production processes, as applicable.

(ii) The GHG monitoring plan may rely on references to existing corporate documents (e.g., standard operating procedures, quality assurance programs under appendix F to 40 C.F.R. Part 60 or appendix B to 40 C.F.R. Part 75, and other documents) provided that the elements required by (e)(i) of this subsection are easily recognizable.

(iii) The owner or operator must revise the GHG monitoring plan as needed to reflect changes in production processes, monitoring instrumentation, and quality assurance procedures; or to improve procedures for the maintenance and repair of monitoring systems to reduce the frequency of monitoring equipment downtime.

(iv) Upon request by ecology, the owner or operator must make all information that is collected in conformance with the GHG monitoring plan available for review during an audit within 15 business days of receipt of the notification, unless a different schedule is agreed to by ecology. Electronic storage of the information in the plan is permissible, provided that the information can be made available in hard copy upon request during an audit.

(f) The results of all required certification and quality assurance tests of continuous monitoring systems, fuel flow meters, and other instrumentation used to provide data for the GHGs reported under this chapter.

(g) Maintenance records for all continuous monitoring systems, flow meters, and other instrumentation used to provide data for the GHGs reported under this chapter.

(h) Suppliers and electric power entities must retain any other data specified in WAC 173-441-122 and 173-441-124.

(7) Annual GHG report revisions.

(a) A person must submit a revised annual GHG report within 45 calendar days of discovering that an annual GHG report that the person previously submitted contains one or more substantive errors. The revised report must correct all substantive errors.

(b) Ecology may notify the person in writing that an annual GHG report previously submitted by the person contains one or more substantive errors. Such notification will identify each such substantive error. The person must, within 45 calendar days of receipt of the notification, either resubmit the report that, for each identified substantive error, corrects the identified substantive error (in accordance with the applicable requirements of this chapter) or provide information demonstrating that the previously submitted report does not contain the identified substantive error or that the identified error is not a substantive error.

(c) A substantive error is an error that impacts the quantity of GHG emissions reported, product data reported, or otherwise prevents the reported data from being validated or verified.

(d) Notwithstanding (a) and (b) of this subsection, upon request by a person, ecology may provide reasonable extensions of the 45-day period for submission of the revised report or information under (a) and (b) of this subsection. If ecology receives a request for extension of the 45-day period, by email, at least five business days prior to the expiration of the 45 calendar day period, and ecology does not respond to the request by the end of such period, the extension request is deemed to be automatically granted for 15 more calendar days. During the automatic 15-day extension, ecology will determine what extension, if any, beyond the automatic extension is reasonable and will provide any such additional extension.

(e) The owner or operator must retain documentation for 10 years to support any revision made to an annual GHG report.

(8) Calibration and accuracy requirements. The owner or operator of a facility that is subject to the requirements of this chapter must meet the applicable flow meter calibration and accuracy requirements of this subsection. The accuracy specifications in this subsection do not apply where either the use of company records (as defined in WAC 173-441-020(3)) or the use of "best available information" is specified in an applicable subsection of this chapter to quantify fuel usage and/or other parameters. Further, the provisions of this subsection do not apply to stationary fuel combustion units that use the methodologies in 40 C.F.R. Part 75 to calculate CO2 mass emissions. Measurement devices used for financial transactions between two or more independent parties meet the calibration and accuracy requirements of this chapter.

(a) Except as otherwise provided in (d) through (f) of this subsection, flow meters that measure liquid and gaseous fuel feed rates, process stream flow rates, product data measuring devices, or feedstock flow rates and provide data for the GHG emissions calculations or product data, must be calibrated prior to January 1, 2012, for emissions data or January 1, 2023, for product data, using the procedures specified in this subsection when such calibration is specified in a relevant section of this chapter. Each of these flow meters must meet the applicable accuracy specification in (b) or (c) of this subsection. All other measurement devices (e.g., weighing devices) that are required by a relevant subsection of this chapter, and that are used to provide data for the GHG emissions calculations or product data, must also be calibrated prior to January 1, 2012, for emissions data or January 1, 2023, for product data; however, the accuracy specifications in (b) and (c) of this subsection do not apply to these devices. Rather, each of these measurement devices must be calibrated to meet the accuracy requirement specified for the device in the applicable subsection of this chapter, or, in the absence of such accuracy requirement, the device must be calibrated to an accuracy within the appropriate error range for the specific measurement technology, based on an applicable operating standard including, but not limited to, manufacturer's specifications and industry standards. The procedures and methods used to quality-assure the data from each measurement device must be documented in the written monitoring plan, pursuant to subsection (6)(e)(i)(C) of this section.

(i) All flow meters and other measurement devices that are subject to the provisions of this subsection must be calibrated according to one of the following: You may use the manufacturer's recommended procedures; an appropriate industry consensus standard method; or a method specified in a relevant section of this chapter. The calibration method(s) used must be documented in the monitoring plan required under subsection (6)(e) of this section.

(ii) For reporters that become subject to this chapter after January 1, 2012, all flow meters and other measurement devices (if any) that are required by the relevant subsection(s) of this chapter to provide data for the GHG emissions calculations or product data must be installed no later than the date on which data collection is required to begin using the measurement device, and the initial calibration(s) required by this subsection (if any) must be performed no later than that date.

(iii) Except as otherwise provided in (d) through (f) of this subsection, subsequent recalibrations of the flow meters and other measurement devices subject to the requirements of this subsection must be performed at one of the following frequencies:

(A) You may use the frequency specified in each applicable subsection of this chapter.

(B) You may use the frequency recommended by the manufacturer or by an industry consensus standard practice, if no recalibration frequency is specified in an applicable subsection.

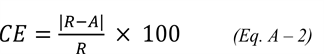

(b) Perform all flow meter calibration at measurement points that are representative of the normal operating range of the meter. Except for the orifice, nozzle, and venturi flow meters described in (c) of this subsection, calculate the calibration error at each measurement point using Equation A–2 of this subsection. The terms "R" and "A" in Equation A–2 must be expressed in consistent units of measure (e.g., gallons/minute, ft3/min). The calibration error at each measurement point must not exceed 5.0 percent of the reference value.

|

Where: | ||||

CE | = | Calibration error | (%) | |

R | = | Reference value | ||

A | = | Flow meter response to the reference value | ||

(c) For orifice, nozzle, and venturi flow meters, the initial quality assurance consists of in situ calibration of the differential pressure (delta-P), total pressure, and temperature transmitters.

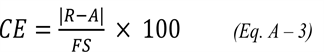

(i) Calibrate each transmitter at a zero point and at least one upscale point. Fixed reference points, such as the freezing point of water, may be used for temperature transmitter calibrations. Calculate the calibration error of each transmitter at each measurement point, using Equation A–3 of this subsection. The terms "R," "A," and "FS" in Equation A–3 of this subsection must be in consistent units of measure (e.g., milliamperes, inches of water, psi, degrees). For each transmitter, the CE value at each measurement point must not exceed 2.0 percent of full-scale. Alternatively, the results are acceptable if the sum of the calculated CE values for the three transmitters at each calibration level (i.e., at the zero level and at each upscale level) does not exceed 6.0 percent.

|

Where: | ||||

CE | = | Calibration error | (%) | |

R | = | Reference value | ||

A | = | Transmitter response to the reference value | ||

FS | = | Full-scale value of the transmitter | ||

(ii) In cases where there are only two transmitters (i.e., differential pressure and either temperature or total pressure) in the immediate vicinity of the flow meter's primary element (e.g., the orifice plate), or when there is only a differential pressure transmitter in close proximity to the primary element, calibration of these existing transmitters to a CE of 2.0 percent or less at each measurement point is still required, in accordance with (c)(i) of this subsection; alternatively, when two transmitters are calibrated, the results are acceptable if the sum of the CE values for the two transmitters at each calibration level does not exceed 4.0 percent. However, note that installation and calibration of an additional transmitter (or transmitters) at the flow monitor location to measure temperature or total pressure or both is not required in these cases. Instead, you may use assumed values for temperature and/or total pressure, based on measurements of these parameters at a remote location (or locations), provided that the following conditions are met:

(A) You must demonstrate that measurements at the remote location(s) can, when appropriate correction factors are applied, reliably and accurately represent the actual temperature or total pressure at the flow meter under all expected ambient conditions.

(B) You must make all temperature and/or total pressure measurements in the demonstration described in (c)(ii)(A) of this subsection with calibrated gauges, sensors, transmitters, or other appropriate measurement devices. At a minimum, calibrate each of these devices to an accuracy within the appropriate error range for the specific measurement technology, according to one of the following: You may calibrate using a manufacturer's specification or an industry consensus standard.

(C) You must document the methods used for the demonstration described in (c)(ii)(A) of this subsection in the written GHG monitoring plan under subsection (6)(e)(i)(C) of this section. You must also include the data from the demonstration, the mathematical correlation(s) between the remote readings and actual flow meter conditions derived from the data, and any supporting engineering calculations in the GHG monitoring plan. You must maintain all of this information in a format suitable for auditing and inspection.

(D) You must use the mathematical correlation(s) derived from the demonstration described in (c)(ii)(A) of this subsection to convert the remote temperature or the total pressure readings, or both, to the actual temperature or total pressure at the flow meter, or both, on a daily basis. You must then use the actual temperature and total pressure values to correct the measured flow rates to standard conditions.

(E) You must periodically check the correlation(s) between the remote and actual readings (at least once a year), and make any necessary adjustments to the mathematical relationship(s).

(d) Fuel billing meters are exempted from the calibration requirements of this section and from the GHG monitoring plan and recordkeeping provisions of subsection (6)(e)(i)(C) and (g) of this section, provided that the fuel supplier and any unit combusting the fuel do not have any common owners and are not owned by subsidiaries or affiliates of the same company. Meters used exclusively to measure the flow rates of fuels that are used for unit startup are also exempted from the calibration requirements of this section.

(e) For a flow meter that has been previously calibrated in accordance with (a) of this subsection, an additional calibration is not required by the date specified in (a) of this subsection if, as of that date, the previous calibration is still active (i.e., the device is not yet due for recalibration because the time interval between successive calibrations has not elapsed). In this case, the deadline for the successive calibrations of the flow meter must be set according to one of the following: You may use either the manufacturer's recommended calibration schedule or you may use the industry consensus calibration schedule.

(f) For units and processes that operate continuously with infrequent outages, it may not be possible to meet the deadline established in (a) of this subsection for the initial calibration of a flow meter or other measurement device without disrupting normal process operation. In such cases, the owner or operator may postpone the initial calibration until the next scheduled maintenance outage. The best available information from company records may be used in the interim. The subsequent required recalibrations of the flow meters may be similarly postponed. Such postponements must be documented in the monitoring plan that is required under subsection (6)(e) of this section.

(g) If the results of an initial calibration or a recalibration fail to meet the required accuracy specification, data from the flow meter must be considered invalid, beginning with the hour of the failed calibration and continuing until a successful calibration is completed. You must follow the missing data provisions provided in the relevant missing data sections during the period of data invalidation.

(h) Missing data substitution procedures. Persons must comply with 40 C.F.R. Part 98 when substituting for missing data. Substitute missing data used for product data or other data required under this section that is not included in your 40 C.F.R. Part 98 report by using the best available estimate of the parameter, based on all available data.

(9) Measurement device installation. 40 C.F.R. § 98.3(j) and 40 C.F.R. § 98.3(d) are adopted by reference as modified in WAC 173-441-120(2).