(1) Scope. Motor vehicles covered by this section include any vehicles that operate on a construction site. The requirements of this section do not apply to the equipment regulated by WAC 296-155-615, Material handling equipment.

(2) General requirements for motor vehicles.

(a) Braking systems.

• All vehicles must have:

– A service brake system;

– An emergency brake system;

and

– A parking brake system.

• These systems must be maintained in operable condition.

• These systems may use common components.

(b) Before leaving a motor vehicle unattended:

(i) The motor must be stopped.

(ii) The parking brake must be engaged and the wheels turned into curb or berm when parked on an incline.

(iii) If parking on an incline and there is no curb or berm, the wheels must be chocked or otherwise secured.

(c) Lighting systems. All vehicles, or combination of vehicles, must have brake lights in operable condition, regardless of light conditions.

• You must meet the requirements in Table 1 below.

Table 1

If: | Then: | |

Visibility conditions warrant additional light. | All vehicles, or combinations of vehicles, in use must be equipped with: | |

• | At least two headlights in operable condition; | |

and | ||

• | At least two taillights in operable condition. | |

(d) All vehicles must be equipped with an operable audible warning device (horn) at the operator's station.

(e) Operating vehicles, other than passenger cars and pickups, with an obstructed view to the rear. You must prohibit the use of any motor vehicle equipment that has an obstructed view to the rear unless the vehicle meets one of the following:

• Has an operable automatic reverse signal alarm audible above the surrounding noise level and audible no less than 15 feet from the rear of the vehicle;

or

• Is backed up when an observer signals that it is safe to do so.

Reference: | For requirements on operating dump trucks in reverse, see (f) of this subsection, Operating dump trucks in reverse. |

Note: | • If the surrounding noise level is so loud that reverse signal alarms are not effective, then an observer must be used. |

• An observer can be any individual at the construction site, except a person performing the duties of a flagger. The observer must: | |

– Be in the direct line-of-sight or able to communicate with the driver. | |

– Be able to see the entire backing zone. | |

– Continue to provide direction to the driver until: | |

■ The driver reaches the destination and stops; | |

or | |

■ There are no longer employees in the backing zone and it is reasonable to expect that no employee(s) will enter the backing zone. |

(f) Operating dump trucks in reverse.

(i) You must make sure the dump truck has an operable automatic reverse signal alarm:

• Audible above the surrounding noise level;

and

• Audible no less than 15 feet from the rear of the vehicle.

(ii) Before backing a dump truck the driver must determine that no one is currently in the backing zone and it is reasonable to expect that no employee(s) will enter the backing zone while operating the dump truck in reverse.

If employee(s) are in the backing zone or it is reasonable to expect that an employee(s) will enter the backing zone, you must make sure the truck is backed up only when:

• An observer signals that it is safe to back;

or

• An operable mechanical device that provides the driver a full view behind the dump truck is used, such as a video camera.

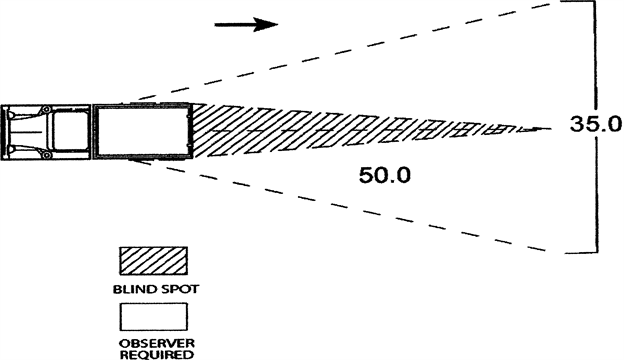

Note: | The following diagram defines the backing zone. Distances are reported in feet. |

DUMP TRUCK BACKING

|

Exemption: | • Employees are considered protected when they are on the opposite side of a fixed barrier such as: |

– A jersey barrier; | |

– Heavy equipment (such as a paving machine); | |

or | |

– A 6-inch concrete curb. |

Note: | The term "dump trucks" includes both belly and rear dump trucks with a minimum payload of 4 yards. |

(g) Windshields.

• All vehicles with cabs must be equipped with:

– Windshields;

– Powered wipers; and

– Rear view mirrors.

• Cracked and broken glass must be replaced.

• Vehicles operating in areas or under conditions that cause fogging or frosting of the windshields must be equipped with operable defogging or defrosting devices.

(h) Haulage vehicles. You must meet the requirement in Table 2 below.

Table 2

If: | Then: | |

Any haulage vehicles payload is filled by: | You must have a cab shield and/or canopy adequate to protect the operator from shifting or falling materials. | |

• | Cranes; | |

• | Power shovels; | |

• | Loaders; | |

or | ||

• | Similar equipment. | |

(i) Securing material and employees.

• Tools and material must be secured to prevent movement when transported in the same compartment as employees.

• Vehicles used to transport employees must have seats firmly secured and adequate for the number of employees to be carried.

• Seat belts and anchorages meeting the requirements of 49 C.F.R. Part 571 (Department of Transportation, Federal Motor Vehicle Safety Standards) must be installed in all motor vehicles and used by all occupants of the vehicle.

(j) Trucks with dump bodies.

• Trucks with dump bodies or raisable platforms, beds, or boxes must be equipped with positive means of support, permanently attached. This positive means of support must be capable of being locked in position to prevent accidental lowering of the body while maintenance or inspection work is being done.

• Operating levers, controlling hoisting or dumping devices on haulage bodies, must be equipped with a latch or other device, such as a detent switch, which will prevent accidental starting or tripping of the mechanism.

• Trip handles for tailgates of dump trucks must be so arranged that, in dumping, the operator will be in the clear.

(k) Fenders on motor vehicle equipment.

• All rubber-tired motor vehicle equipment must be equipped with fenders.

• Mud flaps may be used in lieu of fenders whenever motor vehicle equipment is not designed for fenders.

(l) Vehicle safety inspections.

• You must check all vehicles in use at the beginning of each shift to make sure that the following parts, equipment, and accessories are in safe operating condition and free of apparent damage that could cause failure while in use:

– Service brakes (including trailer brake connections);

– Parking system (hand brake);

– Emergency stopping system (brakes);

– Tires;

– Horn;

– Steering mechanism;

– Coupling devices;

– Seat belts;

– Operating controls;

and

– Safety devices.

• These requirements also apply where such equipment is necessary.

– Lights;

– Reflectors;

– Windshield wipers;

– Defrosters;

– Fire extinguishers;

– Steps and handholds for vehicle access;

and

– Any other necessary equipment.

• All defects must be corrected before the vehicle is placed in service.