WSR 16-01-030

PROPOSED RULES

DEPARTMENT OF

LABOR AND INDUSTRIES

[Filed December 8, 2015, 12:12 p.m.]

Original Notice.

Preproposal statement of inquiry was filed as WSR 14-24-094.

Title of Rule and Other Identifying Information: Chapter 296-45 WAC, Safety standards for electrical workers.

Hearing Location(s): Red Lion Hotel, 1225 North Wenatchee Avenue, Wenatchee, WA, on January 26, 2016, at 9:00 a.m.; at the Enduris Training Facility, 1610 South Technology Boulevard, Suite 100, Spokane, WA, on January 27, 2016, at 9:00 a.m.; at The Heathman Lodge, 7801 Greenwood Drive, Vancouver, WA, on February 1, 2016, at 9:00 a.m.; and at the Department of Labor and Industries (L&I), 7273 Linderson Way S.W., S118 and S119 Rooms, Tumwater, WA, on February 3, 2016, at 9:00 a.m.

Date of Intended Adoption: April 4, 2016.

Submit Written Comments to: Cindy Ireland, Administrative Regulations Analyst, Division of Occupational Safety and Health, P.O. Box 44620, Olympia, WA 98504-4620, Cynthia.Ireland@lni.wa.gov, by 5:00 p.m., on February 17, 2016.

In addition to written comments, the department will accept comments submitted to fax (360) 902-5619. Comments submitted by fax must be ten pages or less.

Assistance for Persons with Disabilities: Contact Cynthia Ireland by January 11, 2016, at (360) 902-5522 or cynthia.ireland@lni.wa.gov.

Purpose of the Proposal and Its Anticipated Effects, Including Any Changes in Existing Rules: This proposed rule making is federally initiated. The department is responding to a Federal Register notice where the Occupational Safety and Health Administration (OSHA) published their final rule relating to Electric Power Generation, Transmission, and Distribution; and Electrical Protective Equipment (29 C.F.R. 1910 and 1926). This was published on April 11, 2014, and effective July 11, 2014. The department is required to update our rules to be at-least-as-effective-as OSHA. The department will have a few provisions that may differ but will be at-least-as-effective-as the OSHA rule. In addition, the rule changes incorporate the most recent national standards or best industry practices, include adoption of various 2014 ANSI standards, update internal references and make minor housekeeping changes throughout our chapters.

AMENDED CHAPTER:

• | Rename the title of this chapter from "Safety Standards for Electrical Workers" to "Electric Power Generation, Transmission, and Distribution." |

AMENDED SECTIONS:

WAC 296-45-015 Scope and application.

• | Add the word "construction" in subsection (1). Add the word electrical to qualified employees in subsections (1)(a), (e)(i), (ii) and (7). |

• | Change "qualified persons" to "qualified electrical employees" in the notes after subsection (2). |

• | Add a reference to chapter 296-27 WAC in subsection (4). |

• | Create a new subsection (12) with current language. |

WAC 296-45-035 Definitions.

• | Add definitions for contract employer, entry, fall restraint system, first-aid training, host employer, may, must, network system, personal fall arrest system, roadway or public highway, shall, should, statistical sparkover voltage, statistical withstand voltage, and work-positioning equipment. |

• | Modify the definitions for automatic circuit recloser, designated employee, enclosed space, line-clearance tree trimmer, line-clearance tree trimming, qualified person or qualified employee, and system operator or power dispatcher. |

• | Delete the definitions of electric utility, public highway, and underground network. |

WAC 296-45-045 NESC applicable.

• | Update the NESC references to 2012. |

WAC 296-45-055 Employer's responsibility.

• | Update a reference in subsection (2). |

WAC 296-45-065 Training.

• | Housekeeping changes in subsections (1), (4), (5), (6) and (8). |

• | Add a new subsection (2) relating to the degree of training, using OSHA language. Renumber the rest of this section. |

• | Add the word "electrical" to qualified employees in subsections (3) and (3)(c). Add language in subsection (3)(c) using OSHA language. Add a new subsection (3)(e), using OSHA language. Add the word "electrical" to qualified employees in the note after subsection (3)(e). |

• | Add notes after subsection (8) using OSHA language. |

• | Add a new subsection (9) relating to line-clearance tree trimmers using OSHA language. |

WAC 296-45-075 Employer's safety program.

• | Update a reference in subsection (5). |

WAC 296-45-105 Work required of leadworkers.

• | Change "lineworkers" to "qualified electrical employees" throughout this section. |

WAC 296-45-125 Medical services and first aid.

• | Add OSHA language in subsections (1)(a) and (3). |

WAC 296-45-135 Job briefing.

• | Reformat part of the language in subsection (1) and move to subsection (3). |

• | Add a new subsection (2) using OSHA language. Renumber the rest of this section. |

WAC 296-45-17505 Lockout/tagout (hazardous control) program.

• | Add the word "designated" after "authorized" throughout this section. |

WAC 296-45-17510 Retraining.

• | Add the word "designated" after "authorized" in subsection (1). |

WAC 296-45-17515 Protective materials and hardware.

• | Update a reference in the note at the end of this section. |

WAC 296-45-17520 Energy isolation and 296-45-17525 Notification.

• | Add the word "designated" after "authorized" in these sections. |

WAC 296-45-17530 Lockout/tagout application.

• | Add the word "designated" after "authorized" throughout this section. |

WAC 296-45-17535 Releasing stored energy.

• | Add the word "designated" after "authorized" in subsection (2). |

WAC 296-45-17540 Release from lockout/tagout, 296-45-17550 Group lockout/tagout, and 296-45-17565 Central system operator.

• | Add the word "designated" after "authorized" throughout these sections. |

WAC 296-45-205 Enclosed spaces.

• | Update this section using OSHA language. Also update references throughout this section. |

WAC 296-45-215 Underground electrical installations.

• | Change "qualified persons" to "qualified electrical employees" throughout this section. |

• | Update a reference in the note. |

WAC 296-45-225 Underground residential distribution (URD).

• | Update the table reference in subsection (1)(b). |

• | Change "qualified employees" to "qualified electrical employees" throughout this section. |

• | Change "qualified employee" to "designated employee" in subsection (1)(c). |

WAC 296-45-255 Protective equipment.

• | Update the table reference in subsection (15). |

WAC 296-45-25505 Personal protective equipment.

• | Update the ANSI reference in subsection (2). |

• | Housekeeping change in subsection (3). |

WAC 296-45-25510 Fall protection.

• | Update this entire section with OSHA language. |

• | Add a reference to Appendix E. |

WAC 296-45-275 Ladders, platforms, and manhole steps.

• | Update references in subsections (1), (2) and the note. |

WAC 296-45-295 Gasoline engine power chain saws.

• | Update the ANSI reference in subsection (1). |

• | Update a reference in subsection (2). |

• | Add a note after subsection (15). |

WAC 296-45-305 Live-line tools.

• | Update the ASTM reference in the note. |

• | Housekeeping change in subsection (2)(c). |

• | Update the IEEE reference in the note. |

WAC 296-45-315 Materials handling and storage.

• | Change "qualified employees" to "qualified electrical employees" throughout this section. |

WAC 296-45-325 Working on or near exposed energized parts.

• | Change "qualified employees" to "qualified electrical employees" throughout this section. |

• | Housekeeping change in subsection (3). |

• | Update the table reference in subsections (4) and (11). Renumber subsections (a) and (b). |

• | Replace Minimum Approach Distance table with a more current table. |

• | Add Table 3, Altitude correction factors using OSHA language. This table is currently in Appendix A. |

• | Add a reference to Appendix A. |

• | Add a new subsection (13) relating to protection from arcs and flames using OSHA language. Delete subsection (12)(b) and (c) and the note, now redundant with the new subsection (13). Renumber section. |

• | Update language referencing Appendix D. |

WAC 296-45-335 Deenergizing lines and equipment for employee protection.

• | Change "designated employees" to "qualified electrical employees" throughout this section. |

• | Add a new subsection (15) relating to network protectors using OSHA language. Renumber the rest of this section. |

• | Housekeeping change in subsection (18). |

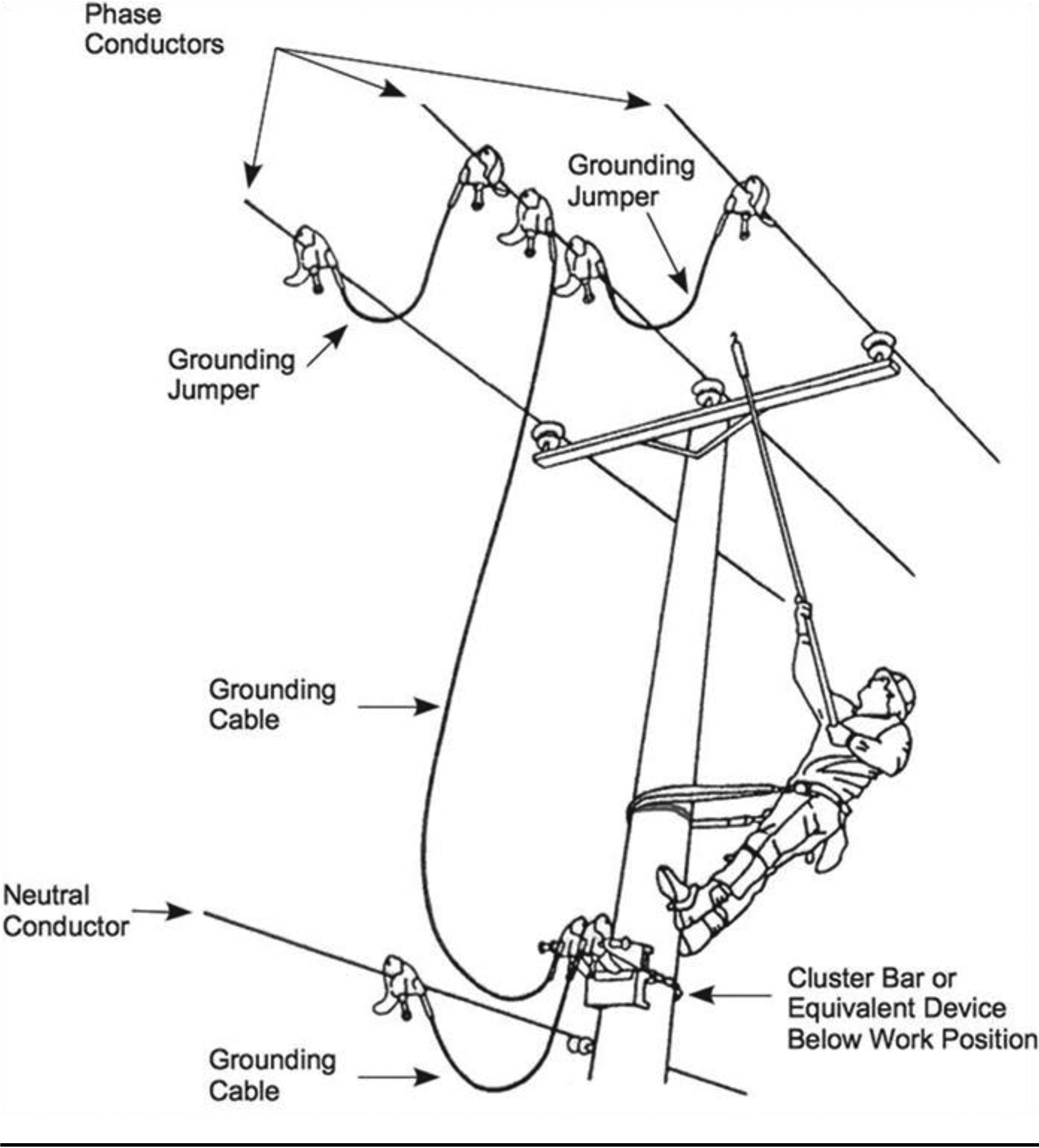

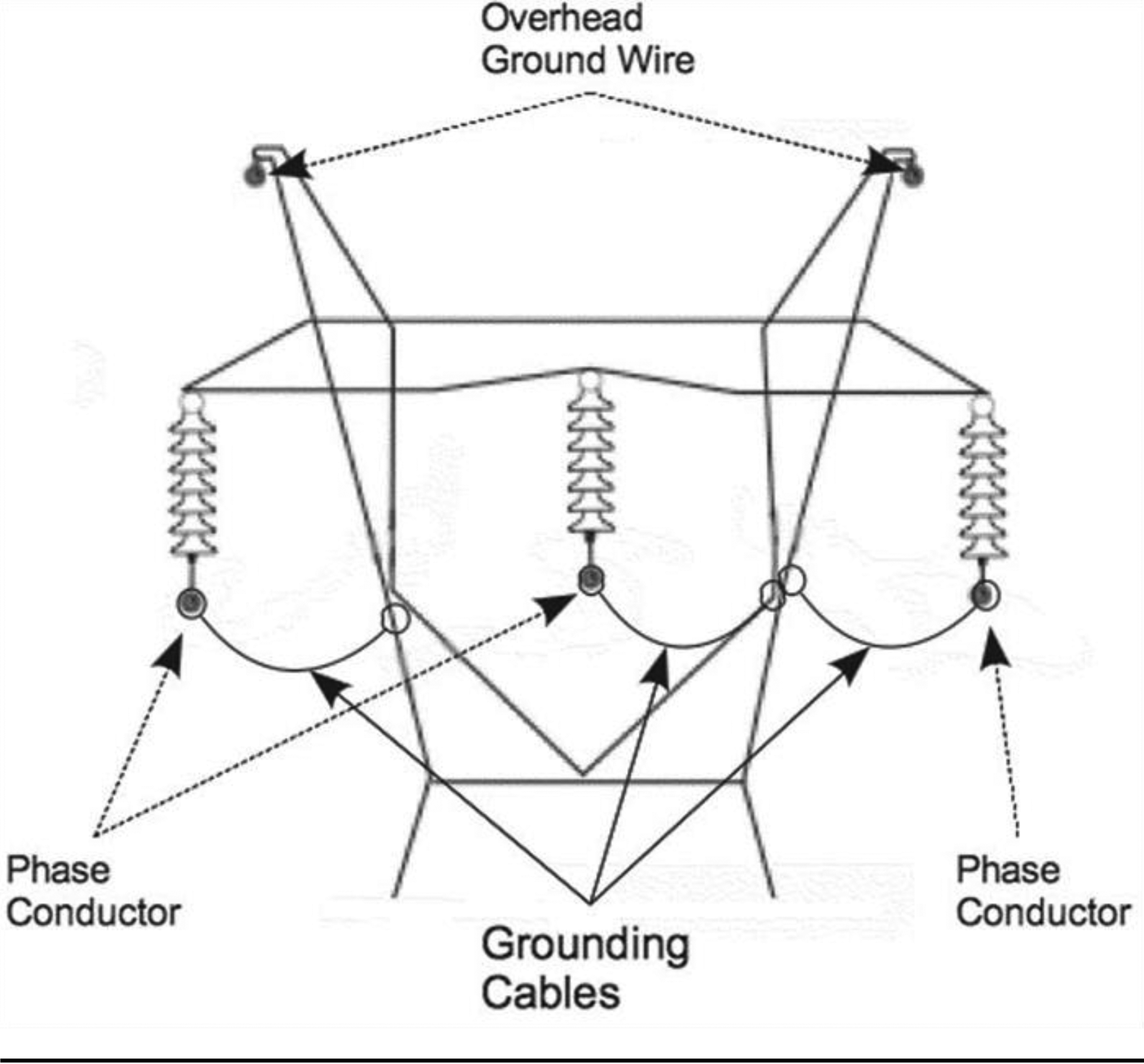

WAC 296-45-345 Grounding for the protection of employees.

• | Add "and bonding jumpers" to subsection (3). Also, add a note relating to bonding jumpers. |

• | Update ASTM reference in the note. |

• | Add language to subsection (6) relating to the order of connection using OSHA language. |

• | Update language referencing Appendix B. |

WAC 296-45-355 Underground grounding.

• | Housekeeping change in subsection (3). |

WAC 296-45-365 Testing and test facilities.

• | Change "qualified employees" to "qualified electrical employees" in the note. |

• | Update language referencing Appendix B. |

WAC 296-45-375 Mechanical equipment, including aerial manlift equipment.

• | Add references in subsections (1)(a) using OSHA language. Renumber subsection. |

• | Housekeeping change in subsection (1)(d). |

• | Update the table reference in subsection (10)(a). Change "qualified employee" to "qualified electrical employee." |

• | Update the table reference in subsection (10)(c)(ii). |

• | Add the word "mechanical" to subsection (10)(c)(iii)(B) to match OSHA. |

• | Update language referencing Appendix B. |

WAC 296-45-385 Overhead lines.

• | Housekeeping change in the note, subsections (1)(c), (13)(d) and (16). |

• | Update language referencing Appendix B and C. |

• | Add language relating to temporary protective grounds to subsection (2)(e) using OSHA language. |

• | Delete subsections (2)(e)(i) through (v) since covered by new OSHA language. Add notes using OSHA language. |

• | Change "qualified employees" to "qualified electrical employees" throughout this section. |

WAC 296-45-455 Line-clearance tree-trimming operations.

• | Change "qualified employees" to "qualified electrical employees" in this section. |

• | Housekeeping change in subsection (2) and (2)(c). |

• | Update the table references in subsections (2)(b), (3), (4) and (5). |

WAC 296-45-45505 Brush chippers.

• | Add a reference in subsection (2) and update a reference in subsection (5). |

WAC 296-45-475 Substations.

• | Update ANSI references throughout this section. |

• | Change "qualified persons" to "qualified electrical employees" throughout this section. |

• | Update the table references in subsection (6). |

WAC 296-45-48515 Access and working space.

• | Update ANSI references throughout this section. |

WAC 296-45-48525 Guarding of energized parts.

• | Update ANSI references throughout this section. |

• | Change "qualified persons" to "qualified electrical employees" in subsection (2). |

WAC 296-45-545 Trolley maintenance, jumpering or bypassing.

• | Change "lineworkers" to "qualified electrical employees" throughout this section. |

WAC 296-45-903 Appendix B—Protection from step and touch potentials—Nonmandatory.

• | Update this appendix to match OSHA. |

WAC 296-45-905 Appendix C—Methods of inspecting and testing wood poles—Nonmandatory.

• | Update this appendix to match OSHA. |

NEW SECTIONS:

WAC 296-45-067 Information transfer.

• | Create this section relating to host and contract employers using OSHA language. |

WAC 296-45-902 Appendix A—Working on exposed energized parts.

• | Add this appendix from 29 C.F.R. 1910.269. |

WAC 296-45-906 Appendix D—Protection from flames and arcs—Nonmandatory.

• | Add this appendix from 29 C.F.R. 1910.269 and add applicable WAC numbers. |

WAC 296-45-907 Appendix E—Work-positioning equipment inspection guidelines—Nonmandatory.

• | Add this appendix from 29 C.F.R. 1910.269. |

WAC 296-45-908 Appendix F—Other applicable safety and health Washington administrative codes.

• | Add this appendix as a resource. |

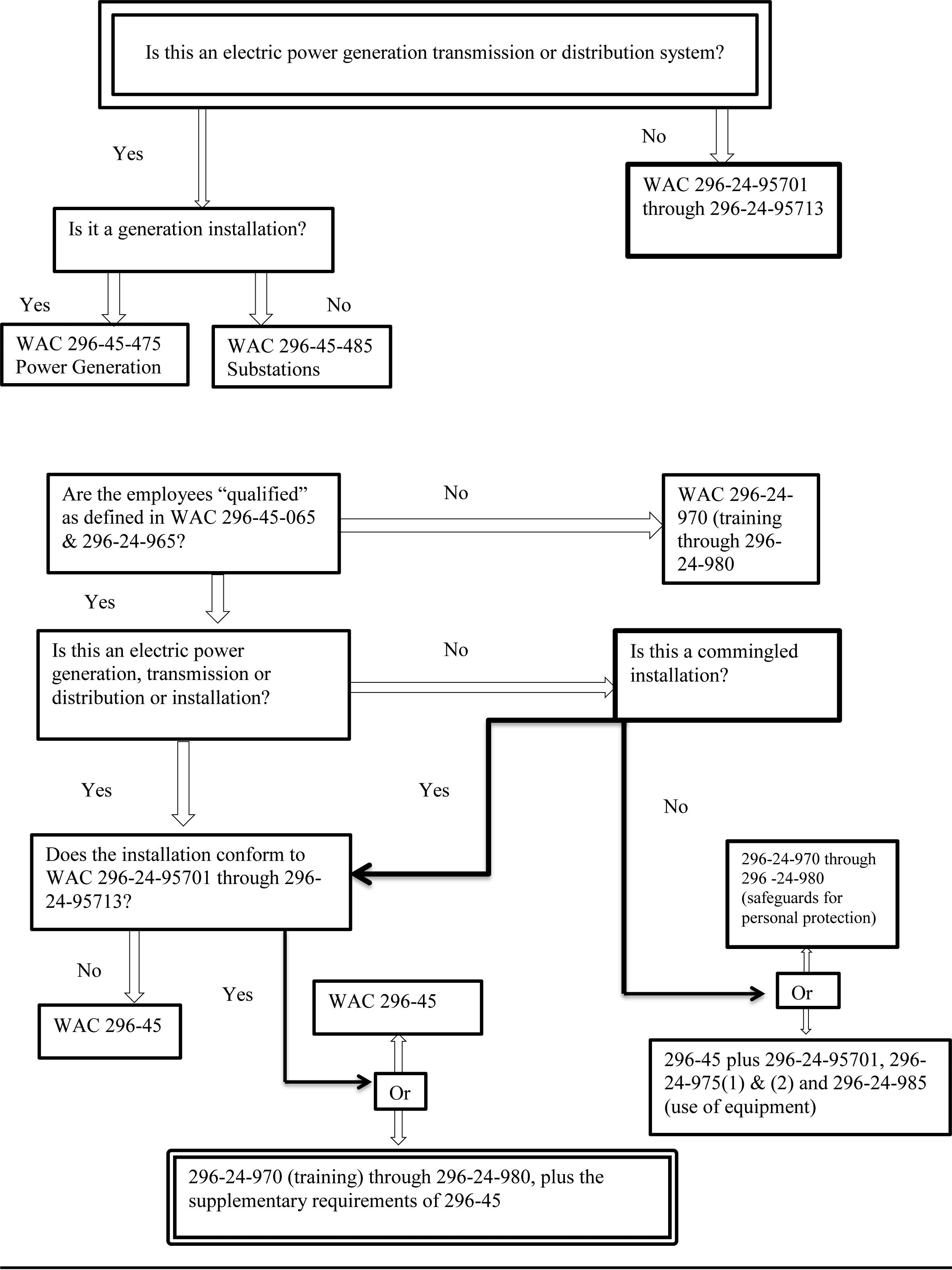

WAC 296-45-909 Appendix G—Flow chart—Nonmandatory.

• | Add this appendix from 29 C.F.R. 1910.269. |

WAC 296-45-910 Appendix H—Reference documents.

• | Add this appendix from 29 C.F.R. 1910.269. |

REPEALED SECTION:

WAC 296-45-901 Appendix A—Nonmandatory.

Reasons Supporting Proposal: By law, L&I's division of occupational safety and health is required to update our rules to be at-least-as-effective-as OSHA.

OSHA's final rule includes new or revised requirements for fall protection, minimum approach distances, and arc-flash protection, and for host employers and contract employers to exchange safety-related information.

Statute Being Implemented: Chapter 49.17 RCW.

Rule is necessary because of federal law, 29 C.F.R. 1910 Subpart R; 29 C.F.R. 1926 Subpart V.

Name of Proponent: L&I, governmental.

Name of Agency Personnel Responsible for Drafting: Chris Miller, Tumwater, Washington, (360) 902-5516; Implementation and Enforcement: Anne Soiza, Tumwater, Washington, (360) 902-5090.

No small business economic impact statement has been prepared under chapter 19.85 RCW. The department estimates that the proposed rule changes will, on average, impose no more than minor costs on a business in any affected industry and a small business economic impact statement report is not required for this rule-making project.

A cost-benefit analysis is required under RCW 34.05.328. A preliminary cost-benefit analysis may be obtained by contacting Cynthia Ireland, P.O. Box 44620, Olympia, WA 98504-4620, phone (360) 902-5522, fax (360) 902-5619, e-mail cynthia.ireland@lni.wa.gov.

December 8, 2015

Joel Sacks

Director

Chapter 296-45 WAC

((SAFETY STANDARDS FOR ELECTRICAL WORKERS)) ELECTRIC POWER GENERATION, TRANSMISSION, AND DISTRIBUTION

AMENDATORY SECTION (Amending WSR 01-11-038, filed 5/9/01, effective 9/1/01)

WAC 296-45-015 Scope and application.

(1) This chapter covers the operation ((and)), maintenance, and construction of electric power generation, control, transformation, transmission, and distribution lines and equipment. These provisions apply to:

(a) Power generation, transmission, and distribution installations, including related equipment for the purpose of communication or metering, which are accessible only to qualified electrical employees;

Note: | The types of installations covered by this chapter include the generation, transmission, and distribution installations of electric utilities, as well as equivalent installations of industrial establishments. Trolley maintenance, jumpering, and bypass is also covered by this chapter. Supplementary electric generating equipment that is used to supply a workplace for emergency, standby, or similar purposes only is covered under Part L of chapter 296-24 WAC and WAC 296-800-280. |

(b) Other installations at an electric power generating station, as follows:

(i) Fuel and ash handling and processing installations, such as coal conveyors;

(ii) Water and steam installations, such as penstocks, pipelines, and tanks, providing a source of energy for electric generators; and

(iii) Chlorine and hydrogen systems.

(c) Test sites where electrical testing involving temporary measurements associated with electric power generation, transmission, and distribution is performed in laboratories, in the field, in substations, and on lines, as opposed to metering, relaying, and routine line work;

(d) Work on or directly associated with the installations covered in subsections (1)(a) through (c) of this section; and

(e) Line-clearance tree-trimming operations, as follows:

(i) This chapter except WAC 296-45-455, applies to line-clearance tree-trimming operations performed by qualified electrical employees (those who are knowledgeable in the construction and operation of electric power generation, transmission, or distribution equipment involved, along with the associated hazards).

(ii) WAC 296-45-065, 296-45-125, 296-45-135, 296-45-255, 296-45-315, 296-45-375, and 296-45-455 through 296-45-45530 apply to line-clearance tree-trimming operations performed by line-clearance tree trimmers who are not qualified electrical employees.

(2) Notwithstanding subsection (1) of this section, this chapter does not apply to electrical installations, electrical safety-related work practices, or electrical maintenance considerations covered by Part L of chapter 296-24 WAC and WAC 296-800-280.

Note 1: | Work practices conforming to WAC 296-24-970 through 296-24-985 are considered as complying with the electrical safety-related work practice requirements of this chapter, provided the work is being performed on a generation or distribution installation meeting WAC 296-24-95601 through 296-24-95699. This chapter also applies to work by qualified ((persons)) electrical employees directly on or associated with installations of electric power generation, transmission, and distribution lines or equipment, regardless of compliance with WAC 296-24-970 through 296-24-985. |

Note 2: | Work practices performed by qualified ((persons)) electrical employees and conforming to this chapter are considered as complying with WAC 296-24-95601 through 296-24-95699. |

(3) This section applies in addition to all other applicable safety and health standards administered by the department. Specific references in this section to other standards are provided for emphasis only.

(4) Operation, conditions, work methods and other work related situations or activities not specifically covered by this chapter are subject to the rules and regulations of chapter 296-24 WAC((,)) General safety and health standards; chapter 296-27 WAC Recordkeeping and reporting; chapter 296-62 WAC((,)) General occupational health standards; chapter 296-155 WAC((,)) Safety standards for construction work; chapter 296-800 WAC((,)) Safety and health core rules; and, insofar as applicable to employee safety and health, chapter 19.29 RCW. Additionally, operations, conditions, work methods and other work related situations or activities may be subject to additional rules and regulations depending upon the nature of the work being performed.

(5) These rules shall not apply to the use of existing electrical installations during their lifetime, provided they are maintained in good condition and in accordance with the applicable safety factor requirements and the rules in effect at the time they were installed, and provided that reconstruction shall conform to the rules as herein provided.

(6) Any rule, regulation or standard contained within this chapter, if subject to interpretation, shall be interpreted so as to achieve employee safety, which is the ultimate purpose of this chapter.

(7) Should a rule or standard contained within this chapter conflict, in any manner, with a standard or rule contained within any other chapter of Title 296 WAC the standard or rule contained herein shall apply so long as the work being done is power generation, transmission, and distribution installations, including related equipment for the purpose of communication or metering, which are accessible only to qualified electrical employees. If there are rules within this chapter that conflict, the rule that provides the greatest employee safety will apply.

(8) Neither the promulgation of these rules, nor anything contained in these rules shall be construed as affecting the relative status or civil rights or liabilities between employers and their employees and/or the employees of others and/or the public generally; nor shall the use herein of the words "duty" and "responsibility" or either, import or imply liability other than provided for in the industrial insurance and safety laws of the state of Washington, to any person for injuries due to negligence predicated upon failure to perform or discharge any such "duty" or "responsibility," but failure on the part of the employees, leadworker, or employer to comply with any compulsory rule may be cause for the department of labor and industries to take action in accordance with the industrial insurance and safety laws.

(9) "Shall" and "must" as used in this chapter make the provisions mandatory. "Should," "may," or "it is recommended" are used to indicate the provisions are not mandatory but are recommended.

(10) If any section, subsection, phrase, or provisions of this chapter or part thereof should be held invalid by any court for any reason, such invalidity shall not in any way affect the validity of the remainder of this chapter, unless such decision renders the remainder of the provision unintelligible, or changes the meaning of such other provision or provisions.

(11) When the language used in this chapter indicates that it is the responsibility, duty, or obligation of the leadworker or other employee, it shall also be the employer's responsibility, obligation, and duty.

(12) Whenever this chapter refers to the provisions of another safety and health standard or statute affecting safety and health, such reference refers to the statute or code in effect at the time the work is being performed.

AMENDATORY SECTION (Amending WSR 14-07-086, filed 3/18/14, effective 5/1/14)

WAC 296-45-035 Definitions.

These definitions apply to chapter 296-45 WAC.

"Aerial manlift equipment" - Equipment such as extended towers, boom-mounted cages or baskets, and truck-mounted ladders, that is primarily designed to place personnel and equipment aloft to work on elevated structures and equipment.

"Affected employee" - An employee whose job requires him or her to operate or use a machine or equipment on which servicing or maintenance is being performed under lockout or tagout, or whose job requires him or her to work in an area in which such servicing or maintenance is being performed.

"Apprentice" - An employee who is being trained to be journey level.

"Approved" - Meets or exceeds the recognized standards of safety within the industry.

"Approved protectors" - Gloves worn over rubber insulating gloves which are of such material or substance and so constructed as to protect the rubber gloves from abrasions, lacerations, or other physical damage which might otherwise occur to rubber gloves. Approved protectors must conform to the standards which are recognized by the industry.

"Attendant" - An employee assigned to remain immediately outside the entrance to an enclosed or other space to render assistance as needed to employees inside the space.

"Authorized employee" - An employee who locks out or tags out machines or equipment in order to perform servicing or maintenance on that machine or equipment. An affected employee becomes an authorized employee when that employee's duties include performing servicing or maintenance covered under this section.

"Automatic ((circuit recloser)) reclosing device" - A self-controlled device for interrupting and reclosing an alternating current circuit with a predetermined sequence of opening and reclosing followed by resetting, hold-closed, or lockout operation.

"Barricade" - A physical obstruction such as tapes, cones, or A-frame type wood or metal structures intended to provide a warning about and to limit access to a hazardous area.

"Barrier" - A physical obstruction which is intended to prevent contact with energized lines or equipment or to prevent unauthorized access to a work area.

"Bond" - The electrical interconnection of conductive parts designed to maintain a common electrical potential.

"Bus" - A conductor or a group of conductors that serve as a common connection for two or more circuits.

"Bushing" - An insulating structure, including a through conductor or providing a passageway for such a conductor, with provision for mounting on a barrier, conducting or otherwise, for the purposes of insulating the conductor from the barrier and conducting current from one side of the barrier to the other.

"Cable" - A conductor with insulation, or a stranded conductor with or without insulation and other coverings (single-conductor cable), or a combination of conductors insulated from one another (multiple-conductor cable).

"Cable sheath" - A conductive protective covering applied to cables.

Note: | A cable sheath may consist of multiple layers of which one or more is conductive. |

"Circuit" - A conductor or system of conductors through which an electric current is intended to flow.

"Clearance" (between objects) - The clear distance between two objects measured surface to surface.

"Clearance" (for work) - Authorization to perform specified work or permission to enter a restricted area.

"Communication lines." (See "Lines, communication.")

"Conductor" - A material, usually in the form of a wire, cable, or bus bar, used for carrying an electric current.

"Contract employer" - An employer, other than a host employer, that performs work covered by this chapter under contract.

"Covered conductor" - A conductor covered with a dielectric having no rated insulating strength or having a rated insulating strength less than the voltage of the circuit in which the conductor is used.

"Current-carrying part" - A conducting part intended to be connected in an electric circuit to a source of voltage. Noncurrent-carrying parts are those not intended to be so connected.

"Deenergized" - Free from any electrical connection to a source of potential difference and from electric charge; not having a potential difference from that of the earth.

Note: | The term is used only with reference to current-carrying parts, which are sometimes energized (alive). |

"Designated employee((/person))" - ((An employee/)) A person who is designated by the employer to perform specific duties under the terms of this ((section)) chapter and who is knowledgeable in the construction and operation of the equipment and the hazards involved.

Note: | Considering an employee to be a designated employee will depend on various circumstances in the workplace, on the level of training they have received, and the proficiency demonstrated by the employee with the tasks required of the job. |

"Electric line truck" - Any vehicle used to transport employees, tools, and material, which serves as a traveling workshop for electric power line construction and maintenance work. It may be equipped with a boom and auxiliary equipment for setting poles, digging holes, and elevating material and/or workers.

"Electric supply equipment" - Equipment that produces, modifies, regulates, controls, or safeguards a supply of electric energy.

"Electric supply lines." (See "Lines, electric supply.")

(("Electric utility" - An organization responsible for the installation, operation, or maintenance of an electric supply system.))

"Emergency" - An unforeseen occurrence endangering life, limb, or property.

"Enclosed" - Surrounded by a case, cage, fence or otherwise which will protect the contained equipment and prevent accidental contact of a person with live parts.

"Enclosed space" - A working space, such as a manhole, vault, tunnel, or shaft, that has a limited means of egress or entry, that is designed for periodic employee entry under normal operating conditions, and that under normal conditions does not contain a hazardous atmosphere, but that may contain a hazardous atmosphere under abnormal conditions.

Note: | Spaces that are enclosed but not designed for employee entry under normal operating conditions are not considered to be enclosed spaces for the purposes of this section. Similarly, spaces that are enclosed and that are expected to contain a hazardous atmosphere are not considered to be enclosed spaces for the purposes of this section. Such spaces meet the definition of permit spaces in ((WAC 296-62-145)) chapter 296-809 WAC, Confined spaces, and entry into them must be performed in accordance with that standard. |

"Energized" (alive, live) - Electrically connected to a source of potential difference, or electrically charged so as to have a potential significantly different from that of earth in the vicinity.

"Energy isolating device" - A physical device that prevents the transmission or release of energy, including, but not limited to, the following: A manually operated electric circuit breaker, a disconnect switch, a manually operated switch, a slide gate, a slip blind, a line valve, blocks, and any similar device with a visible indication of the position of the device. (Push buttons, selector switches, and other control-circuit-type devices are not energy isolating devices.)

"Energy source" - Any electrical, mechanical, hydraulic, pneumatic, chemical, nuclear, thermal, or other energy source that could cause injury to personnel.

"Entry" (as used in WAC 296-45-205 of this chapter) - The action by which a person passes through an opening into an enclosed space. Entry includes ensuing work activities in that space and is considered to have occurred as soon as any part of the entrant's body breaks the plane of an opening into the space.

"Equipment" (electric) - A general term including material, fittings, devices, appliances, fixtures, apparatus, and the like used as part of or in connection with an electrical installation.

"Exposed" - Not isolated or guarded.

"Fall restraint system" - A fall protection system that prevents the user from falling any distance.

"Fault current" - The current that flows in an electrical system because of a defect in the circuit induced accidentally or otherwise.

"First-aid training" - Training in the initial care, including cardiopulmonary resuscitation (which includes chest compressions, rescue breathing, and, as appropriate, other heart and lung resuscitation techniques), performed by a person who is not a medical practitioner, of a sick or injured person until definitive medical treatment can be administered.

"Fixed ladder" - A ladder that is permanently secured to a structure.

"Ground" - A conducting connection, whether intentional or accidental, between an electric circuit or equipment and the earth, or to some conducting body that serves in place of the earth.

"Grounded" - Connected to earth or to some conducting body that serves in place of the earth.

"Grounded system" - A system of conductors in which at least one conductor or point (usually the middle wire, or neutral point of transformer or generator windings) is intentionally grounded either solidly or through a current-limiting device (not a current-interrupting device).

"Groundperson" - A member of crew working on ground under direction of a leadworker.

"Guarded" - Covered, fenced, enclosed, or otherwise protected, by means of suitable covers or casings, barrier rails or screens, mats, or platforms, designed to prevent the possibility, under normal conditions, of dangerous approach or accidental contact by persons or objects.

Note: | Wires which are insulated, but not otherwise protected, are not considered as guarded. |

"Hazardous atmosphere" - An atmosphere that may expose employees to the risk of death, incapacitation, impairment of ability to self-rescue (that is, escape unaided from an enclosed space), injury, or acute illness from one or more of the following causes:

• Flammable gas, vapor, or mist in excess of 10 percent of its lower flammable limit (LFL);

• Airborne combustible dust at a concentration that meets or exceeds its LFL;

Note: | This concentration may be approximated as a condition in which the dust obscures vision at a distance of 5 feet (1.52 m) or less; |

• Atmospheric oxygen concentration below 19.5 percent or above 23.5 percent;

• Atmospheric concentration of any substance for which a dose or a permissible exposure limit is published in chapter 296-62 WAC, Part L, or in chapter 296-62 WAC, toxic and hazardous substances, and which could result in employee exposure in excess of its dose or permissible exposure limit;

Note: | An atmospheric concentration of any substance that is not capable of causing death, incapacitation, impairment of ability to self-rescue, injury, or acute illness due to its health effects is not covered by this provision. |

• Any other atmospheric condition that is "immediately dangerous to life or health" (IDLH).

(("IDLH" - Any condition that poses an immediate or delayed threat to life or that would cause irreversible adverse health effects or that would interfere with an individual's ability to escape unaided from a permit space.

Note: | Some materials (hydrogen fluoride gas and cadmium vapor, for example) may produce immediate transient effects that, even if severe, may pass without medical attention, but are followed by sudden, possibly fatal collapse 12-72 hours after exposure. The victim "feels normal" from recovery from transient effects until collapse. Such materials in hazardous quantities are considered to be "immediately" dangerous to life or health. |

Note: | For air contaminants for which WISHA has not determined a dose or permissible exposure limit, other sources of information, such as Safety Data Sheets that comply with the hazard communication program, WAC 296-901-140, published information, and internal documents can provide guidance in establishing acceptable atmospheric conditions.)) |

"High-power tests" - Tests in which fault currents, load currents, magnetizing currents, and line-dropping currents are used to test equipment, either at the equipment's rated voltage or at lower voltages.

"High-voltage tests" - Tests in which voltages of approximately 1000 volts are used as a practical minimum and in which the voltage source has sufficient energy to cause injury.

"High wind" - A wind of such velocity that the following hazards would be present:

• An employee would be exposed to being blown from elevated locations; or

• An employee or material handling equipment could lose control of material being handled; or

• An employee would be exposed to other hazards not controlled by the standard involved.

Note: | Winds exceeding 40 miles per hour (64.4 kilometers per hour), or 30 miles per hour (48.3 kilometers per hour) if material handling is involved, are normally considered as meeting this criteria unless precautions are taken to protect employees from the hazardous effects of the wind. |

"Host employer" - An employer that operates, or that controls the operating procedures for, an electric power generation, transmission, or distribution installation on which a contract employer is performing work covered by this chapter.

Note: | The division of occupational safety and health (DOSH) will treat the electric utility or the owner of the installation as the host employer if it operates or controls operating procedures for the installation. If the electric utility or installation owner neither operates nor controls operating procedures for the installation, DOSH will treat the employer that the utility or owner has contracted with to operate or control the operating procedures for the installation as the host employer. In no case will there be more than one host employer. |

"IDLH" - Any condition that poses an immediate or delayed threat to life or that would cause irreversible adverse health effects or that would interfere with an individual's ability to escape unaided from a permit space.

Note: | Some materials (hydrogen fluoride gas and cadmium vapor, for example) may produce immediate transient effects that, even if severe, may pass without medical attention, but are followed by sudden, possibly fatal collapse twelve to seventy-two hours after exposure. The victim "feels normal" from recovery from transient effects until collapse. Such materials in hazardous quantities are considered to be "immediately" dangerous to life or health. |

Note: | For air contaminants for which WISHA has not determined a dose or permissible exposure limit, other sources of information, such as safety data sheets that comply with the hazard communication program, WAC 296-901-140, published information, and internal documents can provide guidance in establishing acceptable atmospheric conditions. |

"Insulated" - Separated from other conducting surfaces by a dielectric (including air space) offering a high resistance to the passage of current.

Note: | When any object is said to be insulated, it is understood to be insulated for the conditions to which it is normally subjected. Otherwise, it is, within the purpose of this section, uninsulated. |

"Insulation" (cable) - That which is relied upon to insulate the conductor from other conductors or conducting parts or from ground.

"Insulation shielding" - An envelope which encloses the insulation of a cable and provides an equipotential surface in contact with cable insulation.

"Isolated" - An object that is not readily accessible to persons unless special means of access are used.

"Leadworker" - The person directly in charge of workers doing the work, regardless of title.

"Line-clearance tree trimmer" - An employee who, through related training or on-the-job experience or both, is familiar with the special techniques and hazards involved in line-clearance tree trimming.

Note 1: | An employee who is regularly assigned to a line-clearance tree-trimming crew and who is undergoing on-the-job training and who, in the course of such training, has demonstrated an ability to perform duties safely at his or her level of training and who is under the direct supervision of a line-clearance tree trimmer is considered to be a line-clearance tree trimmer. |

Note 2: | A line-clearance tree trimmer is not considered to be a "qualified electrical employee" under this section unless ((he or she has)) they have the training required for a qualified electrical employee under WAC 296-45-065. However, under the electrical safety-related work practices standard, a line-clearance tree trimmer is considered to be a "qualified employee." Tree trimming performed by such "qualified employees" is not subject to the electrical safety-related work practice requirements contained in WAC 296-24-970. (See also the note following WAC 296-24-970 for information regarding the training an employee must have to be considered a qualified employee.) |

"Line-clearance tree trimming" - The pruning, trimming, repairing, maintaining, removing, or clearing of trees or the cutting of brush that is within ((10 feet (305 cm))) the following distance of electric supply lines and equipment:

• For voltages to ground of 50 kilovolts or less - 3.05 meters (10 feet);

• For voltages to ground of more than 50 kilovolts - 3.05 meters (10 feet) plus 0.10 meters (4 inches) for every 10 kilovolts over 50 kilovolts.

"Lines" -

• "Communication lines" - The conductors and their supporting or containing structures which are used for public or private signal or communication service, and which operate at potentials not exceeding 400 volts to ground or 750 volts between any two points of the circuit, and the transmitted power of which does not exceed 150 watts. If the lines are operating at less than 150 volts, no limit is placed on the transmitted power of the system. Under certain conditions, communication cables may include communication circuits exceeding these limitations where such circuits are also used to supply power solely to communication equipment.

Note: | Telephone, telegraph, railroad signal, data, clock, fire, police alarm, cable television, and other systems conforming with this definition are included. Lines used for signaling purposes, but not included under this definition, are considered as electric supply lines of the same voltage. |

• "Electric supply lines" - Conductors used to transmit electric energy and their necessary supporting or containing structures. Signal lines of more than 400 volts are always supply lines within this section, and those of less than 400 volts are considered as supply lines, if so run and operated throughout.

"Live-line tools and ropes" - Tools and ropes specifically designed for work on energized high voltage lines and equipment.

"Load-break elbow" - A connector designed to close and interrupt current on energized circuits within the design current and voltage rating.

"Manhole" - A subsurface enclosure which personnel may enter and which is used for the purpose of installing, operating, and maintaining submersible equipment or cable.

"Manhole steps" - A series of steps individually attached to or set into the walls of a manhole structure.

"May" and "should" or "it is recommended" are used to indicate the provisions are not mandatory but are recommended.

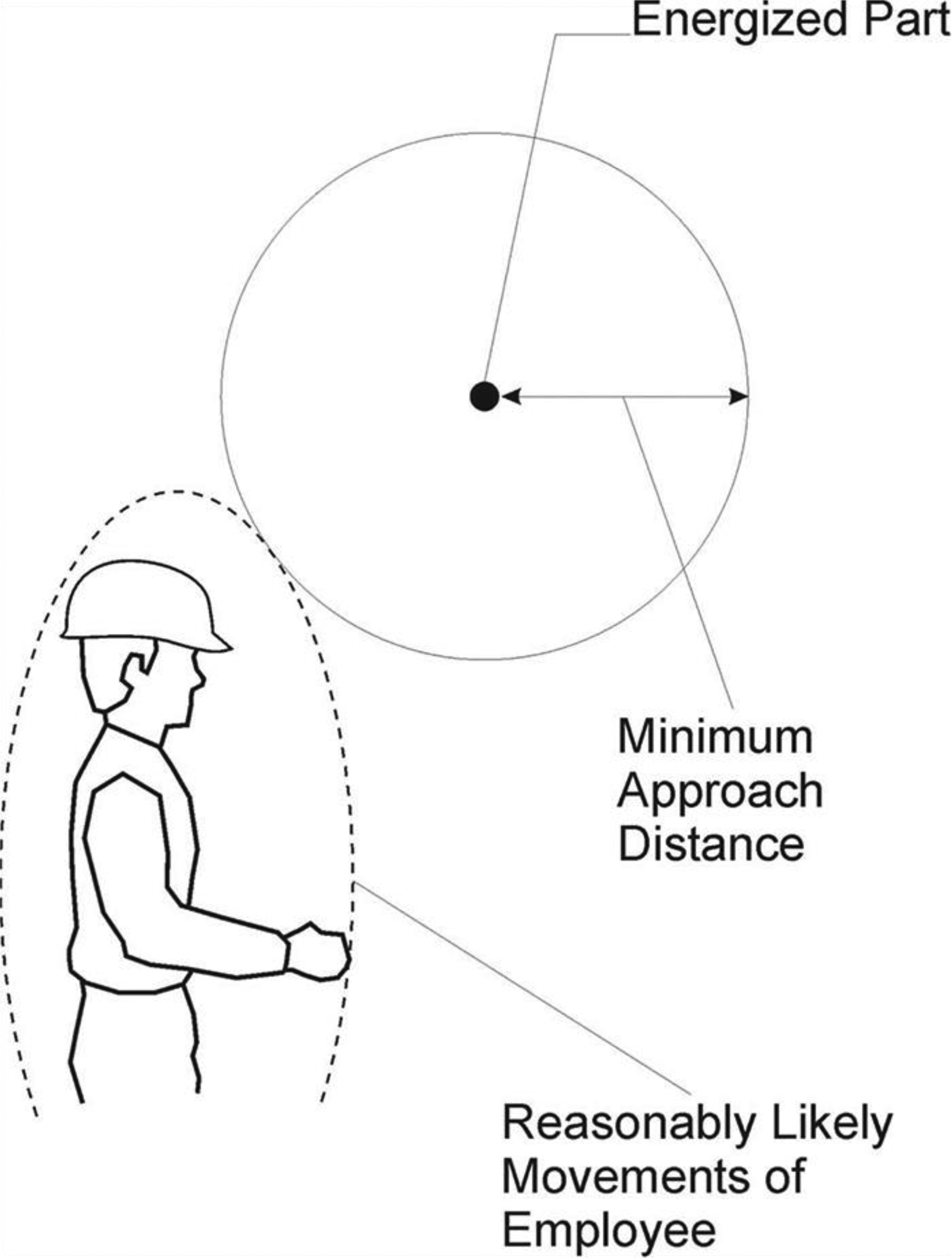

"Minimum approach distance" - The closest distance an employee is permitted to approach an energized or a grounded object.

"Must" and "shall" as used in this chapter make the provisions mandatory.

"Network system" - An electrical installation fed from multiple primary sources directly associated with area-wide secondary network connected into a common grid.

"Neutral" - A system in which one conductor is used as the neutral for one or more circuits; one conductor may be used as the neutral for both primary and secondary circuits of a distribution system.

"Personal fall arrest system" - A system used to arrest an employee in a fall from a working level.

"Pole" - Any device used to support a power distribution or transmission line. The pole may be made of any substance including wood, concrete, metal, is usually cylindrical in shape and comparatively slender. It is the upright standard to which is affixed part of the power distribution and transmission line system as defined in this chapter.

"Power dispatcher" (load dispatcher or system operator) - A person who has been designated by the employer as having authority over switching and clearances of high voltage lines and station equipment.

"Protective devices" - Devices such as rubber gloves, rubber blankets, line hose, rubber boots, or other insulating devices, which are specifically designed for the protection of employees.

(("Public highway" - Every way, land, road, street, boulevard, and every other way or place in the state open as a matter of right to public vehicular travel, both inside and outside the limits of cities and towns, regardless of ownership.))

"Qualified ((person or qualified)) electrical employee" - A person who is familiar ((with)) and knowledgeable in the construction ((of, or)) and operation of the electric power generation, transmission, and distribution equipment involved, and such lines and/or equipment that concerns his/her position and who is fully aware of the hazards connected therewith, or, one who has passed a journey status examination for the particular branch of the electrical trades with which he/she may be connected.

((Note 1:)) Notes: | • An employee must have the training required by WAC 296-45-065(((1))) in order to be considered a qualified electrical employee. |

((Note 2:)) | (((Apprentice) Except under WAC 296-45-25510(12),)) • An employee who is undergoing on-the-job training ((and)) (an apprentice) who, in the course of such training, has demonstrated an ability to perform duties safely at his or her level of training and who is under the direct supervision of a qualified ((person)) electrical employee is considered to be a qualified ((person)) electrical employee for the performance of those duties. |

• An employee having experience and training comparable to journey level would be considered a qualified electrical employee. |

"Roadway or public highway" - Every way, land, road, street, boulevard, and every other way or place in the state open as a matter of right to public vehicular travel, both inside and outside the limits of cities and towns, regardless of ownership.

"Rubber" - Any goods, equipment, or tool made out of either natural or synthetic rubber.

"Secured ladder" - A ladder which is not capable of being dislodged from the top by lateral, or jerking motion(s).

"Shall" and "must" as used in this chapter make the provisions mandatory.

"Sheath" - As applied to tools carried in a lineman's tool belt, a sheath that effectively covers the tool and prevents such tool from falling from the belt.

"Should" and "may" or "it is recommended" are used to indicate the provisions are not mandatory but are recommended.

"Statistical sparkover voltage" - A transient overvoltage level that produces a 97.72 percent probability of sparkover (that is, two standard deviations above the voltage at which there is a 50 percent probability of sparkover).

"Statistical withstand voltage" - A transient overvoltage level that produces a 0.14 percent probability of sparkover (that is, three standard deviations below the voltage at which there is a 50 percent probability of sparkover).

"Step bolt" - A bolt or rung attached at intervals along a structural member and used for foot placement during climbing or standing.

"Supporting structure" - The main supporting unit (usually a pole or tower).

"Switch" - A device for opening and closing or for changing the connection of a circuit. In these rules, a switch is understood to be manually operable, unless otherwise stated.

"System operator or power dispatcher" - A qualified ((person)) electrical employee who has been designated by the employer and having authority over switching, clearances, and operation of the system and its parts.

"Tag" - A system or method of identifying circuits, systems, or equipment for the purpose of alerting employees and others that the circuit, system, or equipment is being worked on.

(("Underground network" - An underground electrical installation fed from multiple primary sources directly associated with area-wide secondary network connected into a common grid.))

"Underground residential distribution system" (URD) - An electrical installation normally fed from a single primary source which may feed one or more transformers with secondaries not connected to a common grid.

"Utility" - An organization responsible for the installation, operation, or maintenance of electric supply or communications systems.

"Vault" - An enclosure, above or below ground, which personnel may enter and which is used for the purpose of installing, operating, or maintaining equipment or cable.

"Vented vault" - A vault that has provision for air changes using exhaust flue stacks and low level air intakes operating on differentials of pressure and temperature providing for airflow which precludes a hazardous atmosphere from developing.

"Voltage" - The effective (rms) potential difference between any two conductors or between a conductor and ground. Voltages are expressed in nominal values unless otherwise indicated. The nominal voltage of a system or circuit is the value assigned to a system or circuit of a given voltage class for the purpose of convenient designation. The operating voltage of the system may vary above or below this value.

Note: | Low voltage includes voltages from 50 to 600 volts. High voltage shall mean those voltages of 601 volts to 230,000. Extra high voltage means any voltage over 230,000 volts. Where the words "high voltage" are used in this chapter it shall include extra high voltage, unless otherwise specified. |

"Work-positioning equipment" - A body belt or body harness system rigged to allow an employee to be supported on an elevated vertical surface, such as a utility pole or tower leg, and work with both hands free while leaning.

AMENDATORY SECTION (Amending WSR 03-17-071, filed 8/19/03, effective 11/1/03)

WAC 296-45-045 NESC applicable.

(1) All electric utilities and entities operating transmission and distribution facilities within the state of Washington must design, construct, operate, and maintain their lines and equipment according to the requirements of the ((2002)) 2012 National Electrical Safety Code (NESC) (ANSI-C2), parts (1), (2), and (3).

Note: | The department has copies of the NESC available for review at each service location across the state. To purchase a copy, write to: |

The Institute of Electrical and Electronics Engineers, Inc. (IEEE, Inc.) 445 Hoes Lane Piscataway, NJ 08855-1331 |

(2) The employer must ensure that climbing space is provided on all poles and structures. The climbing space must meet the requirements of the ((2002)) 2012 National Electrical Safety Code (NESC) (ANSI-C2), except that Rule 236H does not apply.

AMENDATORY SECTION (Amending WSR 14-07-086, filed 3/18/14, effective 5/1/14)

WAC 296-45-055 Employer's responsibility.

(1) The employer shall provide and maintain the necessary protective devices specified in these rules and require the employees to use them properly.

(2) The employer shall develop and maintain a hazard communication program as required by ((WAC 296-901-140)) chapter 296-901 WAC, which will provide information to all employees relative to hazardous chemicals or substances to which they are exposed, or may become exposed, in the course of their employment.

(3) There shall be installed and maintained in every fixed establishment employing eight or more persons a safety bulletin board of a size to display and post safety bulletins, newsletters, posters, accident statistics and other safety educational material. It is recommended that safety bulletin boards be painted green and white.

(4) The employer shall require the leadworker to observe and enforce all safety rules and shall furnish a copy of the electrical workers' safety rules to each employee who is covered by these rules.

(5) The employer shall appoint only competent workers to supervise other employees and those appointed shall be responsible for the safety of the employees under their supervision.

AMENDATORY SECTION (Amending WSR 98-07-009, filed 3/6/98, effective 5/6/98)

WAC 296-45-065 Training.

(1) Each employee((s)) shall be trained and proficient in the safety-related work practices, safety procedures, and other safety requirements in this section that pertain to their respective job assignments. Employees shall also be trained in and proficient with any other safety practices, including applicable emergency procedures (such as pole top, aerial, manhole, and tree rescue), that are not specifically addressed by this section but that are related to their work and are necessary for their safety.

(((1))) (2) The degree of training shall be determined by the risk of the employee for the hazard involved.

(3) Qualified electrical employees shall also be trained and competent in:

(a) The skills and techniques necessary to distinguish exposed live parts from other parts of electric equipment;

(b) The skills and techniques necessary to determine the nominal voltage of exposed live parts;

(c) The minimum approach distances specified in this ((section)) chapter corresponding to the voltages to which the qualified electrical employee will be exposed((;)) and the skills and techniques necessary to maintain those distances;

(d) The proper use of the special precautionary techniques, personal protective equipment, insulating and shielding materials, and insulated tools for working on or near exposed energized parts of electric equipment; and

(e) The recognition of electrical hazards to which the employee may be exposed and the skills and techniques necessary to control or avoid these hazards.

Note: | For the purposes of this section, a person must have this training in order to be considered a qualified ((person)) electrical employee. |

(((2))) (4) The employer shall determine, through regular supervision and through inspections conducted on at least an annual basis, that each employee is complying with the safety-related work practices required by this ((section.

(3))) chapter.

(5) An employee shall receive additional training (or retraining) under any of the following conditions:

(a) If the supervision and annual inspections required by subsection (((2))) (4) of this section indicate that the employee is not complying with the safety-related work practices required by this ((section)) chapter; or

(b) If new technology, new types of equipment, or changes in procedures necessitate the use of safety-related work practices that are different from those which the employee would normally use; or

(c) If ((he or she)) the employee must employ safety related work practices that are not normally used during ((his or her)) their regular job duties.

Note: | ((WISHA)) DOSH would consider tasks that are performed less often than once per year to necessitate retraining before the performance of the work practices involved. |

(((4))) (6) The training required by ((WAC 296-45-065)) this section shall be of the classroom or on-the-job type.

(((5))) (7) The training shall establish employee proficiency in the work practices required by this section and shall introduce the procedures necessary for compliance with this section.

(((6))) (8) The employer shall certify that each employee has received the training required by ((WAC 296-45-065)) this section. This certification shall be made when the employee demonstrates proficiency in the work practices involved and shall be maintained for the duration of the employee's employment.

Notes: | • Employment records that indicate that an employee has received the required training are an acceptable means of meeting this requirement. |

• For an employee with previous training, an employer may determine that the employee has demonstrated the proficiency required by this subsection using the following process: - Confirm that the employee has the training required by this section; - Use an examination or interview to make an initial determination that the employee understands the relevant safety related work practices before he or she performs any work covered by this chapter; and | |

• Supervise the employee closely until that employee has demonstrated proficiency as required by this section. |

(9) Each line-clearance tree trimmer who is not a qualified electrical employee shall also be trained and competent in:

(a) The skills and techniques necessary to distinguish exposed live parts from other parts of electric equipment;

(b) The skills and techniques necessary to determine the nominal voltage of exposed live parts; and

(c) The minimum approach distances specified in this chapter corresponding to the voltages to which the employee will be exposed and the skills and techniques necessary to maintain those distances.

NEW SECTION

WAC 296-45-067 Information transfer.

(1) Host employer responsibilities. Before work begins, the host employer shall inform contract employers of:

(a) The characteristics of the host employer's installation that are related to the safety of the work to be performed and are listed in subsection (4)(a) through (e) of this section;

Note: | This subsection requires the host employer to obtain information listed in subsection (4)(a) through (e) of this section if it does not have this information in existing records. |

(b) Conditions that are related to the safety of the work to be performed, that are listed in subsection (4)(f) through (h) of this section, and that are known to the host employer;

Note: | For the purposes of this subsection, the host employer need only provide information to contract employers that the host employer can obtain from its existing records through the exercise of reasonable diligence. This subsection does not require the host employer to make inspections of worksite conditions to obtain this information. |

(c) Information about the design and operation of the host employer's installation that the contract employer needs to make the assessments required by this chapter; and

Note: | This subsection requires the host employer to obtain information about the design and operation of its installation that contract employers need to make required assessments if it does not have this information in existing records. |

(d) Any other information about the design and operation of the host employer's installation that is known by the host employer, that the contract employer requests, and that is related to the protection of the contract employer's employees.

Note: | For the purposes of this subsection, the host employer need only provide information to contract employers that the host employer can obtain from its existing records through the exercise of reasonable diligence. This subsection does not require the host employer to make inspections of worksite conditions to obtain this information. |

(2) Contract employer responsibilities.

(a) The contract employer shall ensure that each of its employees is instructed in the hazardous conditions relevant to the employee's work that the contract employer is aware of as a result of information communicated to the contract employer by the host employer under subsection (1) of this section.

(b) Before work begins, the contract employer shall advise the host employer of any unique hazardous conditions presented by the contract employer's work.

(c) The contract employer shall advise the host employer of any unanticipated hazardous conditions found during the contract employer's work that the host employer did not mention under subsection (1) of this section. The contract employer shall provide this information to the host employer within two working days after discovering the hazardous condition.

(3) Joint host- and contract-employer responsibilities. The contract employer and the host employer shall coordinate their work rules and procedures so that each employee of the contract employer and the host employer is protected as required by this section.

(4) Existing characteristics and conditions. Existing characteristics and conditions of electric lines and equipment that are related to the safety of the work to be performed shall be determined before work on or near the lines or equipment is started. Such characteristics and conditions include, but are not limited to:

(a) The nominal voltages of lines and equipment;

(b) The maximum switching-transient voltages;

(c) The presence of hazardous induced voltages;

(d) The presence of protective grounds and equipment grounding conductors;

(e) The locations of circuits and equipment, including electric supply lines, communication lines, and fire protective signaling circuits;

(f) The condition of protective grounds and equipment grounding conductors;

(g) The condition of poles; and

(h) Environmental conditions relating to safety.

AMENDATORY SECTION (Amending WSR 01-11-038, filed 5/9/01, effective 9/1/01)

WAC 296-45-075 Employer's safety program.

(1) The employer shall hold safety meetings at least once a month, which meetings shall be held at a reasonable time and place as selected by the employer. The employer shall require all employees subject to provisions of this chapter to attend said meetings: Provided, That employees whose presence is otherwise required by reason of an emergency or whose function is such that they cannot leave their station or cease their work without serious detriment to the service provided, such as dispatcher, may be excused from such meeting under those circumstances. Minutes shall be kept of each safety meeting and retained for a period of one year.

(2) The employer or a representative(s) designated shall investigate all accidents or injuries of a serious nature and, where possible, take the proper remedial steps to prevent the occurrence of similar accidents.

(3) The employer shall furnish instructions stating the proper procedure in event of an emergency, which shall include the names of those individuals to be notified and methods of contacting them.

(4) The employer shall provide and make available to all employees accident report and safety suggestion forms or other approved methods. Safety suggestion forms should, where possible, be used for suggesting the elimination of hazardous conditions and such reported suggestions shall be retained (for one year) by the employer or an authorized representative.

(5) ((The employer must notify the department of employee fatalities or catastrophes according to the requirements of WAC 296-800-320.)) For work-related injuries and illnesses involving any employee that resulted in death, inpatient hospitalization, amputation or loss of an eye, the employer must comply with the recordkeeping and reporting regulations located in chapter 296-27 WAC.

(6) Nothing contained within this chapter shall prohibit an employer or an authorized representative from disciplining employees for failure to comply with the provisions of this or any other safety code.

(7) Existing conditions related to the safety of the work to be performed shall be determined before work on or near electric lines or equipment is started. Such conditions include, but are not limited to, the nominal voltages of lines and equipment, the maximum switching transient voltages, the presence of hazardous induced voltages, the presence and condition of protective grounds and equipment grounding conductors, the condition of poles, environmental conditions relative to safety, and the locations of circuits and equipment, including power and communication lines and fire protective signaling circuits.

AMENDATORY SECTION (Amending WSR 98-07-009, filed 3/6/98, effective 5/6/98)

WAC 296-45-105 Work required of leadworkers.

(1) A leadworker cannot properly supervise the work and look out for the safety of employees under their direction if required to work as a leadworker and a ((lineworker)) qualified electrical employee at the same time.

(2) Leadworkers should be constantly alert and shall not be required to serve in such dual capacity, except in crews of not more than two ((lineworkers)) qualified electrical employees, in which case they may work as one of the ((lineworkers)) qualified electrical employees.

(3) In crews of two ((lineworkers)) qualified electrical employees or less, each ((lineworker)) qualified electrical employee may have a groundworker but, if additional ((lineworkers)) qualified electrical employees or groundworkers are added to the crew, the leadworker shall confine his/her activities to supervising the work, as exhibited below:

Type of Crew |

Minimum Requirements |

2 ((lineworkers)) qualified electrical employees |

One ((lineworker)) qualified electrical employee as person-in-charge. |

2 ((lineworkers)) qualified electrical employees plus 1 groundworker |

One ((lineworker)) qualified electrical employee as person-in-charge or climbing leadworker. |

2 ((lineworkers)) qualified electrical employees plus 2 groundworkers |

One ((lineworker)) qualified electrical employee as person-in-charge or climbing leadworker. |

2 ((lineworkers)) qualified electrical employees plus any combination of 3 ((lineworkers)) qualified electrical employees or groundworkers |

One nonclimbing leadworker. |

AMENDATORY SECTION (Amending WSR 04-07-160, filed 3/23/04, effective 5/1/04)

WAC 296-45-125 Medical services and first aid.

The employer shall provide medical services and first aid as required in WAC 296-800-150. The following requirements also apply:

(1) Cardiopulmonary resuscitation and first-aid training. When employees are performing work on or associated with exposed lines or equipment energized at 50 volts or more, persons trained in first aid including cardiopulmonary resuscitation (CPR) shall be available as follows:

(a) For field work involving two or more employees at a work location, at least two trained persons shall be available. However, for line-clearance tree trimming operations performed by line-clearance tree trimmers who are not qualified electrical employees, only one trained person need be available if all new employees are trained in first aid, including CPR, within 3 months of their hiring dates.

(b) For fixed work locations such as generating stations, the number of trained persons available shall be sufficient to ensure that each employee exposed to electric shock can be reached within 4 minutes by a trained person. However, where the existing number of employees is insufficient to meet this requirement (at a remote substation, for example), all employees at the work location shall be trained.

(2) First-aid supplies. First-aid supplies required by WAC 296-800-150 shall be placed in weatherproof containers if the supplies could be exposed to the weather.

(3) First-aid kits. ((Each first-aid kit)) The employer shall ((be maintained)) maintain each first-aid kit, shall ((be)) ensure that it is readily available for use, and shall ((be inspected)) inspect it frequently enough to ensure that expended items are replaced ((but)). The employer also shall inspect each first-aid kit at least once per year.

AMENDATORY SECTION (Amending WSR 98-07-009, filed 3/6/98, effective 5/6/98)

WAC 296-45-135 Job briefing.

(1) The employer shall ensure that the leadworker conducts a job briefing with the employees involved before they start each job. ((The briefing shall cover at least the following subjects: Hazards associated with the job, work procedures involved, special precautions, energy source controls, and personal protective equipment requirements.

(1))) (2) The employer shall provide the employee in charge of the job with all available information that relates to the determination of existing characteristics and conditions required by WAC 296-45-067(4) of this chapter.

(3) The briefing shall also cover at the least the following subjects:

(a) Hazards associated with the job;

(b) Work procedures involved;

(c) Special precautions;

(d) Energy source controls; and

(e) Personal protective equipment requirements.

(4) Number of briefings. If the work or operations to be performed during the work day or shift are repetitive and similar, at least one job briefing shall be conducted before the start of the first job of each day or shift. Additional job briefings shall be held if significant changes, which might affect the safety of the employees, occur during the course of the work.

(((2))) (5) Extent of briefing. A brief discussion is satisfactory if the work involved is routine and if the employee, by virtue of training and experience, can reasonably be expected to recognize and avoid the hazards involved in the job. A more extensive discussion shall be conducted:

(a) If the work is complicated or particularly hazardous; or

(b) If the employee cannot be expected to recognize and avoid the hazards involved in the job.

Note: | The briefing is always required to touch on all the subjects listed in the introductory text to this section. |

(((3))) (6) Working alone. An employee working alone need not conduct a job briefing. However, the employer shall ensure that the tasks to be performed are planned as if a briefing were required.

AMENDATORY SECTION (Amending WSR 98-07-009, filed 3/6/98, effective 5/6/98)

WAC 296-45-17505 Lockout/tagout (hazardous control) program.

(1) The employer shall establish a program consisting of energy control procedures, employee training, and periodic inspections to ensure that, before any employee performs any servicing or maintenance on a machine or equipment where the unexpected energizing, start up, or release of stored energy could occur and cause injury, the machine or equipment is isolated from the energy source and rendered inoperative.

(2) The employer's energy control program under this section shall meet the following requirements:

(a) If an energy isolating device is not capable of being locked out, the employer's program shall use a tagout system.

(b) If an energy isolating device is capable of being locked out, the employer's program shall use lockout, unless the employer can demonstrate that the use of a tagout system will provide full employee protection as follows:

(i) When a tagout device is used on an energy isolating device which is capable of being locked out, the tagout device shall be attached at the same location that the lockout device would have been attached, and the employer shall demonstrate that the tagout program will provide a level of safety equivalent to that obtained by the use of a lockout program.

(ii) In demonstrating that a level of safety is achieved in the tagout program equivalent to the level of safety obtained by the use of a lockout program, the employer shall demonstrate full compliance with all tagout-related provisions of this standard together with such additional elements as are necessary to provide the equivalent safety available from the use of a lockout device. Additional means to be considered as part of the demonstration of full employee protection shall include the implementation of additional safety measures such as the removal of an isolating circuit element, blocking of a controlling switch, opening of an extra disconnecting device, or the removal of a valve handle to reduce the likelihood of inadvertent energizing.

(3) Whenever replacement or major repair, renovation, or modification of a machine or equipment is performed, and whenever new machines or equipment are installed, energy isolating devices for such machines or equipment shall be designed to accept a lockout device.

(4) Procedures shall be developed, documented, and used for the control of potentially hazardous energy covered by this section.

(5) The procedure shall clearly and specifically outline the scope, purpose, responsibility, authorization, rules, and techniques to be applied to the control of hazardous energy, and the measures to enforce compliance including, but not limited to, the following:

(a) A specific statement of the intended use of this procedure;

(b) Specific procedural steps for shutting down, isolating, blocking and securing machines or equipment to control hazardous energy;

(c) Specific procedural steps for the placement, removal, and transfer of lockout devices or tagout devices and the responsibility for them; and

(d) Specific requirements for testing a machine or equipment to determine and verify the effectiveness of lockout devices, tagout devices, and other energy control measures.

(6) The employer shall conduct a periodic inspection of the energy control procedure at least annually to ensure that the procedure and the provisions of this section are being followed.

(a) The periodic inspection shall be performed by an authorized/designated employee who is not using the energy control procedure being inspected.

(b) The periodic inspection shall be designed to identify and correct any deviations or inadequacies.

(c) If lockout is used for energy control, the periodic inspection shall include a review, between the inspector and each authorized/designated employee, of that employee's responsibilities under the energy control procedure being inspected.

(d) Where tagout is used for energy control, the periodic inspection shall include a review, between the inspector and each authorized/designated and affected employee, of that employee's responsibilities under the energy control procedure being inspected, and the elements set forth in this section.

(e) The employer shall certify that the inspections required by this section have been accomplished. The certification shall identify the machine or equipment on which the energy control procedure was being used, the date of the inspection, the employees included in the inspection, and the person performing the inspection.

Note: | If normal work schedule and operation records demonstrate adequate inspection activity and contain the required information, no additional certification is required. |

(7) The employer shall provide training to ensure that the purpose and function of the energy control program are understood by employees and that the knowledge and skills required for the safe application, usage, and removal of energy controls are acquired by employees. The training shall include the following:

(a) Each authorized/designated employee shall receive training in the recognition of applicable hazardous energy sources, the type and magnitude of energy available in the workplace, and in the methods and means necessary for energy isolation and control.

(b) Each affected employee shall be instructed in the purpose and use of the energy control procedure.

(c) All other employees whose work operations are or may be in an area where energy control procedures may be used shall be instructed about the procedures and about the prohibition relating to attempts to restart or reenergize machines or equipment that are locked out or tagged out.

(8) When tagout systems are used, employees shall also be trained in the following limitations of tags:

(a) Tags are essentially warning devices affixed to energy isolating devices and do not provide the physical restraint on those devices that is provided by a lock.

(b) When a tag is attached to an energy isolating means, it is not to be removed without authorization of the authorized/designated person responsible for it, and it is never to be bypassed, ignored, or otherwise defeated.

(c) Tags must be legible and understandable by all authorized/designated employees, affected employees, and all other employees whose work operations are or may be in the area, in order to be effective.

(d) Tags and their means of attachment must be made of materials which will withstand the environmental conditions encountered in the workplace.

(e) Tags may evoke a false sense of security, and their meaning needs to be understood as part of the overall energy control program.

(f) Tags must be securely attached to energy isolating devices so that they cannot be inadvertently or accidentally detached during use.

AMENDATORY SECTION (Amending WSR 98-07-009, filed 3/6/98, effective 5/6/98)

WAC 296-45-17510 Retraining.

(1) Retraining shall be provided for all authorized/designated and affected employees whenever there is a change in their job assignments, a change in machines, equipment, or processes that present a new hazard or whenever there is a change in the energy control procedures.

(2) Retraining shall also be conducted whenever a periodic inspection reveals, or whenever the employer has reason to believe, that there are deviations from or inadequacies in an employee's knowledge or use of the energy control procedures.

(3) The retraining shall reestablish employee proficiency and shall introduce new or revised control methods and procedures, as necessary.

(4) The employer shall certify that employee training has been accomplished and is being kept up to date. The certification shall contain each employee's name and dates of training.

AMENDATORY SECTION (Amending WSR 98-07-009, filed 3/6/98, effective 5/6/98)

WAC 296-45-17515 Protective materials and hardware.

(1) Locks, tags, chains, wedges, key blocks, adapter pins, self-locking fasteners, or other hardware shall be provided by the employer for isolating, securing, or blocking of machines or equipment from energy sources.

(2) Lockout devices and tagout devices shall be singularly identified; shall be the only devices used for controlling energy; may not be used for other purposes; and shall meet the following requirements:

(a) Lockout devices and tagout devices shall be capable of withstanding the environment to which they are exposed for the maximum period of time that exposure is expected.

(b) Tagout devices shall be constructed and printed so that exposure to weather conditions or wet and damp locations will not cause the tag to deteriorate or the message on the tag to become illegible.

(c) Tagout devices shall be so constructed as not to deteriorate when used in corrosive environments.

(3) Lockout devices and tagout devices shall be standardized within the facility in at least one of the following criteria: Color, shape, size. Additionally, in the case of tagout devices, print and format shall be standardized.

(4) Lockout devices shall be substantial enough to prevent removal without the use of excessive force or unusual techniques, such as with the use of bolt cutters or metal cutting tools.

(5) Tagout devices, including their means of attachment, shall be substantial enough to prevent inadvertent or accidental removal. Tagout device attachment means shall be of a nonreusable type, attachable by hand, self-locking, and nonreleasable with a minimum unlocking strength of no less than fifty pounds and shall have the general design and basic characteristics of being at least equivalent to a one-piece, all-environment-tolerant nylon cable tie.

(6) Each lockout device or tagout device shall include provisions for the identification of the employee applying the device.

(7) Tagout devices shall warn against hazardous conditions if the machine or equipment is energized and shall include a legend such as the following: Do Not Start, Do Not Open, Do Not Close, Do Not Energize, Do Not Operate.

Note: | ((For specific provisions covering accident prevention tags, see chapter 296-24 WAC.)) See ANSI Z535.5, 2011 for the format and design criteria of danger/warning tags. |

AMENDATORY SECTION (Amending WSR 98-07-009, filed 3/6/98, effective 5/6/98)

WAC 296-45-17520 Energy isolation.

Lockout and tagout device application and removal may only be performed by the authorized/designated employees who are performing the servicing or maintenance.

AMENDATORY SECTION (Amending WSR 98-07-009, filed 3/6/98, effective 5/6/98)

WAC 296-45-17525 Notification.