(1) Introduction. Employees must be protected from exposure to hazardous levels of nonionizing radiation. Health standards have been established for ultraviolet, radiofrequency/microwave, and laser radiations which must be used to promote a healthful working environment. These standards refer to levels of nonionizing radiation and represent conditions under which it is believed that nearly all workers may be repeatedly exposed day after day without adverse effects. They are based on the best available information from experimental studies. Because of the wide variations in individual susceptibility, exposure of an occasional individual at, or even below, the permissible limit, may result in discomfort, aggravation of a preexisting condition, or physiological damage.

(a) Permissible exposure limits (PELs) refer to a time weighted average (TWA) of exposure for an eight-hour work day within a forty-hour workweek. Exceptions are those limits which are given a ceiling value.

(b) These PELs should be interpreted and applied only by technically qualified persons.

(c) Ceiling value. There are nonionizing radiations which produce physiological responses from short intense exposure and the PELs for these radiations are more appropriately based on this particular hazard. Nonionizing radiations with this type of hazard are best controlled by a ceiling value which is a maximum level of exposure which must not be exceeded.

(2) The employer must establish and maintain a program for the control and monitoring of nonionizing radiation hazards. This program must provide employees adequate supervision, training, facilities, equipment, and supplies, for the control and assessment of nonionizing radiation hazards.

(3) Radiofrequency/microwave radiation permissible exposure limits.

(a) Definition. Partial body exposure. The case in which only the hands and forearms or the feet and legs below the knee are exposed.

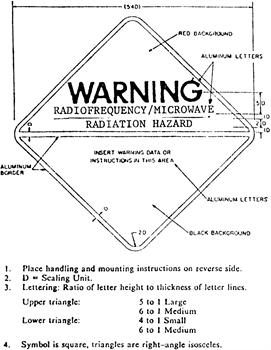

(b) Warning symbol.

(i) The warning symbol for radiofrequency/microwave radiation must consist of a red isosceles triangle above an inverted black isosceles triangle, separated and outlined by an aluminum color border. The words "Warning - Radiofrequency/microwave radiation hazard" must appear in the upper triangle. See Figure 1.

(ii) All areas where entry may result in an exposure to radiofrequency/microwave radiation in excess of the PEL must have a warning symbol prominently displayed at their entrance.

(iii) American National Standard Safety Color Code for Marking Physical Hazards and the Identification of Certain Equipment, Z53.1-1953, must be used for color specification. All lettering and the border must be of aluminum color.

(iv) The inclusion and choice of warning information or precautionary instructions is at the discretion of the user. If such information is included it must appear in the lower triangle of the warning symbol.

|

Figure 1 Radiofrequency/Microwave Radiation Hazard Warning Symbol |

|

(c) These PELs refer to radiofrequency/microwave radiation exposures in the frequency range of 300 kHz to 100 GHz. Based on current knowledge, it is believed that workers may be exposed at these PELs without adverse health effects.

(i) Table I gives the PELs in terms of the mean squared electric (E2) and magnetic (H2) field strengths and in terms of the equivalent plane-wave free-space power density, as a function of frequency.

(ii) The average exposure for any six minute (0.1 hour) period must not exceed the PEL.

(iii) Measurements must be made at distances of 5 cm or greater from any object.

(iv) For mixed or broadband fields at a number of frequencies for which there are different PELs, the fraction of the PEL incurred within each frequency interval must be determined and the sum of these fractions must not exceed unity.

(v) PELs given in Table I for frequencies between 300 kHz and 1 GHz may be exceeded for partial body exposures if the output power of the radiating device is 7 watts or less.

Table I. Radiofrequency/Microwave Radiation

Permissible Exposure Limits (PELs).

Frequency(f) | Power Density* | Electric Field Strength Squared* | Magnetic Field Strength Squared* |

mW/cm2 | V2/m2 | A2/m2 | |

0.3 to 3 MHz | 100 | 400,000 | 2.5 |

3 to 30 MHz | 900/f2 | 4000(900/f2) | 0.025(900/f2) |

30 to 300 MHz | 1.0 | 4000 | 0.025 |

300 to 1500 MHz | f/300 | 4000(f/300) | 0.025(f/300) |

1.5 to 100 GHz | 5.0 | 20,000 | 0.125 |

Note: f = frequency (MHz) | |||

*Ceiling value | |||

(4) Laser radiation permissible exposure limits.

(a) Definitions.

(i) Diffuse reflection. A change of the spatial distribution of a beam of radiation when it is reflected in many directions by a surface or medium.

(ii) Specular reflection. A mirrorlike reflection.

(iii) Accessible radiation. Laser radiation to which human access is possible.

(b) All lasers and laser systems must be classified in accordance with the Federal Laser Product Performance Standards (21 C.F.R. 1040.10) or, if manufactured prior to August 2, 1976, in accordance with ANSI Z136.1-1980.

(i) Class I. Laser systems that are considered to be incapable of producing damaging radiation levels and are thereby exempt from control measures. This is a no hazard category.

(ii) Class II. Visible wavelength laser systems that have a low hazard potential because of the expected aversion response. There is some possibility of injury if stared at. This is a low hazard category.

(iii) Class III. Laser systems in which intrabeam viewing of the direct beam or specular reflections of the beam may be hazardous. This class is further subdivided into IIIa and IIIb. This is a moderate hazard category.

(iv) Class IV. Laser systems whose direct or diffusely reflected radiation may be hazardous and where the beam may constitute a fire hazard. Class IV systems require the use of controls that prevent exposure of the eye and skin to specular or diffuse reflections of the beam. This is a high hazard category.

(c) Warning signs and classification labels must be prepared in accordance with 21 C.F.R. 1040.10 when classifying lasers and laser systems, and ANSI Z136.1 - 1980 when using classified lasers and laser systems. All signs and labels must be conspicuously displayed.

(i) The signal word "CAUTION" must be used with all signs and labels associated with Class II and Class IIIa lasers and laser systems.

(ii) The signal word "DANGER" must be used with all signs and labels associated with Class IIIb and Class IV lasers and laser systems.

(d) Personal protective equipment must be provided at no cost to the employee and must be worn whenever operational conditions or maintenance of lasers may result in a potentially hazardous exposure.

(i) Protective eyewear must be specifically designed for protection against radiation of the wavelength and radiant energy of the laser or laser system. Ocular exposure shall not exceed the recommendations of ANSI Z136.1 - 1980.

(ii) For Class IV lasers and laser systems protective eyewear must be worn for all operational conditions or maintenance which may result in exposures to laser radiation.

(e) Engineering controls must be used whenever feasible to reduce the accessible radiation levels for Class IV lasers and laser systems to a lower classification level. These controls may include, but are not limited to: Protective housings, interlocks, optical system attenuators, enclosed beam paths, remote controls, beam stops, and emission delays with audible warnings.

(f) All employees who may be exposed to laser radiation shall receive laser safety training. The training must ensure that the employees are knowledgeable of the potential hazards and control measures for the laser equipment in use.

(5) Ultraviolet radiation.

(a) These permissible exposure limits refer to ultraviolet radiation in the spectral region between 200 and 400 nanometer (nm) and represent conditions under which it is believed that nearly all workers may be repeatedly exposed without adverse effect. These values for exposure of the eye or the skin apply to ultraviolet radiation from arcs, gas, and vapor discharges, and incandescent sources, but do not apply to ultraviolet lasers or solar radiation. These levels should not be used for determining exposure of photosensitive individuals to ultraviolet radiation. These values must be used in the control of exposure to continuous sources where the exposure relation must not be less than 0.1 sec.

(b) The permissible exposure limit for occupational exposure to ultraviolet radiation incident upon skin or eye where irradiance values are known and exposure time is controlled are as follows:

(i) For the near ultraviolet spectral region (320 to 400 nanometer (nm)), total irradiance incident upon the unprotected skin or eye must not exceed 1.0 milliwatt/sq. centimeter for periods greater than 103 seconds (approximately 16 minutes) and for exposure times less than 103 seconds shall not exceed one Joule/sq. centimeter.

(ii) For the actinic ultraviolet spectral region (200 - 315 nm), radiant exposure incident upon the unprotected skin or eye must not exceed the values given in Table 4 within an 8-hour period.

(iii) To determine the effective irradiance of a broadband source weighted against the peak of the spectral effectiveness curve (270 nanometer (nm)), the following weighting formulas shall be used.

Eeff = ∑ (E-Lambda) (S-Lambda) (Delta-Lambda) | |||

Where: | |||

Eeff | = | effective irradiance relative to a monochromatic source at 270nm | |

E-Lambda | = | spectral irradiance in Watts/sq. centimeter/nanometer. | |

S-Lambda | = | relative spectral effectiveness (unitless) | |

Delta-Lambda | = | band width in nanometers | |

(iv) Permissible exposure time in seconds for exposure to actinic ultraviolet radiation incident upon the unprotected skin or eye may be computed by dividing 0.003 Joules/sq. centimeter by Eeff in Watts/sq. centimeter. The exposure time may also be determined using Table 5 which provides exposure times corresponding to effective irradiances in µW/cm2.

TABLE 4

Wavelength nanometer | PEL millijoules/sq. centimeters | Relative Spectral Effectiveness S Lambda | ||

200 | 100 | 0.03 | ||

210 | 40 | 0.075 | ||

220 | 25 | 0.12 | ||

230 | 16 | 0.19 | ||

240 | 10 | 0.30 | ||

250 | 7.0 | 0.43 | ||

254 | 6.0 | 0.5 | ||

260 | 4.6 | 0.65 | ||

270 | 3.0 | 1.0 | ||

280 | 3.4 | 0.88 | ||

290 | 4.7 | 0.64 | ||

300 | 10 | 0.30 | ||

305 | 50 | 0.06 | ||

310 | 200 | 0.015 | ||

315 | 1000 | 0.003 | ||

TABLE 5

Duration of Exposure Per Day | Effective Irradiance Eeff (µW/cm2) | ||

8 hrs. | 0.1 | ||

4 hrs. | 0.2 | ||

2 hrs. | 0.4 | ||

1 hr. | 0.8 | ||

1/2 hr. | 1.7 | ||

15 min. | 3.3 | ||

10 min. | 5 | ||

5 min. | 10 | ||

1 min. | 50 | ||

30 sec. | 100 | ||

10 sec. | 300 | ||

1 sec. | 3,000 | ||

0.5 sec. | 6,000 | ||

0.1 sec. | 30,000 | ||

TABLE 6

Densities and Transmissions (in Percent); also Tolerances in Densities and Transmissions of Various Shades of Glasses for Protection Against Injurious Rays |

(Shades 3 to 8, inclusive, are for use in goggles, shades 10 to 14, inclusive, for welder's helmets and face shields) |

[CODIFICATION NOTE: The graphic presentation of this table has been varied slightly in order that it would fall within the printing specifications for the Washington Administrative Code. In the following table, the original table had columns relating to (1) "Optical Density" which is now "Part 1," (2) "Total Visible Luminous Transmittance" and "Maximum total Infrared" which are now "Part 2," (3) "Maximum Ultraviolet Transmission" which is now "Part 3," and (4) "Recommended Uses" which is now "Part 4." These columns were all positioned side by side. In the new WAC format these are split up into four separate tables.] |

TABLE 6—Part 1

Optical Density | |||||||

Shade No. | Minimum [C] O.D. | Standard O.D. | Maximum O.D. | ||||

3.0 | .64 | .857 | 1.06 | ||||

4.0 | 1.07 | 1.286 | 1.49 | ||||

5.0 | 1.50 | 1.714 | 1.92 | ||||

6.0 | 1.93 | 2.143 | 2.35 | ||||

7.0 | 2.36 | 2.572 | 2.78 | ||||

8 | 2.79 | 3.000 | 3.21 | ||||

9 | 3.22 | 3.429 | 3.63 | ||||

10 | 3.64 | 3.857 | 4.06 | ||||

11 | 4.07 | 4.286 | 4.49 | ||||

12 | 4.50 | 4.715 | 4.92 | ||||

13 | 4.93 | 5.143 | 5.35 | ||||

14 | 5.36 | 5.571 | 5.78 | ||||

TABLE 6—Part 2

Total Visible | Maximum | ||||||||

Luminous Transmittance | Total | ||||||||

Shade No. | Maximum % | Standard % | Minimum % | Infrared % | |||||

3.0 | 22.9 | 13.9 | 8.70 | 9.0 | |||||

4.0 | 8.51 | 5.18 | 3.24 | 5.0 | |||||

5.0 | 3.16 | 1.93 | 1.20 | 2.5 | |||||

6.0 | 1.18 | .72 | .45 | 1.5 | |||||

7.0 | .44 | .27 | .17 | 1.3 | |||||

8 | .162 | .100 | .062 | 1.0 | |||||

9 | .060 | .037 | .023 | .8 | |||||

10 | .0229 | .0139 | .0087 | .6 | |||||

11 | .0085 | .0052 | .0033 | .5 | |||||

12 | .0032 | .0019 | .0012 | .5 | |||||

13 | .00118 | .00072 | .00045 | .4 | |||||

14 | .00044 | .00027 | .00017 | .3 | |||||

TABLE 6—Part 3

Maximum Ultraviolet Transmission | ||||

Shade No. | 313mu % | 334mu % | 365mu % | 405mu % |

3.0 | .2 | .2 | .5 | 1.0 |

4.0 | .2 | .2 | .5 | 1.0 |

5.0 | .2 | .2 | .2 | .5 |

6.0 | .1 | .1 | .1 | .5 |

7.0 | .1 | .1 | .1 | .5 |

8 | .1 | .1 | .1 | .5 |

9 | .1 | .1 | .1 | .5 |

10 | .1 | .1 | .1 | .5 |

11 | .05 | .05 | .05 | .1 |

12 | .05 | .05 | .05 | .1 |

13 | .05 | .05 | .05 | .1 |

14 | .05 | .05 | .05 | .1 |

TABLE 6—Part 4

Shade | ||||

No. | Recommended Uses | |||

3.0 | Glare of reflected sunlight from snow, water, sand, etc., stray light from cutting and welding metal pouring and work around furnaces and foundries. | |||

4.0 | ||||

5.0 | Light acetylene cutting and welding; light electric spot welding. | |||

6.0 | ||||

7.0 | Acetylene cutting and medium welding; arc welding up to 30 amperes. | |||

8 | ||||

9 | Heavy acetylene welding; arc cutting and welding between 30 and 75 amperes. | |||

10 | ||||

11 | Arc cutting and welding between 75 and 200 amperes. | |||

12 | ||||

13 | Arc cutting and welding between 200 and 400 amperes. | |||

14 | Arc cutting and welding above 400 amperes. | |||

a. | American Standard Safety Code for the Protection of Heads, Eyes, and Respiratory Organs. | |||

b. | Standard density is defined as the logarithms (base 10) of the reciprocal of the transmission. Shade number is determined by the density according to the relations: | |||

Shade number = 7/3 density + 1 with tolerances as given in the table. | ||||

Note: | Safety glasses are available with lenses which protect the eyes against ultraviolet radiation. |