WSR 14-17-101

PERMANENT RULES

WASHINGTON STATE PATROL

[Filed August 19, 2014, 12:35 p.m., effective September 19, 2014]

Effective Date of Rule: Thirty-one days after filing.

Purpose: This proposal would adopt the Society of Automotive Engineers (SAE) J684 standard for this equipment and remove the language concerning the testing requirements currently outlined in the rule. In addition, the proposed language would clean up the remaining sections of the rules so that they meet the current writing standards and ensure that the language does not conflict with other portions of the law.

Citation of Existing Rules Affected by this Order: Repealing WAC 204-70-080, 204-70-090, 204-70-100, 204-70-120, 204-70-99001, 204-70-99002, 204-70-99003, 204-70-99004 and 204-70-99005; and amending WAC 204-70-010, 204-70-020, 204-70-030, 204-70-040, 204-70-050, 204-70-060, and 204-70-070.

Statutory Authority for Adoption: RCW 46.37.005 and 46.37.320.

Adopted under notice filed as WSR 14-14-015 on June 23, 2014.

Number of Sections Adopted in Order to Comply with Federal Statute: New 0, Amended 0, Repealed 0; Federal Rules or Standards: New 0, Amended 0, Repealed 0; or Recently Enacted State Statutes: New 0, Amended 0, Repealed 0.

Number of Sections Adopted at Request of a Nongovernmental Entity: New 0, Amended 0, Repealed 0.

Number of Sections Adopted on the Agency's Own Initiative: New 0, Amended 7, Repealed 9.

Number of Sections Adopted in Order to Clarify, Streamline, or Reform Agency Procedures: New 0, Amended 7, Repealed 9.

Number of Sections Adopted Using Negotiated Rule Making: New 0, Amended 0, Repealed 0; Pilot Rule Making: New 0, Amended 0, Repealed 0; or Other Alternative Rule Making: New 0, Amended 0, Repealed 0.

Date Adopted: August 6, 2014.

John R. Batiste

Chief

AMENDATORY SECTION (Amending WSR 80-03-069, filed 2/28/80)

WAC 204-70-010 Promulgation.

By authority of RCW 46.37.005 and 46.37.320, the state ((commission on equipment)) patrol hereby adopt the following regulations pertaining to vehicle connecting devices and towing methods.

AMENDATORY SECTION (Amending WSR 80-03-069, filed 2/28/80)

WAC 204-70-020 Purpose.

The purpose of this regulation is to provide this state with a uniform minimum requirement for motor vehicle connecting devices and towing methods. ((It is designed to increase highway safety by reducing towing and hitch-related accidents.)) This regulation is not intended to cover the fifth wheel type of connecting device or towing method. Pintle hook type devices ((shall)) will also be excluded from this chapter, except that the safety chain requirements ((shall)) will apply.

AMENDATORY SECTION (Amending WSR 80-03-069, filed 2/28/80)

WAC 204-70-030 Scope.

(1) The scope of this regulation is directed to the regulation of trailer hitches and towing devices, towing methods, testing methods, certification requirements, installation, compliance and other requirements as herein defined in these regulations((.

(2) After the effective date of this regulation, no primary connecting system)) used for drawing a trailer or semitrailer having a gross vehicle weight of 10,000 pounds or less upon the public highways of this state ((shall be sold, offered for sale, or installed for service unless it is a type approved by the commission. The safety chain requirements of this chapter shall apply to all primary coupling systems designed for towing trailers and semitrailers having a gross vehicle weight of 10,000 pounds or less regardless of the date of installation of such primary coupling system. Accordingly, the commission establishes this regulation relating to vehicle connecting arrangements used for drawing trailers by mechanical power on the public highways)).

(2) This regulation is not for those arrangements used for drawing another vehicle by means of a tow truck, semitrailer with a fifth wheel type hitch, or wrecker unless coupled by ball and coupler.

AMENDATORY SECTION (Amending WSR 80-03-069, filed 2/28/80)

WAC 204-70-040 Definitions.

(1) ((The term "commission" as hereinafter referred to within this regulation shall mean the state commission on equipment.

(2) "Chain attaching means" means the bolt, hook, pin, hole, eye, clevis, bracket, bar, or any other device mounted on and used for anchoring or attaching safety chains to the towed or towing vehicle or hitch.

(3))) "Coupling" means that part of the primary connecting system normally mounted on the trailer, such as a socket, by which the connection is actually made and including the supporting attachment to the trailer frame.

(((4) "Family of hitches" means a series of hitches produced by a single manufacturer which have similar traits and characteristics in common with each other. Each regulated manufacturer shall determine which hitches may be appropriately included in a particular family, subject to review by the commission. The necessary criteria which all hitches included within a family must exhibit are as follows:

(a) Similarity of design,

(b) Similar materials of construction,

(c) Similar means of attachment to the towing vehicle, and

(d) Similar strength and performance of characteristics.

(5))) (2) "Gross vehicle weight rating (GVWR)" means the value specified by the vehicle manufacturer as the loaded weight of a single vehicle.

(((6))) (3) "Hitch," defined for specific uses under (a) and (b) ((below, generally)) of this subsection, means that part of the primary connecting system normally mounted on the towing vehicle, including a ball-support platform and those components which are attached to the towing vehicle.

(a) "Weight distributing hitch" means a mechanical device that connects the trailer to the towing vehicle, and by means of a leverage applied on both trailer and ((car)) vehicle structures ((or axles)), when properly adjusted, distributes the imposed vertical load at the hitch and coupling connection between the structures of axles of towing vehicle and trailer. ((The towing vehicle thus loaded tends to retain a level position with respect to the road.))

(b) "Weight carrying hitch" means a mechanical and/or structural device that connects the trailer to the towing vehicle, and that does not employ features designed to redistribute the load imposed at the hitch and coupling connection((. Weight carrying hitches may be designed for bolting or other attachment to the towing vehicle frame, unitized body, bumper structure, or to a combination of these or other points which meet the requirements of WAC 204-70-060(3) and Table 2)).

(((7))) (4) "Maximum gross trailer weight (MGTW)" means the weight of the trailer plus the weight of all cargo, consumables, and equipment loaded on the trailer when in an actual underway towing condition.

(((8))) (5) "Maximum vertical load on hitch (tongue weight)" means the vertical downward static force exerted on the hitch by the coupling at the point of connection of coupling and hitch, with weight distribution features or devices, if any, deactivated. Tongue weight is measured at the trailer coupling, with the trailer on a level surface (detached from the hitch), and with trailer consumables and cargo in maximum loaded conditions.

(7) "Primary connecting system" means the combination of devices and their attaching structures that are normally utilized to maintain the connection between towing vehicle and trailer during towing operations. This includes, but is not limited to, the ball-and-socket type of connection or draft means. Note: This does not include a safety chain, which is part of a secondary system normally utilized only upon failure of the primary connection, nor does it include weight distributing or sway control features or devices whose function is accessory to the maintenance of the towing vehicle-trailer connection.

(((10))) (8) "Safety chains" means flexible tension members connected from the front portion of the towed vehicle to the rear portion of the towing vehicle for the purpose of retaining connection between towed and towing vehicle in the event of failure of the connection provided by the primary connecting system. The term "safety chains" includes not only chains, cable, or wire ropes, or equivalent flexible member meeting the strength requirements of ((Table 3 and approved by the commission)) SAE J684 revised July 2005, but also any splice, clamp, socket, snap, eye, ring, thimble, pin, or other fastening device or forming method which is part of the assembly of any such flexible tension member.

(((11))) (9) "Responsible manufacturer" ((shall)) means that person who manufactures a hitch or hitch component either for resale or for sale where it is not actually installed by the manufacturer.

(((12) "Responsible installer" shall mean a person who installs a pre-manufactured hitch where no custom fabricating is done.

(13) "Custom installer" shall mean that person who custom fabricates a hitch which is installed at the place of fabrication.

Nothing in this section is intended to preclude hitch installers from engaging in the activities covered in definitions (11), (12), and (13) above in any combination.))

AMENDATORY SECTION (Amending WSR 80-03-069, filed 2/28/80)

WAC 204-70-050 ((Light service devices and systems.)) Coupling classification and attachment.

((These are for use with trailers not exceeding 10,000 pounds gross vehicle weight rating. This includes, but is not limited to, such types as the utility, boat, camping, travel and other trailers which are normally towed by the conventional passenger car, or similarly constructed vehicle or light-duty truck. This section is intended basically for the ball-and-socket type of primary connecting system, but is not necessarily limited to this type alone.

(1) Trailer classification

(a) Class 1—Trailers, with a gross weight (trailer weight including load) not exceeding 2,000 pounds.

(b) Class 2—Trailers, with a gross weight (trailer weight including load) over 2,000 pounds, but not exceeding 3,500 pounds.

(c) Class 3—Trailers, with a gross weight (trailer weight including load) over 3,500 pounds, but not exceeding 5,000 pounds.

(d) Class 4—Trailers, with a gross weight (trailer weight including load) over 5,000 pounds, but not exceeding 10,000 pounds.

(2) Couplings

(a) Coupling classification. There shall be four major strength classifications, or designations of couplings. The designation shall be based on the maximum gross trailer weight (MGTW) the coupling is qualified to tow. The No. 1 couplings shall be used for towing Class 1 trailers; No. 2 couplings for Class 2 or smaller trailers; No. 3 couplings for Class 3 or smaller trailers; and No. 4 couplings for Class 4 or smaller trailers. This is not intended to limit the number or variety of couplings in a given class or designation.

(b) Coupling ultimate strength. Each coupling and hitch ball, when subjected to static bench tests in a rigid, nonyielding test fixture, shall withstand the test loads specified in WAC 204-70-99001 Table 1 without incurring failure. For purposes of this regulation, failure occurs at the point at which the coupling or ball will accept no additional test load.

(c) Coupling and hitch ball test procedure. A new coupling or ball shall be used for each mode of load application. Each type of test load is to be applied individually to one component at a time, utilizing a nonyielding test fixture similar in design to the typical test fixture illustrated in Figure 1. When testing a coupling, a hardened ball shall be used; when testing a ball, a hardened coupling shall be used.

(d) Attachment of couplings. Each coupling is to be mounted to the trailer attaching member by bolting, welding or riveting in such manner that the towing loads are safely and adequately transferred to that member.

(e) Provisions for safety.

(i))) (1) Couplings must be classified, tested, attached and labeled by the manufacturer in accordance with SAE J684 revised July 2005.

(2) Each coupling, regardless of classification or designation, must be:

(a) Equipped with a manually operated mechanism so adapted as to prevent disengagement of the unit while in operation. ((In addition to this positive locking mechanism, the coupling shall be so))

(b) Designed so that the trailer can be disconnected from the towing vehicle regardless of the angle of the trailer to the towing vehicle.

(((ii))) (3) Each hitch ball ((shall)) must be equipped and installed with a lock washer or equivalent device, and each replacement hitch ball ((shall)) must be marketed with a lock washer or equivalent device with instructions as to proper installation provided by the responsible manufacturer.

AMENDATORY SECTION (Amending WSR 80-03-069, filed 2/28/80)

WAC 204-70-060 Hitches.

(1) ((Hitch rating.)) Hitches ((shall be rated by)) must be tested and labeled in accordance with SAE standard J684 revised July 2005 by its manufacturer to include the maximum gross trailer weight (MGTW) and the maximum vertical load on hitch (tongue weight) each is qualified to tow.

(2) ((Hitch strength requirements. Each hitch, when subjected to a static bench test, shall conform to the minimum strength requirements contained in Table 2.

(3) Attachment of hitch. Each hitch shall be attached to the structural member or members of the towing vehicle in such a manner that the tension, compression, and transverse thrust loads shown in Table 2 are transferred to the towing vehicle without residual distortion or failure of either the attachment or the vehicle structure which would affect the safe towing of trailers as defined in Table 2.

(4) Maximum vertical load on hitch (tongue weight).)) The weight load carried by the hitch at its connection with the trailer coupling ((shall)) must not, when on a level surface, exceed the maximum tongue weight load recommended by the manufacturer for the hitch.

AMENDATORY SECTION (Amending WSR 80-03-069, filed 2/28/80)

WAC 204-70-070 Safety chains and attaching means required.

(1) ((Strength requirements. Each safety chain and each attaching means shall meet strength requirements as shown in WAC 204-70-99004, Table 3, and defined in WAC 204-70-040)) Every towed vehicle must be coupled to the towing vehicle by means of two safety chains, cables, or wire ropes in addition to the regular drawbar, tongue, or other connection which is certified by its manufacturer as complying with SAE J684 revised July 2005.

(2) ((Installation and connections.)) The means of attachment of safety chains ((shall)) must:

(a) Be located equally distant from and on opposite sides of the longitudinal centerline of the towing vehicle and of the trailer. ((Each means of attachment shall))

(b) Not be common with or utilize fasteners common with a ball or coupling.

(3) No welding operation ((shall)) or repair, such as cold shuts, will be performed on a safety chain subsequent to its manufacture, including the direct welding of a safety chain link to the towed or towing vehicles.

(4) Safety chains ((shall)) must:

(a) Be so connected that the slack for each length of chain between trailer and towing vehicle is the same and is not more than necessary to permit the proper turning of the vehicles. ((When passing forward to the towing vehicle, safety chains must))

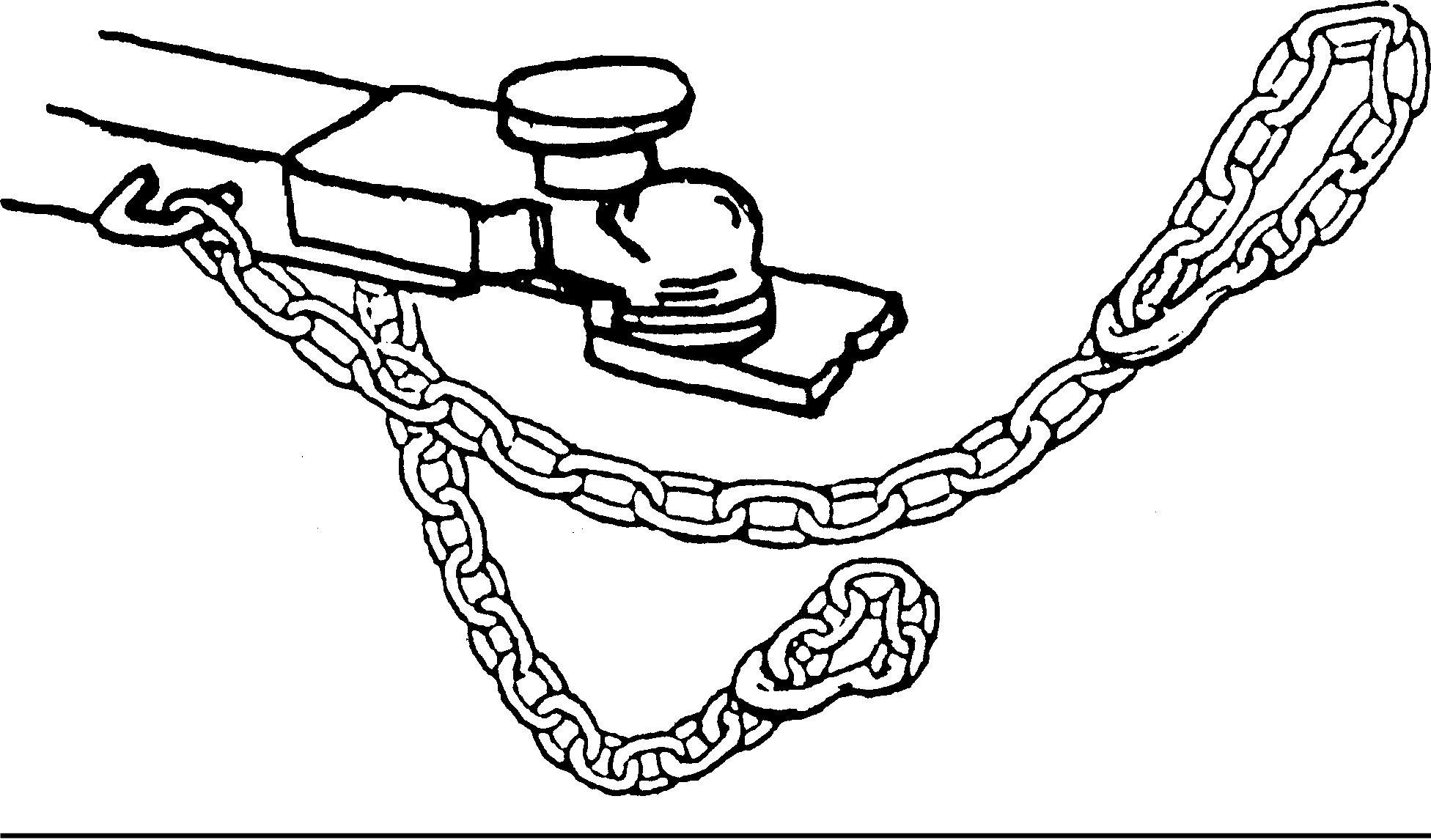

(b) Be crossed in such a manner as to prevent the tongue from dropping to the ground and to maintain connection in the event of failure of the primary connecting system. See Figure ((3. WAC 204-70-99005)) 1.

(((a) Every towed vehicle shall be coupled to the towing vehicle by means of two safety chains, cables, or wire ropes in addition to the regular drawbar, tongue, or other connection. Safety chains, cables, or equivalent devices may be attached to permanently installed hitch components if the components meet the strength requirements of WAC 204-70-99004, Table 3.

(b) Safety chain connections shall)) (c) Be replaced immediately if they contain cut, cracked, or excessively worn links, or frayed, stranded, or otherwise defective wire rope.

(d) Not be ((made)) connected to the hitch ball or to a ball mount designed to be readily removable when not in use.

Figure 1 - Typical double safety chain installation.

|

REPEALER

The following sections of the Washington Administrative Code are repealed:

WAC 204-70-080 |

Identification. |

WAC 204-70-090 |

Identification, installation, maintenance, and compliance. |

WAC 204-70-100 |

Certification and/or testing. |

WAC 204-70-120 |

Effective date. |

WAC 204-70-99001 |

Table 1. |

WAC 204-70-99002 |

Figure 1—Typical coupler and ball test fixture arrangement. |

WAC 204-70-99003 |

Table 2—Hitch test forces. |

WAC 204-70-99004 |

Table 3. |

WAC 204-70-99005 |

Figure 3—Typical double safety chain installation. |