WSR 17-16-132

PERMANENT RULES

DEPARTMENT OF

LABOR AND INDUSTRIES

[Filed August 1, 2017, 9:24 a.m., effective September 1, 2017]

Effective Date of Rule: Thirty-one days after filing.

Purpose: eRules Phase 7, chapter 296-52 WAC, Safety standards for possession, handling and use of explosives; chapter 296-59 WAC, Safety standards for ski area facilities and operations; chapter 296-78 WAC, Safety standards for sawmills and woodworking operations; chapter 296-79 WAC, Safety standards for pulp, paper and paperboard mills and converters; chapter 296-99 WAC, Grain handling facilities; and chapter 296-115 WAC, Safety requirements for charter boats.

The purpose of adopting this rule is to have a consistent format across all department [division] of occupational safety and health (DOSH) rules. The updated format would provide easy access to rules from smart phones and tablet users. It will also provide easy navigation in PDF documents, as well as easier referencing by replacing bullets and dashes with numbers and letters. No rule requirements were changed as a result of this rule-making adoption. References, formatting and minor housekeeping changes were made throughout the chapters in this rule making.

Amended Sections

WAC 296-52-60010 through 296-52-809.

• | Changed bullets, dashes and diamonds to letters or numbers where applicable and renumber[ed]/reletter[ed] the rest of the section or subsection. |

• | Changed uppercase "and" and "or" to lowercase where applicable. |

• | Changed "shall" to "must" where applicable. |

Part A - Purpose, Scope and Application.

• | Added "Definitions" to the title of Part A. |

WAC 296-52-61010 License applicants must provide this information.

• | Added "Individual" to beginning of subsection (1). |

• | Removed bulleted item below subsection (1) that said "An individual must provide:". |

• | Added (b) and (c) to subsection (1). |

WAC 296-52-61015 License applicants must complete department forms.

• | Added (1) to first sentence in this section. |

WAC 296-52-64005 Responsibility to obtain a blaster's license.

• | Added a (1) to the opening paragraph. |

• | Added a (2) to the second paragraph. |

WAC 296-52-65015 Manufacturing site inspections.

• | Added a (1) to the beginning of the section and renumber[ed] the rest. |

• | Added "The department will …" to new subsection (2). |

WAC 296-52-66015 Storage site inspections.

• | Added a (1) to the beginning of the section and renumber[ed] the rest. |

• | Added "The department will …" to new subsection (2). |

WAC 296-52-67170 Bulk delivery/mixing vehicles.

• | Added (iii) to last paragraph in subsection (2)(e). |

WAC 296-52-70010 Building construction for Type 1 magazines.

• | Added a (1) to the opening paragraph of the beginning of the section and then renumber[ed] the rest of the section. |

WAC 296-59-001 through WAC 296-59-130.

• | Changed "the employer" to "you must" where applicable. |

• | Changed bullets and dashes to letters or numbers where applicable and renumber[ed]/reletter[ed] the rest of the section or subsection. |

• | Changed "shall" to "must" where applicable. |

WAC 296-59-007 Definitions.

• | Removed quotation marks from every definition. |

• | Removed the word "means" from every definition and add[ed] a period after the word being defined, making each definition a complete sentence. |

• | Added definitions for "hazardous material system" and "piping system" that were moved from WAC 296-59-080. |

• | Removed definition of "shall" and add[ed] definition of "must." |

WAC 296-59-055 Lockout requirements.

• | Added letters (i)-(v) to unbulleted list in subsection (10)(a). |

WAC 296-59-080 Installation, inspection, and maintenance of pipes, piping systems, and hoses.

• | Removed definitions of "hazardous material system" and "piping system" from subsection (1) and add[ed] them to WAC 296-59-007. |

WAC 296-78-500 through WAC 296-78-84011.

• | Changed "the employer" to "you must" where applicable. |

• | Changed bullets and dashes to letters or numbers where applicable and renumber[ed]/reletter[ed] the rest of the section or subsection. |

• | Changed "shall" to "must" or "will" where applicable. |

• | Removed repetitive "titles" from the beginning of numbered subsections where applicable. |

WAC 296-78-505 Definitions [applicable to this chapter].

• | Removed quotation marks and numbers from all definitions. |

• | Removed the word "means" from applicable definitions, and add[ed] a period after the word being defined, making each definition a complete sentence. |

WAC 296-78-56505 Boats and mechanical devices on waters.

• | Removed the reference to (19) from WAC 296-24-58501 in subsection (8)(h) due to definitions no longer being numbered. |

WAC 296-78-70501 Definitions—Terms, general.

• | Removed numbers and quotation marks from definitions and add a period after every word being defined. |

WAC 296-79-010 through 296-79-320.

• | Changed "The employer" to "You must" where applicable. |

• | Changed bullets and dashes to letters or numbers where applicable and renumber[ed]/reletter[ed] the rest of the section or subsection. |

• | Changed "shall" to "must" where applicable. |

• | Removed repetitive "titles" from the beginning of numbered subsections where applicable. |

WAC 296-79-011 Definitions.

• | Removed quotation marks from all definitions. |

• | Removed the word "means" from applicable definitions, and add[ed] a period after the word being defined, making each definition a complete sentence. |

• | Added definitions of "hazardous material system" and "piping system" that were removed from WAC 296-79-140. |

WAC 296-79-140 Installation, inspection, and maintenance of pipes, piping systems, and hoses.

• | Removed definitions of "hazardous material system" and "piping system" from subsection (1) and move[d] them to WAC 296-79-011 and renumber[ed] the rest of the section. |

WAC 296-79-150 Powered industrial trucks and other equipment.

• | Updated reference in opening sentence of section from "chapter 296-24 WAC, Part D" to "chapter 296-863 WAC." |

• | Updated reference in subsection (14) from "WAC 296-24-230" to "WAC 296-863-40060." |

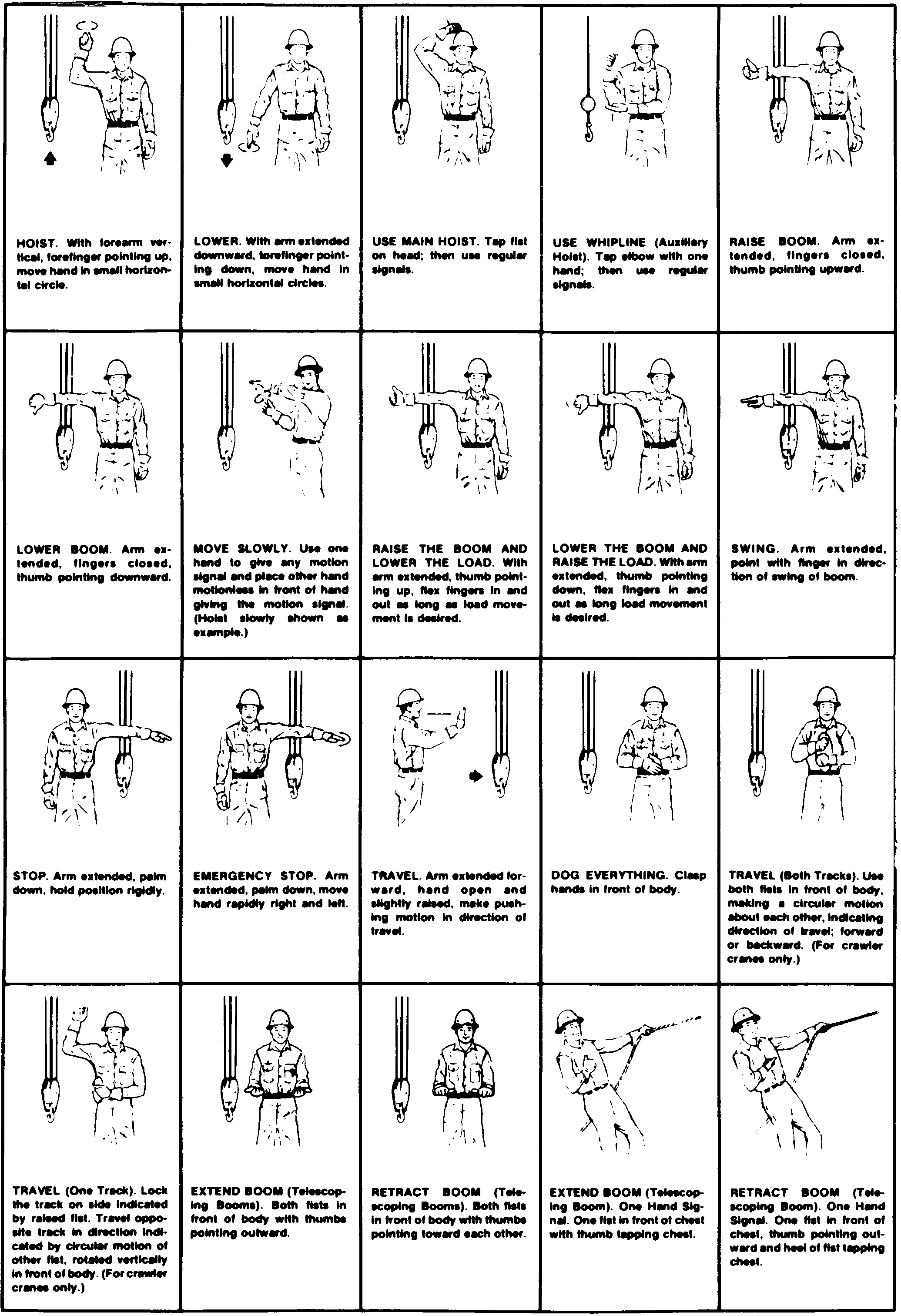

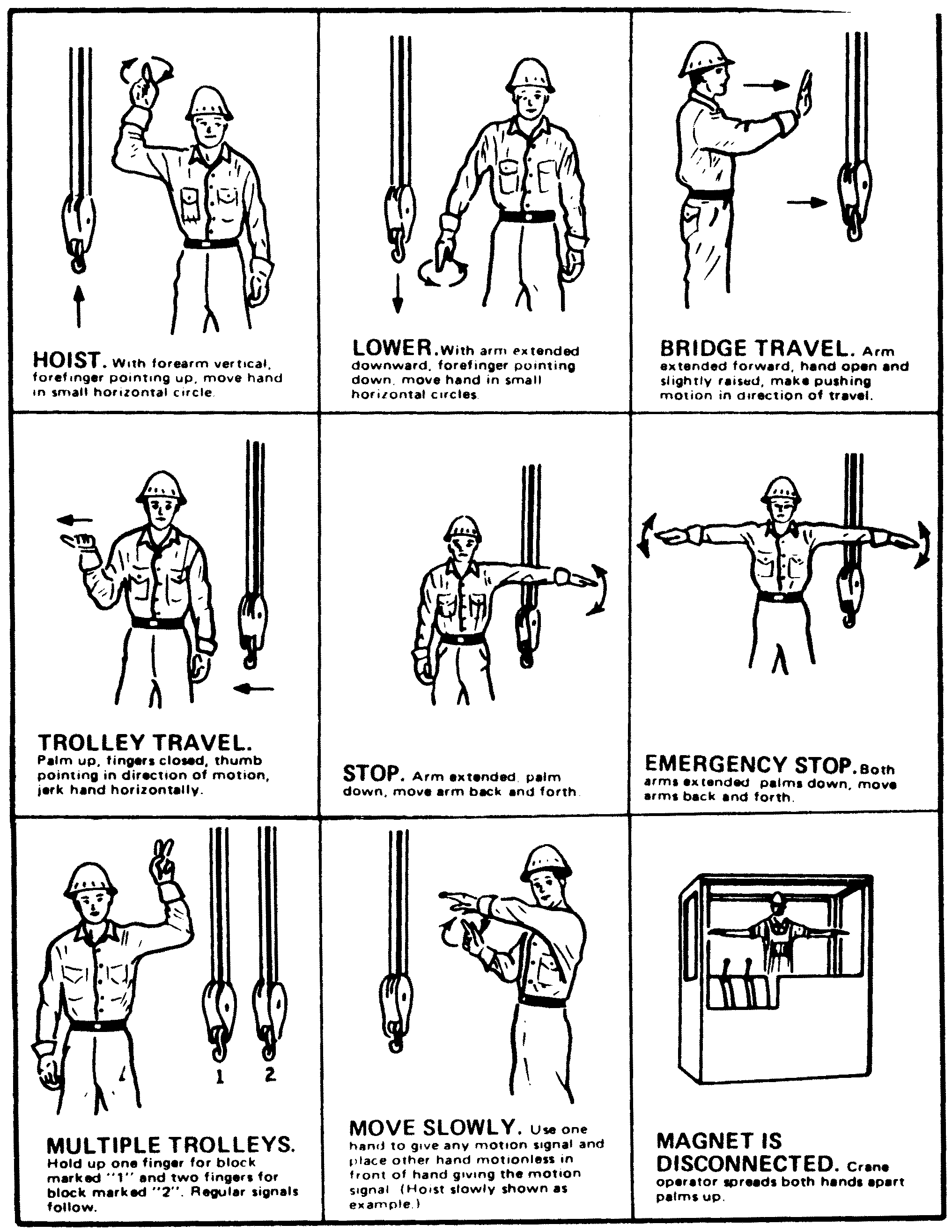

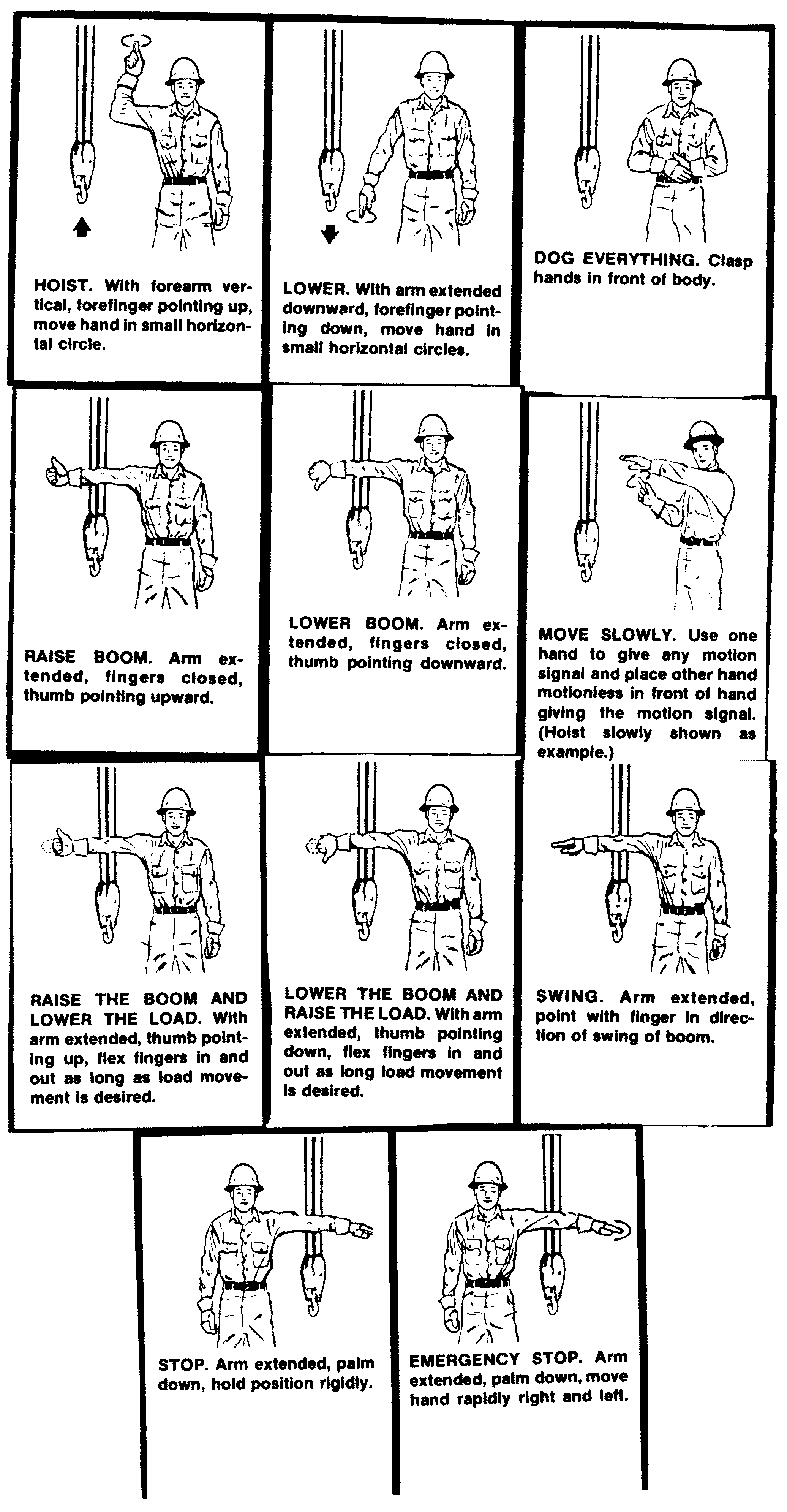

WAC 296-79-170 Requirements for crawler and truck cranes.

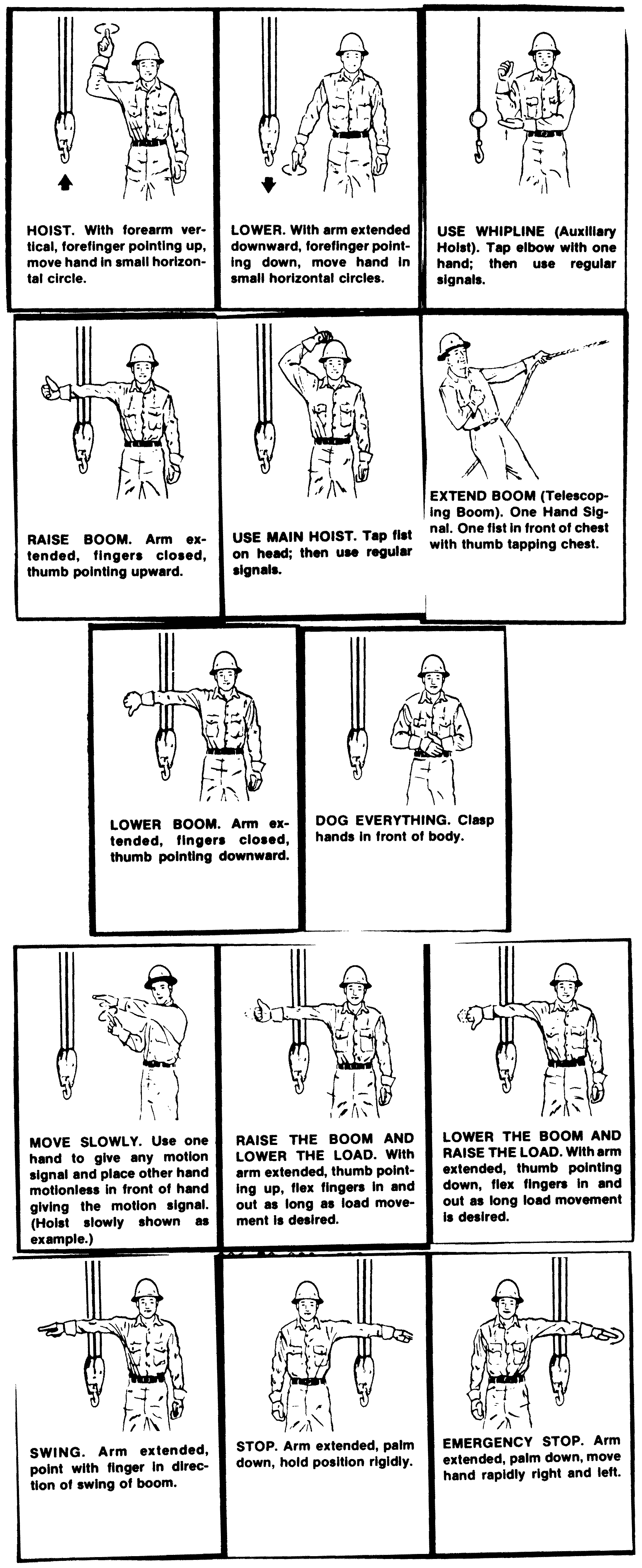

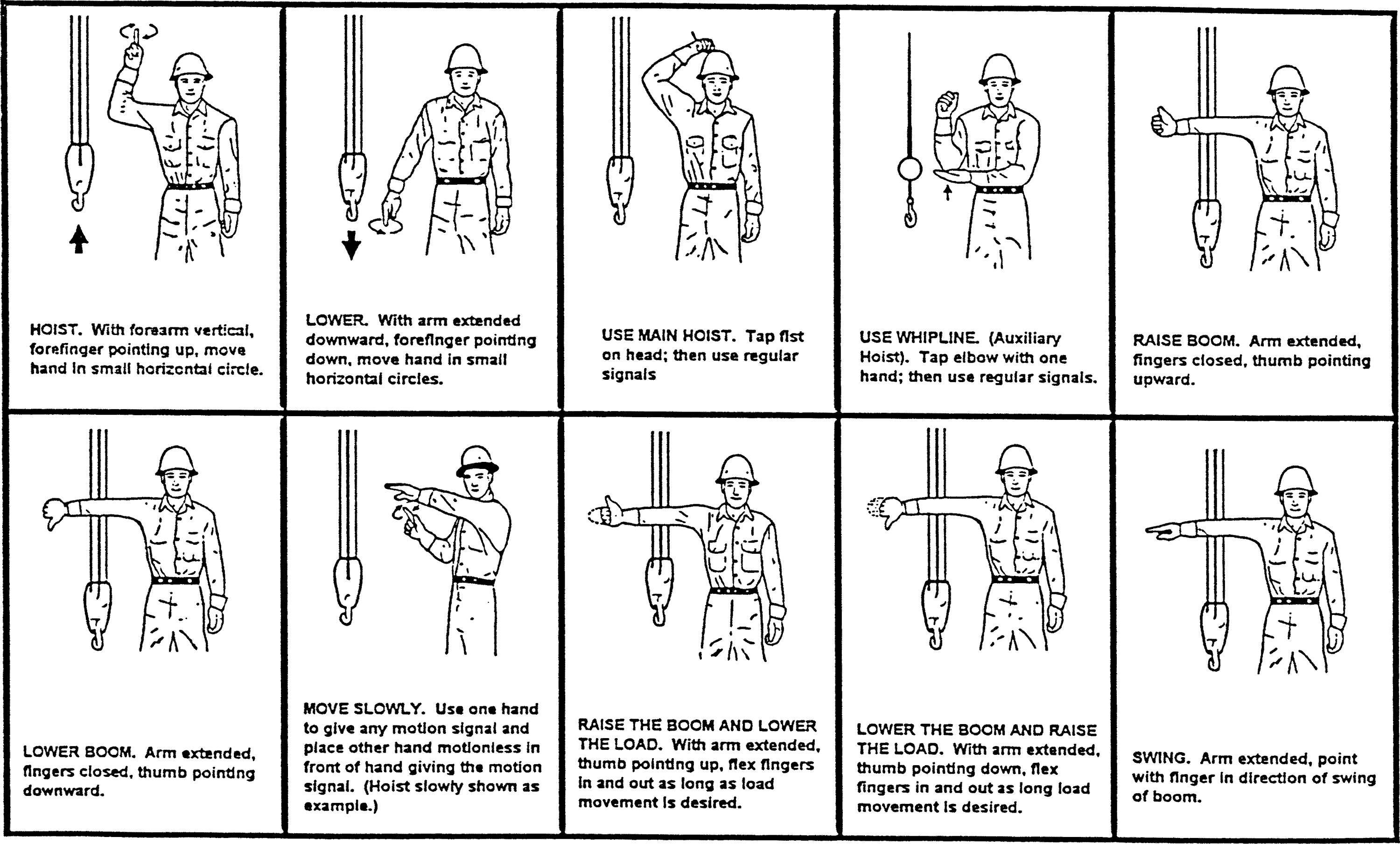

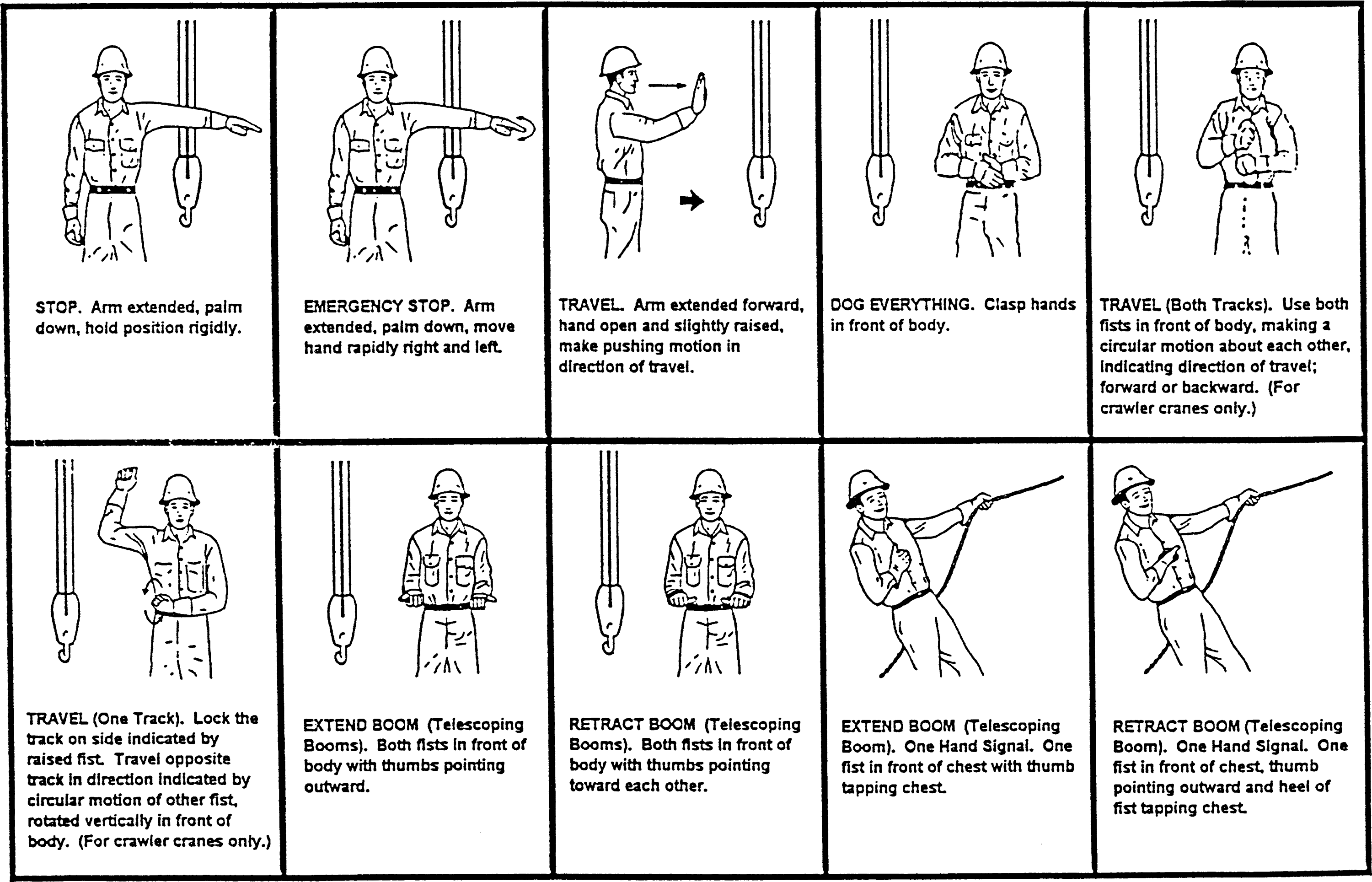

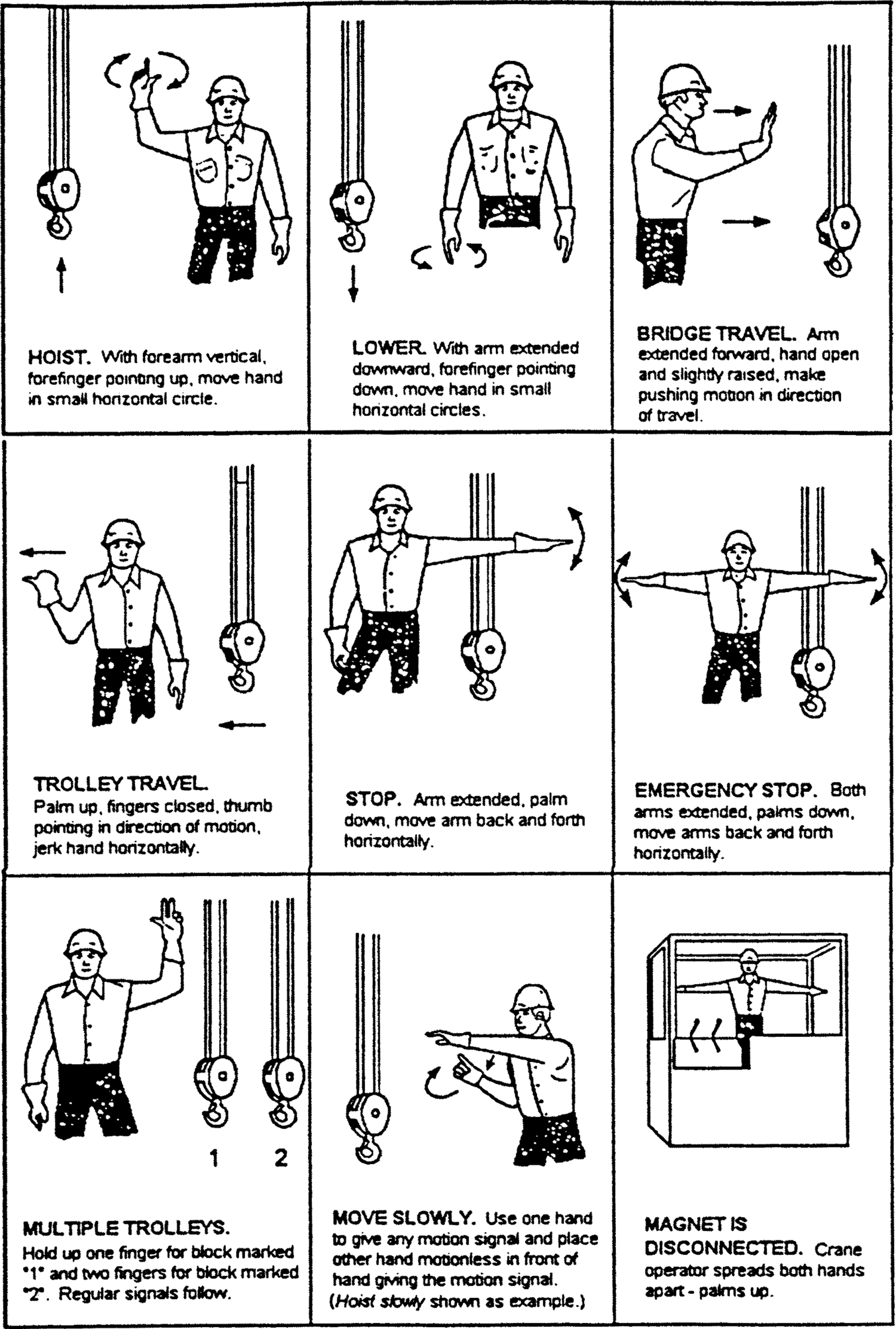

• | Added word "below" to subsection (19) to make a complete sentence: "When using visual signals, standard hand signals as illustrated below, must be used for directing crane operators." |

WAC 296-79-210 For conveyors, maintenance and inspection.

• | Updated reference from "chapter 296-24 WAC, Part D" to "WAC 296-806-420 Conveyors.["] |

WAC 296-79-230 Confined spaces.

• | Updated reference in subsection (1) from "chapter 296-62 WAC, Part M" to "chapter 296-809 WAC." |

WAC 296-099-010 through 296-99-085.

• | Changed "the employer" to "you must" where applicable. |

• | Changed bullets/dashes to letters or numbers where applicable. |

WAC 296-99-085 What special requirements apply to inside bucket elevators?

• | Removed definition of "jogging" from subsection (1) and move[d] it to WAC 296-99-005. |

WAC 296-115-025 through 296-115-060.

• | Changed "the employer" to "you must" where applicable. |

• | Changed bullets and dashes to letters or numbers where applicable and renumber[ed]/reletter[ed] the rest of the section or subsection. |

WAC 296-115-015 Definitions.

• | Removed numbers from all definitions. |

• | Removed the word "means" from applicable definitions, and add[ed] a period after the word being defined, making each definition a complete sentence. |

New Sections

WAC 296-52-099 Definitions and 296-99-005 What definitions apply to this chapter?

Repealed Sections

WAC 296-52-60130 Definitions and 296-99-020 What definitions apply to this chapter?

Citation of Rules Affected by this Order: Amending WAC 296-52-60010 Purpose and intent, 296-52-60015 Coverage, 296-52-60020 Exemptions, 296-52-60030 The department, 296-52-60035 Other government entities, 296-52-60055 Drug use, 296-52-60060 License revocation, suspension, and surrender, 296-52-60080 Entry and access to explosive areas, 296-52-60095 Fire, 296-52-60115 Explosive industry employers, 296-52-60120 Variance from a chapter requirement, 296-52-60125 Using standards from national organizations and federal agencies, 296-52-61010 License applicants must provide this information, 296-52-61015 License applicants must complete department forms, 296-52-61030 Applicant participation, 296-52-61040 Reasons why applicants may be disqualified, 296-52-62010 Dealer applicant information, 296-52-62025 Prohibit explosives items from sale or display in these areas, 296-52-62035 Authorized agent information, 296-52-62040 Verification of customer identity, 296-52-62045 Recordkeeping and reporting, 296-52-63010 Applicant information, 296-52-63020 Authorized agents, 296-52-63025 Explosive order deliveries, 296-52-63030 Notify the department of blaster changes, 296-52-64005 Responsibility to obtain a blaster's license, 296-52-64020 General qualifications for blasters, 296-52-64030 List A qualifications, 296-52-64035 List B qualifications, 296-52-64040 List C qualifications, 296-52-64050 Blaster license applicant information, 296-52-64065 Blaster license limits, 296-52-64085 Changes to a blaster's license classification, 296-52-64090 Blaster license renewal, 296-52-64095 List A and B renewal qualifications, 296-52-64100 List C renewal qualifications, 296-52-65010 Manufacturer applicant information, 296-52-65015 Manufacturing site inspections, 296-52-65030 Site plan, 296-52-66010 Storage applicant information, 296-52-66015 Storage site inspections, 296-52-66020 Demonstration of handling and storage experience, 296-52-66053 Altering or destroying a licensed magazine, 296-52-66057 Transfer, sale or lease of a magazine or mobile storage site, 296-52-67010 Blaster in charge responsibilities, 296-52-67045 Handling explosives, 296-52-67050 Trainee supervision, 296-52-67060 Extraneous electricity and radio frequency (RF) transmitters, 296-52-67070 Storage at blast sites, 296-52-67080 Drilling, 296-52-67085 Loading blast holes, 296-52-67090 Initiation systems, 296-52-67100 Use of detonating cord, 296-52-67110 Precautions after firing, 296-52-67115 Excavation work in pressurized air locks, 296-52-67130 Fixed location mixing, 296-52-67135 Bulk delivery/mixing vehicles, 296-52-67140 Bulk storage bins, 296-52-67165 Fixed location mixing, 296-52-67170 Bulk delivery/mixing vehicles, 296-52-67230 Initiating systems, 296-52-67245 High speed tunneling: Central primer house, 296-52-68010 Public highways, 296-52-68015 Job sites and off-highway roads, 296-52-68020 Safety precautions, 296-52-68030 Cargo, 296-52-68040 Vehicle strength and condition, 296-52-68045 Open top vehicles, 296-52-68050 Vehicle placards, 296-52-68055 Vehicle fire protection, 296-52-68060 Operation of vehicles transporting explosives, 296-52-68065 Transporting detonators and explosives in the same vehicle, 296-52-68075 Powder cars, vehicles, and conveyances, 296-52-68085 Underground transportation, 296-52-69010 Explosives, 296-52-69025 Quantity and distance tables, 296-52-69030 Storage within magazines, 296-52-69040 Notification of fire safety authority, 296-52-69045 Magazine repairs, 296-52-69050 Inventory, 296-52-69055 Inspection, 296-52-69060 Precautions for areas surrounding magazine, 296-52-69065 Deteriorated explosives, 296-52-69070 Explosives recovered from misfires, 296-52-69080 Blast site storage, 296-52-69085 Multiple magazines, 296-52-69090 Blasting agents and supplies, 296-52-69095 Ammonium nitrate, 296-52-69110 Table H-21—Quantity and distance table for separation between magazines, 296-52-69125 Table H-24—Low explosives, 296-52-70005 Type 1 magazines: Permanent storage facilities, 296-52-70010 Building construction for Type 1 magazines, 296-52-70015 Igloos, army-type structures, tunnels, and dugouts, 296-52-70020 Type 2 magazines: Portable field storage, 296-52-70025 Construction for Type 2 magazines, 296-52-70030 Type 3 magazines: Indoor storage facilities, 296-52-70035 Storage facilities for detonators, 296-52-70045 Type 4 magazines: Blasting agent, low explosive, or nonmass detonating detonator storage facilities, 296-52-70050 Construction for Type 4 magazines, 296-52-70055 Type 5 magazines: Blasting agent storage facilities, 296-52-70060 Construction for Type 5 magazines, 296-52-70065 Explosives day box, 296-52-70070 Detonator day box, 296-52-70080 Magazine heating system requirements, 296-52-70085 Lighting, 296-52-71025 Separation from flammable materials, 296-52-71040 Shipping container, 296-52-71045 Storage, 296-52-71060 Separation from flammable materials, 296-52-71065 Storage, 296-52-71095 Hours of transfer, 296-52-71100 Storage in route, 296-52-71105 Railway cars, 296-52-720 Appendix A, sample explosives-blasting ordinance for local jurisdictions, nonmandatory, 296-52-800 Avalanche control, 296-52-803 Storage, makeup, and use of explosives for avalanche control blasting, 296-52-805 Hand charge makeup methods, 296-52-807 Avalanche control blasting, 296-52-809 Retrieving misfired explosives (duds), 296-59-001 Foreword, 296-59-003 Scope and application, 296-59-005 Incorporation of other standards, 296-59-007 Definitions, 296-59-010 Safe place standards, 296-59-015 General requirements, 296-59-020 Management's responsibility, 296-59-025 Employee's responsibility, 296-59-027 Work activities which include skiing, 296-59-030 Safety bulletin board, 296-59-050 Personal protective equipment, general requirements, 296-59-055 Lockout requirements, 296-59-060 Vessel or confined area requirements, 296-59-065 Fire protection and ignition sources, 296-59-070 Illumination, 296-59-075 Electrical equipment and distribution, 296-59-080 Installation, inspection, and maintenance of pipes, piping systems, and hoses, 296-59-085 Scaffolds, construction, use, and maintenance, 296-59-090 Mobile equipment and lift trucks, 296-59-095 Requirements for cranes and hoists—General safety and health standards to prevail, 296-59-115 Ski lift facilities and structures, 296-59-120 Ski lift operations, 296-59-125 Ski lift aerial work platforms, 296-59-130 Ski lift machinery guarding, 296-78-500 Foreword, 296-78-505 Definitions applicable to this chapter, 296-78-510 Education and first-aid standards, 296-78-515 Management's responsibility, 296-78-520 Employee's responsibility, 296-78-525 Accident-prevention programs, 296-78-530 Safety and health committee plan, 296-78-535 Safety bulletin board, 296-78-540 First-aid training and certification, 296-78-560 Safe place standards, 296-78-56501 Log dumps and ponds, 296-78-56503 Log hauls, 296-78-56505 Boats and mechanical devices on waters, 296-78-56507 Log decks, 296-78-56509 Mechanical barkers, 296-78-56511 Head rigs and feed works, 296-78-56513 Log carriages, 296-78-570 Band saws—Saws, 296-78-575 Circular saws, 296-78-580 Edgers, 296-78-585 Equalizer saws, 296-78-590 Gang saws and re-saws, 296-78-595 Jump saws, 296-78-600 Trimmer and slasher saws, 296-78-605 Swing saws, 296-78-610 Circular saws, speeds, repairs, 296-78-615 Saw filing and grinding rooms and equipment, 296-78-620 Miscellaneous woodworking machines—Planers, stickers, molders, matchers, 296-78-625 Planers (stave and headings), 296-78-630 Stave croziers, 296-78-635 Jointers, 296-78-640 Jointers (stave and heading), 296-78-645 Wood shapers, 296-78-650 Boring and mortising machines, 296-78-655 Tenoning machines, 296-78-660 Lathe (pail and barrel), 296-78-665 Sanding machines, 296-78-670 Glue machines, 296-78-675 Lath mills, 296-78-680 Veneer and plywood plants—Peeling and barking, 296-78-685 Veneer lathe, 296-78-690 Veneer slicer and cutter, 296-78-695 Veneer clipper, 296-78-700 Veneer wringer (swede), 296-78-705 The shake and shingle industry, 296-78-70501 Definitions—Terms, general, 296-78-70503 Shake and shingle machinery—General, 296-78-70505 Shake machinery, 296-78-70507 Upright shingle machine, 296-78-70509 Related shake and shingle sawing machinery, 296-78-70511 Safety rules, 296-78-71001 General, 296-78-71003 Floor and wall openings, 296-78-71005 Floors, docks, platforms and runways, 296-78-71007 Footwalks and passageways, 296-78-71009 Stairways and ladders, 296-78-71011 Egress and exit, 296-78-71013 Cableways, 296-78-71015 Tanks and chemicals, 296-78-71017 Dry kilns, 296-78-71019 Exhaust systems, 296-78-71021 Spray painting, 296-78-71023 Lighting, 296-78-71025 Gas piping and appliances, 296-78-71501 General Provisions, 296-78-71505 Mechanical power transmission apparatus, 296-78-720 Boiler and pressure vessels, 296-78-725 Nonionizing radiation, 296-78-730 Electrical service and equipment, 296-78-735 Elevators, moving walks, 296-78-740 Transportation—Lumber handling equipment—Cranes—Construction, 296-78-745 Electrical equipment, 296-78-750 Chains, wire rope, cables and fiber rope, 296-78-755 Natural and synthetic fiber rope slings, 296-78-760 Synthetic web slings, 296-78-765 Floor operated cranes, 296-78-770 Operators, 296-78-775 Signalpersons, 296-78-780 Repairpersons, 296-78-785 Construction requirements, 296-78-790 Crane platforms and footwalks, 296-78-795 Crane cages, 296-78-800 Crane rail stops, bumpers and fenders, 296-78-805 Crawler locomotive and truck cranes, 296-78-810 Chain and electric hoists, 296-78-815 Monorail hoists, 296-78-820 Air hoists, 296-78-825 Jib, pillar, and portable floor cranes, crabs, and winches, 296-78-830 Standard crane hand signals—Illustrations, 296-78-835 Vehicles, 296-78-84001 Loading, piling, storage and conveying—General, 296-78-84003 Conveyors, 296-78-84005 Dry kilns, 296-78-84007 Chippers and hogs, 296-78-84009 Bins and bunkers, 296-78-84011 Burners, 296-79-010 Scope and application, 296-79-011 Definitions, 296-79-020 General requirements, 296-79-030 Guards and guarding, 296-79-050 Personal protection clothing and equipment, 296-79-070 Illumination, 296-79-110 Elevated runways and ramps used by vehicles, 296-79-140 Installation, inspection, and maintenance of pipes, piping systems, and hoses, 296-79-150 Powered industrial trucks and other equipment, 296-79-170 Requirements for crawler and truck cranes, 296-79-180 Privately owned standard gauge railroad operations, 296-79-190 Loading and unloading materials from railway cars or trucks, 296-79-200 Bridge and dock plates, 296-79-210 For conveyors, maintenance and inspection, 296-79-220 Deactivating and lockout requirements, 296-79-230 Confined spaces, 296-79-250 Safety procedure for handling sulfur, 296-79-260 Pulpwood storage and handling, 296-79-270 Pulpwood preparation, 296-79-27003 Log hauls, slips, and carriages, 296-79-27005 Band saws, 296-79-27015 Construction and use of pulpwood splitters, 296-79-280 Chip and hog fuel storage, 296-79-29003 Warning of digester being blown, 296-79-29013 Pulping device procedures, 296-79-29015 Off machine repulping devices, 296-79-29021 Shredders and blowers, 296-79-29027 Guillotine type roll splitters, 296-79-29029 Broke hole, 296-79-29031 Industrial kiln guns and ammunition, 296-79-29033 Chlorine dioxide system, 296-79-300 Machine room equipment and procedures, 296-79-31003 Corrugator, 296-79-320 Sulfite recovery furnace area requirements, 296-99-010 What safety hazards does this chapter require the employer to control?, 296-99-015 What grain-handling operations does this chapter cover?, 296-99-025 What are the requirements for an emergency action plan?, 296-99-030 What training must an employer provide for employees?, 296-99-035 When must an employer issue a hot work permit?, 296-99-040 What practices must an employer follow for entry into grain storage structures?, 296-99-045 What information must an employer provide to contractors?, 296-99-050 What elements must an employer include in the housekeeping program?, 296-99-055 What is the maximum allowable grate opening size?, 296-99-060 How must filter collectors be installed?, 296-99-065 What preventive maintenance program must an employer implement?, 296-99-070 How must grain stream processing equipment be equipped?, 296-99-075 How many means of emergency escape must an employer provide?, 296-99-080 How must continuous-flow bulk raw grain dryers be equipped and installed?, 296-99-085 What special requirements apply to inside bucket elevators?, 296-115-015 Definitions, 296-115-025 Vessel inspection and certification, 296-115-050 General requirements and 296-115-060 Operations; new WAC 296-52-099 Definitions and 296-99-005 What definitions apply to this chapter?; and repealing WAC 296-52-60130 Definitions and 296-99-020 What definitions apply to this chapter?

Adopted under notice filed as WSR 17-08-023 on March 28, 2017.

Changes Other than Editing from Proposed to Adopted Version:

WAC 296-52-60115 Explosive industry employers.

• | In subsections (1) and (2), changed "WISHA" to "DOSH." |

WAC 296-52-60125 Using standards from national organizations and federal agencies.

• | In the opening paragraph, subsections (1) and (2) as well as a note at the bottom of the section, changed "WISHA" to "DOSH." |

WAC 296-52-61015 License applicants must complete department forms.

• | In subsection (2), changed "WISHA" to "DOSH." |

WAC 296-52-62045 Recordkeeping and reporting.

• | In subsection (3), changed "WISHA" to "DOSH." |

Number of Sections Adopted in Order to Comply with Federal Statute: New 0, Amended 0, Repealed 0; Federal Rules or Standards: New 0, Amended 0, Repealed 0; or Recently Enacted State Statutes: New 0, Amended 0, Repealed 0.

Number of Sections Adopted at Request of a Nongovernmental Entity: New 2, Amended 292, Repealed 2.

Number of Sections Adopted on the Agency's own Initiative: New 2, Amended 292, Repealed 2.

Number of Sections Adopted in Order to Clarify, Streamline, or Reform Agency Procedures: New 0, Amended 0, Repealed 0.

Number of Sections Adopted using Negotiated Rule Making: New 0, Amended 0, Repealed 0; Pilot Rule Making: New 0, Amended 0, Repealed 0; or Other Alternative Rule Making: New 0, Amended 0, Repealed 0.

Date Adopted: August 1, 2017.

Joel Sacks

Director

PART A

DEFINITIONS, PURPOSE, SCOPE, AND APPLICATION

NEW SECTION

WAC 296-52-099 Definitions.

Aerial blaster in charge. A person who:

(a) Is fully qualified, by means of training and experience in explosives use;

(b) Is adequately trained, experienced, and capable of recognizing hazardous conditions throughout the blast area;

(c) Is in charge of:

(i) The blast process; and

(ii) All aspects of explosives and blasting agent storage, handling, and use as recommended by the manufacturer and as required by this chapter.

(d) Is in a position of authority:

(i) To take prompt corrective action in all areas of the blast operation; and

(ii) Over all other blasters at the blast sight.

(e) Has a minimum of five missions under the supervision of a licensed aerial blaster in charge; and

(f) Successfully completes a written exam for aerial blaster in charge.

Alien. Any person who is not a citizen or national of the United States.

American table of distances. The American Table of Distances for Storage of Explosives as revised and approved by Institute of the Makers of Explosives (IME).

Approved storage facility. A facility for the storage of explosive materials which is in compliance with the following sections:

(a) Storage license (WAC 296-52-660);

(b) Storage of explosive materials, Part E of this chapter; and

(c) Magazine construction (WAC 296-52-700).

ATF. The Bureau of Alcohol, Tobacco, Firearms and Explosives.

Attended, as attending explosives. The physical presence of an authorized person within the field of vision of explosives. The said attendant shall be awake, alert, and not engage in activities which may divert their attention so that in case of an emergency the attendant can get to the explosives quickly and without interference, except for brief periods of necessary absence, during which absence simple theft of explosives is not ordinarily possible.

Authorized agent. A person delegated by a licensed purchaser, who possesses a basic knowledge of explosives handling safety, to order and receive explosives on the purchaser's behalf.

Authorized agent list. A current list of agents the purchaser has authorized to order or receive explosives on their behalf.

Authorized, approved, or approval. Authorized, approved, or approval by:

(a) The department;

(b) Any other approving agency; and

(c) An individual as specified in this chapter.

Authorized person. A person approved or assigned by an employer, owner, or licensee to perform a specific type of duty or be at a specific location at the job site.

Avalanche. The sliding or falling of a large amount of snow down a steep slope which has a destructive force due to its mass.

Avalanche control pack. A specially designed and constructed pack for carrying explosives.

Avalanche control route. A route or specific path which is used by an authorized person in order to control the occurrence of avalanches.

Avalauncher. A device like a cannon which is used for avalanche control blasting. It has a rotating base calibrated for pointing and the barrel is mounted on an elevating mechanism. It uses a compressed gas to propel a projectile containing an explosive charge and detonating means. The gas source is connected to the gun by high pressure hose with in-line control valves and pressure gauges ahead of the trigger mechanism.

Barricades.

(a) Barricade. Effectively screening a building containing explosives by means of a natural or artificial barrier from a magazine, another building, a railway, or highway;

(b) Artificial barricade. A barricade of such height that a straight line from the top of any sidewall of the building containing explosives to the eave line of any magazine or other building or to a point twelve feet above the center of a railway or highway shall pass through such barrier, an artificial mound or properly revetted wall of earth with a minimum thickness of three feet;

(c) Natural barricade. Any natural hill, mound, wall, or barrier composed of earth, rock, or other solid material at least three feet thick.

Blast area. The area of a blast that is effected by:

(a) Flying rock missiles;

(b) Gases; and

(c) Concussion.

Blast pattern. The plan of the drill holes laid out and a display of the burden distance, spacing distance, and their relationship to each other.

Blast site. The area where explosive material is handled during loading and fifty feet in all directions from loaded blast holes or holes to be loaded.

Blaster. A person trained and experienced in the use of explosives and licensed by the department.

Blaster in charge. A licensed blaster who is:

(a) Fully qualified, by means of training and experience in explosives use;

(b) Adequately trained, experienced, and capable of recognizing hazardous conditions throughout the blast area;

(c) In charge of:

(i) The blast process;

(ii) All aspects of explosives and blasting agent storage, handling, and use as recommended by the manufacturer and as required by this chapter.

(d) In a position of authority:

(i) To take prompt corrective action in all areas of the blast operation;

(ii) Over all other blasters at the blast area.

Blaster's license. An individual license issued by the department under the provisions of chapter 296-52 WAC.

Blasting agent. Any material or mixture consisting of a fuel and oxidizer:

(a) That is intended for blasting;

(b) Not otherwise defined as an explosive;

(c) If the finished product, as mixed for use or shipment, cannot be detonated by means of a number 8 test blasting cap when unconfined;

(d) A number 8 test blasting cap is one containing two grams of a mixture of eighty percent mercury fulminate and twenty percent potassium chlorate, or a blasting cap of equivalent strength. An equivalent strength cap comprises 0.40-0.45 grams of PETN base charge pressed in an aluminum shell with bottom thickness not to exceed 0.03 of an inch, to a specific gravity of not less than 1.4 g/cc., and primed with standard weights of primer depending on the manufacturer.

Blasting cap or cap. When used in connection with the subject of explosives shall mean detonator.

Blockholing. The breaking of boulders by firing a charge of explosives that has been loaded in a drill hole.

Buildings that are not inhabited. A building(s) which has no one in it while explosives are being made up in an adjacent explosives makeup room or while explosives are being held in an adjacent day box or hand charge storage facility.

Competent person. A person who:

(a) Is capable of identifying existing hazardous and the forecasting of hazards of working conditions which might be unsanitary or dangerous to personnel or property; and

(b) Has authorization to take prompt corrective action to eliminate such hazards.

Consumer fireworks.

(a) Any small firework device:

(i) Designed to produce visible effects by combustion;

(ii) That must comply with the construction, chemical composition, and labeling regulations of the U.S. Consumer Product Safety Commission (Title 16 C.F.R., Parts 1500 and 1507).

(b) A small device designed to produce audible effects which include, but are not limited to:

(i) Whistling devices;

(ii) Ground devices containing 50 mg or less of explosive materials;

(iii) Aerial devices containing 130 mg or less of explosive materials.

Note: | Fused set pieces containing components, which, together, exceed 50 mg of salute powder are not included. |

Conveyance. Any unit used for transporting explosives or blasting agents including, but not limited to:

(a) Trucks;

(b) Trailers;

(c) Rail cars;

(d) Barges;

(e) Vessels.

Day box. A box which:

(a) Is a temporary storage facility for storage of explosive materials;

(b) Is not approved for unattended storage of explosives;

(c) May be used at the worksite during working hours to store explosive materials, provided the day box is:

(i) Constructed as required (WAC 296-52-70065 Explosives day box);

(ii) Marked with the word "explosives";

(iii) Used in a manner that safely separates detonators from other explosives; and

(iv) Guarded at all times against theft.

Dealer. Any person who purchases explosives or blasting agents for the sole purpose of resale and not for use or consumption.

Detonating cord. A round flexible cord containing a center core of high explosive and used to initiate other explosives.

Detonator. Any device containing any initiating or primary explosive that is used for initiating detonation and includes, but is not limited to:

(a) Electric and electronic detonators of instantaneous and delay types;

(b) Detonators for use with safety fuses, detonating cord delay connectors, and nonelectric instantaneous delay detonators which use detonating cord, shock tube, or any other replacement for electric leg wires.

Discharge hose. A hose with an electrical resistance high enough to limit the flow of stray electric currents to safe levels, but not high enough to prevent drainage of static electric charges to the ground. Hose not more than 2 megohms resistance over its entire length and of not less than 5,000 ohms per foot meets the requirement.

Display fireworks. Large fireworks designed primarily to produce visible or audible effects by combustion, deflagration, or detonation, and include, but are not limited to:

(a) Salutes containing more than 2 grains (130 mg) of explosive materials;

(b) Aerial shells containing more than 40 grams of pyrotechnic compositions;

(c) Other display pieces, which exceed the limits of explosive materials for classification as "consumer fireworks";

(d) Fused set pieces containing components, which together exceed 50 mg of salute powder.

Dud. An unexploded deployed charge which still has its initiation system in place.

Electric blasting circuitry. Consists of these items:

(a) Bus wire. An expendable wire used in parallel or series, or in parallel circuits, which are connected to the leg wires of electric detonators;

(b) Connecting wire. An insulated expendable wire used between electric detonators and the leading wires or between the bus wire and the leading wires;

(c) Leading wire. An insulated wire used between the electric power source and the electric detonator circuit;

(d) Permanent blasting wire. A permanently mounted insulated wire used between the electric power source and the electric detonator circuit.

Electric delay detonators. Detonators designed to detonate at a predetermined time after energy is applied to the ignition system.

Electric detonator. A blasting detonator designed for and capable of detonation by means of electric current.

Electronic detonator. A detonator that utilizes stored electrical energy as a means of powering an electronic timing delay element/module that provides initiation energy for firing the base charge.

Emulsion. An explosive material containing:

(a) Substantial amounts of oxidizer dissolved in water droplets, surrounded by an immiscible fuel;

(b) Droplets of an immiscible fuel surrounded by water containing substantial amounts of oxidizer.

Explosive actuated power devices. Any tool or special mechanized device, which is activated by explosives and does not include propellant actuated power devices.

Explosives.

(a) Any chemical compound or mechanical mixture:

(i) Commonly intended or used for the purpose of producing an explosion;

(ii) That contains any oxidizing and combustible units or other ingredients in proportions, quantities or packing that an ignition by fire, friction, concussion, percussion, or detonation of any part of the compound or mixture may cause sudden generation of highly heated gases resulting in gaseous pressures capable of producing destructive effects on contiguous objects or of destroying life or limb.

(b) All material classified as Division 1.1, 1.2, 1.3, 1.4, 1.5, or 1.6 explosives by U.S. DOT;

(c) For the purposes of public consumer use, the following are not considered explosives unless they are possessed or used for a purpose inconsistent with small arms use or other legal purposes:

(i) Small arms ammunition;

(ii) Small arms ammunition primers;

(iii) Smokeless powder, not exceeding fifty pounds;

(iv) Black powder, not exceeding five pounds.

Explosives classifications. Explosives classifications include, but are not limited to:

(a) Division 1.1 and Division 1.2 explosives (possess mass explosion or detonating hazard):

(i) Dynamite;

(ii) Nitroglycerin;

(iii) Picric acid;

(iv) Lead azide;

(v) Fulminate of mercury;

(vi) Black powder (exceeding 5 pounds);

(vii) Detonators (in quantities of 1,001 or more);

(viii) Detonating primers.

(b) Division 1.3 explosives (possess a minor blast hazard, a minor projection hazard, or a flammable hazard):

(i) Propellant explosives;

(ii) Smokeless powder (exceeding fifty pounds).

(c) Division 1.4 explosives:

(i) Explosives that present a minor explosion hazard;

(ii) Includes detonators that will not mass detonate in quantities of 1,000 or less.

(d) Division 1.5 explosives:

(i) Explosives with a mass explosion hazard but are so insensitive that there is little probability of initiation;

(ii) ANFO and most other blasting agents are in this division.

(e) Division 1.6 explosives, which are explosives that are extremely insensitive and do not have a mass explosion hazard.

Explosives exemption. The exemption for small arms ammunition, small arms ammunition primers, smokeless powder, not exceeding fifty pounds, and black powder, not exceeding five pounds:

(a) Applies to public consumer use only;

(b) Does not apply to the employer employee relationship covered under the Washington Industrial Safety and Health Act.

Explosives international markings.

(a) The department will accept U.S. DOT and/or ATF international identification markings on explosives and/or explosives containers or packaging;

(b) This exception is under the authority of RCW 70.74.020(3) and in lieu of Washington state designated markings (as defined by RCW 70.74.010(4) (Division 1.1, 1.2, and 1.3) and required by RCW 70.74.300).

Explosives manufacturing building. Any building or structure, except magazines:

(a) Containing explosives where the manufacture of explosives, or any processing involving explosives, is conducted;

(b) Where explosives are used as a component part or ingredient in the manufacture of any article or device.

Explosives manufacturing plant. All lands with buildings used:

(a) In connection with the manufacturing or processing of explosives;

(b) For any process involving explosives;

(c) For the storage of explosives;

(d) To manufacture any article or device where explosives are used as a component part or ingredient in the article or device.

Fireworks. Any composition or device:

(a) Designed to produce a visible or an audible effect by combustion, deflagration, or detonation;

(b) Which meets the definition of "consumer fireworks" or "display fireworks."

Forbidden or not acceptable explosives. Explosives which are forbidden or not acceptable for transportation by common carriers by rail freight, rail express, highway, or water in accordance with the regulations of the Federal Department of Transportation (DOT).

Fuel. A substance, which may react with oxygen to produce combustion.

Fuse (safety). See "safety fuse."

Fuse igniter. A special pyrotechnic device intended to be used to ignite safety fuses.

Hand charge. An explosive charge with a cap and fuse assembly inserted in place.

Handler. Any individual who handles explosives or blasting agents for the purpose of transporting, moving, or assisting a licensed blaster in loading, firing, blasting, or disposal.

Note: | This does not include employees of a licensed manufacturer engaged in manufacturing process, drivers of common carriers, or contract haulers. |

Hand loader. Any person who engages in the noncommercial assembly of small arms ammunition for personal use; specifically, any person who installs new primers, powder, and projectiles into cartridge cases.

Highway. Roads, which are regularly and openly traveled by the general public and includes public streets, alleys, roads, or privately financed, constructed, or maintained roads.

Improvised device. A device, which is:

(a) Fabricated with explosives;

(b) Fabricated with destructive, lethal, noxious, pyrotechnic, or incendiary chemicals, and designed, or has the capacity to disfigure, destroy, distract, and harass.

Inhabited building.

(a) A building which is regularly occupied, in whole or in part, as a habitat for human beings;

(b) Any church, schoolhouse, railroad station, store, or other building where people assemble.

Note: | This does not mean any building or structure occupied in connection with the manufacture, transportation, storage, or use of explosives. |

Low explosives. Explosive materials, which can be caused to deflagrate when, confined. This includes black powder, safety fuses, igniters, igniter cords, fuse lighters, and display fireworks defined as Division 1.2 or Division 1.3 explosives by U.S. DOT (49 C.F.R. Part 173).

Note: | This does not apply to bulk salutes. |

Magazine. Any building, structure, or container approved for storage of explosive materials.

Note: | This does not apply to an explosive manufacturing building. |

Manufacturer. Any person engaged in the business of manufacturing explosive materials for purposes of sale or distribution or for his or her own use.

EXCEPTIONS: | The following exemptions are restricted to materials and components, which are not classified (by U.S. DOT) as explosives until after they are mixed. With this restriction, the definition of manufacturer does not include: |

• Inserting a detonator into a cast booster or a stick of high explosive product to make a primer for loading into a blast hole. | |

• The act of mixing on the blast site, either by hand or by mechanical apparatus, binary components, ammonium nitrate, fuel oil, and/or emulsion products to create explosives for immediate down blast hole delivery. |

Misfire. The complete or partial failure of an explosive charge to explode as planned.

Mudcap (also known as bulldozing and dobying). Covering the required number of cartridges that have been placed on top of a boulder with a three- or four-inch layer of mud, which is free from rocks or other material that could cause a missile hazard.

No-light. The failure of a safety fuse to ignite.

Nonelectric delay detonator. A detonator with an integral delay element in conjunction with and capable of being detonated by a:

(a) Detonation impulse;

(b) Signal from miniaturized detonating cord;

(c) Shock tube.

Oxidizer. A substance that yields oxygen readily to stimulate the combustion of organic matter or other fuel.

Permanent magazines. Magazines that:

(a) Are fastened to a foundation;

(b) Do not exceed permanent magazine capacity limits (RCW 70.74.040);

(c) Are approved and licensed;

(d) Are left unattended.

Person. Any individual, firm, partnership, corporation, company, association, person or joint stock association or trustee, receiver, assignee, or personal representative of that entity.

Person responsible. For an explosives magazine, means:

(a) The person legally responsible for a magazine that actually uses the magazine;

(b) The person is responsible for the proper storage, protection, and removal of explosives, and may be the owner lessee, or authorized operator.

Portable (field) magazines. Magazines that are:

(a) Designed to be unattended;

(b) Not permanently fastened to a foundation;

(c) Constructed or secured to make sure they cannot be lifted, carried, or removed easily by unauthorized persons;

(d) Limited to the capacity of explosives required for efficient blasting operation;

(e) Approved and licensed.

Possess. The physical possession of explosives in one's hand, vehicle, magazine, or building.

Primary blasting. The blasting operation that dislodged the original rock formation from its natural location.

Primer. A unit, package, cartridge, or container of explosives inserted into or attached to a detonator or detonating cord to initiate other explosives or blasting agents.

Propellant actuated power device. Any tool, special mechanized device, or gas generator system, which is actuated by a propellant and releases and directs work through a propellant charge.

Public utility transmission systems.

(a) Any publicly owned systems regulated by:

(i) The utilities and transportation commission;

(ii) Municipalities.

(b) Other public regulatory agencies, which include:

(i) Power transmission lines over 10 kV, telephone cables, or microwave transmission systems;

(ii) Buried or exposed pipelines carrying water, natural gas, petroleum, or crude oil or refined products and chemicals.

Purchaser. Any person who buys, accepts, or receives explosives or blasting agents.

Pyrotechnics (commonly referred to as fireworks). Any combustible or explosive compositions or manufactured articles designed and prepared for the purpose of producing audible or visible effects.

Qualified person. A person who has successfully demonstrated the ability to solve or resolve problems relating to explosives, explosives work, or explosives projects by:

(a) Possession of a recognized degree or certificate;

(b) Professional standing;

(c) Extensive knowledge, training, and experience.

Railroad. Any type of railroad equipment that carries passengers for hire.

Safety fuse (for firing detonators). A flexible cord containing an internal burning medium by which fire is conveyed at a continuous and uniform rate.

Secondary blasting. Using explosives, mudcapping, or blockholing to reduce oversize material to the dimension required for handling.

Shock tube. A small diameter plastic tube:

(a) Used for initiating detonators;

(b) That contains a limited amount of reactive material so energy, transmitted through the tube by means of a detonation wave, is guided through and confined within the walls of the tube.

Small arms ammunition. Any shotgun, rifle, pistol, or revolver cartridge, and cartridges for propellant actuated power devices and industrial guns.

Note: | This does not mean military type ammunition containing explosive bursting incendiary, tracer, spotting, or pyrotechnic projectiles. |

Small arms ammunition primers. Small percussion sensitive explosive charges encased in a detonator or capsule used to ignite propellant power or percussion detonators used in muzzle loaders.

Smokeless powder. Solid chemicals or solid chemical mixtures that function by rapid combustion.

Special industrial explosive devices. Explosive actuated power devices and propellant-actuated power devices.

Special industrial explosives materials. Shaped materials and sheet forms and various other extrusions, pellets, and packages of high explosives, which include:

(a) Dynamite;

(b) Trinitrotoluene (TNT);

(c) Pentaerythritol tetranitrate (PETN);

(d) Hexahydro-1, 3, 5-trinitro-s-triazine (RDX);

(e) Other similar compounds used for high-energy-rate forming, expanding, and shaping in metal fabrication, and for dismemberment and quick reduction of scrap metal.

Springing. The creation of a pocket in the bottom of a drill hole by the use of a moderate quantity of explosives so that larger quantities of explosives may be inserted.

Sprung hole. A drilled hole that has been enlarged by a moderate quantity of explosives to allow for larger quantities of explosives to be inserted into the drill hole.

Stemming. A suitable inert incombustible material or device used to confine or separate explosives in a drill hole or cover explosives in mudcapping.

Trailer. Semi-trailers or full trailers, as defined by U.S. DOT, which are:

(a) Built for explosives;

(b) Loaded with explosives;

(c) Operated in accordance with U.S. DOT regulations.

U.S. DOT. The United States Department of Transportation.

Vehicle. Any car, truck, tractor, semi-trailer, full trailer, or other conveyance used for the transportation of freight.

Water-gels or emulsion explosives. These explosives:

(a) Comprise a wide variety of materials used for blasting. Two broad classes of water-gels are those which:

(i) Are sensitized by material classed as an explosive, such as TNT or smokeless powder;

(ii) Contain no ingredient classified as an explosive which is sensitized with metals, such as aluminum, or other fuels.

(b) Contain substantial proportions of water and high proportions of ammonium nitrate, some ammonium nitrate is in the solution in the water, and may be mixed at an explosives plant, or the blast site immediately before delivery into the drill hole.

AMENDATORY SECTION (Amending WSR 02-03-125, filed 1/23/02, effective 3/1/02)

WAC 296-52-60010 Purpose and intent.

The purpose of this chapter is to define minimum requirements for the prevention and control of hazards related to the possession, handling, and use of explosives in order to:

((•)) (1) Protect the safety and health of the general public;

((•)) (2) Protect the safety and health of explosive industry employees covered under the Washington Industrial Safety and Health Act (chapter 49.17 RCW);

((•)) (3) Develop, support, and maintain safe and healthy use of explosives in Washington state.

AMENDATORY SECTION (Amending WSR 06-19-074, filed 9/19/06, effective 12/1/06)

WAC 296-52-60015 Coverage.

This chapter applies to:

((•)) (1) Any person, partnership, company, corporation, government agency, or other entity;

((•)) (2) All aspects of explosives, blasting agents, and pyrotechnics including:

((–)) (a) Manufacture;

((–)) (b) Sale;

((–)) (c) Possession;

((–)) (d) Purchase;

((–)) (e) Use;

((–)) (f) Storage;

((–)) (g) Transportation;

((–)) (h) Avalanche control.

((•)) (3) Display fireworks.

Note: | Class A and B display fireworks are partially exempt from the requirements of this chapter (see WAC 296-52-60020(5)). |

AMENDATORY SECTION (Amending WSR 14-08-024, filed 3/24/14, effective 5/1/14)

WAC 296-52-60020 Exemptions.

(1) The following are exempt from this chapter:

(a) Explosives or blasting agents transported by railroad, water, highway, or air under the jurisdiction of the Federal Department of Transportation (DOT), the Washington state utilities and transportation commission, and the Washington state patrol.

(b) Laboratories of schools, colleges, and similar institutions if confined to the purpose of instruction or research and if the quantity does not exceed one pound.

(c) Explosives in the forms prescribed by the official United States Pharmacopoeia.

(d) The transportation, storage, and use of explosives or blasting agents in the normal and emergency operations of:

((•)) (i) The United States agencies and departments including the regular United States military departments on military reservations;

((•)) (ii) Arsenals, navy yards, depots, or other establishments owned by, operated by, or on behalf of, the United States;

((•)) (iii) The duly authorized militia of any state; and

((•)) (iv) The emergency operations of any state department or agency, any police, or any municipality or county.

(e) A hazardous devices technician when they are carrying out:

((•)) (i) Normal and emergency operations;

((•)) (ii) Handling evidence;

((•)) (iii) Operating and maintaining a specially designed emergency response vehicle that carries no more than ten pounds of explosive materials;

((•)) (iv) When conducting training and whose employer possesses the minimum safety equipment prescribed by the Federal Bureau of Investigation (FBI) for hazardous devices work.

Note: | A hazardous devices technician is a person who is a graduate of the FBI Hazardous Devices School and who is employed by a state, county, or municipality. |

(f) The importation, sale, possession, and use of fireworks, signaling devices, flares, fuses, and torpedoes.

(g) Reserved.

(h) Any violation under this chapter if any existing ordinance of any city, municipality, or county is more stringent.

(i) The transportation and storage of explosive actuated tactical devices, including noise and flash diversionary devices, by local law enforcement tactical response teams and officers in law enforcement department-issued vehicles designated for use by tactical response teams and officers, provided the explosive devices are stored and secured in compliance with regulations and rulings adopted by the federal bureau of alcohol, tobacco, firearms, and explosives.

(2) Noncommercial military explosives. Storage, handling, and use of noncommercial military explosives are exempt from this chapter while they are under the control of the United States government or military authorities.

(3) Import, sale, possession, or use of:

((•)) (a) Consumer fireworks;

((•)) (b) Signaling devices;

((•)) (c) Flares;

((•)) (d) Fuses;

((•)) (e) Torpedoes.

(4) Consumer fireworks. Fireworks classified as Division 1.4 explosives by U.S. DOT and regulated through the state fireworks law (chapter 70.77 RCW) and the fireworks administrative code (chapter 212-17 WAC) by the Washington state fire marshal.

Note: | Consumer fireworks are classified as fireworks UN0336 and UN0337 by U.S. DOT (49 C.F.R. 72.101). |

(5) Partial exemption—Division 1.1, 1.2, or 1.3 display fireworks. Display fireworks are fireworks classified as Division 1.1, 1.2, or 1.3 explosives by US DOT. Users of Division 1.1, 1.2, or 1.3 display fireworks must comply with all storage or storage related requirements (for example, licensing, construction, and use) of this chapter.

Note: | Display fireworks are classified as fireworks UN0333, UN0334, or UN0335 by U.S. DOT (49 C.F.R. 172.101). |

(6) Conditional exemption small arms explosive materials. Public consumers possessing and using:

((•)) (a) Black powder, under five pounds;

((•)) (b) Smokeless powder, under fifty pounds;

((•)) (c) Small arms ammunition;

((•)) (d) Small arms ammunition primers.

((–)) Unless these materials are possessed or used illegally or for a purpose inconsistent with small arms use.

AMENDATORY SECTION (Amending WSR 02-03-125, filed 1/23/02, effective 3/1/02)

WAC 296-52-60030 The department.

(1) Administration and enforcement. The director of labor and industries administers and enforces all activities governed by the Washington State Explosives Act through chapter 296-52 WAC using the full resources of the department.

(2) Authority to enter, inspect, and issue penalties. The department may enter and inspect any location, facility, or equipment and issue penalties for any violation whenever the director has reasonable cause to think there are:

((•)) (a) Explosives;

((•)) (b) Blasting agents;

((•)) (c) Explosive materials.

(3) Unlicensed activities. Whenever the director requests an unlicensed person to surrender explosives, improvised devices, or their component parts, he may request the attorney general to apply to the county superior court in which the illegal practice was carried out for a temporary restraining order or other appropriate assistance.

AMENDATORY SECTION (Amending WSR 02-03-125, filed 1/23/02, effective 3/1/02)

WAC 296-52-60035 Other government entities.

(1) Law enforcement authorities. The department:

((•)) (a) Acknowledges the legal obligation of other law enforcement agencies to enforce specific aspects or sections of the Washington State Explosives Act under local ordinances and with joint and shared authority granted by RCW 70.74.201.

((•)) (b) Will cooperate with all other law enforcement agencies in carrying out the intent of the Washington State Explosives Act and chapter 296-52 WAC.

(2) Local government authorities.

(a) This chapter does not prevent local jurisdictions from adopting and administering local regulations relating to explosives. Examples of local jurisdictions/regulations include:

((•)) (i) City or county government explosive ordinances;

((•)) (ii) Other government authorities such as the Washington utilities and transportation commission, the Washington state patrol, or Washington administrative codes.

(b) Local regulations must not diminish or replace any regulation of this chapter.

Note: | A nonmandatory sample-blasting ordinance for local jurisdictions is included in Appendix B. |

AMENDATORY SECTION (Amending WSR 02-03-125, filed 1/23/02, effective 3/1/02)

WAC 296-52-60055 Drug use.

Explosives must not be handled by anyone under the influence of:

((•)) (1) Alcohol;

((•)) (2) Narcotics;

((•)) (3) Prescription drugs and/or narcotics that endanger the worker or others;

((•)) (4) Other dangerous drugs.

Note: | This chapter does not apply to persons taking prescription drugs and/or narcotics as directed by a physician provided their use will not endanger the blaster, workers, or any other people. |

AMENDATORY SECTION (Amending WSR 02-03-125, filed 1/23/02, effective 3/1/02)

WAC 296-52-60060 License revocation, suspension, and surrender.

(1) Revocation. The department:

(a) Will revoke and not renew the manufacturer, dealer, purchaser, blaster, or storage license of any person as a result of a disqualifying condition identified in WAC 296-52-61040, Applicant disqualifications.

(b) May revoke the license of any person who has:

(i) Repeatedly violated the requirements of this chapter;

(ii) Had a license suspended twice under this chapter.

(2) Suspension. The department may suspend the license of any person for a period up to six months for any violation of this chapter.

(3) Surrender. Revoked or suspended licenses must be surrendered immediately to the department after the chapter violators have been notified.

AMENDATORY SECTION (Amending WSR 02-03-125, filed 1/23/02, effective 3/1/02)

WAC 296-52-60080 Entry and access to explosive areas.

Only the owner, owner's authorized agent, the director, or law enforcement officer(s) acting in an official capacity may enter into an:

((•)) (1) Explosives manufacturing building;

((•)) (2) Magazine;

((•)) (3) Vehicle;

((•)) (4) Other common carrier containing explosives.

AMENDATORY SECTION (Amending WSR 02-03-125, filed 1/23/02, effective 3/1/02)

WAC 296-52-60095 Fire.

(1) Magazines/buildings. Flame or flame producing devices must not be ignited within fifty feet of any magazine or explosives manufacturing building.

(2) Explosives handling.

(a) All sources of fire or flame, including smoking and matches, are prohibited within one hundred feet of the blast site while explosives are being handled or used.

(b) Explosives must not be handled near:

(i) Open flames;

(ii) Uncontrolled sparks; or

((OR))

(iii) Energized electric circuits.

(3) Fire incident precautions. In the event of a fire:

(a) All employees must be removed to a safe area;

(b) The fire area must be guarded against intruders;

(c) The fire must not be fought where there is danger of contact with explosives.

AMENDATORY SECTION (Amending WSR 02-03-125, filed 1/23/02, effective 3/1/02)

WAC 296-52-60115 Explosive industry employers.

In addition to the requirements of this chapter:

(1) Explosive industry employers must comply with other applicable ((WISHA)) DOSH requirements:

((•)) (a) Chapter 296-800 WAC, Safety and health core rules;

((•)) (b) Chapter 296-24 WAC, General safety and health standards;

((•)) (c) Chapter 296-62 WAC, General occupational health standards;

((•)) (d) Chapter 296-155 WAC, Safety standards for construction;

((•)) (e) Other industry specific standards that may apply.

(2) Manufacturers of explosives or pyrotechnics must comply with ((WISHA)) DOSH safety standards for process safety management of highly hazardous chemicals, chapter 296-67 WAC.

AMENDATORY SECTION (Amending WSR 02-03-125, filed 1/23/02, effective 3/1/02)

WAC 296-52-60120 Variance from a chapter requirement.

The director may approve a variance from a chapter requirement pursuant to RCW 49.17.080 or 49.17.090:

((•)) (1) After an application for a variance is received((,));

((•)) (2) After the department has conducted an investigation((,));

((•)) (3) When conditions exist that make the requirement impractical to use((,)); and

((•)) (4) When equivalent means of protection are provided.

Note: | Variance application forms may be obtained from and should be submitted to: Department of Labor and Industries, WISHA Services Division, Post Office Box 44650, Olympia, WA 98504-4650. |

AMENDATORY SECTION (Amending WSR 02-03-125, filed 1/23/02, effective 3/1/02)

WAC 296-52-60125 Using standards from national organizations and federal agencies.

To be in compliance with ((WISHA)) DOSH rules, the information provided in this section must be followed when safety and health standards from national organizations and federal agencies are referenced in ((WISHA)) DOSH rules.

((•)) (1) The edition of the standard specified in the ((WISHA)) DOSH rule must be used.

((•)) (2) Any edition published after the edition specified in the ((WISHA)) DOSH rule may be used.

Note: | The federal and national consensus standards referenced in the ((WISHA)) DOSH rules are available through the issuing organization and the local or state library. |

AMENDATORY SECTION (Amending WSR 08-15-139, filed 7/22/08, effective 12/1/08)

WAC 296-52-61010 License applicants must provide this information.

(1) Individual applicants must provide the following information to the department:

((• An individual must provide:

–)) (a) Their name((,));

(b) Their address((,)); and

(c) Their citizenship.

((•)) (2) A partnership must provide:

((–)) (a) The name, address, and citizenship for each partner;

((–)) (b) The name and address of the applicant.

((•)) (3) An association or corporation must provide:

((–)) (a) The name, address, and citizenship for each officer and director;

((–)) (b) The name and address of the applicant.

(((2))) (4) Applicants must:

((•)) (a) Meet any license specific requirements;

((•)) (c) Provide any information requested by the department before a new or renewal license will be issued.

AMENDATORY SECTION (Amending WSR 02-03-125, filed 1/23/02, effective 3/1/02)

WAC 296-52-61015 License applicants must complete department forms.

(1) Applications must be completed on department forms.

((•)) (2) License application forms may be obtained from and submitted to:

Department of Labor and Industries, ((WISHA)) DOSH Services Division

Post Office Box 44655((,))

Olympia, WA 98504-4655.

Note: | Purchaser and blaster license applications may also be obtained from explosive dealers or department service locations. (You will find a complete list of L&I service locations at www.lni.wa.gov.) |

AMENDATORY SECTION (Amending WSR 08-15-139, filed 7/22/08, effective 12/1/08)

WAC 296-52-61030 Applicant participation.

(1) Applicants((:

•)) must cooperate and assist the department in all aspects of the application review.

((•)) (2) Applicants must provide all information requested by the department to:

((–)) (a) Verify application statements;

((–)) (b) Help with any questions.

((•)) (3) Applicants must furnish their fingerprints to the department on department forms.

((–)) Fingerprinting and criminal history record information checks are required for management officials directly responsible for explosives operations.

((•)) (4) Applicants must pay the fee to the department for processing the fingerprint card (RCW 70.74.360(1)).

AMENDATORY SECTION (Amending WSR 06-19-074, filed 9/19/06, effective 12/1/06)

WAC 296-52-61040 Reasons why applicants may be disqualified.

(1) Licenses will not be issued for the manufacture, retail sale or purchase of explosives to any applicant who is any of the following:

((•)) (a) Does not provide proof of a valid explosive license or permit issued by the Bureau of Alcohol, Tobacco, Firearms, and Explosives (ATF);

((•)) (b) Under twenty-one years of age;

((•)) (c) Whose license is suspended or revoked, except as provided in this section;

((•)) (d) Convicted in any court of a crime punishable by imprisonment for a term exceeding one year;

((•)) (e) Legally determined at the time of application to be:

((–)) (i) Mentally ill;

((–)) (ii) Insane;

((–)) (iii) Committed to a mental institution;

((–)) (iv) Incompetent due to any mental disability or disease at the time of application.

Note: | The department will not reissue a license until competency has been legally restored. |

((•)) (f) Physically ill or disabled, and cannot use explosives safely. Disqualifying disabilities may include, but are not limited to:

((–)) (i) Blindness;

((–)) (ii) Deafness;

((–)) (iii) Epileptic or diabetic seizures or coma.

Note: | The department will not reissue a license until the applicant's physical ability is verified by a qualified physician through the appeal process (WAC 296-52-60065, Violation appeals). |

((•)) (g) Who is an alien, unless:

((–)) (i) They are lawfully admitted for permanent residence ((–)); and

((–)) (ii) They are in lawful nonimmigrant status.

((•)) (h) Who has been dishonorably discharged from the United States armed forces;

((•)) (i) Who has renounced their citizenship from the United States.

(2) A user (blaster) license will not be issued if the applicant is denied a receiver or employee possessor designation by ATF.

AMENDATORY SECTION (Amending WSR 05-08-110, filed 4/5/05, effective 6/1/05)

WAC 296-52-62010 Dealer applicant information.

The dealer applicant must:

((•)) (1) Give the reason they want to participate in the business of dealing in explosives.

((•)) (2) Provide information required by WAC 296-52-61010, License applicants must provide this information.

((•)) (3) Provide other pertinent information required by the department.

AMENDATORY SECTION (Amending WSR 02-03-125, filed 1/23/02, effective 3/1/02)

WAC 296-52-62025 Prohibit explosives items from sale or display in these areas.

Explosives, improvised devices, or blasting agents cannot be sold, displayed, or exposed for sale on any:

((•)) (1) Highway;

((•)) (2) Street;

((•)) (3) Sidewalk;

((•)) (4) Public way; or

((OR

•)) (5) Public place.

AMENDATORY SECTION (Amending WSR 02-03-125, filed 1/23/02, effective 3/1/02)

WAC 296-52-62035 Authorized agent information.

A dealer must make sure the purchaser provides a list of people on their authorized agent list with the following information:

((•)) (1) Name;

((•)) (2) Address;

((•)) (3) Driver's license number or valid identification;

((•)) (5) Place of birth;

((•)) (6) Date of birth.

AMENDATORY SECTION (Amending WSR 02-03-125, filed 1/23/02, effective 3/1/02)

WAC 296-52-62040 Verification of customer identity.

(1) Orders.

(a) An order for explosives can be placed:

((•)) (i) In person;

((•)) (ii) By telephone; or

((OR

•)) (iii) In writing.

(b) The dealer must receive proper authorization and identification from the person placing the order to verify the person is either the:

((•)) (i) Purchaser; or

((OR

•)) (ii) Purchaser's authorized agent.

Note: | This requirement does not apply to licensed common carrier companies when the common carrier: |

((•)) 1. Is transferring explosive materials from the seller to the purchaser; and | |

((AND)) | |

((•)) 2. Complies with transfer practices of the state and federal U.S. DOT regulations. |

(2) Deliveries. The dealer must:

(a) Not distribute explosive materials to an unauthorized person((.));

(b) Make sure the recipient is the purchaser or the purchaser's authorized agent((.));

(c) Verify the recipient's identity from a photo identification card (for example, driver's license)((.));

(d) Obtain the:

(i) Purchaser's magazine license number when explosives are delivered to a storage magazine.

(ii) Legal signature of the purchaser or the purchaser's authorized agent on a receipt documenting the explosives were received.

AMENDATORY SECTION (Amending WSR 02-03-125, filed 1/23/02, effective 3/1/02)

WAC 296-52-62045 Recordkeeping and reporting.

(1) Sale documentation. A dealer must document the following information when an explosive materials order is placed. A dealer's record must include the:

((•)) (a) Date explosive materials were sold;

((•)) (b) Purchaser's name and license number;

((•)) (c) Name of the person authorized by the purchaser to physically receive the explosive materials;

((•)) (d) Kind of explosive materials sold;

((•)) (e) Amount of explosive materials sold;

((•)) (f) Date code.

Note: | Black powder sales less than five pounds are not required to be reported to the department. |

(2) Retention of records and receipts. Dealers must keep:

((•)) (a) Signed receipts for a minimum of one year from the date explosives were purchased;

((•)) (b) Records of explosives purchased and sold for a minimum of five years.

(3) Monthly report.

((•)) (a) A monthly report of the dealer's records must be submitted to the department at the following address:

Department of Labor and Industries

((WISHA)) DOSH Services Division

Post Office Box 44655

Olympia, WA 98504-4655

((•)) (b) Dealer records must be received by the 10th day of each month.

AMENDATORY SECTION (Amending WSR 05-08-110, filed 4/5/05, effective 6/1/05)

WAC 296-52-63010 Applicant information.

Applicants must provide the following information to the department:

((•)) (1) The reason explosives or blasting agents will be used;

((•)) (2) The location where explosives or blasting agents will be used;

((•)) (3) The kind of explosives or blasting agents to be used;

((•)) (4) The amount of explosives or blasting agents to be used;

((•)) (5) An explosives storage plan:

((–)) (a) Documenting proof of ownership of a licensed storage magazine; or

((OR

–)) (b) With a signed authorization to use another person's licensed magazine; or

((OR

–)) (c) With a signed statement certifying that the explosives will not be stored.

((•)) (6) An authorized agent list, if the purchaser chooses to authorize others to order or receive explosives on their behalf;

((•)) (7) The identity and current license of the purchaser's blaster;

((•)) (8) Information required by WAC 296-52-61010, License applicants must provide this information;

((•)) (9) Any other pertinent information requested by the department.

AMENDATORY SECTION (Amending WSR 02-03-125, filed 1/23/02, effective 3/1/02)

WAC 296-52-63020 Authorized agents.

(1) Required information.

The purchaser must provide the following written information for people on their authorized agent list:

((•)) (a) Legal name;

((•)) (b) Address;

((•)) (c) Driver's license number or other valid identification;

((•)) (d) Date of birth;

((•)) (e) Place of birth.

(2) List distribution. The purchaser must provide a current authorized agent list to:

((•)) (a) The department when applying for a new or renewal license;

((•)) (b) Any dealer the purchaser plans to order explosive materials from, prior to placing the order.

(3) Notification of list changes. The purchaser must make sure the dealer's and department's authorized agent lists are updated as changes occur.

AMENDATORY SECTION (Amending WSR 02-03-125, filed 1/23/02, effective 3/1/02)

WAC 296-52-63025 Explosive order deliveries.

(1) Receiver identification. Any person receiving explosives purchased from a dealer must:

((•)) (a) Provide proper identification and prove to the satisfaction of the dealer that they are:

((–)) (i) The purchaser; or

((OR

–)) (ii) Their authorized agent.

((•)) (b) Sign their legal signature on the dealer's receipt.

(2) Delivery locations. Explosives must be delivered into:

((•)) (a) Authorized magazines;

((•)) (b) Approved temporary storage; or

((OR

•)) (c) Handling areas.

AMENDATORY SECTION (Amending WSR 02-03-125, filed 1/23/02, effective 3/1/02)

WAC 296-52-63030 Notify the department of blaster changes.

The purchaser must:

((•)) (1) Notify the department when the licensed blaster changes.

((•)) (2) Provide their current blaster's license number to the department.

AMENDATORY SECTION (Amending WSR 06-19-074, filed 9/19/06, effective 12/1/06)

WAC 296-52-64005 Responsibility to obtain a blaster's license.

(1) No one may conduct a blasting operation without a valid blaster's license issued by the department.

Note: | A blaster's license is not required for a "hand loader." |

(2) Blaster license classifications table. The following information shows classifications for blasting licenses((.)):

((•)) (a) Classification list assignment. Classification list assignment is determined by the use of single or multiple series charges; and the knowledge, training, and experience required to perform the type of blasting competently and safely.

((•)) (b) Multiple list applications. When an applicant wants to apply for multiple classifications and the classifications desired are from two or more classification table lists:

((–)) (i) All classifications must be requested on the application;

((–)) (ii) Qualifying documentation for all classifications being applied for must be included in the applicant's resume (WAC 296-52-64050, Applicant information). Training and experience may fulfill qualification requirements in multiple classifications.

((•)) (c) Request classifications not lists. Applicants must request specific classifications (not list designations) on their blaster application. Licenses are not issued or endorsed for Classification Table lists A, B, or C.

((•)) (d) License additions. To add a classification to an existing license, see WAC 296-52-64085, Changes to a blaster's license classification.

License Classifications Table |

|||||

LIST A |

LIST B |

LIST C |

|||

AB |

Aerial Blasting |

DE |

Demolition |

BT |

Bomb Technician* |

AG |

Agriculture |

SB |

Surface Blasting* |

UL |

Unlimited* |

AV |

Avalanche Control |

UB |

Underground Blasting |

||

ED |

Explosives Disposal* |

UW |

Underwater Blasting |

||

FO |

Forestry* |

||||

LE |

Law Enforcement* |

||||

IO |

Industrial Ordnance |

||||

SE |

Seismographic |

||||

TS |

Transmission Systems |

||||

WD |

Well Drilling |

||||

* | Detailed classification information. |

((•)) (e) Aerial blasting. Will require experience and passing aerial blasting test.

((•)) (f) Bomb technician. Disposal of bombs, illegal fireworks and explosive devices.

((•)) (g) Explosives disposal. Disposal of explosive materials by licensed blasters.

((•)) (h) Forestry. Includes logging, trail building, and tree topping.

((•)) (i) Law enforcement. Diversionary devices, explosive detection K-9 dog handlers, crowd control devices (stingers) requires taking a handlers test. Tactical entry (breaching) requires taking the tactical entry test.

((•)) (j) Surface blasting. Includes construction, quarries, and surface mining.

((•)) (k) Unlimited. Includes all classifications except underground blasting and law enforcement.

AMENDATORY SECTION (Amending WSR 02-03-125, filed 1/23/02, effective 3/1/02)

WAC 296-52-64020 General qualifications for blasters.

(1) Physical condition. An applicant must be in good physical condition.

(2) Drug use. An applicant cannot be addicted to narcotics, intoxicants, or similar types of drugs.

Note: | This rule does not apply to physician prescribed drugs and/or narcotics when taken as directed if their use will not place the blaster, or other employees in danger. |

(3) Knowledge, experience, and performance in transportation, storage, handling, and use of explosives. A blaster applicant must:

((•)) (a) Have working knowledge of state and local explosives laws and regulations;

((•)) (b) Have adequate blaster training, experience, and knowledge;

((•)) (c) Be able to:

((–)) (i) Safely perform the type of blasting to be used; and

((AND

–)) (ii) Recognize hazardous conditions.

((•)) (d) Be competent in the use of each type of blasting method to be used

((•)) (e) Have the ability to understand and give written and oral directions.

AMENDATORY SECTION (Amending WSR 06-19-074, filed 9/19/06, effective 12/1/06)

WAC 296-52-64030 List A qualifications.

To be considered for a blaster's license, limited to one or more List A classifications, an applicant must have a minimum of forty hours documented training accrued during the previous six years.

(1) The training must include a minimum of one of these three requirements:

((•)) (a) Eight hours basic blaster safety classroom training and thirty-two hours classification specific field training experience under a qualified blaster;

((•)) (b) Sixteen hours basic blaster safety classroom training and twenty-four hours classification specific field training experience under a qualified blaster;

((•)) (c) Twelve months classification specific field training experience.

(2) Aerial blasting classification ((shall)) will require:

((•)) (a) Standard avalanche control blaster's license;

((•)) (b) Experience requirement of five missions under the supervision of a licensed aerial blaster;

((•)) (c) Successful completion of a written exam.

Note: | Additional personnel on board with a standard avalanche control blaster's license may log each mission toward the aerial blasting endorsement experience requirement. |

AMENDATORY SECTION (Amending WSR 02-03-125, filed 1/23/02, effective 3/1/02)

WAC 296-52-64035 List B qualifications.

To be considered for a blaster's license, which includes one or more List B classifications, the applicant must meet one of the following requirements listed below:

((•)) (1) Eighteen months of documented blasting experience which includes a minimum of twelve months of documented experience in List A and six months documented blasting experience in each classification being applied for in List B;

((•)) (2) Twelve months of documented blasting experience in the past six years in the specific classification being applied for in List B.

Note: | Up to eighty hours of classroom training may be substituted for experience. |

AMENDATORY SECTION (Amending WSR 05-08-110, filed 4/5/05, effective 6/1/05)

WAC 296-52-64040 List C qualifications.

(1) Unlimited classification. To be considered for unlimited classification, the applicant must submit a detailed resume documenting:

((•)) (a) Experience in the majority of the classifications in Lists A and B;