|

PROPOSED SECTION AND TITLE | TYPE OF CHANGE | DESCRIPTION | |

1. | Chapter 51-11RWAC title for WSEC, Residential Provisions. | Editorial | The title was corrected to the 2021 edition. |

2. | R101.1 Title. | Editorial | The effective date was changed to March 15, 2024, consistent with the amendatory rule filed under WSR 23-20-022. |

3. | R104.1 Fees. | The internal section reference was corrected. | |

4. | R105.2 Required inspections. | Editorial | The internal section references were corrected. |

5. | R108.1 Referenced codes and standards. | Editorial | Internal chapter and section references were corrected. |

6. | Advanced Framed Walls. | Editorial | The reference to Appendix A was corrected to point to the commercial provisions. |

7. | R302.2 Exterior design conditions. | Editorial | The internal appendix reference was corrected. |

8. | R402.1.1 Vapor retarder. | Editorial | The internal section reference was corrected. |

9. | Table R402.1.2 Insulation and fenestration requirements by component. | Editorial | The U-factor for above grade wall was corrected. It was mistakenly left unchanged after the changes from the 2021 International Energy Conservation Code were incorporated. This will correlate to the change made to the wood frame Wall R-value. |

10. | Table R402.1.3 Insulation minimum R-values and fenestration requirements by components. | Editorial | The reference to Appendix A in Footnote A was corrected to point to the commercial provisions. |

11. | R402.3 Fenestration. | Editorial | The internal section reference was corrected. |

12. | R402.3.5 Combustion air openings. | Editorial | The redundant reference to climate zones was removed and the section references in Exception 2 were clarified. |

13. | R404.2 Air leakage. | Editorial | The internal section reference was corrected. |

14. | R402.4.1.2 Testing. | Editorial | Correction of a typographical error. |

15. | R402.4.2 Air leakage of fenestration; R402.4.3 Recessed lighting; R402.4.4 Electrical and communication outlet boxes. | Editorial | Section numbering was corrected. |

16. | Table R402.4.1.1 Air barrier and insulation installation. | Editorial | Section references under "Basement, crawlspace and slab foundation" and "Recessed lighting" were corrected. |

17. | R403.3.1 Ducts located outside conditioned space. | Editorial | Correction of a typographical error. |

18. | R403.3.3.1 Effective R-value of deeply buried ducts. | Editorial | Updated the text to reference the correct title for Section R405. |

19. | R403.5.5 Water heater installation location. | EPCA | Added three new exceptions to correlate with the allowance of other types of water heaters besides heat pump water heaters. |

20. | 403.5.6 Water heater insulation. | EPCA | Changed out reference from "electric" to "tank-type" water heater. |

21. | R403.5.7: | EPCA | Removed the section requiring the installation of a heat pump water heater and renumbered subsequent section. |

22. | R403.13: | EPCA | Removed the section requiring the installation of a heat pump space heater. |

23. | R405.2 Performance based compliance. | EPCA | Added some missing text to the first sentence, updated the table reference, and switched the references from carbon emissions to site energy. This changes the performance metric to site energy so that the proposed design will be evaluated against a prescriptive baseline on a one-to-one energy basis in accordance with EPCA (f)(3)(c). |

24. | Table R405.2 Mandatory compliance measures for total building performance. | EPCA | The number of the table was corrected since Table R405.2(2) was removed. Reference to R402.2.10.1 was removed as this section does not exist in WSEC. References to R403.5.7 and R403.13 were removed, as these sections were removed from the WSEC. |

25. | Table R405.2(2) Carbon emissions factors. | EPCA | This table was removed from the code as a step to change the performance metric from carbon emissions to site energy. |

26. | R405.3 Documentation. | Editorial | The internal section reference was corrected. |

27. | Table R405.4.1(1) Specifications for the standard reference and proposed design. | Editorial | The table number was corrected. Section references under "Heating systems" and "Cooling systems" were corrected. A typographical error in "Service water heating" was corrected. |

28. | Table R405.4.2(2) Default distribution system efficiencies for proposed design. | Editorial | The table number was corrected. |

29. | R405.5.1 Minimum capabilities. | Editorial | An internal section reference was corrected. |

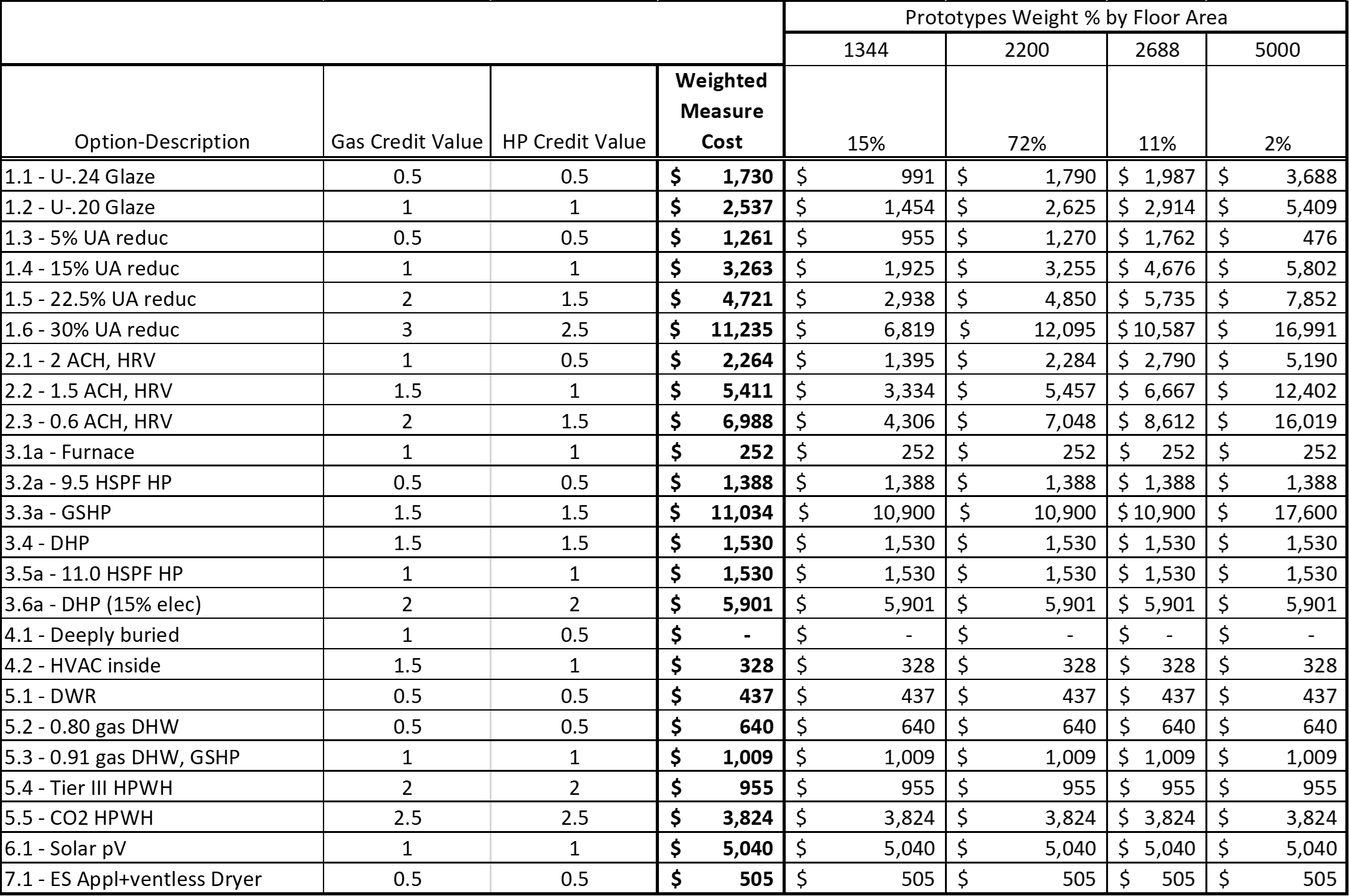

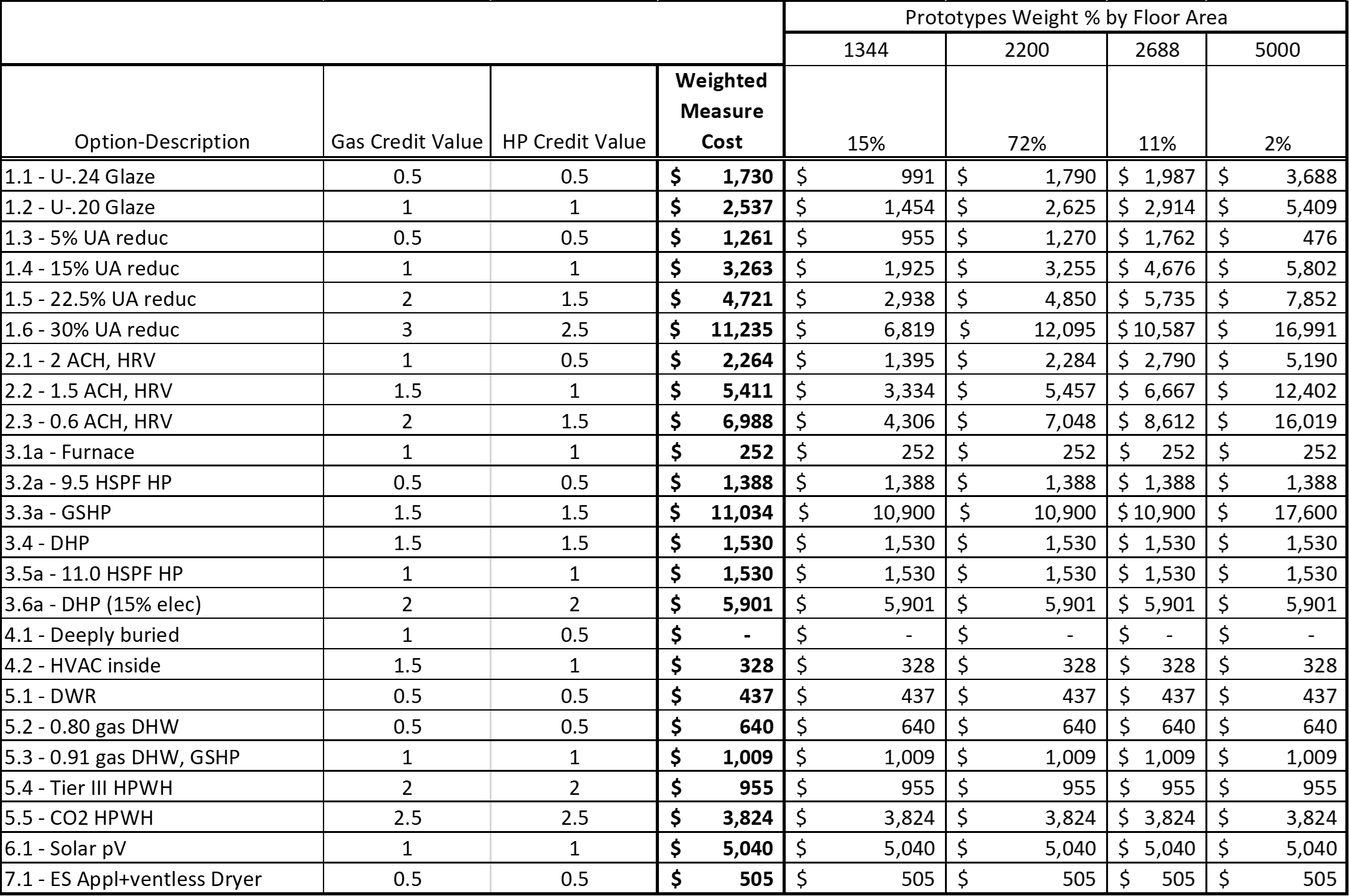

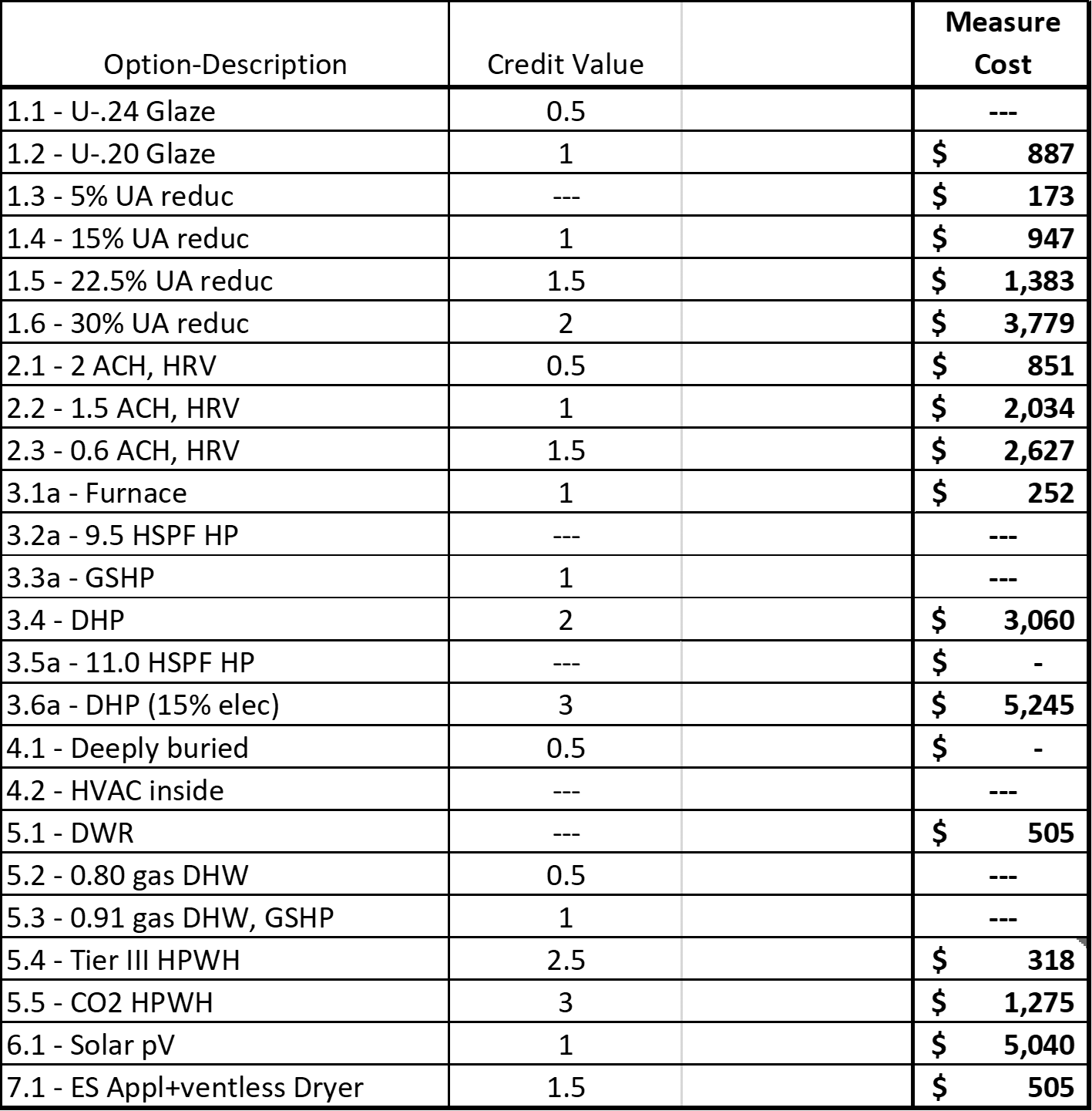

30. | Table R406.2 Energy Equalization Credits. | EPCA | The table title was changed to reflect the energy difference of compliant heating equipment and the baseline moved from heat pump heating to a combustion heating system with the credits redistributed to account for relative site energy use. |

31. | R406.3 Additional energy efficiency requirements. | EPCA | With the move from a heat pump to a combustion heating system baseline, the required credits to be achieved were adjusted to account for the relevant efficiency losses to the baseline. |

32. | Table R406.3 Energy Credits. | EPCA | The envelope credit and air leakage options were adjusted to allow for the greater impact on efficiency with the change to a combustion heating system baseline. Additional options were added for high performance combustion heating systems and service water heating. A typographical error was corrected in Option 6.1. |

33. | R501.6 Historic buildings. | Editorial | A typographical error was corrected. |

34. | R502.1 General. | Editorial | The internal section references were corrected. |

35. | R502.3.1.1 Existing ceilings with attic spaces. | Editorial | The metric conversion was corrected. |

36. | R503.1.1 Building envelope. | Editorial | Internal section references were corrected. |

37. | R503.1.2 Heating and cooling systems. | EPCA | Exception 3, referring to the removed Section R403.13, was deleted. |

38. | R503.1.3 Service hot water systems. | EPCA | Exception 2, referring to the removed Section R403.5.7 language, was deleted. |

39. | Chapter 6 Referenced standards. | Editorial and EPCA | Cited section references were updated and typographical errors corrected. Two new gas appliance standards and one gas water heater standard were added as referenced in Table R406.3. |

|

|

2017 Industry NAICS Code | NAICS Code Title | Minor Cost Estimate | 1% of Avg Annual Payroll | 0.3% of Avg Annual Gross Business Income |

236116 | New Multifamily Housing Construction (except For-Sale Builders) | $32,067.43 | $17,160.94* 2020 Dataset pulled from USBLS | $32,067.43 2020 Dataset pulled from DOR |

236118 | Residential Remodelers | $1,457.74 | $1,457.74* 2020 Dataset pulled from USBLS | $901.20 2020 Dataset pulled from DOR |

238150 | Glass and Glazing Contractors | $5,255.36 | $9,574.95 2019 Dataset pulled from CBP | $5,255.36 2020 Dataset pulled from DOR |

238160 | Roofing Contractors | $3,589.99 | $5,007.86 2019 Dataset pulled from CBP | $3,589.99 2020 Dataset pulled from DOR |

238170 | Siding Contractors | $1,905.61 | $2,485.86 2019 Dataset pulled from CBP | $1,905.61 2020 Dataset pulled from DOR |

238210 | Electrical Contractors and Other Wiring Installation Contractors | $5,941.60 | $9,599.33 2019 Dataset pulled from CBP | $5,941.60 2020 Dataset pulled from DOR |

238220 | Plumbing; Heating; and Air-Conditioning Contractors | $5,353.76 | $11,047.00 2019 Dataset pulled from CBP | $5,353.76 2020 Dataset pulled from DOR |

238290 | Other Building Equipment Contractors | $4,335.21 | $16,142.07 2019 Dataset pulled from CBP | $4,335.21 2020 Dataset pulled from DOR |

238310 | Drywall and Insulation Contractors | $3,725.66 | $9,461.67 2019 Dataset pulled from CBP | $3,725.66 2020 Dataset pulled from DOR |

238990 | All Other Specialty Trade Contractors | $3,585.74 | $3,677.28 2019 Dataset pulled from CBP | $3,585.74 2020 Dataset pulled from DOR |

321911 | Wood Window and Door Manufacturing | $45,151.12 | $18,811.08 2020 Dataset pulled from ESD | $45,151.12 2020 Dataset pulled from DOR |

332321 | Metal Window and Door Manufacturing | $26,369.28 | $14,505.40 2020 Dataset pulled from ESD | $26,369.28 2020 Dataset pulled from DOR |

332322 | Sheet Metal Work Manufacturing | $23,337.23 | $23,337.23 2020 Dataset pulled from ESD | $16,556.52 2020 Dataset pulled from DOR |

335129 | Other Lighting Equipment Manufacturing | $6,281.32 | $6,281.32 2020 Dataset pulled from ESD | $2,494.40 2020 Dataset pulled from DOR |

423720 | Plumbing and Heating Equipment and Supplies (Hydronics) Merchant Wholesalers | $24,486.53 | $16,589.10 2020 Dataset pulled from ESD | $24,486.53 2020 Dataset pulled from DOR |

541310 | Architectural Services | $9,221.65 | $9,221.65 2020 Dataset pulled from ESD | $3,738.99 2020 Dataset pulled from DOR |

541330 | Engineering Services | $14,801.92 | $14,801.92 2020 Dataset pulled from USBLS | $7,177.43 2020 Dataset pulled from DOR |

EXCEPTION: | Systems serving multiple dwelling units shall be inspected in accordance with Section C104.2.4. |

Door Type | No Glazed Fenestration | Single Glazing | Double Glazing with 1/4 in. Airspace | Double Glazing with 1/2 in. Airspace | Double Glazing with e = 0.10, 1/2 in. Argon | |

SWINGING DOORS (Rough opening - 38 in. x 82 in.) | ||||||

Slab Doors | ||||||

Wood slab in wood framea | 0.46 | |||||

6% glazed fenestration (22 in. x 8 in. lite) | - | 0.48 | 0.47 | 0.46 | 0.44 | |

25% glazed fenestration (22 in. x 36 in. lite) | - | 0.58 | 0.48 | 0.46 | 0.42 | |

45% glazed fenestration (22 in. x 64 in. lite) | - | 0.69 | 0.49 | 0.46 | 0.39 | |

More than 50% glazed fenestration | Use Table R303.1.3(1) | |||||

Insulated steel slab with wood edge in wood framea | 0.16 | |||||

6% glazed fenestration (22 in. x 8 in. lite) | - | 0.21 | 0.20 | 0.19 | 0.18 | |

25% glazed fenestration (22 in. x 36 in. lite) | - | 0.39 | 0.28 | 0.26 | 0.23 | |

45% glazed fenestration (22 in. x 64 in. lite) | - | 0.58 | 0.38 | 0.35 | 0.26 | |

More than 50% glazed fenestration | Use Table R303.1.3(1) | |||||

Foam insulated steel slab with metal edge in steel frameb | 0.37 | |||||

6% glazed fenestration (22 in. x 8 in. lite) | - | 0.44 | 0.42 | 0.41 | 0.39 | |

25% glazed fenestration (22 in. x 36 in. lite) | - | 0.55 | 0.50 | 0.48 | 0.44 | |

45% glazed fenestration (22 in. x 64 in. lite) | - | 0.71 | 0.59 | 0.56 | 0.48 | |

More than 50% glazed fenestration | Use Table R303.1.3(1) | |||||

Cardboard honeycomb slab with metal edge in steel frameb | 0.61 | |||||

Style and Rail Doors | ||||||

Sliding glass doors/French doors | Use Table R303.1.3(1) | |||||

Site-Assembled Style and Rail Doors | ||||||

Aluminum in aluminum frame | - | 1.32 | 0.99 | 0.93 | 0.79 | |

Aluminum in aluminum frame with thermal break | - | 1.13 | 0.80 | 0.74 | 0.63 | |

Note: | Appendix A Tables A107.1(2) through A107.1(4) of chapter 51-11C WAC may also be used if applicable. | |

a | Thermally broken sill (add 0.03 for nonthermally broken sill). | |

b | Nonthermally broken sill. | |

EXCEPTION: | The following buildings, or portions thereof, separated from the remainder of the building by building thermal envelope assemblies complying with this code shall be exempt from the building thermal envelope provisions of this code. |

1. Those with a peak design rate of energy usage less than 3.4 Btu/h ft2 (10.7 W/m2) or 1.0 watt/ft2 of floor area for space conditioning purposes. | |

2. Those that do not contain conditioned space. | |

3. Greenhouses isolated from any conditioned space and not intended for occupancy. |

CLIMATE ZONE 5 AND MARINE 4 | ||

Fenestration U-factorb | 0.30 | |

Skylight U-factor | 0.50 | |

Ceiling U-factor | 0.024 | |

Above-Grade Wall U-factor | ((0.056))0.045 | |

Floor U-factor | 0.029 | |

Slab on Grade F-factor | 0.54 | |

Below Grade 2' Depth | ||

Wall U-factor | 0.042 | |

Slab F-factor | 0.59 | |

Below Grade 3.5' Depth | ||

Wall U-factor | 0.040 | |

Slab F-factor | 0.56 | |

Below Grade 7' Depth | ||

Wall U-factor | 0.035 | |

Slab F-factor | 0.50 | |

a | U-factors or F-factors shall be obtained from measurement, calculation, or an approved source or as specified in Section R402.1.5. |

b | A maximum U-factor of 0.32 shall apply to vertical fenestration products installed in buildings located above 4000 feet in elevation above sea level, or in windborne debris regions where protection of openings is required under Section R301.2.1.2 of the International Residential Code. |

Climate Zone 5 and Marine 4 | |

Fenestrationb,jU-Factor | 0.30 |

SkylightbU-Factor | 0.50 |

CeilingeR-Value | 60 |

Wood Frame Wallg,iR-Value | 20+5 or 13+10 |

Floor R-Value | 30 |

Below-Grade Wallc,hR-Value | 10/15/21 int + 5TB |

Slabd,fR-Value and Depth | 10, 4 ft. |

For SI: | 1 foot = 304.8 mm, ci = continuous insulation, int = intermediate framing. |

aR-values are minimums. U-factors and SHGC are maximums. When insulation is installed in a cavity which is less than the label or design thickness of the insulation, the compressed R-value of the insulation from Appendix A Table A101.4 of chapter 51-11C WAC shall not be less than the R-value specified in the table. | |

b The fenestration U-factor column excludes skylights. | |

c "10/15/21+5TB" means R-10 continuous insulation on the exterior of the wall, or R-15 on the continuous insulation on the interior of the wall, or R-21 cavity insulation plus a thermal break between the slab and the basement wall at the interior of the basement wall. "10/15/21+5TB" shall be permitted to be met with R-13 cavity insulation on the interior of the basement wall plus R-5 continuous insulation on the interior or exterior of the wall. "TB" means R-5 thermal break between floor slab and basement wall. | |

d R-10 continuous insulation is required under heated slab on grade floors. See Section R402.2.9.1. | |

e For single rafter- or joist-vaulted ceilings, the insulation may be reduced to R-38 if the full insulation depth extends over the top plate of the exterior wall. | |

f R-7.5 continuous insulation installed over an existing slab is deemed to be equivalent to the required perimeter slab insulation when applied to existing slabs complying with Section R503.1.1. If foam plastic is used, it shall meet the requirements for thermal barriers protecting foam plastics. | |

g For log structures developed in compliance with Standard ICC 400, log walls shall meet the requirements for climate zone 5 of ICC 400. | |

h Int. (intermediate framing) denotes framing and insulation as described in Section A103.2.2 including standard framing 16 inches on center, 78 percent of the wall cavity insulated and headers insulated with a minimum of R-10 insulation. | |

i The first value is cavity insulation, the second value is continuous insulation. Therefore, as an example "13+10" means R-13 cavity insulation plus R-10 continuous insulation. | |

j A maximum U-factor of 0.32 shall apply to vertical fenestration products installed in buildings located above 4000 feet in elevation above sea level, or in windborne debris regions where protection of openings is required under Section R301.2.1.2 of the International Residential Code. |

EXCEPTIONS: | 1. Direct vent appliances with both intake and exhaust pipes installed continuous to the outside. |

2. Fireplaces and stoves complying with Section((s)) R402.3.6 of this code and Section R1006 of the International Residential Code. |

EXCEPTION: | Additions less than 500 square feet of conditioned floor area. |

EXCEPTION: | Additions tested with the existing home having a combined maximum air leakage rate of 7 air changes per hour. To qualify for this exception, the date of construction of the existing dwelling must be prior to the 2009 Washington State Energy Code. |

EXCEPTIONS: | 1. Field-fabricated fenestration products (windows, skylights and doors). |

2. Custom exterior fenestration products manufactured by a small business provided they meet the applicable provisions of Chapter 24 of the International Building Code. Once visual inspection has confirmed the presence of a gasket, operable windows and doors manufactured by small business shall be permitted to be sealed off at the frame prior to the test. |

COMPONENT | AIR BARRIER CRITERIA | INSULATION CRITERIA |

General requirements | A continuous air barrier shall be installed in the building envelope. | Air-permeable insulation shall not be used as a sealing material. |

Breaks or joints in the air barrier shall be sealed. | ||

Cavity insulation installation | All cavities in the thermal envelope shall be filled with insulation. The density of the insulation shall be at the manufacturers' product recommendation and said density shall be maintained for all volume of each cavity. Batt type insulation will show no voids or gaps and maintain an even density for the entire cavity. Batt insulation shall be installed in the recommended cavity depth. Where an obstruction in the cavity due to services, blocking, bracing or other obstruction exists, the batt product will be cut to fit the remaining depth of the cavity. Where the batt is cut around obstructions, loose fill insulation shall be placed to fill any surface or concealed voids, and at the manufacturers' specified density. Where faced batt is used, the installation tabs must be stapled to the face of the stud. There shall be no compression to the batt at the edges of the cavity due to inset stapling installation tabs. | |

Insulation that upon installation readily conforms to available space shall be installed filling the entire cavity and within the manufacturers' density recommendation. | ||

Ceiling/attic | The air barrier in any dropped ceiling/soffit shall be aligned with the insulation and any gaps in the air barrier sealed. | The insulation in any dropped ceiling/soffit shall be aligned with the air barrier. |

Access openings, drop down stair or knee wall doors to unconditioned attic spaces shall be sealed. | Batt insulation installed in attic roof assemblies may be compressed at exterior wall lines to allow for required attic ventilation. | |

Walls | The junction of the foundation and sill plate shall be sealed. The junction of the top plate and top of exterior walls shall be sealed. Knee walls shall be sealed. | Cavities within corners and headers of frame walls shall be insulated by completely filling the cavity with a material having a thermal resistance of R-3 per inch minimum. Exterior thermal envelope insulation for framed walls shall be installed in substantial contact and continuous alignment with the air barrier. |

Windows, skylights and doors | The space between window/door jambs and framing and skylights and framing shall be sealed. | |

Rim joists | Rim joists shall include an exterior air barrierb. | Rim joists shall be insulated so that the insulation maintains permanent contact with the exterior rim boardb. |

The junctions of the rim board to the sill plate and the rim board and the subfloor shall be air sealed. | ||

Floors (including above garage and cantilevered floors) | The air barrier shall be installed at any exposed edge of insulation. | Floor framing cavity insulation shall be installed to maintain permanent contact with the underside of subfloor decking or floor framing cavity insulation shall be permitted to be in contact with the topside of sheathing or continuous insulation installed on the underside of floor framing and extend from the bottom to the top of all perimeter floor framing members. |

Basement, crawl space, and slab foundations | Exposed earth in unvented crawl spaces shall be covered with a Class I, black vapor retarder with overlapping joints taped. | Crawl space insulation, where provided instead of floor insulation, shall be installed in accordance with Section R402.2.10. |

Penetrations through concrete foundation walls and slabs shall be air sealed. | Conditioned basement foundation wall insulation shall be installed in accordance with Section ((R402.2.8.1))R402.2.8. | |

Class I vapor retarders shall not be used as an air barrier on below-grade walls and shall be installed in accordance with Section R702.7 of the International Residential Code. | Slab on grade floor insulation shall be installed in accordance with Section R402.2.10. | |

Shafts, penetrations | Duct and flue shafts to exterior or unconditioned space shall be air sealed. | Insulation shall be fitted tightly around utilities passing through shafts and penetrations in the building thermal envelope to maintain required R-value. |

Utility penetrations of the air barrier shall be caulked, gasketed, or otherwise sealed and shall allow for expansion and contraction of materials and mechanical vibration. | ||

Narrow cavities | Narrow cavities, of an inch or less, not able to be insulated, shall be air sealed. | Batts in narrow cavities shall be cut to fit and installed to the correct density without any voids or gaps or compression, or narrow cavities shall be filled by insulation that on installation readily conforms to the available cavity space. |

Garage separation | Air sealing shall be provided between the garage and conditioned spaces. | Insulated portions of the garage separation assembly shall be installed in accordance with Sections R303 and R402.2.8. |

Recessed lighting | Recessed light fixtures installed in the building thermal envelope shall be air sealed in accordance with Section ((R402.4.5))R402.4.3. | Recessed light fixtures installed in the building thermal envelope shall be air tight and IC rated and shall be buried or surrounded with insulation. |

Plumbing, wiring, or other obstructions | All holes created by wiring, plumbing, or other obstructions in the air barrier assembly shall be air sealed. | Batt insulation shall be cut neatly to fit around wiring and plumbing in exterior walls. There shall be no voids or gaps or compression where cut to fit. Insulation that on installation readily conforms to available space shall extend behind piping and wiring. Insulation shall be installed to fill the available space and surround wiring, plumbing, or other obstructions, unless the required R-value can be met by installing insulation and air barrier systems completely to the exterior side of the obstructions. |

Shower/tub on exterior wall | The air barrier installed at exterior walls adjacent to showers and tubs shall separate the wall from the showers and tubs. | Exterior walls adjacent to showers and tubs shall be insulated. |

Electrical/phone box on exterior wall | The air barrier shall be installed behind electrical or communication boxes or air sealed boxes shall be installed. | |

HVAC register boots | HVAC supply and return register boots shall be sealed to the subfloor, wall covering or ceiling penetrated by the boot. | |

Concealed sprinklers | When required to be sealed, concealed fire sprinklers shall only be sealed in a manner that is recommended by the manufacturer. Caulking or other adhesive sealants shall not be used to fill voids between fire sprinkler cover plates and walls or ceilings. |

IC = insulation contact. |

a In addition, inspection of log walls shall be in accordance with the provisions of ICC-400. |

b Insulation installed in unconditioned/ventilated attic spaces is not required to be enclosed within an air barrier assembly. |

EXCEPTION: | Sections of the supply duct that are less than 3 feet (914 mm) from the supply outlet shall not be required to comply with these requirements. |

EXCEPTIONS: | 1. Air-impermeable spray foam products shall be permitted to be applied without additional joint seals. |

2. For ducts having a static pressure classification of less than 2 inches of water column (500 Pa), additional closure systems shall not be required for continuously welded joints and seams, and locking-type joints and seams of other than the snap-lock and button-lock types. |

EXCEPTION: | A duct air leakage test shall not be required for ducts serving ventilation systems that are not integrated with the ducts serving heating or cooling systems. |

EXCEPTION: | Pipe insulation is permitted to be discontinuous where it passes through studs, joists or other structural members and where the insulated pipes pass other piping, conduit or vents, provided the insulation is installed tight to each obstruction. |

EXCEPTIONS: | 1. Where the hot water system efficiency is greater than or equal to 2.0 UEF. |

2. Tankless water heaters. | |

3. Gas heat pump water heaters intended for exterior installation. | |

4. Atmospheric vented gas water heaters. |

EXCEPTIONS: | 1. Resistance heating elements integrated into heat pump equipment. |

2. Electric water heaters with a rated water storage volume of no greater than 20 gallons. | |

3. Dwelling units with no more than 1,000 square feet of conditioned floor area. | |

4. Supplementary water heating systems in accordance with Section R403.5.7.1, provided the system capacity does not exceed the capacity of the heat pump water heating system. | |

5. Solar water heating systems. | |

6. Waste heat and energy recovery systems. | |

7. Heat trace freeze protection systems. | |

8. Snow and ice melt systems. |

EXCEPTION: | Heat trace temperature maintenance systems, provided the system capacity does not exceed the capacity of the heat pump water heating system. |

EXCEPTIONS: | 1. Detached one- and two-family dwellings and multiple-single family dwellings (townhouses up to three stories in height above grade having an installed HVAC heating capacity no greater than 1.5 watts of electric resistance heating per square foot of dwelling unit conditioned floor area, or up to 500 watts, whichever is greater. |

2. Group R-2 dwelling or sleeping units having an installed HVAC heating capacity no greater than 750 watts in Climate Zone 4, and 1,000 watts in Climate Zone 5, in any separate habitable room with exterior fenestration are permitted to be heated using electric resistance appliances. For buildings in location with exterior design conditions below 4°F (-15.6°C), an additional 250 watts above that allowed for Climate Zone 5 is permitted. | |

2.1. A room within a dwelling or sleeping unit that has two primary walls facing different cardinal directions, each with exterior fenestration, is permitted to have an installed HVAC heating capacity no greater than 1,000 watts in Climate Zone 4, and 1,300 watts in Climate Zone 5. Bay windows and other minor offsets are not considered primary walls. For buildings in location with exterior design conditions below 4°F (-15.6°C), an additional 250 watts above that allowed for Climate Zone 5 is permitted. | |

3. Resistance heating elements integrated into heat pump equipment. | |

4. Solar thermal systems. | |

5. Waste heat, radiant heat exchanger, and energy recovery systems. | |

6. Supplementary heat in accordance with Section R403.1.2. | |

7. Where there is no electric utility service available at the building site. | |

8. Heating systems that rely primarily on biomass are allowed in Climate Zone 5.)) |

Sectiona | Title | Comments |

General | ||

R401.3 | Certificate | |

Envelope | ||

R402.1.1 | Vapor retarder | |

R402.2.3 | Eave baffle | |

R402.2.4.1 | Access hatches and doors | |

((R402.2.10.1 | Crawlspace wall insulation installations)) | |

R402.4 | Air leakage | |

R402.5 | Maximum fenestration U-factor | |

Systems | ||

R403.1 | Controls | |

R403.3 | Ducts | Except for R403.3.2 and R403.3.3 |

R403.4 | Mechanical system piping insulation | |

R403.5.1 | Heated water circulation and temperature maintenance system | |

R403.5.3 | Drain water heat recovery units | |

((R403.5.7 | Heat pump water heating)) | |

R403.6 | Mechanical ventilation | |

R403.7 | Equipment sizing and efficiency rating | |

R403.8 | Systems serving multiple dwelling units | |

R403.9 | Snow melt system controls | |

R403.10 | Energy consumption of pools and spas | |

R403.11 | Portable spas | |

R403.12 | Residential pools and permanent residential spas | |

((R403.13 | Heat pump space heating)) | |

Electrical Power and Lighting | ||

R404.1 | Lighting equipment | |

R404.2 | Interior lighting controls | |

a | Reference to a code section includes all the relative subsections except as indicated in the table. |

Type | CO2e (lb/unit) | Unit |

Electricity | 0.44 | kWh |

Natural gas | 11.7 | Therm |

Oil | 19.2 | Gallon |

Propane | 10.5 | Gallon |

Othera | 195.00 | mmBtu |

On-site renewable energy | 0.00 |

a | District energy systems may use alternative emission factors supported by calculations approved by the code official.)) |

BUILDING COMPONENT | STANDARD REFERENCE DESIGN | PROPOSED DESIGN |

Above-grade walls | Type: Mass wall if proposed wall is mass; otherwise wood frame. Gross area: Same as proposed U-factor: From Table R402.1.2 Solar absorptance = 0.75 Emittance = 0.90 | As proposed As proposed As proposed As proposed As proposed |

Below-grade walls | Type: Same as proposed Gross area: Same as proposed U-factor: From Table R402.1.2, with insulation layer on interior side of walls. | As proposed As proposed As proposed |

Above-grade floors | Type: Wood frame Gross area: Same as proposed U-factor: From Table R402.1.2 | As proposed As proposed As proposed |

Ceilings | Type: Wood frame Gross area: Same as proposed U-factor: From Table R402.1.2 | As proposed As proposed As proposed |

Roofs | Type: Composition shingle on wood sheathing Gross area: Same as proposed Solar absorptance = 0.75 Emittance = 0.90 | As proposed As proposed As proposed As proposed |

Attics | Type: Vented with aperture = 1 ft2 per 300 ft2 ceiling area | As proposed |

Foundations | Type: Same as proposed foundation wall area above and below-grade Soil characteristics: Same as proposed. | As proposed As proposed |

Opaque doors | Area: 40 ft2 Orientation: North U-factor: Same as fenestration from Table R402.1.2. | As proposed As proposed As proposed |

Vertical fenestration other than opaque doorsa | Total areah = (a) The proposed glazing area; where proposed glazing area is less than 15% of the conditioned floor area. (b) 15% of the conditioned floor area; where the proposed glazing area is 15% or more of the conditioned floor area. | As proposed |

Orientation: Equally distributed to four cardinal compass orientations (N, E, S & W). | As proposed | |

U-factor: From Table R402.1.2 | As proposed | |

SHGC: From Table R402.1.1 except that for climates with no requirement (NR) SHGC = 0.40 shall be used. | As proposed | |

Interior shade fraction: 0.92 - (0.21 × SHGC for the standard reference design) External shading: None | 0.92 - (0.21 × SHGC as proposed) As proposed | |

Skylights | None | As proposed |

Air exchange rate | Air leakage rate of 4 air changes per hour at a pressure of 0.2 inches w.g. (50 Pa). The mechanical ventilation rate shall be in addition to the air leakage rate and the same as in the proposed design, but no greater than 0.01 × CFA +7.5 × (Nbr + 1) where: CFA = conditioned floor area Nbr = number of bedrooms - The mechanical ventilation system type shall be the same as in the proposed design. Energy recovery shall not be assumed for mechanical ventilation. | As proposeda. The mechanical ventilation rateb shall be in addition to the air leakage rate and shall be as proposed. |

Mechanical ventilation | None, except where mechanical ventilation is specified by the proposed design, in which case: Annual vent fan energy use: kWh/yr = (1ef) × (0.0876 × CFA + 65.7 × (Nbr + 1) where: ef = the minimum fan efficacy from Table R403.6.1 corresponding to the system type at a flow rate of 0.01 × CFA + 7.5 × (Nbr + 1) CFA = conditioned floor area Nbr = number of bedrooms | As proposed |

Internal gains | IGain = 17,900 + 23.8 × CFA + 4104 × Nbr (Btu/day per dwelling unit) | Same as standard reference design |

Internal mass | An internal mass for furniture and contents of 8 pounds per square foot of floor area. | Same as standard reference design, plus any additional mass specifically designed as a thermal storage elementc but not integral to the building envelope or structure. |

Structural mass | For masonry floor slabs, 80% of floor area covered by R-2 carpet and pad, and 20% of floor directly exposed to room air. | As proposed |

For masonry basement walls, as proposed, but with insulation required by Table R402.1.2 located on the interior side of the walls. | As proposed | |

For other walls, for ceilings, floors, and interior walls, wood frame construction. | As proposed | |

Heating systemsd, e | The standard reference design shall be an air source heat pump meeting the requirements of Section C403 of the WSEC—Commercial Provisions. Capacity: Sized in accordance with Section ((R403.6))R403.7 | As proposed |

Cooling systemsd, f | Same system type as proposed. Same system efficiency as required by prevailing minimum federal standard. Capacity: Sized in accordance with Section ((R403.6.))R403.7 | As proposed |

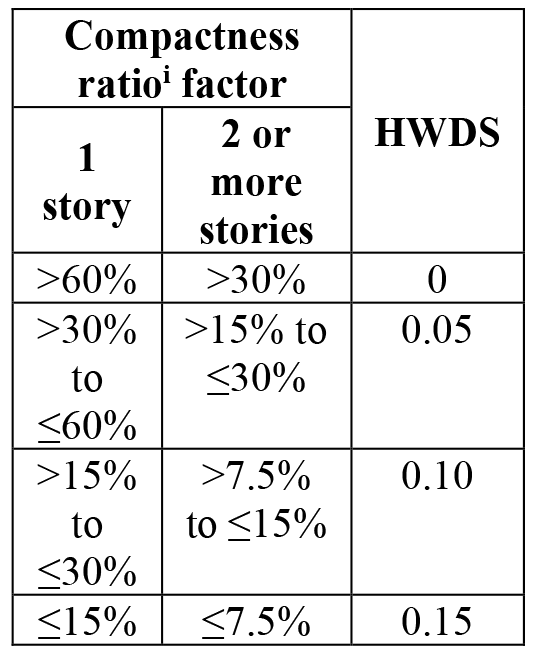

Service water heatingd, e, f, g | The standard reference design shall be a heat pump water ((heating))heater meeting the standards for Tier 1 of NEEA's Advanced Water Heating Specifications. Use, in units of gal/day = 25.5 + (8.5 x Nbr) Where Nbr = number of bedrooms | As proposed Use, in units of gal/day = 25.5 + (8.5 x Nbr) x (1 - HWDS) Where: Nbr= number of bedrooms HWDS = factor for the compactness of the hot water distribution system  |

Thermal distribution systems | Duct insulation: From Section R403.3.3. Duct location: Same as proposed design. A thermal distribution system efficiency (DSE) of 0.93 shall be applied to both the heating and cooling system efficiencies for all systems. Exception: For nonducted heating and cooling systems that do not have a fan, the standard reference design distribution system efficiency ( DSE) shall be 1. | Duct insulation: As proposed. Duct location: As proposed. As specified in Table R405.5.2(2). |

Thermostat | Type: Manual, cooling temperature setpoint = 75°F; Heating temperature setpoint = 72°F | Same as standard reference |

For SI: | 1 square foot = 0.93 m2, 1 British thermal unit = 1055 J, 1 pound per square foot = 4.88 kg/m2, 1 gallon (U.S.) = 3.785 L, °C = (°F-3)/1.8, 1 degree = 0.79 rad |

a | Where required by the code official, testing shall be conducted by an approved party. Hourly calculations as specified in the ASHRAE Handbook of Fundamentals, or the equivalent, shall be used to determine the energy loads resulting from infiltration. |

b | The combined air exchange rate for infiltration and mechanical ventilation shall be determined in accordance with Equation 43 of 2001 ASHRAE Handbook of Fundamentals, page 26.24 and the "Whole-house Ventilation" provisions of 2001 ASHRAE Handbook of Fundamentals, page 26.19 for intermittent mechanical ventilation. |

c | Thermal storage element shall mean a component not part of the floors, walls or ceilings that is part of a passive solar system, and that provides thermal storage such as enclosed water columns, rock beds, or phase-change containers. A thermal storage element must be in the same room as fenestration that faces within 15 degrees (0.26 rad) of true south, or must be connected to such a room with pipes or ducts that allow the element to be actively charged. |

d | For a proposed design with multiple heating, cooling or water heating systems using different fuel types, the applicable standard reference design system capacities and fuel types shall be weighted in accordance with their respective loads as calculated by accepted engineering practice for each equipment and fuel type present. |

e | For a proposed design without a proposed heating system, a heating system with the prevailing federal minimum efficiency shall be assumed for both the standard reference design and proposed design. |

f | For a proposed design home without a proposed cooling system, an electric air conditioner with the prevailing federal minimum efficiency shall be assumed for both the standard reference design and the proposed design. |

g | For a proposed design with a nonstorage-type water heater, a 40-gallon storage-type water heater with the prevailing federal minimum energy factor for the same fuel as the predominant heating fuel type shall be assumed. For the case of a proposed design without a proposed water heater, a 40-gallon storage-type water heater with the prevailing federal minimum efficiency for the same fuel as the predominant heating fuel type shall be assumed for both the proposed design and standard reference design. |

h | For residences with conditioned basements, R-2 and R-4 residences and townhouses, the following formula shall be used to determine fenestration area: |

AF = As x FA x F | ||

Where: | ||

AF | = | Total fenestration area. |

As | = | Standard reference design total fenestration area. |

FA | = | (Above-grade thermal boundary gross wall area)/(above-grade boundary wall area + 0.5 x below-grade boundary wall area). |

F | = | (Above-grade thermal boundary wall area)/(above-grade thermal boundary wall area + common wall area) or 0.56, whichever is greater. |

and where: | ||

Thermal boundary wall is any wall that separates conditioned space from unconditioned space or ambient conditions. | ||

Above-grade thermal boundary wall is any thermal boundary wall component not in contact with soil. | ||

Below-grade boundary wall is any thermal boundary wall in soil contact. | ||

Common wall area is the area of walls shared with an adjoining dwelling unit. | ||

L and CFA are in the same units. | ||

i | The factor for the compactness of the hot water distribution system is the ratio of the area of the rectangle that bounds the source of hot water and the fixtures that it serves (the "hot water rectangle") divided by the floor area of the dwelling. |

1. Sources of hot water include water heaters, or in multifamily buildings with central water heating systems, circulation loops, or electric heat traced pipes. | |

2. The hot water rectangle shall include the source of hot water and the points of termination of all hot water fixture supply piping. | |

3. The hot water rectangle shall be shown on the floor plans and the area shall be computed to the nearest square foot. | |

4. Where there is more than one water heater and each water heater serves different plumbing fixtures and appliances, it is permissible to establish a separate hot water rectangle for each hot water distribution system and add the area of these rectangles together to determine the compactness ratio. | |

5. The basement or attic shall be counted as a story when it contains the water heater. | |

6. Compliance shall be demonstrated by providing a drawing on the plans that shows the hot water distribution system rectangle(s), comparing the area of the rectangle(s) to the area of the dwelling and identifying the appropriate compactness ratio and HWDS factor. |

DISTRIBUTION SYSTEM CONFIGURATION AND CONDITION | DISTRIBUTION SYSTEM EFFICIENCY |

Distribution system components located in unconditioned space | 0.88 |

Distribution systems entirely located in conditioned spaceb | 0.93 |

Zonal systemsc | 1.00 |

For SI: | 1 cubic foot per minute = 0.47 L/s, 1 square foot = 0.093m2, 1 pound per square inch = 6895 Pa, 1 inch water gauge = 1250 Pa. |

a Values given by this table are for distribution systems, which must still meet all prescriptive requirements for duct and pipe system insulation and leakage. | |

b Entire system in conditioned space shall mean that no component of the distribution system, including the air-handler unit, is located outside of the conditioned space. All components must be located on the interior side of the thermal envelope (inside the insulation) and also inside of the air barrier. Refrigerant compressors and piping are allowed to be located outside. | |

c Zonal systems are systems where the heat source is located within each room. Systems shall be allowed to have forced airflow across a coil but shall not have any ducted airflow external to the manufacturer's air-handler enclosure. Hydronic systems do not qualify. |

System Type | Description of Heating Sources | Credits | |

All Other | Group R-2a | ||

1 | For combustion heating system using equipment meeting minimum federal efficiency standards for the equipment listed in Table C403.3.2(5) or C403.3.2(6) | ((-3.0))0 | 0 |

2 | For an initial heating system using a heat pump that meets federal standards for the equipment listed in Table C403.3.2(2) and supplemental heating provided by electric resistance or a combustion furnace meeting minimum standards listed in Table C403.3.2(5)b | ((0))1.5 | 0 |

3 | For heating system based on electric resistance only (either forced air or zonal) | ((-1.0))0.5 | -0.5 |

4c | For a heating system using a heat pump that meets federal standards for the equipment listed in Table C403.3.2(2) or C403.3.2(9) or Air to water heat pump units that are configured to provide both heating and cooling and are rated in accordance with AHRI 550/590 | ((1.5))3.0 | 2.0 |

5 | For heating system based on electric resistance with: 1. Inverter-driven ductless mini-split heat pump system installed in the largest zone in the dwelling or 2. With 2 kW or less total installed heating capacity per dwelling | ((0.5))2.0 | 0 |

a | See Section R401.1 and residential building in Section R202 for Group R-2 scope. |

b | The gas back-up furnace will operate as fan-only when the heat pump is operating. The heat pump shall operate at all temperatures above 38°F (3.3°C) (or lower). Below that "changeover" temperature, the heat pump would not operate to provide space heating. The gas furnace provides heating below 38°F (3.3°C) (or lower). |

c | Additional points for this HVAC system are included in Table R406.3. |

1. | Small Dwelling Unit: | ((2.5))5.0 credits | |

Dwelling units less than 1500 square feet in conditioned floor area with less than 300 square feet of fenestration area. Additions to existing building that are greater than 500 square feet of heated floor area but less than 1500 square feet. | |||

2. | Medium Dwelling Unit: | ((5.0))8.0 credits | |

All dwelling units that are not included in #1, #3, or #4. | |||

3. | Large Dwelling Unit: | ((6.0))9.0 credits | |

Dwelling units exceeding 5000 square feet of conditioned floor area. | |||

4. | Dwelling units serving Group R-2 occupancies. See Section R401.1 and residential building in Section R202 for Group R-2 scope. | ((4.5))6.5 credits | |

5. | Additions 150 square feet to 500 square feet: | 2.0 credits |

OPTION | DESCRIPTION | CREDIT(S) | |

All Other | Group R-2b | ||

1. EFFICIENT BUILDING ENVELOPE OPTIONS Only one option from Items 1.1 through 1.4 may be selected in this category. Compliance with the conductive UA targets is demonstrated using Section R402.1.5, Total UA alternative, where [1-(Proposed UA/Target UA)] ˃; the required %UA reduction | |||

1.1 | Prescriptive compliance is based on Table R402.1.3 with the following modifications: Vertical fenestration U = 0.22. | 0.5 | 0.5 |

1.2 | Prescriptive compliance is based on Table R402.1.3 with the following modifications: Vertical fenestration U = 0.25 Floor R-38 Basement wall R-21 int plus R-5 ci Ceiling and single-rafter or joist-vaulted R-60 advanced Slab on grade R-10 perimeter and under entire slab Below grade slab R-10 perimeter and under entire slab or Compliance based on Section R402.1.5: Reduce the Total conductive UA by 15%. | ((0.5))1.0 | 1.0 |

1.3 | Prescriptive compliance is based on Table R402.1.3 with the following modifications: Vertical fenestration U = 0.18 Ceiling and single-rafter or joist-vaulted R-60 advanced Floor R-38 Basement wall R-21 int plus R-12 ci Slab on grade R-10 perimeter and under entire slab Below grade slab R-10 perimeter and under entire slab or Compliance based on Section R402.1.5: Reduce the Total conductive UA by 22.5%. | ((1.0))1.5 | 1.5 |

1.4 | Prescriptive compliance is based on Table R402.1.3 with the following modifications: Vertical fenestration U = 0.18 Ceiling and single-rafter or joist-vaulted R-60 advanced Wood frame wall R-21 int plus R-16 ci Floor R-48 Basement wall R-21 int plus R-16 ci Slab on grade R-20 perimeter and under entire slab Below grade slab R-20 perimeter and under entire slab or Compliance based on Section R402.1.5: Reduce the Total conductive UA by 30%. | ((1.5))2.5 | 2.0 |

2. AIR LEAKAGE CONTROL AND EFFICIENT VENTILATION OPTIONS Only one option from Items 2.1 through 2.3 may be selected in this category. | |||

2.1 | Compliance based on Section R402.4.1.2: Reduce the tested air leakage to 2.0 air changes per hour maximum at 50 Pascals or For R-2 Occupancies, optional compliance based on Section R402.4.1.2: Reduce the tested air leakage to 0.25 cfm/ft2 maximum at 50 Pascals and All whole house ventilation requirements as determined by Section M1505.3 of the International Residential Code or Section 403.8 of the International Mechanical Code shall be met with a heat recovery ventilation system with minimum sensible heat recovery efficiency of 0.65. To qualify to claim this credit, the building permit drawings shall specify the option being selected and shall specify the maximum tested building air leakage and shall show the heat recovery ventilation system. | ((0.5))1.0 | 1.0 |

2.2 | Compliance based on Section R402.4.1.2: Reduce the tested air leakage to 1.5 air changes per hour maximum at 50 Pascals or For R-2 Occupancies, optional compliance based on Section R402.4.1.2: Reduce the tested air leakage to 0.20 cfm/ft2 maximum at 50 Pascals and All whole house ventilation requirements as determined by Section M1505.3 of the International Residential Code or Section 403.8 of the International Mechanical Code shall be met with a heat recovery ventilation system with minimum sensible heat recovery efficiency of 0.75. To qualify to claim this credit, the building permit drawings shall specify the option being selected and shall specify the maximum tested building air leakage and shall show the heat recovery ventilation system. | ((1.0))1.5 | 1.5 |

2.3 | Compliance based on Section R402.4.1.2: Reduce the tested air leakage to 0.6 air changes per hour maximum at 50 Pascals or For R-2 Occupancies, optional compliance based on Section R402.4.1.2: Reduce the tested air leakage to 0.15 cfm/ft2 maximum at 50 Pascals and All whole house ventilation requirements as determined by Section M1505.3 of the International Residential Code or Section 403.8 of the International Mechanical Code shall be met with a heat recovery ventilation system with minimum sensible heat recovery efficiency of 0.80. Duct installation shall comply with Section ((R403.3.7))R403.3.2. To qualify to claim this credit, the building permit drawings shall specify the option being selected and shall specify the maximum tested building air leakage and shall show the heat recovery ventilation system. | ((1.5))2.0 | 2.0 |

3. HIGH EFFICIENCY HVAC EQUIPMENT OPTIONS Only one option from Items 3.1 through 3.8 may be selected in this category. Item 3.9 may be taken with Items 3.1 or 3.3c only. | |||

3.1a | For a System Type 1 in Table R406.2: Energy Star rated (U.S. North) gas or propane furnace with minimum AFUE of 95%. or Energy Star rated (U.S. North) gas or propane boiler with minimum AFUE of 90% To qualify to claim this credit, the building permit drawings shall specify the option being selected and shall specify the heating equipment type and the minimum equipment efficiency. | 1.0 | 1.0 |

3.2a | For secondary heating system serving System Type 2 in Table R406.2: Energy Star rated (U.S. North) Gas or propane furnace with minimum AFUE of 95% or Energy Star rated (U.S. North) Gas or propane boiler with minimum AFUE of 90%. To qualify to claim this credit, the building permit drawings shall specify the option being selected and shall specify the heating equipment type and the minimum equipment efficiency. | 0.5 | 0.5 |

3.3a,c,d | Air-source centrally ducted heat pump with minimum HSPF of 9.5. In areas where the winter design temperature as specified in Appendix RC is 23°F or below, a cold climate heat pump found on the NEEP cc ASHP qualified product list shall be used. To qualify to claim this credit, the building permit drawings shall specify the option being selected and shall specify the heating equipment type and the minimum equipment efficiency. | 0.5 | N/A |

3.4a,d | Closed-loop ground source heat pump; with a minimum COP of 3.3 or Open loop water source heat pump with a maximum pumping hydraulic head of 150 feet and minimum COP of 3.6. To qualify to claim this credit, the building permit drawings shall specify the option being selected and shall specify the heating equipment type and the minimum equipment efficiency. | 1.5 | 1.0 |

3.5d | Ductless mini-split heat pump system, zonal control: In homes where the primary space heating system is zonal electric heating, a ductless mini-split heat pump system with a minimum HSPF of 10.0 shall be installed and provide heating to the largest zone of the housing unit. To qualify to claim this credit, the building permit drawings shall specify the option being selected and shall specify the heating equipment type and the minimum equipment efficiency. | 1.5 | 2.0 |

3.6a,d | Air-source, centrally ducted heat pump with minimum HSPF of 11.0. A centrally ducted air source cold climate variable capacity heat pump (cc VHP) found on the NEEP cc VCHP qualified product list with a minimum of 10 HSPF may be used to satisfy this requirement. In areas where the winter design temperature as specified in Appendix RC is 23°F or below, an air source centrally ducted heat pump shall be a cold climate variable capacity heat pump as listed on the NEEP qualified product list. To qualify to claim this credit, the building permit drawings shall specify the option being selected and shall specify the heating equipment type and the minimum equipment efficiency. | 1.0 | N/A |

3.7a,d,e | Ductless split system heat pumps with no electric resistance heating in the primary living areas. A ductless heat pump system with a minimum HSPF of 10 shall be sized and installed to provide heat to entire dwelling unit at the design outdoor air temperature. Exception: In homes with total heating loads of 24,000 or less using multi-zone mini-split systems with nominal ratings of 24,000 or less, the minimum HSPF to claim this credit shall be 9 HSPF. To qualify to claim this credit, the building permit drawings shall specify the option being selected, the heated floor area calculation, the heating equipment type(s), the minimum equipment efficiency, and total installed heat capacity (by equipment type). | 2.0 | 3.0 |

3.8a,d | Air-to-water heat pump with minimum COP of 3.2 at 47°F, rated in accordance with AHRI 550/590 by an accredited or certified testing lab. To qualify to claim this credit, the building permit drawings shall specify the option being selected, the heated floor area calculation, the heating equipment type(s), the minimum equipment efficiency, and total installed heat capacity (by equipment type). | 1.0 | N/A |

3.9c | Connected thermostat meeting ENERGY STAR Certified Smart Thermostats/EPA ENERGY STAR specifications. To qualify to claim this credit, the building permit drawings shall specify the option being selected and shall specify the thermostat model. | 0.5 | 0.5 |

3.10 | Gas-fired heat pump(s) meeting ANSI Z21.40.2 and Z21.40.4 or CSA, with a minimum UEF of 1.15. For R-2 Occupancy, gas-fired heat pump(s) meeting ANSI Z21.40.2 and Z21.40.4 or CSA, with a minimum UEF of 1.15, shall serve all units. | 1.5 | 1.5 |

3.11f | Combination water heating and space heating system shall include one of the following: Gas-fired heat pump water heater(s) meeting Tier 2 of the NEEA Advanced Water Heating Specification for Gas-Fueled Residential Storage Water Heaters Version 1.0. or For R-2 Occupancy, gas-fired heat pump water heater(s) meeting Tier 2 of the NEEA Advanced Water Heating Specification for Gas-Fueled Residential Storage Water Heaters Version 1.0., shall serve all units. or For R-2 Occupancy, gas-fired heat pump(s) meeting ANSI Z21.40.2 and Z21.40.4 or CSA, with a minimum UEF of 1.15, shall serve all units. To qualify to claim this credit, the building permit drawings shall specify the option being selected and shall specify the water heater equipment type and the minimum equipment efficiency and, for solar water heating systems, the calculation of the minimum energy savings. | 2.5 | 2.5 |

4. HIGH EFFICIENCY HVAC DISTRIBUTION SYSTEM OPTIONS | |||

4.1 | HVAC equipment and associated duct system(s) installation shall comply with the requirements of Section R403.3.2. Electric resistance heat, hydronic heating and ductless heat pumps are not permitted under this option. To qualify to claim this credit, the building permit drawings shall specify the option being selected and shall specify the heating equipment type and shall show the location of the heating and cooling equipment and all the ductwork. | 0.5 | N/A |

5. EFFICIENT WATER HEATING OPTIONS Only one option from Items 5.3 through ((5.5))5.8 may be selected in this category. Items 5.1 and 5.2 may be combined with any option. | |||

5.1 | A drain water heat recovery unit(s) shall be installed, which captures wastewater heat from at least two showers, including tub/shower combinations. It is acceptable, but not required, for sink water to be connected. Unit shall have a minimum efficiency of 40% if installed for equal flow or a minimum efficiency of 54% if installed for unequal flow. Such units shall be rated in accordance with CSA B55.1 or IAPMO IGC 346-2017 and be so labeled. To qualify to claim this credit, the building permit drawings shall include a plumbing diagram that specifies the drain water heat recovery units and the plumbing layout needed to install it. Labels or other documentation shall be provided that demonstrates that the unit complies with the standard. | 0.5 | 0.5 |

5.2 | For Compact Hot Water Distribution system credit, the volume shall store not more than 16 ounces of water between the nearest source of heated water and the termination of the fixture supply pipe where calculated using Section R403.5.2. Construction documents shall indicate the ounces of water in piping between the hot water source and the termination of the fixture supply. When the hot water source is the nearest primed plumbing loop or trunk, this must be primed with an On Demand recirculation pump and must run a dedicated ambient return line from the furthest fixture or end of loop to the water heater. To qualify for this credit, the dwelling must have a minimum of 1.5 bathrooms. | 0.5 | 0.5 |

5.3 | Water heating system shall include the following: Energy Star rated gas or propane water heater with a minimum UEF of 0.80. To qualify to claim this credit, the building permit drawings shall specify the option being selected and shall specify the water heater equipment type and the minimum equipment efficiency. | 0.5 | 0.5 |

5.4 | Water heating system shall include one of the following: Energy Star rated gas or propane water heater with a minimum UEF of 0.91. or Solar water heating supplementing a minimum standard water heater. Solar water heating will provide a rated minimum savings of 85 therms or 2000 kWh based on the Solar Rating and Certification Corporation (SRCC) Annual Performance of OG-300 Certified Solar Water Heating Systems or Water heater heated by ground source heat pump meeting the requirements of Option ((3.3))3.4. To qualify to claim this credit, the building permit drawings shall specify the option being selected and shall specify the water heater equipment type and the minimum equipment efficiency and, for solar water heating systems, the calculation of the minimum energy savings. | 1.0 | 1.0 |

((5.4))5.5 | Water heating system shall include one of the following: Gas-fired heat pump water heater(s) meeting Tier 2 of the NEEA Advanced Water Heating Specification for Gas-Fueled Residential Storage Water Heaters Version 1.0. or For R-2 Occupancy, gas-fired heat pump water heater(s) meeting Tier 2 of the NEEA Advanced Water Heating Specification for Gas-Fueled Residential Storage Water Heaters Version 1.0. shall supply domestic hot water to all units. or For R-2 Occupancy, gas-fired heat pump water heater(s) meeting ANSI Z21.40.2 and Z21.40.4 or CSA, with a minimum UEF of 1.15, shall supply domestic hot water to all units. To qualify to claim this credit, the building permit drawings shall specify the option being selected and shall specify the water heater equipment type and the minimum equipment efficiency and, for solar water heating systems, the calculation of the minimum energy savings. | 1.5 | 1.5 |

5.6 | Water heating system shall include one of the following: Electric heat pump water heater meeting the standards for Tier III of NEEA's advanced water heating specification. or For R-2 Occupancy, electric heat pump water heater(s), meeting the standards for Tier III of NEEA's advanced water heating specification, shall supply domestic hot water to all units. If one water heater is serving more than one dwelling unit, all hot water supply and recirculation piping shall be insulated with R-8 minimum pipe insulation. To qualify to claim this credit, the building permit drawings shall specify the option being selected and shall specify the water heater equipment type and the minimum equipment efficiency. | 2.0 | 2.5 |

((5.5))5.7 | Water heating system shall include one of the following: Electric heat pump water heater with a minimum UEF of 2.9 and utilizing a split system configuration with the air-to-refrigerant heat exchanger located outdoors. Equipment shall meet Section 4, requirements for all units, of the NEEA standard Advanced Water Heating Specification with the UEF noted above. or For R-2 Occupancy, electric heat pump water heater(s), meeting the standards for Tier III of NEEA's advanced water heating specification and utilizing a split system configuration with the air-to-refrigerant heat exchanger located outdoors, shall supply domestic hot water to all units. If one water heater is serving more than one dwelling unit, all hot water supply and recirculation piping shall be insulated with R-8 minimum pipe insulation. To qualify to claim this credit, the building permit drawings shall specify the option being selected and shall specify the water heater equipment type and the minimum equipment efficiency. | 2.5 | 3.0 |

5.8 | Combination water heating and space heating system shall include one of the following: Gas-fired heat pump water heater(s) meeting Tier 2 of the NEEA Advanced Water Heating Specification for Gas-Fueled Residential Storage Water Heaters Version 1.0. or For R-2 Occupancy, gas-fired heat pump water heater(s) meeting Tier 2 of the NEEA Advanced Water Heating Specification for Gas-Fueled Residential Storage Water Heaters Version 1.0., shall supply all units. or For R-2 Occupancy, gas-fired heat pump(s) meeting ANSI Z21.40.2 and Z21.40.4 or CSA, with a minimum UEF of 1.15, shall supply all units. To qualify to claim this credit, the building permit drawings shall specify the option being selected and shall specify the water heater equipment type and the minimum equipment efficiency and, for solar water heating systems, the calculation of the minimum energy savings. | TBD | TBD |

6. RENEWABLE ELECTRIC ENERGY OPTION | |||

6.1 | For each 600 kWh of electrical generation per housing unit provided annually by on-site wind or solar equipment a 0.5 credit shall be allowed, up to 4.5 credits. Generation shall be calculated as follows: For solar electric systems, the design shall be demonstrated to meet this requirement using the National Renewable Energy Laboratory calculator PVWATTs or approved ((alternate))alternative by the code official. Documentation noting solar access shall be included on the plans. For wind generation projects designs shall document annual power generation based on the following factors: The wind turbine power curve; average annual wind speed at the site; frequency distribution of the wind speed at the site and height of the tower. To qualify to claim this credit, the building permit drawings shall specify the option being selected and shall show the photovoltaic or wind turbine equipment type, provide documentation of solar and wind access, and include a calculation of the minimum annual energy power production. | 0.5 – 4.5 | 0.5 – 4.5 |

7. APPLIANCE PACKAGE OPTION | |||

7.1 | All of the following appliances shall be new and installed in the dwelling unit and shall meet the following standards: 1. Dishwasher, standard - Energy Star rated, Most Efficient 2021 or Dishwasher, compact – Energy Star rated (Version 6.0) 2. Refrigerator (if provided) - Energy Star rated (Version 5.1) 3. Washing machine (Residential) - Energy Star rated (Version 8.1) 4. Dryer - Energy Star rated, Most Efficient 2022 To qualify to claim this credit, the building permit drawings shall specify the option being selected and shall show the appliance type and provide documentation of Energy Star compliance. At the time of inspection, all appliances shall be installed and connected to utilities. Dryer ducts and exterior dryer vent caps are not permitted to be installed in the dwelling unit. | 0.5 | 1.5 |

a | An alternative heating source sized at a maximum of 0.5 Watts/ft2 (equivalent) of heated floor area or 500 Watts, whichever is bigger, may be installed in the dwelling unit. |

b | See Section R401.1 and residential building in Section R202 for Group R-2 scope. |

c | Option 3.9 can only be taken with Options 3.1 and 3.3. To qualify to claim option 3.8 with 3.3, the system shall be a 1-2 speed heat pump system. Variable capacity heat pumps are ineligible from claiming this option. |

d | This option may only be claimed if serving System Type 4 or 5 from Table R406.2. |

e | Primary living areas include living, dining, kitchen, family rooms, and similar areas. |

f | Option 3.11 may only be taken with Efficient Water Heating Options 5.1 or 5.2. Equipment sizing for space heating shall be calculated as provided in Section R403.7 with increased capacity to provide a minimum of 75 percent of peak hot water demand or shall be sized in accordance with approved manufacturer's specifications or guidance. Supplementary heat for water heating system shall be in accordance with Section R403.5.7. |

EXCEPTION: | Where the total building performance option in Section R405 is used to comply with this section, the annual energy use of the proposed design is permitted to be 110 percent of the annual energy use otherwise allowed by Section R405.3. |

EXCEPTION: | Where nonconditioned space is changed to conditioned space, the building envelope of the addition shall comply where the UA, as determined in Section R402.1.5, of the existing building and the addition, and any alterations that are part of the project, is less than or equal to UA generated for the existing building. |

EXCEPTION: | The following need not comply with the testing requirements of Section R403.3.3: |

1. Additions of less than 150 square feet. | |

2. Duct systems that are documented to have been previously sealed as confirmed through field verification and diagnostic testing in accordance with procedures in WSU RS-33. | |

3. Existing duct systems constructed, insulated or sealed with asbestos. |

EXCEPTION: | The following alterations need not comply with the requirements for new construction provided the energy use of the building is not increased: |

1. Storm windows installed over existing fenestration. | |

2. Existing ceiling, wall or floor cavities exposed during construction provided that these cavities are filled with insulation. 2 x 4 framed walls shall be insulated to a minimum of R-15 and 2 x 6 framed walls shall be insulated to a minimum of R-21. | |

3. Construction where the existing roof, wall or floor cavity is not exposed. | |

4. Roof recover. | |

5. Roofs without insulation in the cavity and where the sheathing or insulation is exposed during reroofing shall be insulated either above or below the sheathing. | |

6. Surface-applied window film installed on existing single pane fenestration assemblies to reduce solar heat gain provided the code does not require the glazing fenestration to be replaced. |

EXCEPTIONS: | 1. Where ducts from an existing heating and cooling system are extended, duct systems with less than 40 linear feet in unconditioned spaces shall not be required to be tested in accordance with Section R403.2.2. |

2. Existing duct systems constructed, insulated or sealed with asbestos. | |

((3. Replacements of space heating equipment shall not be required to comply with Section R403.13 where the rated capacity of the new equipment does not exceed the rated capacity of the existing equipment.)) |

EXCEPTION((S)): | ((1.)) Replacement of water heating equipment shall not be required to comply with Section R403.5.5. |

((2. Replacement of water heating equipment shall not be required to comply with Section R403.5.7 where the rated capacity of the new equipment does not exceed the rated capacity of the existing equipment.)) |

EXCEPTION: | Alterations that replace less than 10 percent of the luminaires in a space, provided that such alterations do not increase the installed interior lighting power. |

AAMA | American Architectural Manufacturers Association | ||

1827 Walden Office Square | |||

Suite 550 | |||

Schaumburg, IL 60173-4268 | |||

Standard reference number | Title | Referenced in code section number | |

AAMA/WDMA/CSA 101/I.S.2/A C440-17 | North American Fenestration Standard/Specifications for Windows, Doors and Unit Skylights | . . . . . . . . | ((R402.4.3))R402.4.2 |

ACCA | Air Conditioning Contractors of America | ||

2800 Shirlington Road, Suite 300 | |||

Arlington, VA 22206 | |||

Standard reference number | Title | Referenced in code section number | |

Manual J-16 | Residential Load Calculation Eighth Edition | . . . . . . . . | R403.7 |

Manual S-14 | Residential Equipment | . . . . . . . . | R403.7 |

ANSI | American National Standards Institute 25 West 43rd Street, 4th Floor New York, NY 10036 | ||

Standard reference number | Title | Referenced in code section number | |

Z21.50-2016/CSA 2.22-2016 | Vented Decorative Gas Appliances | . . . . . . . . | ((R402.4.2.1, R403.1.3)) R403.7.1 |

Z21.88-2017/CSA 2.33-2017 | Vented Gas Fireplace Heaters | . . . . . . . . | ((R402.4.2.1))R403.7.1 |

Z21.40.2-1996 | Gas-fired, Work Activated Air-Conditioning and Heat Pump Appliances (Internal Combustion) | . . . . . . . . | Table R406.3 |

Z21.40.4-1996 | Performance Testing and Rating of Gas-Fired, Air-Conditioning and Heat Pump Appliances | . . . . . . . . | Table R406.3 |

APSP | The Association of Pool and Spa Professionals | ||

2111 Eisenhower Avenue, Suite 500 | |||

Alexandria, VA 22206 | |||

Standard reference number | Title | Referenced in code section number | |

ANSI/APSP/ICC 14-2019 | American National Standard for Portable Electric Spa Energy Efficiency | . . . . . . . . | R403.11 |

ANSI/APSP/ICC 15a-2011 | American National Standard for Residential Swimming Pool and Spa Energy Efficiency—Includes Addenda A approved January 9, 2013 | . . . . . . . . | R403.12 |

ASHRAE | American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. | ||

1791 Tullie Circle, N.E. | |||

Atlanta, GA 30329-2305 | |||

Standard reference number | Title | Referenced in code section number | |

ASHRAE-2021 | ASHRAE Handbook of Fundamentals | . . . . . . . . | R402.1.5, Table R405.5.2(1) |

ASHRAE 193-2010 (RA 2014) | Method of Test for Determining the Airtightness of HVAC Equipment | . . . . . . . . | ((R403.3.2.1))R403.3.4.1 |

ASTM | ASTM International | ||

100 Barr Harbor Drive | |||

West Conshohocken, PA 19428-2859 | |||

Standard reference number | Title | Referenced in code section number | |

C1363-11 | Standard Test Method for Thermal Performance of Building Materials and Envelope Assemblies by Means of a Hot Box Apparatus | . . . . . . . . | R303.1.4.1 |

E283-2004 (2012) | Test Method for Determining the Rate of Air Leakage Through Exterior Windows, Curtain Walls and Doors Under Specified Pressure Differences Across the Specimen | . . . . . . . . | ((R402.4.5))R402.4.3 |

E779-2010 (2018) | Standard Test Method for Determining Air Leakage Rate by Fan Pressurization | . . . . . . . . | R402.4.1.2 |

E1554/E1554M-E2013 | Standard Test Method for Determining Air Leakage of Air Distribution Systems by Fan Pressurization | . . . . . . . . | R403.3.5 |

E1827-2011 (2017) | Standard Test Methods for Determining Airtightness of Building Using an Orifice Blower Door | . . . . . . . . | R402.4.1.2 |

E2178-2013 | Standard Test Method for Air Permeance of Building Materials | . . . . . . . . | R303.1.5 |

E3158-2018 | Standard Test Method for Measuring the Air Leakage Rate of a Large or Multizone Building | . . . . . . . . | R402.4.1.2 |

CSA | Canadian Standards Association | ||

5060 Spectrum Way | |||

Mississauga, Ontario, Canada L4W 5N6 | |||

Standard reference number | Title | Referenced in code section number | |

AAMA/WDMA/CSA 101/I.S.2/A440-17 | North American Fenestration Standard/Specification for Windows, Doors and Unit Skylights | . . . . . . . . | ((R402.4.3))R402.4.2 |

CSA 55.1-2015 | Test Method for Measuring Efficiency and Pressure Loss of Drain Water Heat Recovery Systems | . . . . . . . . | R403.5.4, Table R406.2 |

CSA 55.2-2015 | Drain Water Heat Recovery Units | . . . . . . . . | R403.5.4 |

CSA P.4.1-15 | Testing Method for Measuring Annual Fireplace Efficiency | . . . . . . . . | ((R402.4.2.1))R403.7.1 |

DASMA | Door and Access Systems Manufacturers Association | ||

1300 Sumner Avenue | |||

Cleveland, OH 44115-2851 | |||

105-2017 | Test Method for Thermal Transmittance and Air Infiltration of Garage Doors and Rolling Doors | . . . . . . . . | R303.1.3 |

HVI | Home Ventilating Institute | ||

1000 North Rand Road, Suite 214 | |||

Wauconda, IL 60084 | |||

916-18 | Airflow Test Procedure | . . . . . . . . | R303.1.3 |

ICC | International Code Council, Inc. | ||

500 New Jersey Avenue, N.W. | |||

6th Floor | |||

Washington, DC 20001 | |||

Standard reference number | Title | Referenced in code section number | |

ANSI/APSP/ICC 14-2019 | American National Standard for Portable Electric Spa Energy Efficiency | . . . . . . . . | R403.11 |

ANSI/APSP/ICC 15a-2011 | American National Standard for Residential Swimming Pool and Spa Energy Efficiency—Includes Addenda A approved January 9, 2013 | . . . . . . . . | R403.12 |

ANSI/RESNET/ICC 380-2019 | Standard for Testing Airtightness of building, Dwelling Unit and Sleeping Unit Enclosures; Airtightness of Heating and Cooling Air Distribution Systems, and Airflow of Mechanical Ventilation Systems | . . . . . . . . | R402.4.1.2 |

IBC-21 | International Building Code | . . . . . . . . | R201.3, R303.2, R402.11, R4501.4 |

ICC 400-17 | Standard on the Design and Construction of Log Structures | . . . . . . . . | Table R402.1.1 |

ICC 500-2020 | ICC/NSSA Standard for the Design and Construction of Storm Shelters | . . . . . . . . | R402.5 |

IFC-21 | International Fire Code | . . . . . . . . | R201.3, R501.4 |

IFGC-21 | International Fuel Gas Code | . . . . . . . . | R201.3, R501.4 |

IFGC-21 | International Mechanical Code | . . . . . . . . | R201.3, R403.3.2, R403.6, R501.4 |

IPMC-21 | International Property Maintenance Code | . . . . . . . . | R501.4 |

IRC-21 | International Residential Code | . . . . . . . . | R104.2.1, R201.3, R303.2, R401.2, R403.2.2, R403.5, R406.1, R406.2, Table R406.2 |

IEEE | The Institute of Electrical and Electronic Engineers, Inc. | ||

3 Park Avenue | |||

New York, NY 10016-5997 | |||

Standard reference number | Title | Referenced in code section number | |

515.1-2012 | IEEE Standard for the Testing, Design, Installation and Maintenance of Electrical Resistance Trace Heating for Commercial Applications | . . . . . . . . | R403.5.1.2 |

ISO | International Organization for Standardization | ||

1, rue de Varembe, Case postale 56, CH-1211 | |||

Geneva, Switzerland | |||

Standard reference number | Title | Referenced in code section number | |

ISO/IEC ((17024-212))17024-2012 | Conformity Assessment: General requirements for bodies operating certification of persons | . . . . . . . . | R402.4.1.2 |

NEEA | Northwest Energy Efficiency Alliance | ||

421 S.W. 6th Ave., Suite 600 | |||

Portland, OR 97204 | |||

Standard reference number | Title | Referenced in code section number | |

NEEA-2011 | Northern Climate Specification for Heat Pump Water Heaters, Vers. 4.0 | . . . . . . . . | Table ((R406.2))R406.3 |

NEEA-2019 | Advanced Water Heating Specifications for Gas-Fueled Residential Storage Water Heaters, Version 1.0. | . . . . . . . . | Table R406.3 |

NEEP | Northeast Energy Efficiency Partnership, Inc. | ||

24 School Street, 2nd Floor | |||

Boston, MA 02108-4314 | |||

Standard reference number | Title | Referenced in code section number | |

ccASHP Version 3.1 | Cold Climate Air Source Heat Pump (ccASHP) Product List and Specifications:

https://neep.org/heating-electrification/ccashp-specification-product-list

| . . . . . . . . | Table R406.3 |

NEMA | National Electrical Manufacturers Association | ||

1300 17th Street N No. 900 | |||

Arlington, VA 22209 | |||

Standard reference number | Title | Referenced in code section number | |

OS4-2016 | Requirements for Air-Sealed Boxes for Electrical and Communications Applications | . . . . . . . . | ((R402.4.6))R402.4.4 |

NFPA | National Fire Protection Association | ||

1 Batterymarch Park | |||

Quincy, MA 02169-7417 | |||

Standard reference number | Title | Referenced in code section number | |

70-20 | National Electrical Code | . . . . . . . . | R501.4 |

NFRC | National Fenestration Rating Council, Inc. | ||

6305 Ivy Lane, Suite 140 | |||

Greenbelt, MD 20770 | |||

Standard reference number | Title | Referenced in code section number | |

100-2020 | Procedure for Determining Fenestration Products U-factors | . . . . . . . . | R303.1.3 |

200-2020 | Procedure for Determining Fenestration Product Solar Heat Gain Coefficients and Visible Transmittance at Normal Incidence | . . . . . . . . | R303.1.3 |

400-2020 | Procedure for Determining Fenestration Product Air Leakage | . . . . . . . . | ((R402.4.3))R402.4.2 |

UL | Underwriters Laboratory | ||

333 Pfingsten Road | |||

Northbrook, IL 60062 | |||

Standard reference number | Title | Referenced in code section number | |

UL 127-11 | Factory Built Fireplace | . . . . . . . . | ((R402.4.2))R402.3.6 |

UL 515-11 | Electric Resistance Heat Tracing for Commercial and Industrial Applications | . . . . . . . . | R403.5.1.2 |

UL 907-94 | Fireplace Accessories (with revisions through April 2010) | . . . . . . . . | ((R402.4.2))R402.3.6 |

US-FTC | United States-Federal Trade Commission | ||

600 Pennsylvania Avenue N.W. | |||

Washington, DC 20580 | |||

Standard reference number | Title | Referenced in code section number | |

C.F.R. Title 16 (2015) | R-value Rule | . . . . . . . . | Rule R303.1.4 |

WDMA | Window and Door Manufacturers Association | ||

1400 East Touhy Avenue, Suite 470 | |||

Des Plaines, IL 60018 | |||

Standard reference number | Title | Referenced in code section number | |

AAMA/WDMA/CSA 101/I.S.2/A440-17 | North American Fenestration Standard/Specification for Windows, Doors and Unit Skylights | . . . . . . . . | ((R402.4.3))R402.4.2 |

WSU | Washington State University Energy Extension Program | ||

905 Plum Street S.E., Bldg 3 | |||

P.O. Box 43165 | |||

Olympia, WA 98506-3166 | |||

Standard reference number | Title | Referenced in code section number | |

WSU RS 33 | Duct Testing Standard for New and Existing Construction Publication No. WSUEEP15-016 | . . . . . . . . | R403.3.3 |