WSR 23-23-104

PERMANENT RULES

BUILDING CODE COUNCIL

[Filed November 15, 2023, 9:59 a.m., effective March 16, 2024]

Effective Date of Rule: March 16, 2024.

Purpose: Reconciling state amendments with section renumbering and model code modifications in the 2021 International Residential Code; correcting errors and omissions.

Citation of Rules Affected by this Order: Amending 36 sections in chapter 51-51 WAC.

Adopted under notice filed as WSR 23-15-030 on July 10, 2023.

Changes Other than Editing from Proposed to Adopted Version:

WAC | Section | Change | Rationale/Discussion |

51-51-003 | International Residential Code | Appendix references are renamed to add the letter "A" before named appendices. | The modification provides consistency with the model code format. There is no intended change in regulatory effect. |

51-51-008 | Implementation | Implementation date is changed from October 29, 2023, to March 15, 2024. | The state building code council voted to delay implementation of all codes on September 15, 2023. |

51-51-01010 | R101.2 Exceptions | Appendix references are renamed to add the letter "A" before named appendices. | The modification provides consistency with the model code format. There is no intended change in regulatory effect. |

51-51-0102 | R102.7.2 Exception #2 | Appendix references are renamed to add the letter "A" before named appendices. | The modification provides consistency with the model code format. There is no intended change in regulatory effect. |

51-51-0302 | R302.13 Exception #1 | Appendix references are renamed to add the letter "A" before named appendices. | The modification provides consistency with the model code format. There is no intended change in regulatory effect. |

52-52-0331 | R331.1 | Changes section numbering from R331 to R331.1 | Editorial correction; there is no change in regulatory effect. |

51-51-0408 | R408.2 Exception | Appendix references are renamed to add the letter "A" before named appendices. | The modification provides consistency with the model code format. There is no intended change in regulatory effect. |

R408.3 | Appendix references are renamed to add the letter "A" before named appendices. | The modification provides consistency with the model code format. There is no intended change in regulatory effect. |

51-51-0507 | T507.5 Footnote (i) | Figure number changed from R507.5 to R507.6 | Editorial correction; there is no change in regulatory effect. |

51-51-1505 | T1505.4.4.3 | Changes value for hood over electric range from 60% to 65%. | The modification provides consistency with the International Mechanical Code. |

51-51-60104 | Appendix AQ | Adds letter "A" to appendix title letter. | The modification provides consistency with the model code format. There is no intended change in regulatory effect. |

51-51-60105 | Appendix AWU | Adds letter "A" to appendix title letter. | The modification provides consistency with the model code format. There is no intended change in regulatory effect. |

51-51-60106 | Appendix AT | Adds letter "A" to appendix title letter. | The modification provides consistency with the model code format. There is no intended change in regulatory effect. |

51-51-60107 | Appendix AWV | Adds letter "A" to appendix title letter. | The modification provides consistency with the model code format. There is no intended change in regulatory effect. |

Appendix AWV | Changes format of all section numbering from "WAV" to "AWV." | The modification provides consistency with the model code format. There is no intended change in regulatory effect. |

51-51-60108 | Appendix AWY | Adds letter "A" to appendix title letter. | The modification provides consistency with the model code format. There is no intended change in regulatory effect. |

| Appendix AWY | Changes format of all section numbering from "WAY" to "AWY." | The modification provides consistency with the model code format. There is no intended change in regulatory effect. |

51-51-60108 | Appendix AWZ | Adds letter "A" to appendix title letter. | The modification provides consistency with the model code format. There is no intended change in regulatory effect. |

| Appendix AWZ | Changes format of all section numbering from "WAZ" to "AWZ." | The modification provides consistency with the model code format. There is no intended change in regulatory effect. |

Number of Sections Adopted in Order to Comply with Federal Statute: New 0, Amended 0, Repealed 0; Federal Rules or Standards: New 0, Amended 0, Repealed 0; or Recently Enacted State Statutes: New 0, Amended 0, Repealed 0.

Number of Sections Adopted at the Request of a Nongovernmental Entity: New 0, Amended 0, Repealed 0.

Number of Sections Adopted on the Agency's own Initiative: New 0, Amended 36, Repealed 0.

Number of Sections Adopted in Order to Clarify, Streamline, or Reform Agency Procedures: New 0, Amended 0, Repealed 0.

Number of Sections Adopted using Negotiated Rule Making: New 0, Amended 0, Repealed 0; Pilot Rule Making: New 0, Amended 0, Repealed 0; or Other Alternative Rule Making: New 0, Amended 36, Repealed 0.

Date Adopted: October 20, 2023.

Tony Doan

Council Chair

OTS-4745.6

AMENDATORY SECTION(Amending WSR 23-02-058, 23-12-104, and 23-20-024, filed 1/3/23, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-51-003International Residential Code.

The 2021 edition of the International Residential Code as published by the International Code Council is hereby adopted by reference with the following additions, deletions, and exceptions: Provided that chapters 11 and 25 through 43 of this code are not adopted. Energy Code is regulated by chapter 51-11R WAC; Plumbing Code is regulated by chapter 51-56 WAC; Electrical Code is regulated by chapter 296-46B WAC or Electrical Code as adopted by the local jurisdiction. Appendix AF, Radon Control Methods, Appendix AQ, Tiny Homes, and Appendix AWU, Dwelling Unit Fire Sprinkler Systems, are included in adoption of the International Residential Code.

AMENDATORY SECTION(Amending WSR 23-02-058, 23-12-104, and 23-20-024, filed 1/3/23, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-51-008Implementation.

The International Residential Code adopted by chapter 51-51 WAC shall become effective in all counties and cities of this state on ((July 1, 2023))March 15, 2024.

AMENDATORY SECTION(Amending WSR 23-02-058, 23-12-104, and 23-20-024, filed 1/3/23, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-51-01010Section R101—Scope and general requirements.

R101.2 Scope. The provisions of the International Residential Code for One- and Two-Family Dwellings shall apply to the construction, alteration, movement, enlargement, replacement, repair, equipment, use and occupancy, location, removal and demolition of detached one- and two-family dwellings, adult family homes, and townhouses not more than three stories above grade plane in height with a separate means of egress and their accessory structures not more than three stories above grade plane in height.

EXCEPTIONS: | 1. Live/work units located in townhouses and complying with the requirements of Section 508.5 of the International Building Code shall be permitted to be constructed in accordance with the International Residential Code for One- and Two-Family Dwellings. An automatic sprinkler system required by Section 508.5.7 of the International Building Code where constructed under the International Residential Code for One- and Two-Family Dwellings shall conform to Appendix AWU. |

| 2. Owner-occupied lodging houses with one or two guestrooms shall be permitted to be constructed in accordance with the International Residential Code forOne- and Two-Family Dwellings. |

| 3. Owner-occupied lodging homes with three to five guestrooms shall be permitted to be constructed in accordance with the International Residential Code for One- and Two-Family Dwellings where equipped with an automatic fire sprinkler system in accordance with Appendix AWU. |

| 4. A care facility with five or fewer persons receiving custodial care within a dwelling unit shall be permitted to be constructed in accordance with the International Residential Code for One- and Two-Family Dwellings where equipped with an automatic fire sprinkler system in accordance with Appendix AWU. |

| 5. A care facility with five or fewer persons receiving medical care within a dwelling unit shall be permitted to be constructed in accordance with the International Residential Code for One- and Two-Family Dwellings where equipped with an automatic fire sprinkler system in accordance with Appendix AWU. |

| 6. A care facility with five or fewer persons receiving care that are within a single-family dwelling shall be permitted to be constructed in accordance with the International Residential Code for One- and Two-Family Dwellings where equipped with an automatic fire sprinkler system in accordance with Appendix AWU. |

AMENDATORY SECTION(Amending WSR 23-02-058, 23-12-104, and 23-20-024, filed 1/3/23, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-51-0102Section R102—Applicability.

R102.5 Appendices. Provisions in the appendices shall not apply unless specifically referenced in the adopting ordinance. An appendix adopted by a local jurisdiction shall not be effective unless approved by the state building code council pursuant to RCW

19.27.060 (1)(a).

EXCEPTIONS: | 1. The state building code council has determined that a local ordinance providing specifications for light straw-clay or strawbale construction, ((or)) requiring a solar-ready zone, ((or)) requiring fire sprinklers, or addressing construction and demolition material management or building deconstruction in accordance with Appendix AR, AS, ((or V))AT, AWV, AWY, or AWZ of this ((chapter))code may be adopted by any local government upon notification of the council. |

| 2. Appendix AF, Radon Control Methods, Appendix AQ, Tiny Homes, and Appendix AWU, Dwelling Unit Fire Sprinkler Systems, are included in adoption of the International Residential Code. |

R102.7.1 Additions, alterations, change of use, repairs, or relocations.Additions, alterations, repairs, or relocations shall be permitted to conform to the requirements of the provisions of Chapter 45 or shall conform to the requirements for new structure without requiring the existing structure to comply with the requirements of this code, unless otherwise stated. Additions, alterations, repairs, and relocations shall not cause an existing structure to become less compliant with the provisions of this code than the existing building or structure was prior to the addition, alteration, repair, or relocation. Where additions, alterations, or changes of use to an existing structure result in a use or occupancy, height, or means of egress outside the scope of this code, the building shall comply with the International Existing Building Code.

EXCEPTIONS: | 1. Additions with less than 500 square feet of conditioned floor area are exempt from the requirements for Whole-House Ventilation Systems, Section M1505.4. |

| 2. Additions or alterations to existing buildings which do not require the construction of foundations, crawlspaces, slabs or basements shall not be required to meet the requirements for radon protection in Section R332.1 and Appendix AF. |

R102.7.2 Moved buildings. Buildings or structures moved into or within a jurisdiction shall comply with the provisions of this code, the International Building Code (chapter 51-50 WAC), the International Mechanical Code (chapter 51-52 WAC), the International Fire Code (chapter 51-54A WAC), the Uniform Plumbing Code and Standards (chapter 51-56 WAC), and the Washington State Energy Code (chapter 51-11R WAC) for new buildings or structures.

EXCEPTION: | Group R-3 buildings or structures are not required to comply if: |

| 1. The original occupancy classification is not changed; and |

| 2. The original building is not substantially remodeled or rehabilitated. For the purposes of this section a building shall be considered to be substantially remodeled when the costs of remodeling exceed 60 percent of the value of the building exclusive of the costs relating to preparation, construction, demolition or renovation of foundations. |

AMENDATORY SECTION(Amending WSR 23-02-058, 23-12-104, and 23-20-024, filed 1/3/23, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-51-0301Section R301—Design criteria.

R301.2 Climatic and geographic design criteria. Buildings shall be constructed in accordance with the provisions of this code as limited by the provisions of this section. Additional criteria shall be established by the local jurisdiction and set forth in Table R301.2(((1))). The local jurisdiction shall designate the salt water coastal areas within their jurisdiction.

R301.2.2.10 Anchorage of water heaters. In Seismic Design Categories D0, D1 and D2, and in townhouses in Seismic Design Category C, water heaters and thermal storage units shall be anchored against movement and overturning in accordance with Section M1307.2 or the Uniform Plumbing Code Section 507.2.

R301.5 Live load. The minimum uniformly distributed live load shall be as provided in Table R301.5.

TABLE R301.5

MINIMUM UNIFORMLY DISTRIBUTED LIVE LOADS

(in pounds per square foot)

| Use | Uniform Load (psf) | Concentrated Load (lb) | |

| Uninhabitable attics without storageb | 10 | - | |

| Uninhabitable attics with limited storageb, g | 20 | - | |

| Habitable attics and attics served with fixed stairs | 30 | - | |

| Balconies (exterior) and deckse | 60j | - | |

| Fire escapes | 40 | - | |

| Guards | - | 200h,i | |

| Guard in-fill componentsf | - | 50h | |

| Handraild | ((200h))- | ((-))200h | |

| Passenger vehicle garagesa | 50a | 2,000((h))a | |

| Areas other than sleeping areas | 40 | - | |

| Sleeping areas | 30 | - | |

| Stairs | 40c | 300c | |

For SI: 1 pound per square foot = 0.0479 kPa, 1 square inch = 645 mm, 1 pound = 4.45 N |

a. | Elevated garage floors shall be capable of supporting the uniformly distributed live load or a 2,000-pound concentrated load applied on an area of 4-1/2 inches by 4-1/2 inches, whichever produces the greater stresses. |

b. | Uninhabitable attics without storage are those where the clear height between joists and rafters is not more than 42 inches, or where there are not two or more adjacent trusses with web configurations capable of accommodating an assumed rectangle 42 inches in height by 24 inches in width, or greater, within the plane of the trusses. This live load need not be assumed to act concurrently with any other live load requirements. |

c. | Individual stair treads shall be capable of supporting the uniformly distributed live load or a 300-pound concentrated load applied on an area of 2 inches by 2 inches, whichever produces the greater stresses. |

d. | A single concentrated load applied in any direction at any point along the top. For a guard not required to serve as a handrail, the load need not be applied to the top element of the guard in a direction parallel to such element. |

e. | See Section R507.1 for decks attached to exterior walls. |

f. | Guard in-fill components (all those except the handrail), balusters and panel fillers shall be designed to withstand a horizontally applied normal load of 50 pounds on an area equal to 1 square foot. This load need not be assumed to act concurrently with any other live load requirement. |

g. | Uninhabitable attics with limited storage are those where the clear height between joists and rafters is 42 inches or greater, or where there are two or more adjacent trusses with web configurations capable of accommodating an assumed rectangle 42 inches in height by 24 inches in width, or greater, within the plane of the trusses. The live load need only be applied to those portions of the joists or truss bottom chords where all of the following conditions are met: |

g.1. | The attic area is accessed from an opening not less than 20 inches in width by 30 inches in length that is located where the clear height in the attic is not less than 30 inches. |

g.2. | The slopes of the joists or truss bottom chords are not greater than 2 ((inches))units vertical to 12 units horizontal. |

g.3. | Required insulation depth is less than the joist or truss bottom chord member depth. The remaining portions of the joists or truss bottom chords shall be designed for a uniformly distributed concurrent live load of not less than 10 pounds per square foot. |

h. | Glazing used in handrail assemblies and guards shall be designed with a load adjustment factor of 4. The load adjustment factor shall be applied to each of the concentrated loads applied to the top of the rail, and to the load on the in-fill components. These loads shall be determined independent of one another, and loads are assumed not to occur with any other live load. |

i. | Where the top of a guard system is not required to serve as a handrail, the single concentrated load shall be applied at any point along the top, in the vertical downward direction and in the horizontal direction away from the walking surface. Where the top of a guard is also serving as the handrail, a single concentrated load shall be applied in any direction at any point along the top. Concentrated loads shall not be applied concurrently. |

j. | Where structural tables in Section R507 only specify snow loads, the values corresponding to 70 psf snow loads shall be used. |

AMENDATORY SECTION(Amending WSR 23-02-058, 23-12-104, and 23-20-024, filed 1/3/23, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-51-0302Section R302—Fire-resistant construction.

R302.2.2 Common walls. Common walls separating townhouse units shall be assigned a fire resistance rating in accordance with Item 1 or 2 and shall be rated for fire exposure from both sides. Common walls shall extend to and be tight against the exterior sheathing of the exterior walls, or the inside face of exterior walls without stud cavities, and the underside of the roof sheathing. The common wall shared by two townhouse units shall be constructed without plumbing or mechanical equipment, ducts or vents, other than water-filled fire sprinkler piping in the cavity of the common wall. Electrical installations shall be in accordance with chapter 296-46B WAC, Electrical safety standards, administration, and installation. Penetrations of the membrane of common walls for electrical outlet boxes shall be in accordance with Section R302.4.

1. Where an automatic sprinkler system in accordance with Section P2904 is provided, the common wall shall be not less than a 1-hour fire-resistance-rated wall assembly tested in accordance with ASTM E119, UL 263 or Section 703.2.2 of the International Building Code.

2. Where an automatic sprinkler system in accordance with Section P2904 is not provided, the common wall shall be not less than a 2-hour fire-resistance-rated wall assembly tested in accordance with ASTM E119, UL 263 or Section 703.2.2 of the International Building Code.

EXCEPTION: | Common walls are permitted to extend to and be tight against the interior side of the exterior walls if the cavity between the end of the common wall and the exterior sheathing is filled with a minimum of 2-inch nominal thickness wood studs. |

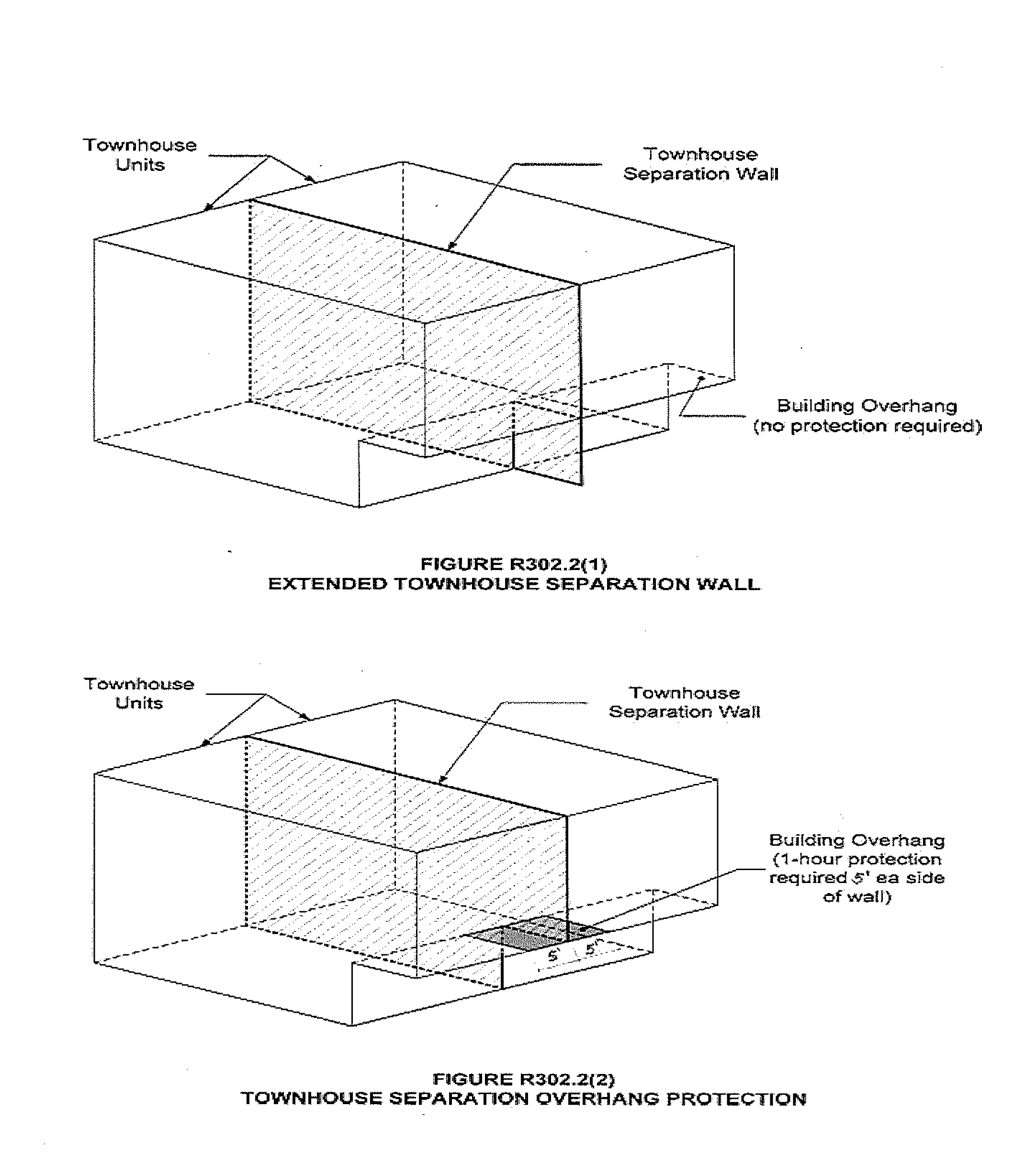

R302.2.3Continuity. The fire-resistance-rated wall or assembly separating townhouse units shall be continuous from the foundation to the underside of the roof sheathing, deck or slab. The fire-resistance rating shall extend the full length of the wall or assembly, including wall extensions through and separating attached enclosed accessory structures.

Where a story extends beyond the exterior wall of a story below:

1. The fire-resistance-rated wall or assembly shall extend to the outside edge of the upper story (see Figure R302.2(1)); or

2. The underside of the exposed floor-ceiling assembly shall be protected as required for projections in Section R302 (see Figure R302.2(2)).

R302.2.4 Parapets for townhouses. Parapets constructed in accordance with Section R302.2.5 shall be constructed for townhouses as an extension of exterior walls or common walls separating townhouse units in accordance with the following:

1. Where roof surfaces adjacent to the wall or walls are at the same elevation, the parapet shall extend not less than 30 inches (762 mm) above the roof surfaces.

2. Where roof surfaces adjacent to the wall or walls are at different elevations and the higher roof is not more than 30 inches (762 mm) above the lower roof, the parapet shall extend not less than 30 inches (762 mm) above the lower roof surface.

EXCEPTION: | A parapet is not required in the preceding two cases where the roof covering complies with a minimum Class C rating as tested in accordance with ASTM E108 or UL 790 and the roof decking or sheathing is of noncombustible materials or fire retardant-treated wood for a distance of 4 feet (1219 mm) on each side of the wall or walls, or one layer of 5/8-inch (15.9 mm) Type X gypsum board is installed directly beneath the roof decking or sheathing, supported by not less than nominal 2-inch (51 mm) ledgers attached to the sides of the roof framing members, for a distance of not less than 4 feet (1219 mm) on each side of the wall or walls and any openings or penetrations in the roof are not within 4 feet (1219 mm) of the common walls. Fire retardant-treated wood shall meet the requirements of Sections R802.1.5 and R803.2.1.2. |

3. A parapet is not required where roof surfaces adjacent to the wall or walls are at different elevations and the higher roof is more than 30 inches (762 mm) above the lower roof. The common wall construction from the lower roof to the underside of the higher roof deck shall have not less than a 1-hour fire-resistance rating. The wall shall be rated for exposure from both sides.

TABLE R302.1(1)

EXTERIOR WALLS

No Change to the Table

a | The fire-resistance rating shall be permitted to be reduced to 0 hours on the underside of the eave overhang if fireblocking is provided from the wall top plate to the underside of the roof sheathing. |

b | The fire-resistance rating shall be permitted to be reduced to 0 hours on the underside of the rake overhang where ventilation openings are not installed in the rake overhang or in walls that are common to attic areas. |

TABLE R302.1(2)

EXTERIOR WALLS - DWELLINGS WITH FIRE SPRINKLERS

No Change to the Table

a | For residential subdivisions where all dwellings are equipped throughout with an automatic sprinkler system installed in accordance with Section P2904, the fire separation distance for exterior walls not fire-resistance-rated and for fire-resistance-rated projections shall be permitted to be reduced to 0 feet, and unlimited unprotected openings and penetrations shall be permitted, where the adjoining lot provides an open setback yard that is 6 feet or more in width on the opposite side of the property line. |

b | The fire-resistance rating shall be permitted to be reduced to 0 hours on the underside of the eave overhang if fireblocking is provided from the wall top plate to the underside of the roof sheathing. |

c | The fire-resistance rating shall be permitted to be reduced to 0 hours on the underside of the rake overhang where ventilation openings are not installed in the rake overhang or in walls that are common to attic areas. |

R302.3 Two-family dwellings. Wall and floor/ceiling assemblies separating dwelling units in two-family dwellings shall be constructed in accordance with Section R302.3.1 through R302.3.5. One accessory dwelling unit constructed within an existing dwelling unit need not be considered a separated dwelling unit in a two-family dwelling where all required smoke alarms, in the accessory dwelling unit and the primary dwelling unit, are interconnected in such a manner that the actuation of one alarm will activate all alarms in both the primary dwelling unit and the accessory dwelling unit.

R302.3.1 Separation.Dwelling units in two-family dwellings shall be separated from each other by wall and floor assemblies having not less than a 1-hour fire-resistance rating where tested in accordance with ASTM E119, UL 263 or Section 703.2.2 of the International Building Code.

EXCEPTIONS: | 1. A fire-resistance rating of 1/2 hour shall be permitted in buildings equipped throughout with an automatic sprinkler system installed in accordance with ((NFPA 13D))Section 2904. |

| 2. Where an accessory dwelling unit is added within an existing single-family residence to create a two-family dwelling, fire-rated separation between the accessory dwelling unit and the primary dwelling unit is not required when all required smoke alarms are interconnected in such a manner that the actuation of one alarm will activate all alarms in both the primary dwelling unit and the accessory dwelling unit. |

R302.3.2 Continuity. Fire-resistance-rated floor/ceiling and wall assemblies shall extend to and be tight against the exterior wall, and wall assemblies shall extend from the foundation to the underside of the roof sheathing.

EXCEPTION: | Wall assemblies need not extend through attic spaces where the ceiling is protected by not less than 5/8-inch (15.9 mm) Type X gypsum board, an attic draft stop constructed as specified in Section R302.12.1 is provided above and along the wall assembly separating the dwellings and the structural framing supporting the ceiling is protected by not less than 1/2-inch (12.7 mm) gypsum board or equivalent. |

R302.3.3 Supporting construction. Where floor/ceiling assemblies are required to be fire-resistance rated by Section R302.3, the supporting construction of such assemblies shall have an equal or greater fire-resistance rating.

R302.3.4((.)) Openings protection between two-family dwellings. Openings in the common fire-resistance-rated wall assembly located between units of a two-family dwelling shall be equipped with not less than a 45-minute fire-rated door assembly equipped with a self-closing or automatic-closing device.

EXCEPTION: | A 20-minute fire-rated door assembly is permitted in buildings equipped throughout with an automatic sprinkler system installed in accordance with Section P2904 or NFPA 13D. |

R302.3.5 Shared accessory rooms. Shared accessory rooms shall be separated from each individual dwelling unit in accordance with Table R302.3.5. Openings between the shared accessory room and the dwelling unit shall comply with Section R302.3.5.1. Attachment of gypsum board shall comply with Table R702.3.5.

R302.3.5.1 Opening protection. Openings from a shared accessory room or area directly into a room used for sleeping purposes shall not be permitted. Other openings between the shared accessory room or area shall be equipped with solid wood doors not less than 1 3/8 inches in thickness, solid or honeycomb core steel doors not less than 1 3/8 inches thick, or a fire door assembly with a 20-minute fire-protection rating, equipped with a self-closing or automatic-closing device.

R302.3.5.2 Duct penetration. Ducts penetrating the walls or ceilings separating the dwelling from the shared accessory room shall be constructed of a minimum No. 26 gage (0.48 mm) sheet steel or other approved material and shall not have openings into the shared accessory room.

R302.3.5.3 Other penetrations. Penetrations through the walls, ceiling, and floor level separation required in Section R302.3.5 shall be protected as required by Section R302.11, Item 4.

TABLE R302.3.5

DWELLING-SHARED ACCESSORY ROOM SEPARATION

SEPARATION | MATERIAL |

From the dwelling units and attics. | Not less than 1/2-inch gypsum board or equivalent applied to the accessory room side wall. |

From habitable rooms above or below the shared accessory room. | Not less than 5/8-inch Type X gypsum board or equivalent. |

Structures supporting floor/ceiling assemblies used for separation required by this section. | Not less than 1/2-inch gypsum board or equivalent. |

R302.13 Fire protection of floors. Floor assemblies that are not required elsewhere in this code to be fire-resistance rated, shall be provided with a 1/2-inch (12.7 mm) gypsum wallboard membrane, 5/8-inch (16 mm) wood structural panel membrane, or equivalent on the underside of the floor framing member. Penetrations or openings for ducts, vents, electrical outlets, lighting, devices, luminaires, wires, speakers, drainage, piping and similar openings or penetrations shall be permitted.

EXCEPTIONS: | 1. Floor assemblies located directly over a space protected by an automatic sprinkler system in accordance with Appendix AWU, NFPA 13D, or other approved equivalent sprinkler system. |

| 2. Floor assemblies located directly over a crawl space not intended for storage or fuel-fired appliances. |

| 3. Portions of floor assemblies shall be permitted to be unprotected when complying with the following: |

| 3.1. The aggregate area of the unprotected portions shall not exceed 80 square feet (7.4 m2) per story. |

| 3.2. Fire blocking in accordance with Section R302.11.1 is installed along the perimeter of the unprotected portion to separate the unprotected portion from the remainder of the floor assembly. |

| 4. Wood floor assemblies using ((dimensional))dimension lumber or structural composite lumber with a cross sectional area equal to or greater than 2-inch by 10-inch (50.8 mm by 254 mm) nominal dimension, or other approved floor assemblies demonstrating equivalent fire performance. |

AMENDATORY SECTION(Amending WSR 23-02-058, 23-12-104, and 23-20-024, filed 1/3/23, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-51-0303Section R303—Light, ventilation and heating.

R303.1 Natural light. All habitable rooms shall have an aggregate glazing area of not less than 8 percent of the floor area of such rooms.

EXCEPTION: | The glazed areas need not be installed in rooms where artificial light is provided capable of producing an average illumination of 6 footcandles (65 lux) over the area of the room at a height of 30 inches (762 mm) above the floor level. |

R303.2 Adjoining rooms. For the purpose of determining light requirements, any room shall be considered as a portion of an adjoining room when at least one-half of the area of the common wall is open and unobstructed and provides an opening of not less than one-tenth of the floor area of the interior room but not less than 25 square feet (2.3 m2).

EXCEPTION: | Openings required for light shall be permitted to open into a sunroom with thermal isolation or a patio cover, provided there is an openable area between the adjoining room and the sunroom or a patio cover of not less than one-tenth of the floor area of the interior room but not less than 20 square feet (2 m2). |

R303.3 Bathrooms. This section is not adopted.

R303.4 Minimum ventilation performance. Dwelling units shall be equipped with local exhaust and whole-house ventilation systems designed and installed as specified in Section M1505.

EXCEPTION: | Additions with less than 500 square feet of conditioned floor area are exempt from the requirements in this Code for Whole-House Ventilation Systems. |

R303.5.1 Intake openings. Mechanical and gravity outdoor air intake openings shall be located a minimum of 10 feet (3048 mm) from any hazardous or noxious contaminant, such as vents, chimneys, plumbing vents, streets, alleys, parking lots and loading docks, except as otherwise specified in this code.

For the purpose of this section, the exhaust from dwelling unit toilet rooms, bathrooms and kitchens shall not be considered as hazardous or noxious.

EXCEPTIONS: | 1. The 10-foot (3048 mm) separation is not required where the intake opening is located 3 feet (914 mm) or greater below the contaminant source. |

| 2. Vents and chimneys serving fuel-burning appliances shall be terminated in accordance with the applicable provisions of Chapters 18 and 24. |

| 3. Clothes dryer exhaust ducts shall be terminated in accordance with Section M1502.3. |

R303.5.2 Exhaust openings. Exhaust air shall not be directed onto walkways. All exhaust ducts shall terminate outside the building. Terminal elements shall have at least the equivalent net free area of the duct work.

R303.5.2.1 Exhaust ducts. Exhaust ducts shall be equipped with back-draft dampers. All exhaust ducts in unconditioned spaces shall be insulated to a minimum of R-4.

R303.7 Interior stairway illumination. Interior stairways shall be provided with an artificial light source to illuminate the landings and treads. Stairway illumination shall receive primary power from the building wiring. The light source shall be capable of illuminating treads and landings to levels not less than 1 foot-candle (11 lux) measured at the center of treads and landings. There shall be a wall switch at each floor level to control the light source where the stairway has six or more risers.

EXCEPTION: | A switch is not required where remote, central or automatic control of lighting is provided. |

R303.8 Exterior stairway illumination. Exterior stairways shall be provided with an artificial light source located at the top landing of the stairway. Stairway illumination shall receive primary power from the building wiring. Exterior stairways providing access to a basement from the outdoor grade level shall be provided with an artificial light source located at the bottom landing of the stairway.

R303.9 Required glazed openings. Required glazed openings shall open directly onto a street or public alley, or a yard or court located on the same lot as the building.

EXCEPTIONS: | 1. Required glazed openings that face into a roofed porch where the porch abuts a street, yard or court are permitted where the longer side of the porch is not less than 65 percent unobstructed and the ceiling height is not less than 7 feet (2134 mm). |

| 2. Eave projections shall not be considered as obstructing the clear open space of a yard or court. |

| 3. Required glazed openings that face into the area under a deck, balcony, bay or floor cantilever are permitted where an unobstructed pathway of not less than 36 inches (914 mm) in height, 36 inches (914 mm) in width, and no greater than 60 inches (1524 mm) in length is provided and opens to a yard or court. The pathway shall be measured from the exterior face of the glazed opening, or if the glazed opening is in a window well, at the window well wall furthest from the exterior face of the glazed opening. |

R303.10 Required heating. When the winter design temperature in Table R301.2(((1))) is below 60°F (16°C), every dwelling unit shall be provided with heating facilities capable of maintaining a minimum room temperature of 68°F (20°C) at a point 3 feet (914 mm) above the floor and 2 feet (610 mm) from exterior walls in all habitable rooms at design temperature. The installation of one or more portable heaters shall not be used to achieve compliance with this section.

EXCEPTION: | Unheated recreational tents or yurts not exceeding 500 square feet provided it is not occupied as a permanent dwelling. |

R303.10.1 Definitions. For the purposes of this section only, the following definitions apply.

DESIGNATED AREAS are those areas designated by a county to be an urban growth area in chapter

36.70A RCW and those areas designated by the U.S. Environmental Protection Agency as being in nonattainment for particulate matter.

SUBSTANTIALLY REMODELED means any alteration or restoration of a building exceeding 60 percent of the appraised value of such building within a 12-month period. For the purpose of this section, the appraised value is the estimated cost to replace the building and structure in kind, based on current replacement costs.

R303.10.2 Primary heating source. Primary heating sources in all new and substantially remodeled buildings in designated areas shall not be dependent upon wood stoves.

R303.10.3 Solid fuel burning devices. No new or used solid fuel burning device shall be installed in new or existing buildings unless such device is U.S. Environmental Protection Agency certified or exempt from certification by the United States Environmental Protection Agency and conforms with RCW

70A.15.1005,

70A.15.3500,

70A.15.3510, and

70A.15.3530.

EXCEPTIONS: | 1. Wood cook stoves. |

| 2. Antique wood heaters manufactured prior to 1940. |

AMENDATORY SECTION(Amending WSR 23-02-058, 23-12-104, and 23-20-024, filed 1/3/23, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-51-0311Section R311—Means of egress.

R311.4 Vertical egress. Egress from habitable levels including habitable attics and basements not provided with an egress door in accordance with Section R311.2 shall be by a ramp in accordance with Section R311.8 or a stairway in accordance with Section R311.7.

EXCEPTION: | Stairways, alternating tread devices, ship's ladders, or ladders within an individual dwelling unit or sleeping unit used for access to areas of 200 square feet (18.6 m2) or less, are exempt from the requirements of Sections R311.4 and R311.7, where such devices do not provide exclusive access to a kitchen or bathroom. Such areas shall not be located more than 10 feet (3048 mm) above the finished floor of the space below. |

R311.7.11 Alternating tread devices.Alternating tread devices shall not be used as an element of a means of egress. Alternating tread devices shall be permitted provided that a required means of egress stairway or ramp serves the same space at each adjoining level or where a means of egress is not required. The clear width at and below the handrails shall be not less than 20 inches (508 mm).

R311.7.12 Ship's ladders. Ship's ladders shall not be used as an element of a means of egress. Ship's ladders shall be permitted provided that a required means of egress stairway or ramp serves the same space at each adjoining level or where a means of egress is not required. The clear width at and below the handrails shall be not less than 20 inches (508 mm).

AMENDATORY SECTION(Amending WSR 23-02-058, 23-12-104, and 23-20-024, filed 1/3/23, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-51-0312Section R312—Guards and window fall protection.

R312.1.1 Where required.Guards shall be provided for those portions of open-sided walking surfaces, including floors, mezzanines, lofts in accordance with Section R333, stairs, ramps, and landings, that are located more than 30 inches (762 mm) measured vertically to the floor or grade below at any point within 36 inches (914 mm) horizontally to the edge of the open side. Insect screening shall not be considered as a guard.

R312.1.2 Height. Required guards at open-sided walking surfaces, including stairs, porches, balconies or landings, shall be not less than 36 inches (914 mm) in height as measured vertically above the adjacent walking surface or the line connecting the nosings.

EXCEPTIONS: | 1. Guards on the open sides of stairs shall have a height of not less than 34 inches (864 mm) measured vertically from a line connecting the nosings. |

| 2. Where the top of the guard serves as a handrail on the open sides of stairs, the top of the guard shall be not less than 34 inches (864 mm) and not more than 38 inches (965 mm) as measured vertically from a line connecting the nosings. |

| 3. In areas with ceiling heights of 7 feet (2134 mm) or less in lofts constructed in accordance with Section R333, guards shall not be less than 36 inches (914 mm) in height or one-half of the clear height from the loft floor to the loft ceiling, whichever is less. |

AMENDATORY SECTION(Amending WSR 23-02-058, 23-12-104, and 23-20-024, filed 1/3/23, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-51-0314Section R314—Smoke alarms and heat detection.

R314.1 General. Smoke alarms, heat detectors, and heat alarms shall comply with NFPA 72 and this section.

R314.1.1 Listings. Smoke alarms shall be listed in accordance with UL 217. Heat detectors and heat alarms shall be listed for the intended application. Combination smoke and carbon monoxide alarms shall be listed in accordance with UL 217 and UL 2034.

R314.2 Where required. Smoke alarms, heat detectors, and heat alarms shall be provided in accordance with this section.

R314.2.1 New construction. Smoke alarms shall be provided in dwelling units. A heat detector or heat alarm shall be provided in new attached garages.

R314.2.2 Alterations, repairs and additions. Where alterations, repairs or additions requiring a permit occur, or where one or more sleeping rooms are added or created in existing dwellings, or where an accessory dwelling unit is created within an existing dwelling unit, each dwelling unit shall be equipped with smoke alarms as required for new dwellings.

EXCEPTIONS: | 1. Work involving the exterior surfaces of dwellings, such as the replacement of roofing or siding, the addition or replacement of windows or doors, or the addition of a porch or deck are exempt from the requirements of this section. |

| 2. Installation, alteration or repairs of plumbing, electrical or mechanical systems are exempt from the requirements of this section. |

R314.2.3 New attached garages. A heat detector or heat alarm rated for the ambient outdoor temperatures and humidity shall be installed in new garages that are attached to or located under new and existing dwellings. Heat detectors and heat alarms shall be installed in a central location and in accordance with the manufacturer's instructions.

EXCEPTION: | Heat detectors and heat alarms shall not be required in dwellings without commercial power. |

R314.3 Location. Smoke alarms shall be installed in the following locations:

1. In each sleeping room.

2. Outside each separate sleeping area in the immediate vicinity of the bedrooms.

3. On each additional story of the dwelling, including basements and habitable attics but not including crawl spaces and uninhabitable attics. In dwellings or dwelling units with split levels and without an intervening door between the adjacent levels, a smoke alarm installed on the upper level shall suffice for the adjacent lower level provided that the lower level is less than one full story below the upper level.

4. Smoke alarms shall be installed not less than 3 feet (914 mm) horizontally from the door or opening of a bathroom that contains a bathtub or shower unless this would prevent placement of a smoke alarm required by Section R314.3.

5. In napping areas in a family home child care.

6. In the hallway and in the room open to the hallway in dwelling units where the ceiling height of a room open to a hallway serving bedrooms exceeds that of the hallway by 24 inches (610 mm) or more.

7. Within the room to which a loft is open, in the immediate vicinity of the loft.

R314.4 Interconnection. Where more than one smoke alarm is required to be installed within an individual dwelling unit in accordance with Section ((R314.2))R314.3, the alarm devices shall be interconnected in such a manner that the actuation of one alarm will activate all of the alarms in the individual dwelling unit. Where an accessory dwelling unit is created within an existing dwelling unit all required smoke alarms, in the accessory dwelling unit and the primary dwelling unit, shall be interconnected in such a manner that the actuation of one alarm will activate all alarms in both the primary dwelling unit and the accessory dwelling unit. Physical interconnection of smoke alarms shall not be required where listed wireless alarms are installed and all alarms sound upon activation of one alarm.

EXCEPTION: | Smoke alarms and alarms installed to satisfy Section R314.4.1 shall not be required to be interconnected to existing smoke alarms where such existing smoke alarms are not interconnected or where such new smoke alarm or alarm is not capable of being interconnected to the existing smoke alarms. |

R314.4.1 Heat detection interconnection. Heat detectors and heat alarms shall be connected to an alarm or a smoke alarm that is installed in the dwelling. Alarms and smoke alarms that are installed for this purpose shall be located in a hallway, room, or other location that will provide occupant notification.

R314.6 Power source. Smoke alarms, heat alarms, and heat detectors shall receive their primary power from the building wiring where such wiring is served from a commercial source and, where primary power is interrupted, shall receive power from a battery. Wiring shall be permanent and without a disconnecting switch other than those required for overcurrent protection.

EXCEPTIONS: | 1. Smoke alarms shall be permitted to be battery operated where installed in buildings without commercial power. |

| 2. Smoke alarms installed in accordance with Section R314.2.2 shall be permitted to be battery powered. |

AMENDATORY SECTION(Amending WSR 20-21-041, filed 10/13/20, effective 11/13/20)

WAC 51-51-03240Section R324—Solar energy systems.

R324.3 Photovoltaic systems. Installation, modification, or alteration of solar photovoltaic power systems shall comply with this section and the

International Fire Code. Section R104.11 ((

alternate))

alternative materials and methods of this code shall be considered when approving the installation of solar photovoltaic power systems. Photovoltaic systems shall be designed and installed in accordance with Sections R324.3.1 through R324.6 and chapter

19.28 RCW. Inverters shall be listed and labeled in accordance with UL 1741. Systems connected to the utility grid shall use inverters listed for utility interaction.

EXCEPTION: | Detached, nonhabitable Group U structures shall not be subject to the requirements of this section for structural and fire safety. |

R324.4 Rooftop-mounted photovoltaic systems. Rooftop-mounted photovoltaic panel systems installed on or above the roof covering shall be designed and installed in accordance with Section R907.

EXCEPTION: | The roof structure shall be deemed adequate to support the load of the rooftop solar photovoltaic system if all of the following requirements are met: |

| 1. The solar photovoltaic panel system shall be designed for the wind speed of the local area, and shall be installed per the manufacturer's specifications. |

| 2. The ground snow load does not exceed 70 pounds per square foot (3.35 kPa). |

| 3. The total dead load of modules, supports, mountings, raceways, and all other appurtenances weigh no more than 4 pounds per square foot (19.5 kg/m2). |

| 4. Photovoltaic modules are not mounted higher than 18 inches (457 mm) above the surface of the roofing to which they are affixed. |

| 5. Supports for solar modules are to be installed to spread the dead load across as many roof-framing members as needed, so that no point load exceeds 50 pounds (22.7 kg). |

R324.7.1 This section is not adopted.

AMENDATORY SECTION(Amending WSR 23-02-058, 23-12-104, and 23-20-024, filed 1/3/23, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-51-0326Section R326—Habitable attics.

R326.1 General.Habitable attics shall comply with Sections ((R326))R326.1 through R326.4.

EXCEPTION: | Lofts in dwelling units and sleeping units shall be permitted to comply with Section R333, subject to the limitations in Section R333.1. |

AMENDATORY SECTION(Amending WSR 20-03-023, filed 1/6/20, effective 7/1/20)

WAC 51-51-0330Section R330—Adult family homes.

R330.1 General. This section shall apply to all newly constructed adult family homes and all existing single-family homes being converted to adult family homes. This section shall not apply to those adult family homes licensed by the state of Washington department of social and health services prior to July 1, 2001.

R330.2 Reserved.

R330.3 Sleeping room classification. Each sleeping room in an adult family home shall be classified as:

1. Type S - Where the means of egress contains stairs, elevators, or platform lifts.

2. Type NS1 - Where one means of egress is at grade level or a ramp constructed in accordance with Section R330.9 is provided.

3. Type NS2 - Where two means of egress are at grade level or ramps constructed in accordance with Section R330.9 are provided.

R330.4 Types of locking devices and door activation. All bedroom and bathroom doors shall be openable from the outside when locked.

Every closet shall be readily openable from the inside.

Operable parts of door handles, pulls, latches, locks, and other devices installed in adult family homes shall be operable with one hand and shall not require tight grasping, pinching or twisting of the wrist. Pocket doors shall have graspable hardware available when in the closed or open position.

The force required to activate operable parts shall be 5.0 pounds (22.2 N) maximum. Required exit doors shall have no additional locking devices.

Required exit door hardware shall unlock inside and outside mechanisms when exiting the building allowing reentry into the adult family home without the use of a key, tool or special knowledge.

R330.5 Smoke and carbon monoxide alarm requirements. All adult family homes shall be equipped with smoke and carbon monoxide alarms installed as required in Sections R314 and R315.1. Alarms shall be installed in such a manner so that the detection device warning is audible from all areas of the dwelling upon activation of a single alarm.

R330.6 Escape windows and doors. Every sleeping room shall be provided with emergency escape and rescue windows as required by Section R310. No alternatives to the sill height such as steps, raised platforms or other devices placed by the openings will be approved as meeting this requirement.

R330.7 Fire apparatus access roads and water supply for fire protection. Adult family homes shall be served by fire apparatus access roads and water supplies meeting the requirements of the local jurisdiction.

R330.8 Grab bar general requirements. Where facilities are designated for use by adult family home clients, grab bars for water closets, bathtubs, and shower stalls shall be installed according to this section.

R330.8.1 Grab bar cross section. Grab bars with a circular cross section shall have an outside diameter of 1 1/4 inch (32 mm) minimum and 2 inches (50 mm) maximum. Grab bars with noncircular cross section shall have a cross section dimension of 2 inches (50 mm) maximum and a perimeter dimension of 4 inches (102 mm) minimum and 4 5/8 inches maximum.

R330.8.2 Grab bar installation. Grab bars shall have a spacing of 1 1/2 inch (32 mm) between the wall and the bar. Projecting objects, control valves and bathtub or shower stall enclosure features above, below and at the ends of the grab bar shall have a clear space of 1 1/2 inch (32 mm) to the grab bar.

EXCEPTION: | Swing-up grab bars shall not be required to meet the 1 1/2 inch (32 mm) spacing requirement. |

Grab bars shall have a structural strength of 250 pounds applied at any point on the grab bar, fastener, mounting device or supporting structural member. Grab bars shall not be supported directly by any residential grade fiberglass bathing or showering unit. Acrylic bars found in bathing units shall be removed.

Fixed position grab bars, when mounted, shall not rotate, spin or move and have a graspable surface finish.

R330.8.3 Grab bars at water closets. Water closets shall have grab bars mounted on both sides. Grab bars can be a combination of fixed position and swing-up bars. Grab bars shall meet the requirements of Section R330.8. Grab bars shall mount between 33 inches (838 mm) and 36 inches (914 mm) above floor grade. Centerline distance between grab bars, regardless of type used, shall be between 25 inches (635 mm) minimum and 30 inches (762 mm) maximum.

R330.8.3.1 Fixed position grab bars. Fixed position grab bars shall be a minimum of 36 inches (914 mm) in length and start 12 inches (305 mm) from the rear wall.

R330.8.3.2 Swing-up grab bars. Swing-up grab bars shall be a minimum of 28 inches (711 mm) in length from the rear wall.

R330.8.4 Grab bars at bathtubs. Horizontal and vertical grab bars shall meet the requirements of Section R330.8.

R330.8.4.1 Vertical grab bars. Vertical grab bars shall be a minimum of 18 inches (457 mm) long and installed at the control end wall and head end wall. Grab bars shall mount within 4 inches (102 mm) of the exterior of the bathtub edge or within 4 inches (102 mm) within the bathtub. The bottom end of the bar shall start between 36 inches (914 mm) and 42 inches (1067 mm) above floor grade.

EXCEPTION: | The required vertical grab bar can be substituted with a floor to ceiling grab bar meeting the requirements of Section R325.8 at the control end and head end entry points. |

R330.8.4.2 Horizontal grab bars. Horizontal grab bars shall be provided at the control end, head end, and the back wall within the bathtub area. Grab bars shall be mounted between 33 inches (838 mm) and 36 inches (914 mm) above floor grade. Control end and head end grab bars shall be 24 inches (610 mm) minimum in length. Back wall grab bars shall be 36 inches (914 mm) minimum in length.

R330.8.5 Grab bars at shower stalls. Where shower stalls are provided to meet the requirements for bathing facilities, grab bars shall meet the requirements of Section R330.8.

EXCEPTION: | Shower stalls with permanent built-in seats are not required to have vertical or horizontal grab bars at the seat end wall. A vertical floor to ceiling grab bar shall be installed within 4 inches of the exterior of the shower aligned with the nose of the built-in seat. |

R330.8.5.1 Vertical grab bars. Vertical grab bars shall be 18 inches (457 mm) minimum in length and installed at the control end wall and head end wall. Vertical bars shall be mounted within 4 inches (102 mm) of the exterior of the shower stall or within 4 inches (102 mm) inside the shower stall. The bottom end of vertical bars mount between 36 inches (914 mm) and 42 inches (1067 mm) above floor grade.

R330.8.5.2 Horizontal grab bars. Horizontal grab bars shall be installed on all sides of the shower stall mounted between 33 inches (838 mm) and 36 inches (914 mm) above the floor grade. Horizontal grab bars shall be a maximum of 6 inches (152 mm) from adjacent walls. Horizontal grab bars shall not interfere with shower control valves.

R330.9 Ramps. All interior and exterior ramps, when provided, shall be constructed in accordance with Section R311.8 with a maximum slope of 1 vertical to 12 horizontal. The exception to Section R311.8.1 is not allowed for adult family homes. Handrails shall be installed in accordance with Section R330.9.1.

R330.9.1 Handrails for ramps. Handrails shall be installed on both sides of ramps between the slope of 1 vertical to 12 horizontal and 1 vertical and 20 horizontal in accordance with Sections R311.8.3.1 through R311.8.3.3.

R330.10 Stair treads and risers. Stair treads and risers shall be constructed in accordance with Section R311.7.5. Handrails shall be installed in accordance with Section R330.10.1.

R330.10.1 Handrails for treads and risers. Handrails shall be installed on both sides of treads and risers numbering from one riser to multiple risers. Handrails shall be installed in accordance with Sections R311.7.8.1 through R311.7.8.4.

R330.11 Shower stalls. Where provided to meet the requirements for bathing facilities, the minimum size of shower stalls for an adult family home shall be 30 inches (762 mm) deep by 48 inches (1219 mm) long.

AMENDATORY SECTION(Amending WSR 23-02-058, 23-12-104, and 23-20-024, filed 1/3/23, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-51-0333Section R333—Lofts.

R333.1 General. Where provided in dwelling units or sleeping units, lofts shall comply with this code as modified by Sections R333.1 through R333.5. Lofts constructed in compliance with this section shall be considered a portion of the story below. Such lofts shall not contribute to the number of stories as regulated by this code.

EXCEPTION: | Lofts need not comply with Section R333 where they meet any of the following conditions: |

| 1. The loft has a maximum depth of less than 3 feet (914 mm). |

| 2. The loft has a floor area of less than 35 square feet (3.3 m2). |

| 3. The loft is not provided with a permanent means of egress. |

R333.2 Loft limitations. Lofts shall comply with the following conditions:

1. The loft floor area shall be less than 70 square feet (6.5 m2).

2. The loft ceiling height shall not exceed 7 feet (2134 mm) for more than one half of the loft floor area.

The provisions of Sections R333.3 through R333.5 shall not apply to lofts that do not comply with Items 1 and 2 of this section.

R333.3 Loft ceiling height. The ceiling height below a loft shall not be less than 7 feet (2134 mm). The ceiling height above the finished floor of the loft shall not be less than 3 feet (914 mm). Portions of the loft with a sloped ceiling measuring less than 3 feet (914 mm) from the finished floor to the finished ceiling shall not contribute to the loft floor area.

R333.4 Loft area. The aggregate area of all lofts and mezzanines within a room shall comply with Section R325.3.

EXCEPTION: | The area of a single loft located within a dwelling unit or sleeping unit equipped with an automatic sprinkler system in accordance with Section P2904 shall not be greater than two-thirds of the area of the room in which it is located, provided that no other lofts or mezzanines are open to the room in which the loft is located. |

R333.5 Permanent egress for lofts. Where a permanent means of egress is provided for lofts, the means of egress shall comply with Section R311 as modified by Section R333.5.1.

R333.5.1 Ceiling height at loft means of egress. A minimum ceiling height of 3 feet (914 mm) shall be provided for the entire width of the means of egress from the loft.

AMENDATORY SECTION(Amending WSR 23-02-058, 23-12-104, and 23-20-024, filed 1/3/23, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-51-0403Section R403—Footings.

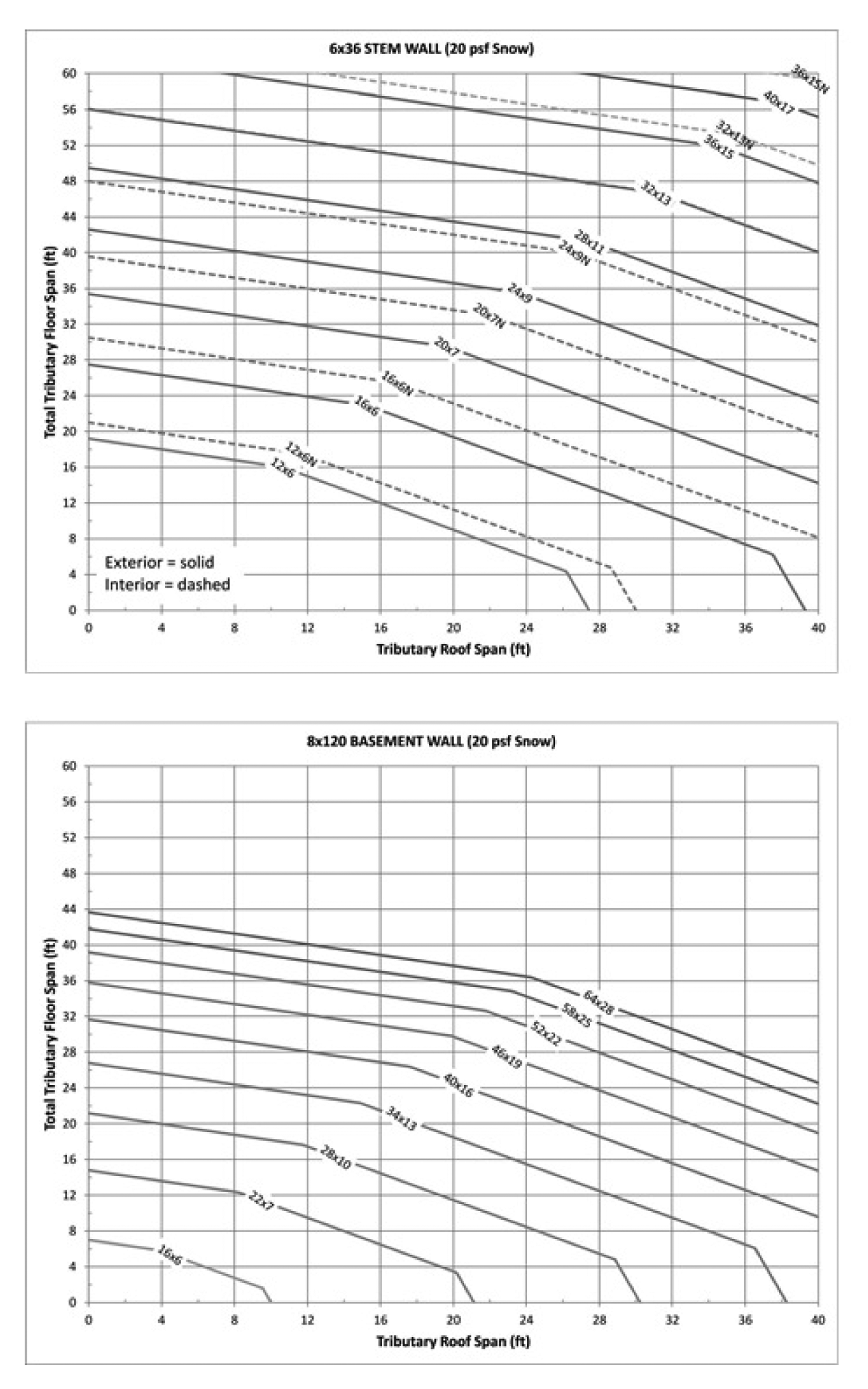

R403.1.1 Minimum size. The minimum width, W, and thickness, T, for concrete footings shall be in accordance with Tables R403.1(1) through R403.1(3) and Figure R403.1(1) or R403.1.3, as applicable, but not less than 12 inches (305 mm) in width and 6 inches (152 mm) in depth. The footing width shall be based on the load-bearing value of the soil in accordance with Table R401.4.1. Footing projections, P, shall be not less than 2 inches (51 mm) and shall not exceed the thickness of the footing. Footing thickness and projection for fireplaces shall be in accordance with Section R1001. The size of footings supporting piers and columns shall be based on the tributary load and allowable soil pressure in accordance with Table R401.4.1. Footings for wood foundations shall be in accordance with the details set forth in Section R403.2, and Figures R403.1(2) and R403.1(3). Footings for precast foundation shall be in accordance with the details set forth in Section R403.4, Table R403.4, and Figures R403.4(1) and R403.4(2).

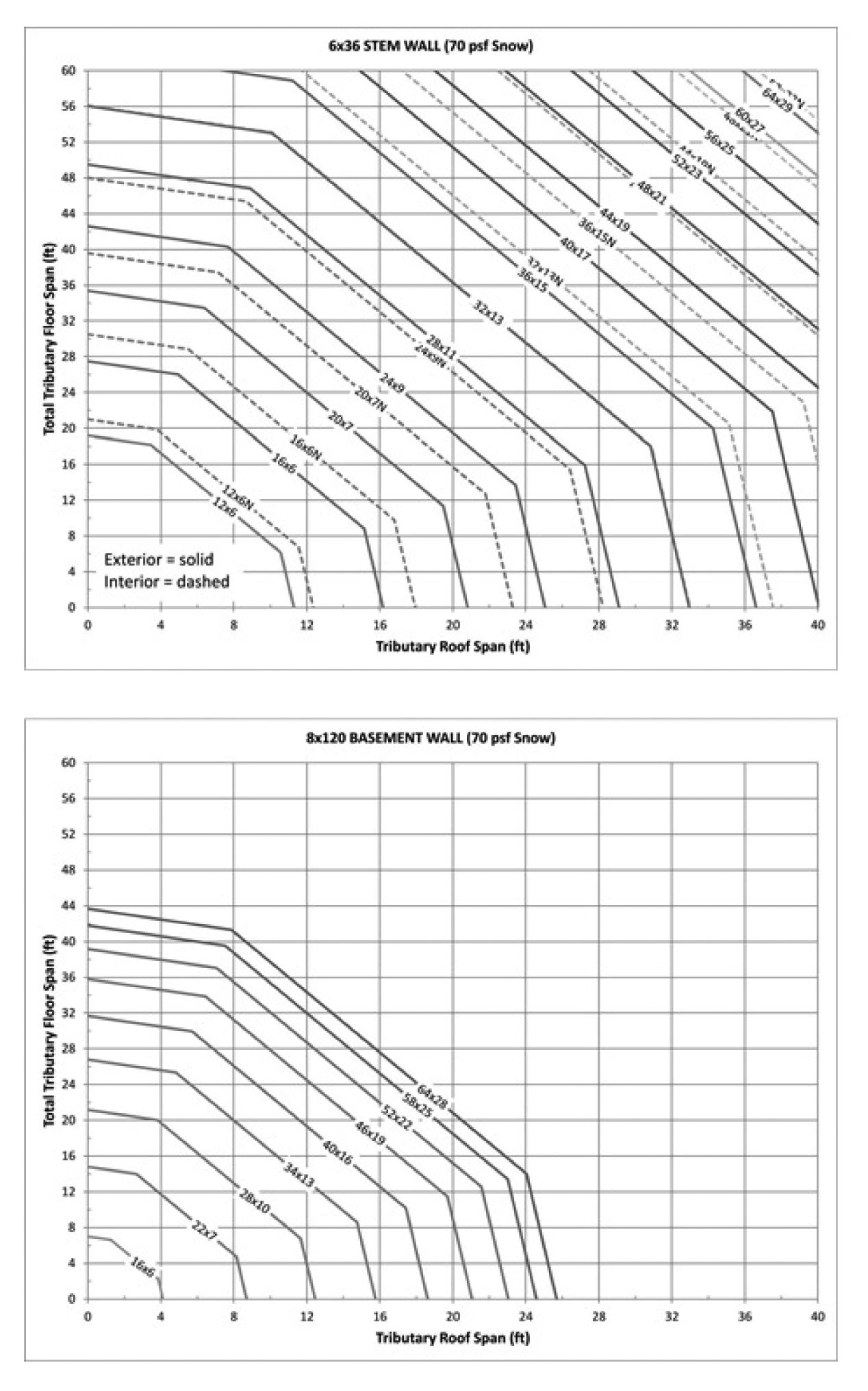

EXCEPTION: | Light-frame construction shall be permitted to have minimum footing size in accordance with Figures R403.1.1(1) through R403.1.1(4) in lieu of that determined by Table R403.1(1). |

Figure R403.1.1(1)

Alternative Minimum Footing Size for Light-Frame Construction a,b,c,d,e,f,g,h,i

20 PSF Snow Load

Notes: | a | The minimum footing size is based on the following assumptions: Material weights per Section R301.2.2.2.1 and soil density = 120 pcf. Wood-framed walls = 10 foot; crawlspace stem wall = 6 inches × 36 inches; basement wall = 8 inches × 120 inches. Total load (TL) equal to the maximum of three load combinations: LC1=D+L, LC2=D+S and LC3=D=0.75(L+S), where D=dead load, L=live load, S=snow load. TL=max (LC1, LC2, LC3). |

| b | Use tributary span of floor and roof. Figure may be used to size exterior and interior footings. |

| c | Add 4 feet to tributary floor span for each wood-framed wall above first level (i.e., ((4'))4 feet for 2-story, ((8'))8 feet for 3-story). |

| d | Multiply floor span by 1.25 for interior footings supporting continuous joists. |

| e | Multiply footing width by (1500 psf/capacity) for soil capacity other than 1500 psf. See Section R403.1.1 for thickness. |

| f | Dashed line may be used for interior footing size only. |

| g | Use footing size indicated on line above the span combination used. |

| h | For span combinations above the upper line, a design professional is required. |

| i | Interpolation between footing sizes is allowed. Extrapolation is not allowed. |

Figure R403.1.1(2)

Alternative Minimum Footing Size for Light-Frame Construction a,b,c,d,e,f,g,h,i

30 PSF Snow Load

Notes: | a | The minimum footing size is based on the following assumptions: Material weights per Section R301.2.2.2.1 and soil density = 120 pcf. Wood-framed walls = 10 foot; crawlspace stem wall = 6 inches × 36 inches; basement wall = 8 inches × 120 inches. Total load (TL) equal to the maximum of three load combinations: LC1=D+L, LC2=D+S and LC3=D=0.75(L+S), where D=dead load, L=live load, S=snow load. TL=max (LC1, LC2, LC3). |

| b | Use tributary span of floor and roof. Figure may be used to size exterior and interior footings. |

| c | Add 4 feet to tributary floor span for each wood-framed wall above first level (i.e., ((4'))4 feet for 2-story, ((8'))8 feet for 3-story). |

| d | Multiply floor span by 1.25 for interior footings supporting continuous joists. |

| e | Multiply footing width by (1500 psf/capacity) for soil capacity other than 1500 psf. See Section R403.1.1 for thickness. |

| f | Dashed line may be used for interior footing size only. |

| g | Use footing size indicated on line above the span combination used. |

| h | For span combinations above the upper line, a design professional is required. |

| i | Interpolation between footing sizes is allowed. Extrapolation is not allowed. |

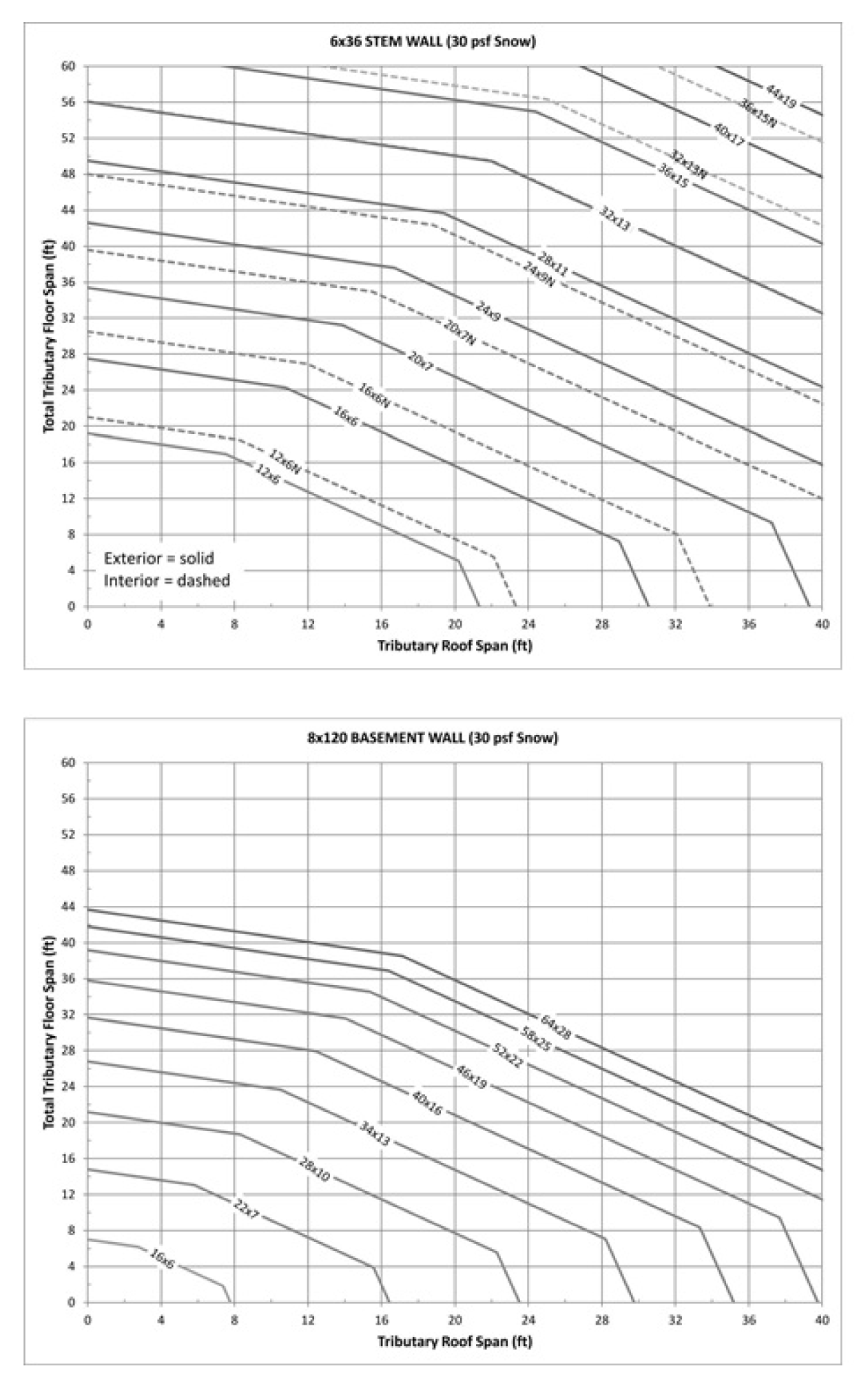

Figure R403.1.1(3)

Alternative Minimum Footing Size for Light-Frame Construction a,b,c,d,e,f,g,h,i

50 PSF Snow Load

Notes: | a | The minimum footing size is based on the following assumptions: Material weights per Section R301.2.2.2.1 and soil density = 120 pcf. Wood-framed walls = 10 foot; crawlspace stem wall = 6 inches × 36 inches; basement wall = 8 inches × 120 inches. Total load (TL) equal to the maximum of three load combinations: LC1=D+L, LC2=D+S and LC3=D=0.75(L+S), where D=dead load, L=live load, S=snow load. TL=max (LC1, LC2, LC3). |

| b | Use tributary span of floor and roof. Figure may be used to size exterior and interior footings. |

| c | Add 4 feet to tributary floor span for each wood-framed wall above first level (i.e., ((4'))4 feet for 2-story, ((8'))8 feet for 3-story). |

| d | Multiply floor span by 1.25 for interior footings supporting continuous joists. |

| e | Multiply footing width by (1500 psf/capacity) for soil capacity other than 1500 psf. See Section R403.1.1 for thickness. |

| f | Dashed line may be used for interior footing size only. |

| g | Use footing size indicated on line above the span combination used. |

| h | For span combinations above the upper line, a design professional is required. |

| i | Interpolation between footing sizes is allowed. Extrapolation is not allowed. |

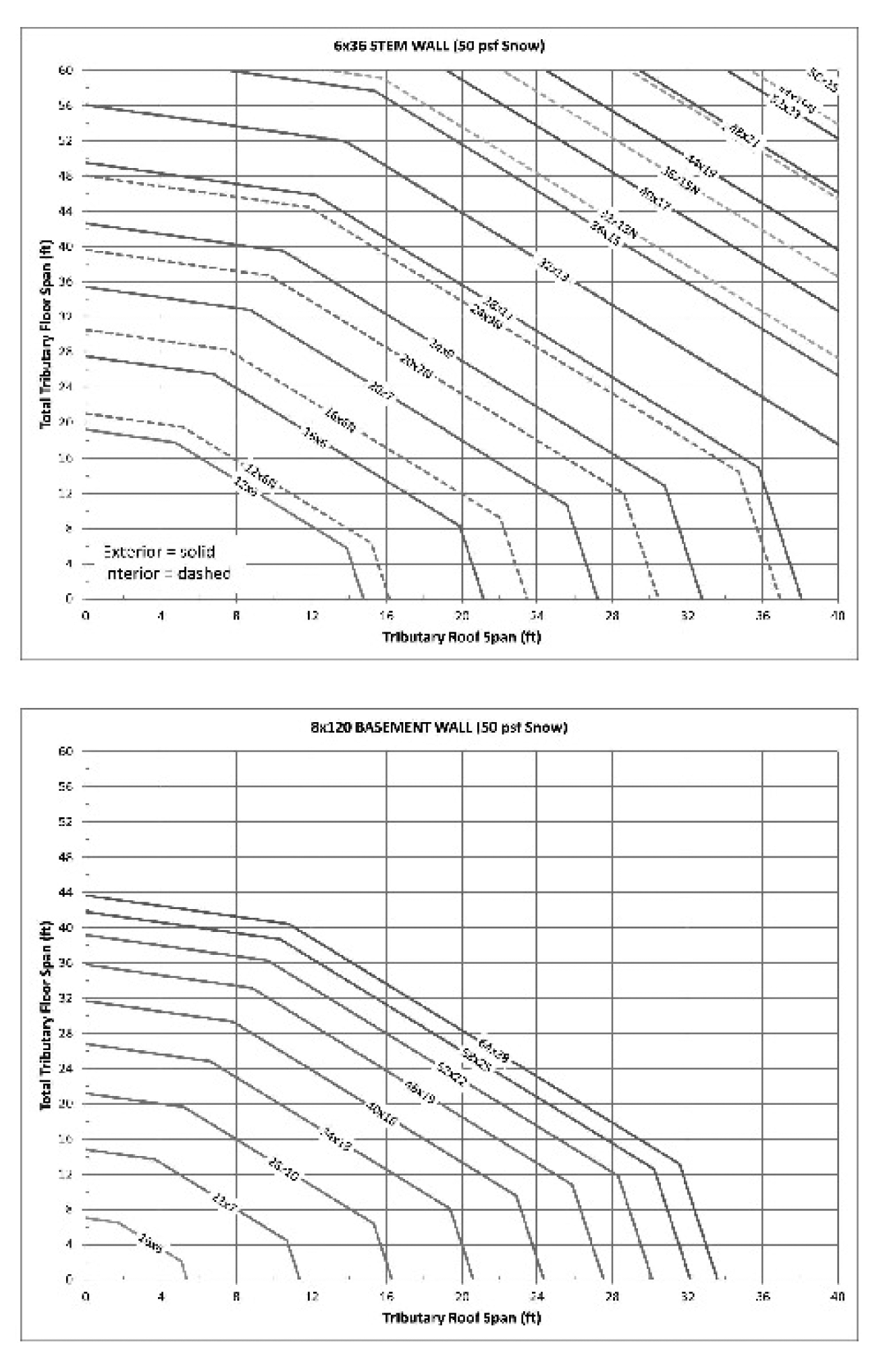

Figure R403.1.1(4)

Alternative Minimum Footing Size for Light-Frame Construction a,b,c,d,e,f,g,h,i

70 PSF Snow Load

Notes: | a | The minimum footing size is based on the following assumptions: Material weights per Section R301.2.2.2.1 and soil density = 120 pcf. Wood-framed walls = 10 foot; crawlspace stem wall = 6 inches × 36 inches; basement wall = 8 inches × 120 inches. Total load (TL) equal to the maximum of three load combinations: LC1=D+L, LC2=D+S and LC3=D=0.75(L+S), where D=dead load, L=live load, S=snow load. TL=max (LC1, LC2, LC3). |

| b | Use tributary span of floor and roof. Figure may be used to size exterior and interior footings. |

| c | Add 4 feet to tributary floor span for each wood-framed wall above first level (i.e., ((4'))4 feet for 2-story, ((8'))8 feet for 3-story). |

| d | Multiply floor span by 1.25 for interior footings supporting continuous joists. |

| e | Multiply footing width by (1500 psf/capacity) for soil capacity other than 1500 psf. See Section R403.1.1 for thickness. |

| f | Dashed line may be used for interior footing size only. |

| g | Use footing size indicated on line above the span combination used. |

| h | For span combinations above the upper line, a design professional is required. |

| i | Interpolation between footing sizes is allowed. Extrapolation is not allowed. |

AMENDATORY SECTION(Amending WSR 23-02-058, 23-12-104, and 23-20-024, filed 1/3/23, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-51-0408Section R408—Under-floor space.

R408.1 Ventilation. The under-floor space between the bottom of the floor joists and the earth under any building (except space occupied by a basement) shall have ventilation openings through foundation walls or exterior walls. A ground cover of six mil (0.006 inch thick) black polyethylene or approved equal shall be laid over the ground within crawl spaces. The ground cover shall be overlapped ((six))6 inches (152 mm) minimum at the joints and shall extend to the foundation wall.

EXCEPTION: | The ground cover may be omitted in crawl spaces if the crawl space has a concrete slab floor with a minimum thickness of ((two))2 inches (51 mm). |

R408.2 Openings for under-floor ventilation. The minimum net area of ventilation openings shall not be less than 1 square foot (0.0929 m2) for each 300 square feet (28 m2) of under-floor area. Required openings shall be evenly placed to provide cross ventilation of the space except one side of the building shall be permitted to have no ventilation openings. Ventilation openings shall be covered for their height and width with any of the following materials provided that the least dimension of the covering shall not exceed 1/4 inch (6.4 mm), and operational louvers are permitted:

1. Perforated sheet metal plates not less than 0.070 inch (1.8 mm) thick.

2. Expanded sheet metal plates not less than 0.047 inch (1.2 mm) thick.

3. Cast-iron grill or grating.

4. Extruded load-bearing brick vents.

5. Hardware cloth of 0.035 inch (0.89 mm) wire or heavier.

6. Corrosion-resistant wire mesh, with the least dimension being 1/8 inch (3.2 mm).

EXCEPTION: | The total area of ventilation openings shall be permitted to be reduced to 1/1,500 of the under-floor area where the ground surface is covered with an approved Class I vapor retarder material and the required openings are placed to provide cross ventilation of the space. The installation of operable louvers shall not be prohibited. If the installed ventilation is less than 1/300, or if operable louvers are installed, a radon vent shall be installed to originate from a point between the ground cover and soil. The radon vent shall be installed in accordance with the requirements of Appendix AF (Radon) of this code. |

R408.3 Unvented crawl space. Ventilation openings in under-floor spaces specified in Section R408.2 shall not be required where:

1. Exposed earth is covered with a continuous Class I vapor retarder. Joints of the vapor retarder shall overlap by 6 inches (152 mm) and shall be sealed or taped. The edges of the vapor retarder shall extend at least 6 inches (152 mm) up the stem wall and shall be attached and sealed to the stem wall; and a radon system shall be installed that meets the requirements of Appendix AF (Radon) of this code.

2. Continuously operated mechanical exhaust ventilation is provided at a rate equal to 1 cubic foot per minute (0.47 L/s) for each 50 square feet (4.7 m2) of crawlspace floor area. Exhaust ventilation shall terminate to the exterior.

EXCEPTION: | Plenum in existing structures complying with Section M1601.5, if under-floor space is used as a plenum. |

R408.8 Under-floor vapor retarder. This section is not adopted.

AMENDATORY SECTION(Amending WSR 23-02-058, 23-12-104, and 23-20-024, filed 1/3/23, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-51-0507Section R507—Decks.

TABLE R507.3.1

MINIMUM FOOTING SIZE FOR DECKS

LIVE OR GROUND SNOW LOAD (psf) | TRIBUTARY AREA((c)) (sq.ft.) | LOAD-BEARING VALUE OF SOILSacd(psf) |

1500e((psf)) | 2000e((psf)) | ≥ 3000e((psf)) |

Side of a square footing (inches) | Diameter of a round footing (inches) | Thicknessf (inches) | Side of a square footing (inches) | Diameter of a round footing (inches) | Thicknessf (inches) | Side of a square footing (inches) | Diameter of a round footing (inches) | Thicknessf (inches) |

60 Live or 70 Ground Snow Load | 5 | 7 | 8 | 6 | 7 | 8 | 6 | 7 | 8 | 6 |

20 | 12 | 14 | 6 | 11 | 13 | 6 | 9 | 10 | 6 |

40 | 18 | 20 | 6 | 15 | 17 | 6 | 12 | 14 | 6 |

60 | 21 | 24 | 8 | 19 | 21 | 6 | 15 | 17 | 6 |

80 | 25 | 28 | 9 | 21 | 24 | 8 | 18 | 20 | 6 |

100 | 28 | 31 | 11 | 24 | 27 | 9 | 20 | 22 | 7 |

120 | 30 | 34 | 12 | 26 | 30 | 10 | 21 | 24 | 8 |

140 | 33 | 37 | 13 | 28 | 32 | 11 | 23 | 26 | 9 |

160 | 35 | 40 | 15 | 30 | 34 | 12 | 25 | 28 | 9 |

For SI: 1 inch = 25.4 mm, 1 square foot = 0.0929 m2, 1 pound per square foot = 0.0479 kPa. |

a. | Interpolation permitted, extrapolation not permitted. |

b. | Reserved. |

c. | Footing dimensions shall allow complete bearing of the post. |

d. | If the support is a brick or CMU pier, the footing shall have a minimum 2-inch projection on all sides. |

e. | Area, in square feet, of deck surface supported by post and footings. |

f. | Minimum thickness shall only apply to plain concrete footings, |

R507.4 Deck posts. For single-level decks, wood post size shall be in accordace with Table R507.4.

TABLE R507.4

DECK POST HEIGHT

((LOADSb (psf) | POST SPECIESc | POST SIZEd | MAXIMUM DECK POST HEIGHTa (feet-inches) |

Tributary Areag,h (sq. ft.) |

20 | 40 | 60 | 80 | 100 | 120 | 140 | 160)) |

| | | TRIBUTARY AREAg,h (sq. ft.) |

| | | 20 | 40 | 60 | 80 | 100 | 120 | 140 | 160 |

LOADSb (psf) | POST SPECIESc | POST SIZEd | MAXIMUM DECK POST HEIGHTa (feet-inches) |

60 Live Load, ≤60 Ground Snow Load | Douglas Fire, Hem-fire, SPFe | 4 x 4 | 14-0 | 10-10 | 8-7 | 7-0 | 5-8 | 4-1 | NP | NP |

4 x 6 | 14-0 | 13-10 | 11-1 | 9-5 | 8-2 | 7-3 | 6-4 | 5-4 |

6 x 6 | 14-0 | 14-0 | 14-0 | 14-0 | 14-0 | 13-3 | 10-9 | 6-11 |

8 x 8 | 14-0 | 14-0 | 14-0 | 14-0 | 14-0 | 14-0 | 14-0 | 14-0 |

Redwoodf, Western Cedarsf, Ponderosa Pinef, Red Pinef | 4 x 4 | 14-0 | 10-3 | 7-0 | NP | NP | NP | NP | NP |

4 x 6 | 14-0 | 13-6 | 10-6 | 8-4 | 5-10 | NP | NP | NP |

6 x 6 | 14-0 | 14-0 | 14-0 | 14-0 | 11-11 | NP | NP | NP |

8 x 8 | 14-0 | 14-0 | 14-0 | 14-0 | 14-0 | 14-0 | 14-0 | 14-0 |

70 Ground Snow Load | Douglas Fire, Hem-fire, SPFe | 4 x 4 | 14-0 | 10-1 | 7-11 | 6-6 | 5-3 | 3-7 | NP | NP |

4 x 6 | 14-0 | 12-10 | 10-3 | 8-9 | 7-7 | 6-8 | 5-10 | 4-11 |

6 x 6 | 14-0 | 14-0 | 14-0 | 14-0 | 14-0 | 12-2 | 9-9 | 5-9 |

8 x 8 | 14-0 | 14-0 | 14-0 | 14-0 | 14-0 | 14-0 | 14-0 | 14-0 |

Redwoodf, Western Cedarsf, Ponderosa Pinef, Red Pinef | 4 x 4 | 14-0 | 9-5 | 6-5 | NP | NP | NP | NP | NP |

4 x 6 | 14-0 | 12-6 | 9-8 | 7-7 | 5-3 | NP | NP | NP |

6 x 6 | 14-0 | 14-0 | 14-0 | 14-0 | 10-8 | NP | NP | NP |

8 x 8 | 14-0 | 14-0 | 14-0 | 14-0 | 14-0 | 14-0 | 14-0 | 14-0 |

For SI: 1 inch = 25.4 mm, 1 foot = 304.8 mm, 1 square foot = 0.0929 m2, 1 pound per square foot = 0.0479 kPa, NP = Not permitted. |

a. | Measured from the underside of the beam to top of footing or pier. |

b. | 10 psf dead load. Snow load not assumed to be concurrent with live load. |

c. | No. 2 grade, wet service factor included. |

d. | Notched deck posts shall be sized to accommodate beam size ((per)) in accordance with Section R507.5.2. |

e. | Includes incising factor. |

f. | Incising factor not included. |

g. | Area, in square feet, of deck surface supported by post and footing. |

h. | Interpolation permitted. Extrapolation not permitted. |

R507.5 Deck beams. Maximum allowable spans for wood deck beams, as shown in Figure R507.5, shall be in accordance with Table R507.5. Beam plies shall be fastened together with two rows of 10d (3-inch × 0.128-inch) nails minimum at 16 inches (406 mm) on center along each edge. Beams shall be permitted to cantilever at each end up to one-fourth of the ((allowable))actual beam span. Deck beams of other materials shall be permitted where designed in accordance with accepted engineering practices.

Tables R507.5(1) through R507.5(4) are not adopted.

TABLE R507.5

MAXIMUM DECK BEAM SPAN - 60 PSF LIVE LOAD or

70 PSF GROUND SNOW LOADc

BEAM SPECIESd | BEAM SIZEe | EFFECTIVE DECK JOIST SPAN LENGTHa,i (feet) |

6 | 8 | 10 | 12 | 14 | 16 | 18 |

| MAXIMUM DECK BEAM SPAN LENGTHa,b,f (feet-inches) |

Douglas fir-larchg, Hem-firg, Spruce-pine-firg | 1-2×6 | 3-5 | 2-10 | 2-5 | 2-2 | 2-0 | 1-10 | 1-9 |

1-2×8 | 4-7 | 3-8 | 3-2 | 2-10 | 2-7 | 2-5 | 2-4 |

1-2×10 | 5-8 | 4-9 | 4-1 | 3-8 | 3-4 | 3-1 | 2-11 |

1-2×12 | 6-7 | 5-8 | 5-0 | 4-6 | 4-1 | 3-10 | 3-7 |

2-2×6 | 5-2 | 4-6 | 4-0 | 3-5 | 3-1 | 2-10 | 2-7 |

2-2×8 | 6-11 | 6-0 | 5-3 | 4-7 | 4-1 | 3-8 | 3-5 |

2-2×10 | 8-5 | 7-4 | 6-6 | 5-10 | 5-2 | 4-9 | 4-5 |

2-2×12 | 9-10 | 8-6 | 7-7 | 6-11 | 6-4 | 5-9 | 5-4 |

3-2×6 | 6-6 | 5-7 | 5-0 | 4-7 | 4-2 | 3-9 | 3-5 |

3-2×8 | 8-8 | 7-6 | 6-8 | 6-1 | 5-6 | 5-0 | 4-7 |

3-2×10 | 10-7 | 9-2 | 8-2 | 7-6 | 6-11 | 6-4 | 5-10 |

3-2×12 | 12-4 | 10-8 | 9-7 | 8-9 | 8-1 | 7-7 | 7-1 |

Redwoodh, Western Cedarsh, Ponderosa Pineh, Red Pineh | 1-2×6 | 3-6 | 2-11 | 2-6 | 2-3 | 2-0 | 1-11 | 1-9 |

1-2×8 | 4-6 | 3-10 | 3-3 | 2-11 | 2-8 | 2-6 | 2-4 |

1-2×10 | 5-6 | 4-9 | 4-2 | 3-9 | 3-5 | 3-2 | 3-0 |

1-2×12 | 6-4 | 5-6 | 4-11 | 4-6 | 4-2 | 3-11 | 3-8 |

2-2×6 | 5-3 | 4-7 | 4-1 | 3-6 | 3-2 | 2-11 | 2-8 |

2-2×8 | 6-8 | 5-9 | 5-2 | 4-8 | 4-2 | 3-10 | 3-6 |

2-2×10 | 8-2 | 7-1 | 6-4 | 5-9 | 5-4 | 4-10 | 4-6 |

2-2×12 | 9-5 | 8-2 | 7-4 | 6-8 | 6-2 | 5-9 | 5-5 |

3-2×6 | 6-4 | 5-8 | 5-1 | 4-8 | 4-3 | 3-10 | 3-6 |

3-2×8 | 8-4 | 7-3 | 6-5 | 5-11 | 5-5 | 5-1 | 4-8 |

3-2×10 | 10-2 | 8-10 | 7-11 | 7-2 | 6-8 | 6-3 | 5-11 |

3-2×12 | 11-10 | 10-3 | 9-2 | 8-4 | 7-9 | 7-3 | 6-10 |

For SI: 1 inch = 25.4 mm, 1 foot = 304.8 mm, 1 pound per square foot = 0.0479 kPa, 1 pound = 0.454 kg. |

a. | Interpolation allowed. Extrapolation is not allowed. |

b. | Beams supporting a single span of joists with or without cantilever. |

c. | Dead load = 10 psf, L/Δ = 360 at mainspan, L/Δ = 180 at cantilever. Snow load not assumed to be concurrent with live load. |

d. | No. 2 grade, wet service factor included. |

e. | Beam depth shall be equal to or greater than the depth of intersecting joist for a flush beam connection. |

f. | Beam cantilevers are limited to the adjacent beam's span divided by 4. |

g. | Includes incising factor. |

h. | Incising factor not included. |

i. | Deck joist span as shown in Figure R507.5. |

j. | For calculation of effective joist span, the actual joist span length shall be multiplied by the joist span factor in accordance with Table R507.5(5). |

R507.6 Deck joists. Maximum allowable spans for wood deck joists, as shown in Figure R507.6, shall be in accordance with Table R507.6. The maximum joist spacing shall be limited by the decking materials in accordance with Table R507.7.

TABLE R507.6

MAXIMUM DECK JOIST SPANS

LOADa (psf) | JOIST SPECIESb | JOIST SIZE | ALLOWABLE JOIST SPANb,c (feet-inches) | MAXIMUM CANTILEVERd,f((,g)) (feet-inches) |

Joist Spacing (inches) | Adjacent Joist Back Spang (feet) |

12 | 16 | 24 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 |

60 Live Load or 70 Ground Snow Load | Douglas fir-larche, Hem-fire, Spruce-pine-fire | 2×6 | 7-11 | 7-1 | 5-9 | 1-0 | 1-6 | NP | NP | NP | NP | NP | NP |

2×8 | 10-5 | 9-5 | 7-8 | 1-0 | 1-6 | 2-0 | 2-1 | NP | NP | NP | NP |

2×10 | 13-3 | 11-6 | 9-5 | 1-0 | 1-6 | 2-0 | 2-6 | 2-8 | NP | NP | NP |

2×12 | 15-5 | 13-4 | 10-11 | 1-0 | 1-6 | 2-0 | 2-6 | 3-0 | 3-3 | NP | NP |

Redwoodf, Western Cedarsf, Ponderosa Pinef, Red Pinef | 2×6 | 7-4 | 6-8 | 5-10 | 1-0 | 1-4 | NP | NP | NP | NP | NP | NP |

2×8 | 9-8 | 8-10 | 7-4 | 1-0 | 1-6 | 1-11 | NP | NP | NP | NP | NP |

2×10 | 12-4 | 11-0 | 9-0 | 1-0 | 1-6 | 2-0 | 2-6 | 2-6 | NP | NP | NP |

2×12 | 14-9 | 12-9 | 10-5 | 1-0 | 1-6 | 2-0 | 2-6 | 3-0 | 3-0 | NP | NP |

For SI: 1 inch = 25.4 mm, 1 foot = 304.8 mm, 1 pound per square foot = 0.0479 kPa, 1 pound = 0.454 kg, NP = Not permitted. |

a. | Dead load = 10 psf dead load. Snow load not assumed to be concurrent with live load. |

b. | No. 2 grade, wet service factor included. |

c. | L/Δ = 360 at main span. |

d. | L/Δ = 180 at cantilever with 220-pound point load applied to end. |

e. | Includes incising factor. |

f. | Incising factor not included. |

g. | Interpolation permitted. Extrapolation not permitted. |

R507.9.1.2 Band joist details. Band joists supporting a ledger shall be a minimum 2-inch-nominal (51 mm), solid-sawn, spruce-pine-fir or better lumber or minimum 1-inch (25 mm) nominal engineered wood rim boards in accordance with Section R502.1.7. Band joists shall bear fully on the primary structure capable of supporting all required loads.

TABLE R507.9.1.3(1)

DECK LEDGER CONNECTION TO BAND JOIST

LOADc (psf) | JOIST SPANa (feet) | ON-CENTER SPACING OF FASTENERSb (inches) |

1/2-inch diameter lag screw with 1/2-inch maximum sheathingd,e | 1/2-inch diameter bolt with 1/2-inch maximum sheathinge | 1/2-inch diameter bolt with 1-inch maximum sheathingf |

60 Live Load or 70 Ground Snow Load | 6 | 22 | 36 | 35 |

8 | 16 | 31 | 26 |

10 | 13 | 25 | 21 |

12 | 11 | 20 | 17 |

14 | 9 | 17 | 15 |

16 | 8 | 15 | 13 |

18 | 7 | 13 | 11 |