WSR 24-12-058

EXPEDITED RULES

BUILDING CODE COUNCIL

[Filed June 3, 2024, 11:12 a.m.]

Title of Rule and Other Identifying Information: Editorial corrections and clarifications to the 2021 Washington State Energy Code, Commercial, chapter 51-11C WAC.

Purpose of the Proposal and Its Anticipated Effects, Including Any Changes in Existing Rules: Making editorial corrections and clarifications to the 2021 Washington State Energy Code, Commercial, chapter 51-11C WAC.

Reasons Supporting Proposal: After adoption of this rule, several editorial and cross-referencing errors were identified in the rule. The following editorial corrections are being made:

Definition of "Residential Building" was amended to reflect the language adopted under the 2021 Washington State Energy Code, Residential Provisions to correlate the codes. |

C402.1.1.1 Low Energy Buildings: A typographical error was corrected in the first sentence. |

Table C402.1.3 Opaque thermal envelope R-value requirements: • Reference to footnote c was reinstated in the Mass Wall Above Grade row. • A typographical error was corrected in footnote j and the name of the associated sub-table. • In the note 1b for Table 402.1.3(j), a typographical error was corrected. |

C402.1.4.1.2 Joints Staggered:A missing word ("in") was added so the sentence makes sense. |

Table C402.1.4 Opaque thermal envelope U-factor requirements: • Reference to footnote d was reinstated in the Mass Wall Above Grade row. • In the Mass Transfer Deck row, the footnote was corrected from "i" to "j." • Footnote I was corrected to correlate with the requirement in the Opaque Doors rows. • The section reference in Footnote j was corrected. |

C402.2 Specific insulation requirements.A section reference was corrected. |

Table C402.4 Fenestration maximum U-factor and SHGC requirements. Missing reference to footnote f was added for SHGC. |

C402.4.1.1.2 High-Performance Fenestration. The subparagraph numbering was corrected to match the model code numbering conventions. |

C402.4.2 Minimum Skylight Fenestration Area. A section reference in exception 1.5 was corrected. |

C402.5.2 Enclosure Testing for Dwelling Units. The title was corrected. |

C402.5.5 Rooms Containing Fuel-Burning Appliances. A section reference in the exception was corrected. |

C403.2 System Design. A typographical error in the first sentence was corrected. The section reference should be "C403.2.1 through C403.2.4" rather than "C403.2.1 and C403.2.4." |

C403.3.2.4 Water-Cooled Centrifugal Chilling Packages. A missing space was added to in the last paragraph. |

Table C403.3.2(3) Water Chilling Packages. A typographical error was corrected in the title row for the integrated part-load value. |

C403.3.4 Boiler requirements. The section scoping was clarified to show the actual subsection references rather than the generic "the following." |

C403.3.5.1 DOAS with energy recovery ventilation. The first sentence was simplified for clarity. |

C403.3.5.5 Supplemental heating and cooling.A typo in the exception was corrected. |

C403.4.1.7 Demand responsive controls. A typo was corrected in the third sentence. |

C403.4.12 Pressure independent control valves. Corrected a typo - "chiller" should be "chilled." |

C403.5 Economizers. Exception 1b was corrected to remove the reference to another exception that no longer exists. |

C403.6.10 High efficiency VAV systems.Item 9 was modified to correlate with the new fan power terms used in the code. |

C403.7.6.1 Ventilation for Group R-2 occupancy. Since this is a repeat of the requirement in C403.3.6, the exception from that section was included here as well, for correlation and clarity. |

C403.8.3 Fan efficiency.Two typographical errors in the exception is corrected. One of them is an errata item from the model code. The other is a simple misspelling. |

C404.11.4 Heat recovery.A section reference in the exception is corrected. |

Table C405.2.1 Occupant Sensor Compliance Requirements for Space Types. The number and title of the table are corrected. |

C405.2.1.1 Occupant sensor control function.Item 4 is a duplication of item 3 and is deleted. |

C405.2.1.4 Occupant sensor control function in enclosed fire rated stairways. The section reference to the IBC requirements is corrected. |

C405.2.4 Light-reduction controls. A typographical error is corrected in exception 2. |

C405.2.4.1 Light-reduction control function.Light-reduction is hyphenated for consistency and "reasonable" corrected to "reasonably." |

C405.2.5.1.1 Dimming.This section was mistakenly left out when the numbering was changed and is restored to the correct location. |

Table C405.4.2(2) Interior Lighting Power Allowance—Space by Space Method. • Footnote j was restored to the title row for common space types. • Footnote c was clarified by adding the word "allowance" after "additional power." |

C405.9.2 Escalators and moving walks. An extraneous word was removed. |

C406.1.1 Tenant spaces. The tense in exception 2 was corrected. |

C406.1.1.1 Applicable envelope, renewable and elevator energy credits. The internal section references were corrected. |

C406.1.1.2 Applicable HVAC and service water heating credits. The internal section references were corrected. |

Table C406.2(1) Efficiency Measure Credits. • The applicable section citation for Item 1, Dwelling unit HVAC control, was corrected. • The applicable section citations for items 26 and 27, air leakage, were corrected. • Footnote a was corrected to reference the appropriate items. • The section reference in footnote h was corrected. |

Table C406.2(2) Efficiency Measure Credits for Fossil Fuel Compliance Path. • The applicable section citation for Item 1, Dwelling unit HVAC control, was corrected. • Footnote a was corrected to reference the appropriate items. |

C406.2.2 More efficient HVAC system performance. The section reference in item 3 was corrected. |

C406.2.2.6 High performance DOAS.The section reference in item 3.2 was corrected. |

C409.3 End-use metering. The section reference in Exception 4.3 was corrected. |

Table C410.3.1(1) Walk-in Cooler and Freezer Display Doors. The table title row was corrected from "Class description" to "Class descriptor." |

Table C410.3.1(2) Walk-in Cooler and Freezer Nondisplay Doors. • The table title row was corrected from "Class description" to "Class descriptor." • Footnote a is corrected to reflect this is the table for nondisplay doors. |

Table C410.3.1(3) Walk-in Cooler and Freezer Refrigeration System. • The table title row was corrected from "Class description" to "Class descriptor." • For clarity, the test procedure is specified on each row. • The annual energy factor AWEF is corrected for two of the classes. |

C410.4 Refrigerated case and walk-in display doors. A typo in the title was corrected. |

C410.5 Refrigeration systems. A typo was corrected. |

C411.1 On-site renewable energy.The commas in the first sentence were removed. The intent was that the requirement be applied to buildings larger than 10,000 square feet and the commas caused confusion. |

C411.3 Solar readiness. A section reference in the exception was corrected. |

C412.7 Compressed air system acceptance. The section number was corrected. |

C502.2 Prescriptive compliance.The section references and subsection numbering were corrected. |

C502.2.2 Skylights. This section was moved down into the building envelope section and renumbered as C502.3.2. |

C502.2.4 Building mechanical systems. C502.2.5 Service water heating systems. C502.2.6 Pools and permanent spas. C502.2.7 Electrical power and lighting systems and motors. C502.2.8 Refrigeration systems. Section C409.5 was relocated to C506.1 in the 2021 WSEC. The section reference is updated in the above sections. |

C503.3.2 Vertical fenestration. • The section reference in item 2.1 was corrected. • Item 2.4 was updated to match the changes made to C407, moving back to site energy use target rather than carbon emissions. |

C503.3.3 Skylights. Item 2.2 was updated to match the changes made to C407, moving back to site energy use target rather than carbon emissions. |

C503.4 Building mechanical systems.Section C409.5 was relocated to C506.1 in the 2021 WSEC. The section reference is updated accordingly. |

C503.4.1 New building mechanical systems.Section C409.5 was relocated to C506.1 in the 2021 WSEC. The section reference is updated accordingly. |

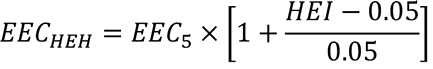

Table C503.4.3 Economizer Compliance Options for Alterations. Footnote n was modified to show the correct calculation for a 15% decrease in IPLV and NPLV requirements. |

C503.5 Service water heating equipment. C503.6 Pools and permanent spas. C503.7.1 New lighting systems and controls. Section C409.5 was relocated to C506.1 in the 2021 WSEC. The section reference is updated in the above sections. |

C503.7.4 New or moved lighting panel. Removed the extraneous "remaining" that no longer makes sense in context. |

C503.7.7 Controlled receptacles.Specified the correct reference in Exception 3. Previously, there was only one exception in the specified section. |

C503.8 Refrigeration systems.Section C409.5 was relocated to C506.1 in the 2021 WSEC. The section reference is updated accordingly. |

C505.1 General (Change of space conditioning, occupancy or use). • Corrected two typographical errors in paragraphs 1 and 3. • Item 2 was updated to match the changes made to C407, moving back to site energy use target rather than carbon emissions. |

C505.2 Change in space conditioning. Clarified item 2. Semi-heated space is technically conditioned space, so the language should specify that the space is altered to no longer fit the definition of semi-heated. |

C505.4 Prescriptive compliance.Corrected the subsection numbering. |

C505.4.2 Building mechanical systems. C505.4.3 Service water heating systems. C505.4.4 Pools and permanent spas. C505.4.5 Electrical power and lighting systems and motors. C505.4.6 Refrigeration systems. Section C409.5 was relocated to C506.1 in the 2021 WSEC. The section reference is updated in the above sections. |

C506.1 Metering in existing buildings. The title of the section was simplified. |

Statute Being Implemented: Chapter

19.27A RCW.

Rule is not necessitated by federal law, federal or state court decision.

Name of Proponent: State building code council (SBCC), governmental.

Name of Agency Personnel Responsible for Drafting and Implementation: Krista Braaksma, 1500 Jefferson Street S.E., Olympia, 360-407-9278; Enforcement: Local jurisdictions.

This notice meets the following criteria to use the expedited adoption process for these rules:

Corrects typographical errors, makes address or name changes, or clarifies language of a rule without changing its effect.

NOTICE

THIS RULE IS BEING PROPOSED UNDER AN EXPEDITED RULE-MAKING PROCESS THAT WILL ELIMINATE THE NEED FOR THE AGENCY TO HOLD PUBLIC HEARINGS, PREPARE A SMALL BUSINESS ECONOMIC IMPACT STATEMENT, OR PROVIDE RESPONSES TO THE CRITERIA FOR A SIGNIFICANT LEGISLATIVE RULE. IF YOU OBJECT TO THIS USE OF THE EXPEDITED RULE-MAKING PROCESS, YOU MUST EXPRESS YOUR OBJECTIONS IN WRITING AND THEY MUST BE SENT TO Daimon Doyle, Chair, SBCC, P.O. Box 41449, Olympia, WA 98504-1449, phone 360-407-9255, email sbcc@des.wa.gov, AND RECEIVED BY August 6, 2024.

May 24, 2024

Daimon Doyle

Council Chair

OTS-5452.2

AMENDATORY SECTION(Amending WSR 22-14-091, 23-12-101, and 23-20-021, filed 7/1/22, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-11C-20218Section C202.18—R.

RADIANT HEATING SYSTEM. A heating system that transfers heat to objects and surfaces within a conditioned space, primarily by infrared radiation.

READY ACCESS (TO). That which enables a device, appliance or equipment to be directly reached, without requiring the removal or movement of any panel or similar obstruction.

REFRIGERANT DEW POINT. The refrigerant vapor saturation temperature at a specified pressure.

REFRIGERATED WAREHOUSE COOLER. An enclosed storage space that has a total chilled storage area of 3,000 ft2 or greater and is designed to maintain a temperature of greater than 32°F but less than 55°F.

REFRIGERATED WAREHOUSE FREEZER. An enclosed storage space that has a total chilled storage area of 3,000 ft2 or greater and is designed to maintain a temperature at or below 32°F.

REFRIGERATION SYSTEM, LOW TEMPERATURE. Systems for maintaining food product in a frozen state in refrigeration applications.

REFRIGERATION SYSTEM, MEDIUM TEMPERATURE. Systems for maintaining food product above freezing in refrigeration applications.

REGISTERED DESIGN PROFESSIONAL. An individual who is registered or licensed to practice their respective design profession as defined by the statutory requirements of the professional registration laws of the state or jurisdiction in which the project is to be constructed.

RENEWABLE ENERGY RESOURCES. Energy derived from solar radiation, wind, waves, tides, biogas, biomass or extracted from hot fluid or steam heated within the earth.

RENEWABLE POWER PURCHASE AGREEMENT. A power purchase agreement for off-site renewable energy where the owner agrees to purchase renewable energy output and the associated renewable energy certificates at a fixed price schedule.

REPAIR. The reconstruction or renewal of any part of an existing building.

REPLACEMENT AIR. Outdoor air that is used to replace air removed from a building through an exhaust system. Replacement air may be derived from one or more of the following: Make-up air, supply air, transfer air and infiltration. However, the ultimate source of all replacement air is outdoor air. When replacement air exceeds exhaust, the result is exfiltration.

REROOFING. The process of recovering or replacing an existing roof covering. See "Roof Recover" and "Roof Replacement."

RESIDENTIAL BUILDING. For this code, ((includes))the following building types are residential buildings:

1. Detached one- and two-family dwellings ((and)).

2. Multiple single-family dwellings (townhouses) ((as well as)).

3. Group R-2 and R-3 buildings three stories or less in height above grade plane whose dwelling units are accessed directly from the exterior.

4. Accessory structures to residential buildings.

Group R-2 buildings with dwelling units accessed from interior corridors or other interior spaces are not residential buildings.

ROOF ASSEMBLY. A system designed to provide weather protection and resistance to design loads. The system consists of a roof covering and roof deck or a single component serving as both the roof covering and the roof deck. A roof assembly includes the roof covering, underlayment, roof deck, insulation, vapor retarder and interior finish. See also attic and other roofs, metal building roof, roof with insulation entirely above deck and single-rafter roof.

ROOF RECOVER. The process of installing an additional roof covering over a prepared existing roof covering without removing the existing roof covering.

ROOF REPAIR. Reconstruction or renewal of any part of an existing roof for the purposes of its maintenance.

ROOF REPLACEMENT. The process of removing the existing roof covering, repairing any damaged substrate and installing a new roof covering.

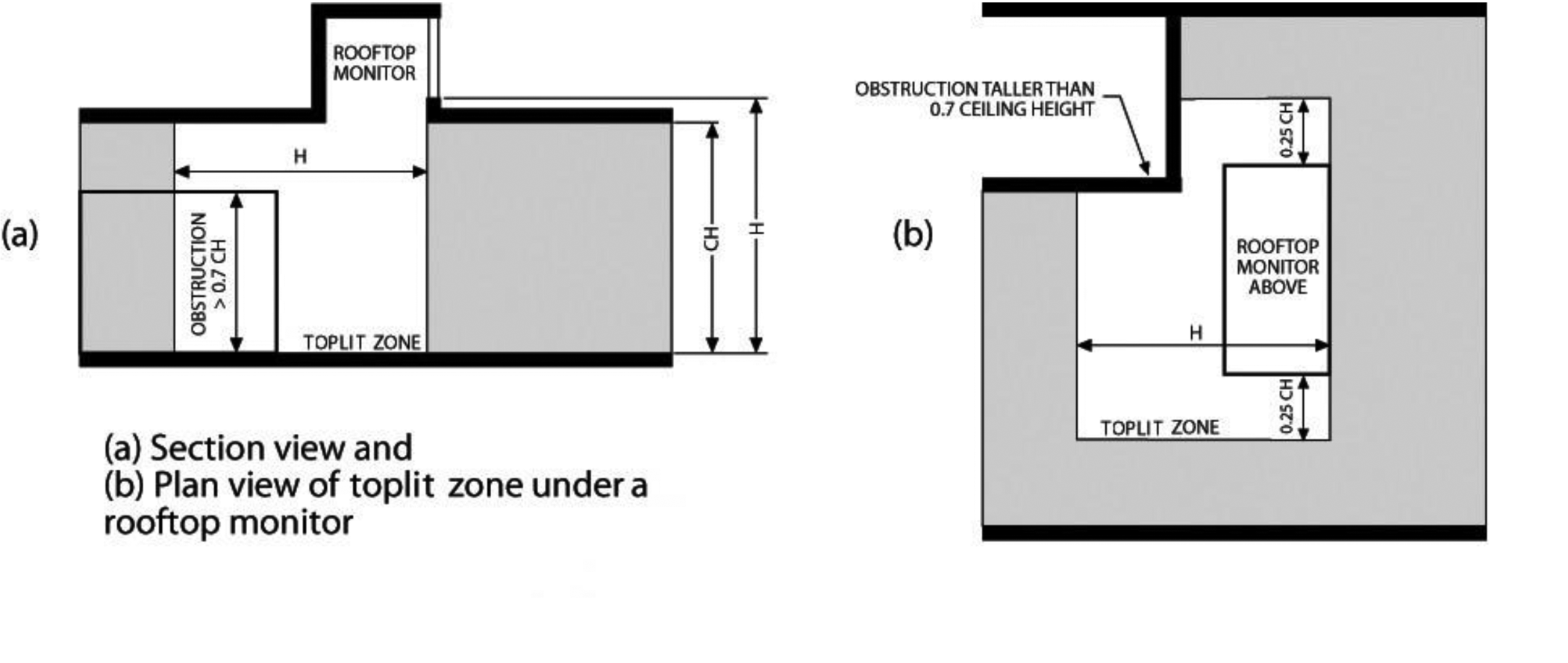

ROOFTOP MONITOR. A raised section of a roof containing vertical fenestration along one or more sides.

R-VALUE (THERMAL RESISTANCE). The inverse of the time rate of heat flow through a body from one of its bounding surfaces to the other surface for a unit temperature difference between the two surfaces, under steady state conditions, per unit area (h • ft2 • °F/Btu) [(m2 • K)/W].

Reviser's note: The brackets and enclosed material in the text of the above section occurred in the copy filed by the agency and appear in the Register pursuant to the requirements of RCW 34.08.040. AMENDATORY SECTION(Amending WSR 22-14-091, 23-12-101, and 23-20-021, filed 7/1/22, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-11C-40211Section C402.1.1—Low energy buildings.

C402.1.1Low energy buildings, semi-heated buildings and greenhouses. Low energy buildings shall comply with Section C402.1.1.1. Semi-heated buildings and spaces shall comply with Section C402.1.1.2. Greenhouses shall comply with Section C402.1.1.3.

C402.1.1.1 Low energy buildings. The following buildings, or enclosed portions thereof, separated from the remainder of the building by building thermal envelope assemblies complying with this code shall be exempt from all thermal envelope provisions of this code:

1. Those that are heated and/or cooled with a peak design rate of energy usage less than 3.4 Btu/h × ft2 (10.7 W/m2) or 1.0 watt/ft2 (10.7 W/m2) of floor area for space conditioning purposes.

2. Those that do not contain conditioned space.

3. Unstaffed equipment shelters or cabinets used solely for personal wireless service facilities.

C402.1.1.2 Semi-heated buildings and spaces. The building envelope of semi-heated buildings, or portions thereof, shall comply with the same requirements as that for conditioned spaces in Section C402, except as modified by this section. The total installed output capacity of mechanical space conditioning systems serving a semi-heated building or space shall comply with Section C202. Building envelope assemblies separating conditioned space from semi-heated space shall comply with exterior envelope insulation requirements. Semi-heated spaces are not required to comply with the opaque wall insulation provisions of Section C402.2.3 for walls that separate semi-heated spaces from the exterior or low energy spaces. Fenestration that forms part of the building thermal envelope enclosing semi-heated spaces shall comply with Section C402.4. Semi-heated spaces shall be calculated separately from other conditioned spaces for compliance purposes.

Opaque walls in semi-heated spaces shall be calculated as fully code compliant opaque walls for both the target and proposed for the Target UA calculations for Component Performance compliance per Section C402.1.5, and for the Baseline Building Design for Total Building Performance compliance per Section C407. The capacity of heat trace temperature maintenance systems complying with Section C404.7.2 that are provided for freeze protection of piping and equipment only shall not be included in the total installed output capacity of mechanical space conditioning systems.

EXCEPTION: | Provided the total installed heating output capacity of mechanical space conditioning does not exceed the criteria for semi-heated space as defined in Section C202, a semi-heated building or space may comply with this section when served by heat pumps without electric resistance back up and connected to a heating only thermostat. |

C402.1.1.3 Greenhouses.Greenhouse structures or areas that comply with all of the following shall be exempt from the building envelope requirements of this code:

1. Exterior opaque envelope assemblies complying with Sections C402.2 and C402.4.4.

EXCEPTION: | Low energy greenhouses that comply with Section C402.1.1.1. |

2. Interior partition building thermal envelope assemblies that separate the greenhouse from conditioned space complying with Sections C402.2, C402.4.3 and C402.4.4.

3. Fenestration assemblies complying with the thermal envelope requirements in Table C402.1.1.3. The U-factor for the skylight shall be for the roof assembly or a roof that includes the assembly and an internal curtain system.

EXCEPTION: | Unheated greenhouses. |

4. No mechanical cooling is provided.

5. For heated greenhouses, heating is provided by a radiant heating system, a condensing natural gas-fired or condensing propane-fired heating system, or a heat pump with cooling capacity permanently disabled as preapproved by the jurisdiction.

Table C402.1.1.3

Fenestration Thermal Envelope Maximum Requirements

Component | U-Factor BTU/h-ft2-°F |

Skylights | 0.5 |

Vertical fenestration | 0.6 |

AMENDATORY SECTION(Amending WSR 22-14-091, 23-12-101, and 23-20-021, filed 7/1/22, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-11C-402121Table C402.1.3—Opaque thermal envelope assembly R-value requirements.

Table C402.1.3

Opaque Thermal Envelope Insulation Component

Minimum Requirements, R-value Methoda, j

CLIMATE ZONE | 5 AND MARINE 4 |

| All Other | Group R |

Roofs |

Insulation entirely above deck | R-38ci | R-38ci |

Metal buildingsb | R-25 + R-22 LS | R-25 + R-22 LS |

Attic and other | R-49 | R-49 |

Walls, Above Gradei |

Massh | R-9.5cci | R-13.3ci |

Mass transfer deck slab edgeg | | |

Metal buildings | R-13 + R-14ci | R-13 + R-14ci |

Steel framed | R-13 + R-10ci | R-19 + R-8.5ci |

Wood framed and other | R-13 + R-7.5ci std or R-20 + R-3.8ci std | R-13 + R-7.5ci std or R-20 + R-3.8ci std or R-25 std |

Walls, Below Grade |

Below-grade walld,h | Same as above grade | Same as above grade |

Floors |

Massf | R-30ci | R-30ci |

Joist/framing | R-30e | R-30e |

Slab-on-Grade Floors |

Unheated slabs | R-10 for 24" below | R-10 for 24" below |

Heated slabs | R-10 perimeter & under entire slab | R-10 perimeter & under entire slab |

For SI: | 1 inch = 25.4 mm. ci = Continuous insulation. NR = No requirement. |

LS = | Liner system—A continuous membrane installed below the purlins and uninterrupted by framing members. Uncompressed, unfaced insulation rests on top of the membrane between the purlins. |

a | Assembly descriptions can be found in Chapter 2 and Appendix A. |

b | Where using R-value compliance method, a thermal spacer block with minimum thickness of 1/2-inch and minimum R-value of R-3.5 shall be provided, otherwise use the U-factor compliance method in Table C402.1.4. |

c | Exception: Integral insulated concrete block walls complying with ASTM C90 with all cores filled and meeting both of the following: |

| 1. At least 50 percent of cores must be filled with vermiculite or equivalent fill insulation; and |

| 2. The building thermal envelope encloses one or more of the following uses: Warehouse (storage and retail), gymnasium, auditorium, church chapel, arena, kennel, manufacturing plant, indoor swimming pool, pump station, water and waste water treatment facility, storage facility, storage area, motor vehicle service facility. Where additional uses not listed (such as office, retail, etc.) are contained within the building, the exterior walls that enclose these areas may not utilize this exception and must comply with the appropriate mass wall R-value from Table C402.1.3/U-factor from Table C402.1.4. |

d | Where heated slabs are below grade, they shall comply with the insulation requirements for heated slabs. |

e | Steel floor joist systems shall be insulated to R-38 + R-10ci. |

f | "Mass floors" shall include floors weighing not less than: |

| 1. 35 pounds per square foot of floor surface area; or |

| 2. 25 pounds per square foot of floor surface area where the material weight is not more than 120 pounds per cubic foot. |

g | Component performance in accordance with Section C402.1.5 shall be required for buildings with a mass transfer deck slab. |

h | Peripheral edges of intermediate concrete floors are included in the above-grade mass wall category and therefore must be insulated as above-grade mass walls unless they meet the definition of Mass Transfer Deck Slab Edge. The area of the peripheral edges of concrete floors shall be defined as the thickness of the slab multiplied by the perimeter length of the edge condition. See Table A103.3.7.2 for typical default U-factors for above-grade slab edges and footnote c for typical conditions of above-grade slab edges. |

i | Where the total area of through-wall mechanical equipment is greater than 1 percent of the opaque above-grade wall area, use of the R-value method is not permitted. See Section C402.1.4.3. |

j | For roof, wall or floor assemblies where the proposed assembly would not be continuous insulation, alternate nominal R-value compliance options for assemblies with isolated metal fasteners that penetrate otherwise continuous insulation are as shown in columns B and C of Table C402.1.3(((i)))(j): |

Table C402.1.3(((i)))(j)

Continuous Insulation Equivalents

Column A | Column B | Column C |

Assemblies with continuous insulation (see definition) | Alternate option for assemblies with metal penetrations, greater than 0.04% but less than 0.08% | Alternate option for assemblies with metal penetrations, greater than or equal to 0.08% but less than 0.12% |

R-9.5ci | R-11.9ci | R-13ci |

R-11.4ci | R-14.3ci | R-15.7ci |

R-13.3ci | R-16.6ci | R-18.3ci |

R-15.2ci | R-19ci | R-21ci |

R-30ci | R-38ci | R-42ci |

R-38ci | R-48ci | R-53ci |

R-13 + R-7.5ci | R-13 + R-9.4ci | R-13 + R-10.3ci |

R-13 + R-10ci | R-13 + R-12.5ci | R-13 + R-13.8ci |

R-13 + R-12.5ci | R-13 + R-15.6ci | R-13 + R-17.2ci |

R-13 + R-13ci | R-13 + R-16.3ci | R-13 + R-17.9ci |

R-19 + R-8.5ci | R-19 + R-10.6ci | R-19 + R-11.7ci |

R-19 + R-14ci | R-19 + R-17.5ci | R-19 + R-19.2ci |

R-19 + R-16ci | R-19 + R-20ci | R-19 + R-22ci |

R-20 + R-3.8ci | R-20 + R-4.8ci | R-20 + R-5.3ci |

R-21 + R-5ci | R-21 + R-6.3ci | R-21 + R-6.9ci |

Notes for Table C402.1.3(j) |

| These alternate nominal R-value compliance options are allowed for projects complying with all of the following: |

1a. | The ratio of the cross-sectional area, as measured in the plane of the surface, of metal penetrations of otherwise continuous insulation to the opaque surface area of the assembly is greater than 0.0004 (0.04%), but less than 0.0008 (0.08%), for use of Column B equivalents, and greater than or equal to ((0.008))0.0008 (0.08%), but less than 0.0012 (0.12%), for use of Column C equivalents. |

1b. | Where all metal penetrations are stainless steel, Column B is permitted to be used for penetrations greater than 0.12%, but less than 0.24% of opaque surface area, and Column C is permitted to be used for penetrations greater than or equal to 0.24%, but less than 0.48% of opaque surface area. |

2. | The metal penetrations of otherwise continuous insulation are isolated or discontinuous (e.g., brick ties or other discontinuous metal attachments, offset brackets supporting shelf angles that allow insulation to go between the shelf angle and the primary portions of the wall structure). No continuous metal elements (e.g., metal studs, z-girts, z-channels, shelf angles) penetrate the otherwise continuous portion of the insulation. |

3. | Building permit drawings shall contain details showing the locations and dimensions of all the metal penetrations (e.g., brick ties or other discontinuous metal attachments, offset brackets, etc.) of otherwise continuous insulation. In addition, calculations shall be provided showing the ratio of the cross-sectional area of metal penetrations of otherwise continuous insulation to the overall opaque wall area. |

For other cases where the proposed assembly is not continuous insulation, see Section C402.1.4 for determination of U-factors for assemblies that include metal other than screws and nails.

AMENDATORY SECTION(Amending WSR 22-14-091, 23-12-101, and 23-20-021, filed 7/1/22, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-11C-40214Section C402.1.4—Assembly U-factor, C-factor, or F-factor-based method.

C402.1.4 Assembly U-factor, C-factor, or F-factor-based method. Building thermal envelope opaque assemblies shall meet the requirements of Section C402.2 based on the climate zone specified in Chapter 3. Building thermal envelope opaque assemblies intended to comply on an assembly U-, C-, or F-factor basis shall have a U-, C-, or F-factor not greater than that specified in Table C402.1.4. Commercial buildings or portions of commercial buildings enclosing Group R occupancies shall use the U-, C-, or F-factor from the "Group R" column of Table C402.1.4. Commercial buildings or portions of commercial buildings enclosing occupancies other than Group R shall use the U-, C-, or F-factor from the "All other" column of Table C402.1.4. The U-factors for typical construction assemblies are included in Appendix A. These values shall be used for all calculations. Where proposed construction assemblies are not represented in Appendix A, values shall be calculated in accordance with the ASHRAE Handbook—Fundamentals using the framing factors listed in Appendix A where applicable and shall include the thermal bridging effects of framing materials.

C402.1.4.1 Roof/ceiling assembly. The maximum roof/ceiling assembly U-factor shall not exceed that specified in Table C402.1.4 based on construction materials used in the roof/ceiling assembly.

C402.1.4.1.1 Suspended ceilings. Insulation installed on suspended ceilings having removable ceiling tiles shall not be considered part of the assembly U-factor of the roof/ceiling construction.

C402.1.4.1.2 Joints staggered. Continuous insulation board shall be installed in not less than two layers, and the edge joints between each layer of insulation shall be staggered, except where insulation tapers to the roof deck at a gutter edge, roof drain, or scupper.

C402.1.4.2 Thermal resistance of cold-formed steel stud walls.U-factors of walls with cold-formed steel studs shall be permitted to be determined in accordance with Equation 4-1:

Equation 4-1:

U = 1/[Rs + (ER)] |

Where: |

Rs | = | The cumulative R-value of the wall components along the path of heat transfer, excluding the cavity insulation and steel studs. |

ER | = | The effective R-value of the cavity insulation with steel studs as specified in Table C402.1.4.2. |

C402.1.4.3 Thermal resistance of mechanical equipment penetrations. When the total area of penetrations from through-wall mechanical equipment or equipment listed in Table C403.3.2(4) exceeds 1 percent of the opaque above-grade wall area, the mechanical equipment penetration area shall be calculated as a separate wall assembly with a default U-factor of 0.5. Mechanical system ducts and louvers, including those for supply, exhaust and relief, and for condenser air intake and outlet, are not considered to be mechanical equipment for the purposes of this section.

EXCEPTION: | Where mechanical equipment has been tested in accordance with approved testing standards, the mechanical equipment penetration area is permitted to be calculated as a separate wall assembly using the U-factor determined by such test. |

Reviser's note: The brackets and enclosed material in the text of the above section occurred in the copy filed by the agency and appear in the Register pursuant to the requirements of RCW 34.08.040. AMENDATORY SECTION(Amending WSR 22-14-091, 23-12-101, and 23-20-021, filed 7/1/22, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-11C-402141Table C402.1.4—Opaque thermal envelope requirements, U-factor method.

Table C402.1.4

Opaque Thermal Envelope Requirementsa,f

CLIMATE ZONE | 5 AND MARINE 4 |

| All Other | Group R |

Roofs |

Insulation entirely above deck | U-0.027 | U-0.027 |

Metal buildings | U-0.031 | U-0.031 |

Attic and other | U-0.021 | U-0.021 |

Joist or single rafter | U-0.027 | U-0.027 |

Walls, Above Gradek |

Massd,g | U-0.104 | U-0.078 |

Mass transfer deck slab((i))j | U-0.20 | U-0.20 |

Metal building | U-0.050 | U-0.050 |

Steel framed | U-0.055 | U-0.055 |

Wood framed and other | U-0.051 | U-0.051 |

Walls, Below Grade |

Below-grade wallb, g | Same as above grade | Same as above grade |

Floors |

Masse | U-0.031 | U-0.031 |

Joist/framing | U-0.029 | U-0.029 |

Slab-on-Grade Floors |

Unheated slabs | F-0.54 | F-0.54 |

Heated slabsc | F-0.55 | F-0.55 |

Opaque Doors |

Nonswinging door | U-0.31 | U-0.31 |

Swinging doorh | U-0.37 | U-0.37 |

Garage door <14% glazing | U-0.31 | U-0.31 |

Garage door ≥14% and <50% glazingi | U-0.34 | U-0.34 |

a | Use of opaque assembly U-factors, C-factors, and F-factors from Appendix A is required unless otherwise allowed by Section C402.1.4. |

b | Where heated slabs are below grade, they shall comply with the F-factor requirements for heated slabs. |

c | Heated slab F-factors shall be determined specifically for heated slabs. Unheated slab factors shall not be used. |

d | Exception: Integral insulated concrete block walls complying with ASTM C90 with all cores filled and meeting both of the following: |

| 1. At least 50 percent of cores must be filled with vermiculite or equivalent fill insulation; and |

| 2. The building thermal envelope encloses one or more of the following uses: Warehouse (storage and retail), gymnasium, auditorium, church chapel, arena, kennel, manufacturing plant, indoor swimming pool, pump station, water and waste water treatment facility, storage facility, storage area, motor vehicle service facility. Where additional uses not listed (such as office, retail, etc.) are contained within the building, the exterior walls that enclose these areas may not utilize this exception and must comply with the appropriate mass wall R-value from Table C402.1.3/U-factor from Table C402.1.4. |

e | "Mass floors" shall include floors weighing not less than: 1. 35 pounds per square foot of floor surface area; or 2. 25 pounds per square foot of floor surface area where the material weight is not more than 120 pounds per cubic foot. |

f | Opaque assembly U-factors based on designs tested in accordance with ASTM C1363 shall be permitted. The R-value of continuous insulation shall be permitted to be added or subtracted from the original test design. |

g | Peripheral edges of intermediate concrete floors are included in the above-grade mass wall category and therefore must be insulated as above-grade mass walls unless they meet the definition of Mass Transfer Deck Slab. The area of the peripheral edges of concrete floors shall be defined as the thickness of the slab multiplied by the perimeter length of the edge condition. See Table A103.3.7.2 for typical default U-factors for above-grade slab edges and footnote c for typical conditions of above-grade slab edges. |

h | Swinging door U-factors shall be determined in accordance with NFRC-100. |

i | Garage doors having a single row of fenestration shall have an assembly U-factor less than or equal to 0.44, provided that the fenestration area is not less than 14 percent and not more than ((25))50 percent of the total door area. |

j | Component performance in accordance with Section C402.1.5 shall be required for buildings with a mass transfer deck slab. A mass transfer deck, due to its configuration, is not insulated. The table value (U-0.20) shall be used as the baseline value for component performance or total building performance path calculations. For the proposed value, the appropriate value from Table ((A104.3.7.2))A103.3.7.2 shall be used. |

k | Through-wall mechanical equipment subject to Section C402.1.4.3 shall be calculated at the U-factor defined in Section C402.1.4.3. The area-weighted U-factor of the wall, including through-wall mechanical equipment, shall not exceed the value in the table. |

AMENDATORY SECTION(Amending WSR 22-14-091, 23-12-101, and 23-20-021, filed 7/1/22, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-11C-40220Section C402.2—Specific insulation requirements.

C402.2 Specific building thermal envelope insulation requirements. Insulation in building thermal envelope opaque assemblies shall comply with Sections C402.2.1 through ((C402.2.8))C402.2.9 and Table C402.1.3.

Where this section refers to installing insulation levels as specified in Section C402.1.3, assemblies complying prescriptively with Section C402.1.4 and buildings complying with Section C402.1.5 are allowed to install alternate levels of insulation so long as the U-factor of the insulated assembly is less than or equal to the U-factor required by the respective path.

AMENDATORY SECTION(Amending WSR 22-14-091, 23-12-101, and 23-20-021, filed 7/1/22, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-11C-402300Table C402.4—Building envelope requirements—Fenestration.

Table C402.4

Building Envelope Fenestration Maximum U-factor and SHGC Requirements

CLIMATE ZONE | 5 AND MARINE 4 |

U-factor for Class AW windows rated in accordance with AAMA/CSA101/I.S.2/A440, vertical curtain walls and site-built fenestration productsa |

FixedbU-factor | U-0.34 |

OperablecU-factor | U-0.36 |

Entrance doorsd |

U-factor | U-0.60 |

U-factor for all other vertical fenestration |

Fixed U-factor | U-0.26 |

Operable or mulled windows with fixed and operable sections U-factor | U-0.28 |

SHGC for all vertical fenestrationf |

| Fixed | Operable |

PF < 0.2 | 0.38 | 0.33 |

0.2 ≤ PF < 0.5 | 0.46 | 0.40 |

PF ≥ 0.5 | 0.61 | 0.53 |

Skylights |

U-factor | U-0.50 |

SHGC | 0.35 |

a | U-factor and SHGC shall be rated in accordance with NFRC 100. |

b | "Fixed" includes curtain wall, storefront, picture windows, and other fixed windows. |

c | "Operable" includes openable fenestration products other than "entrance doors." |

d | "Entrance door" includes glazed swinging entrance doors. Other doors which are not entrance doors, including sliding glass doors, are considered "operable." |

e | Reserved. |

f | Fenestration that is entirely within the conditioned space or is between conditioned and other enclosed space is exempt from solar heat gain coefficient requirements and not included in the SHGC calculation. |

AMENDATORY SECTION(Amending WSR 22-14-091, 23-12-101, and 23-20-021, filed 7/1/22, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-11C-40231Section C402.4.1—Maximum area.

C402.4.1 Maximum area. The total building vertical fenestration area (not including opaque doors and opaque spandrel panels) shall not exceed 30 percent of the total building gross above-grade wall area. The skylight area shall not exceed 5 percent of the total building gross roof area (skylight-to-roof ratio).

For buildings with more than one space conditioning category, compliance with the maximum allowed window-to-wall ratio and skylight-to-roof ratio shall be demonstrated separately for each space conditioning category. Interior partition ceiling, wall, fenestration and floor areas that separate space conditioning areas shall not be applied to the window-to-wall ratio and skylight-to-roof ratio calculations.

C402.4.1.1 Vertical fenestration maximum area withhigh performance alternates. For buildings that comply with Section C402.4.1.1.1 or C402.4.1.1.2, the total building vertical fenestration area is permitted to exceed 30 percent but shall not exceed 40 percent of the gross above grade wall area for the purpose of prescriptive compliance with Section C402.1.4.

When determining compliance using the component performance alternative in accordance with Section C402.1.5, the total building vertical fenestration area allowed in Equation 4-2 is 40 percent of the above grade wall area for buildings that comply with the vertical fenestration alternates described in this section.

C402.4.1.1.1 Optimized daylighting. All of the following requirements shall be met:

1. Not less than 50 percent of the total conditioned floor area in the building is within a daylight zone that includes daylight responsive controls complying with Section C405.2.5.1.

2. Visible transmittance (VT) of all vertical fenestration in the building is greater than or equal to 1.1 times the required solar heat gain coefficient (SHGC) in accordance with Section C402.4, or 0.50, whichever is greater. It shall be permitted to demonstrate compliance based on the area weighted average VT being greater than or equal to the area weighted average of the minimum VT requirements.

EXCEPTION: | Fenestration that is outside the scope of NFRC 200 is not required to comply with Item 2. |

C402.4.1.1.2 High-performance fenestration. All of the following requirements shall be met:

1. All vertical fenestration in the building shall comply with the following U-factors:

((a.))1.1U-factor for Class AW windows rated in accordance with AAMA/CSA101/I.S.2/A440, vertical curtain walls and site-built fenestration products (fixed) = 0.31

((b.))1.2U-factor for Class AW windows rated in accordance with AAMA/CSA101/I.S.2/A440, vertical curtain walls and site-built fenestration products (operable) = 0.36

((c.))1.3 Entrance doors = 0.60

((d.))1.4U-factor for all other vertical fenestration, fixed = 0.23

((e.))1.5U-factor for all other vertical fenestration, operable, or mulled windows with fixed and operable sections = 0.24

2. The SHGC of the vertical fenestration shall be no more than 0.90 times the maximum SHGC values listed in Table C402.4.

An area-weighted average shall be permitted to satisfy the U-factor requirement for each fenestration product category listed in Item 1 of this section. Individual fenestration products from different fenestration product categories shall not be combined in calculating the area-weighted average U-factor, except that fenestration from lines a. and b. are permitted to be combined.

AMENDATORY SECTION(Amending WSR 22-14-091, 23-12-101, and 23-20-021, filed 7/1/22, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-11C-40232Section C402.4.2—Minimum skylight fenestration area.

C402.4.2 Minimum skylight fenestration area. Skylights shall be provided in enclosed spaces that meet all the following criteria:

1. Floor area of enclosed spaces is greater than 2,500 square feet (232 m2).

2. Space is located directly under a roof and have a ceiling height greater than 15 feet (4572 mm) for no less than 75 percent of the ceiling area.

3. Space type is one of the following: Office, lobby, atrium, concourse, corridor, gymnasium/exercise center, convention center, automotive service, manufacturing, nonrefrigerated warehouse, retail store, distribution/sorting area, transportation, and workshop.

Skylights in these spaces are required to provide a total toplit daylight zone area not less than 50 percent of the floor area and shall provide one of the following:

1. A minimum ratio of skylight area to toplit daylight zone area under skylights of not less than 3 percent where all skylights have a VT of at least 0.40, or VTannual of not less than 0.26, as determined in accordance with Section C303.1.3.

2. A minimum skylight effective aperture, determined in accordance with Equation 4-5, of:

2.1. Not less than 1 percent using a skylight's VT rating; or

2.2. Not less than 0.66 percent using a tubular daylight device's VTannual rating.

| Skylight Effective Aperture | = | (0.85 x Skylight Area x Skylight VT x WF)/ Toplit daylight zone | |

(Equation 4-5)

Where: | | |

Skylight area | = | Total fenestration area of skylights. |

Skylight VT | = | Area weighted average visible transmittance of skylights. |

WF | = | Area weighted average well factor, where well factor is 0.9 if light well depth is less than 2 feet (610 mm), or 0.7 if light well depth is 2 feet (610 mm) or greater, or 1.0 for tubular daylighting devices (TDD) with VTannual ratings measured in accordance with NFRC 203. |

Light well depth | = | Measure vertically from the underside of the lowest point of the skylight glazing to the ceiling plane under the skylight. |

EXCEPTIONS: | 1. Skylights above daylight zones of enclosed spaces are not required in: |

| 1.1. Spaces designed as storm shelters complying with ICC 500. |

| 1.2. Spaces where the designed general lighting power densities are less than 0.5 W/ft2 (5.4 W/m2) and at least 10 percent lower than the lighting power allowance in Section C405.4.2. |

| 1.3. Areas where it is documented that existing structures or natural objects block direct beam sunlight on at least half of the roof over the enclosed area for more than 1,500 daytime hours per year between 8 a.m. and 4 p.m. |

| 1.4. Spaces where the daylight zone under rooftop monitors is greater than 50 percent of the enclosed space floor area. |

| 1.5. Spaces where the total floor area minus the sidelit daylight zone area is less than 2,500 square feet (232 m2), and where the lighting in the daylight zone is controlled in accordance with Section ((C405.2.3.1))C405.2.4.1. |

| 2. The skylight effective aperture, calculated in accordance with Equation 4-5, is permitted to be 0.66 percent in lieu of 1 percent if the VTannual of the skylight or TDD, as measured by NFRC 203, is greater than 38 percent. |

C402.4.2.1 Lighting controls in daylight zones under skylights. Daylight responsive controls shall be provided to control all electric lights within toplit daylight zones.

C402.4.2.2 Haze factor. Skylights in office, storage, automotive service, manufacturing, nonrefrigerated warehouse, retail store, and distribution/sorting area spaces shall have a glazing material or diffuser with a haze factor greater than 90 percent when tested in accordance with ASTM D 1003.

EXCEPTION: | Skylights and tubular daylighting devices designed and installed to exclude direct sunlight entering the occupied space by the use of fixed or automated baffles, or the geometry of skylight and light well. |

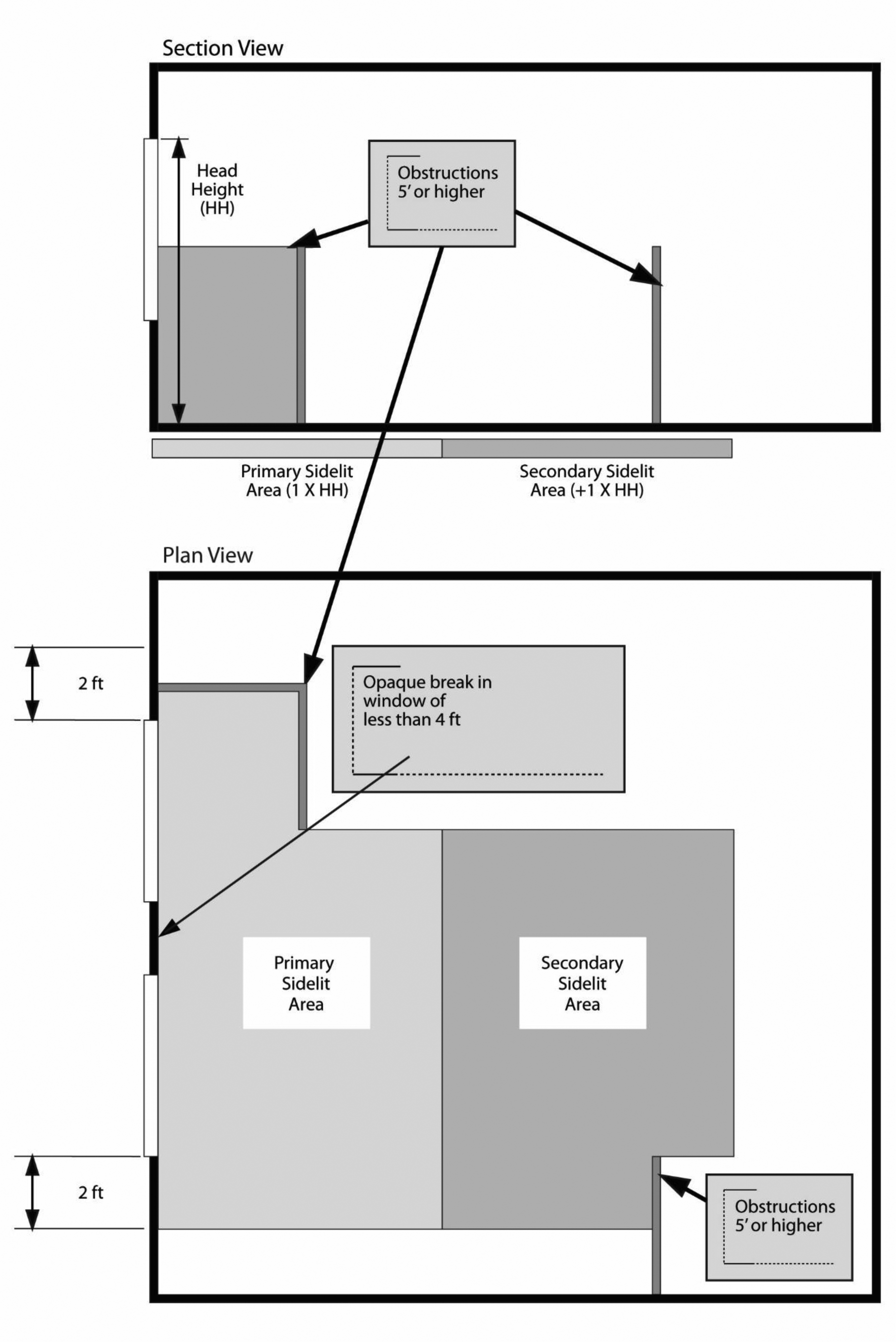

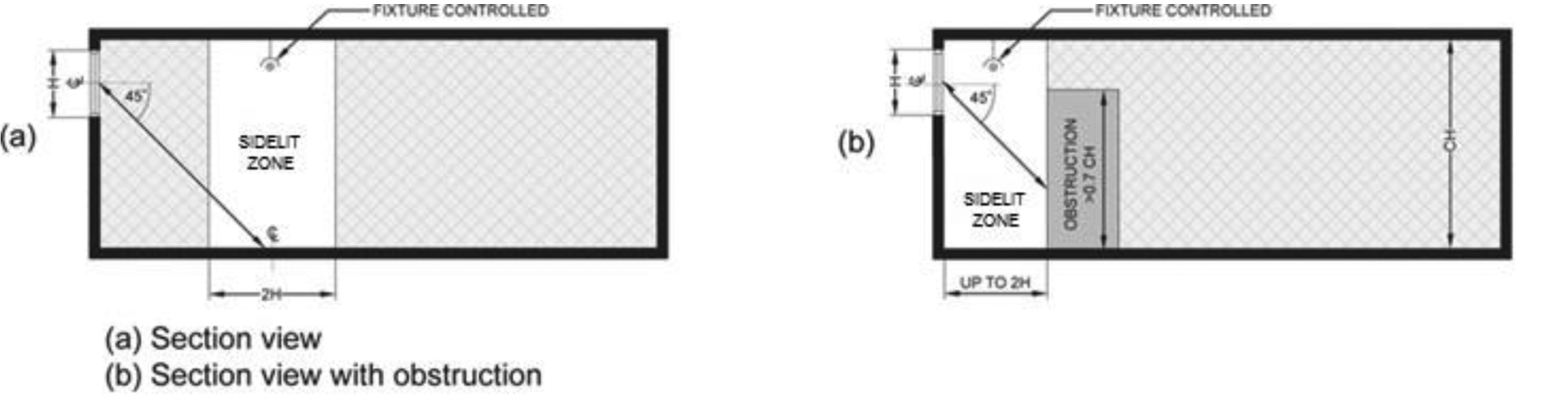

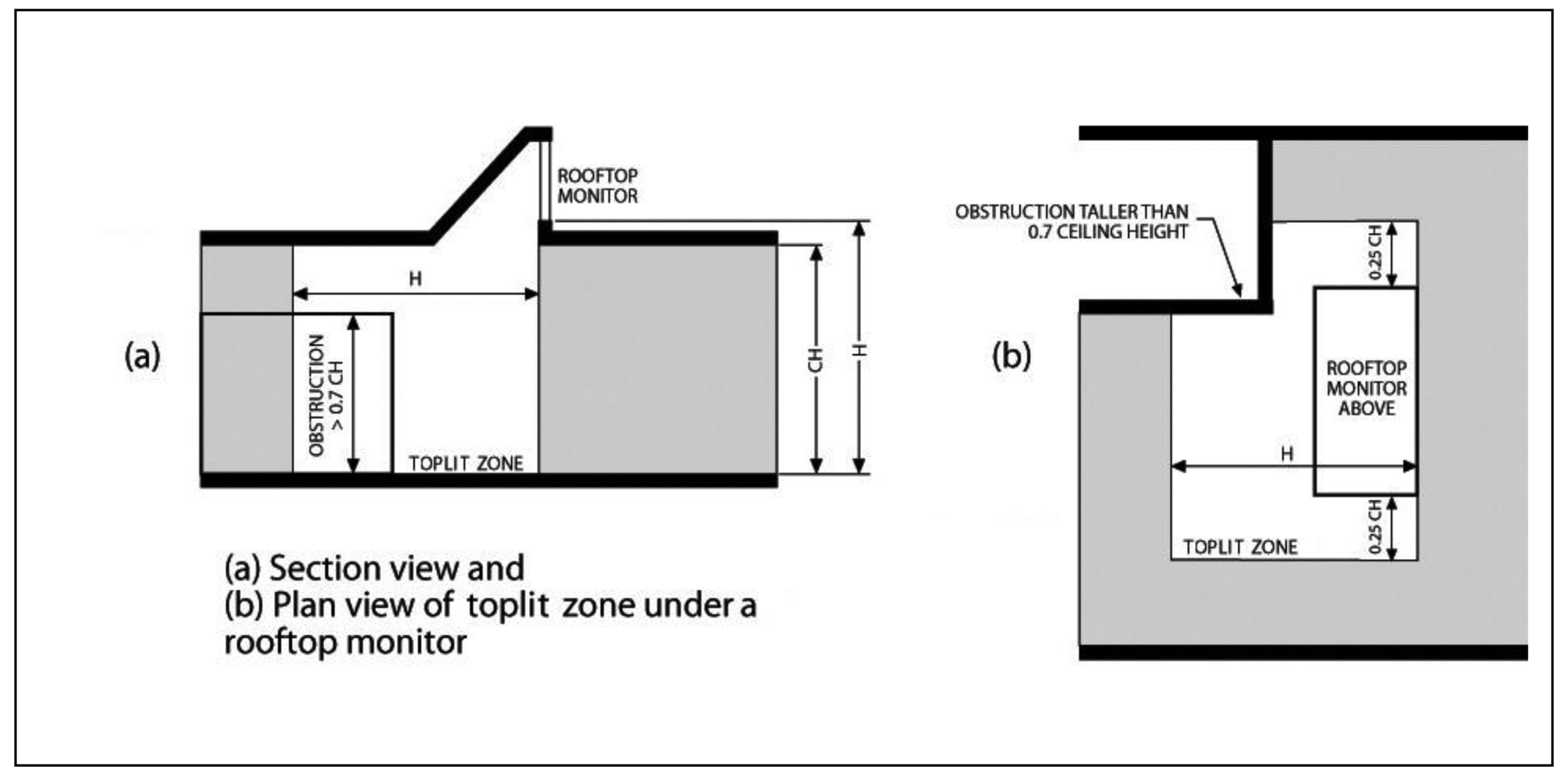

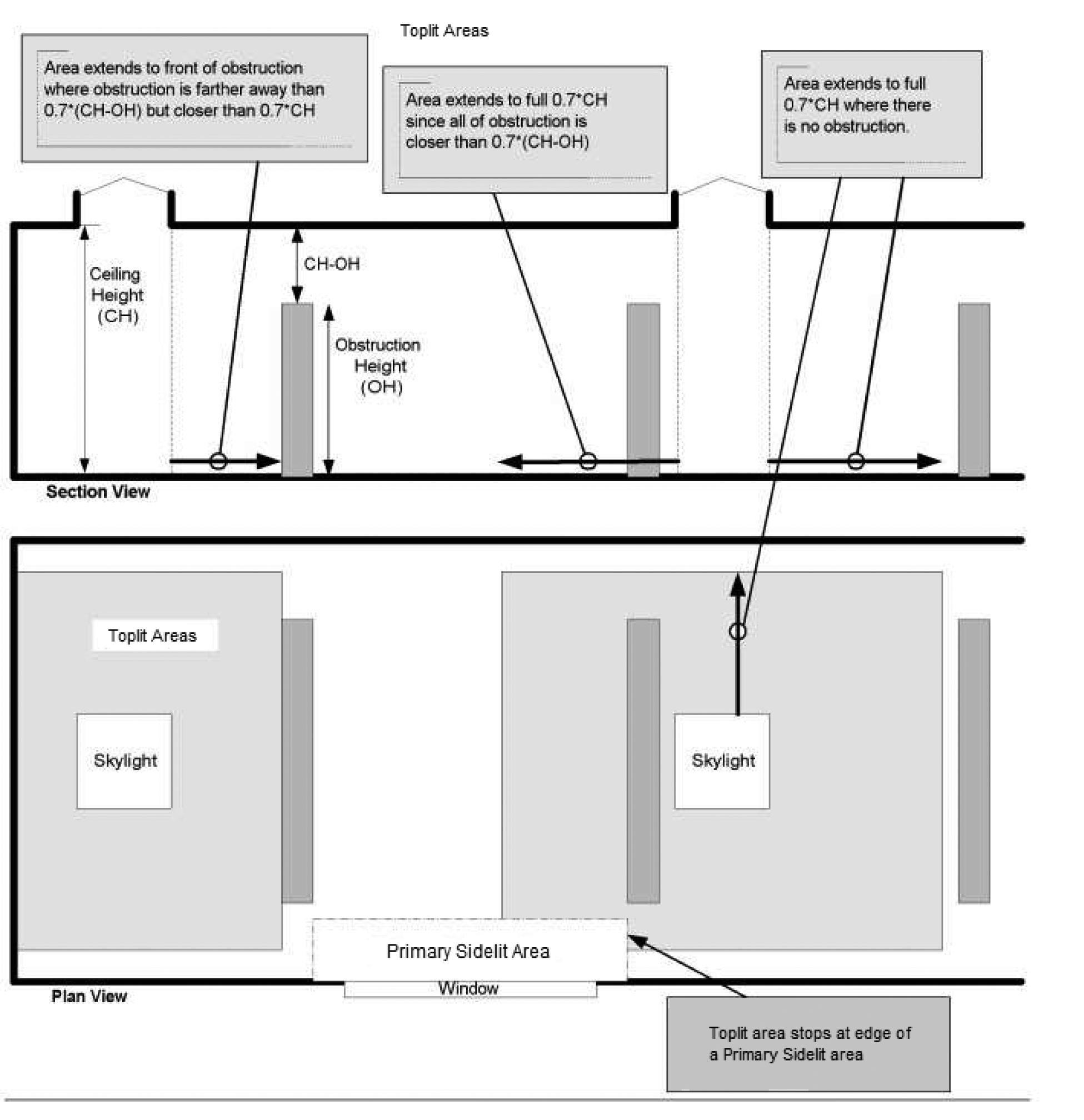

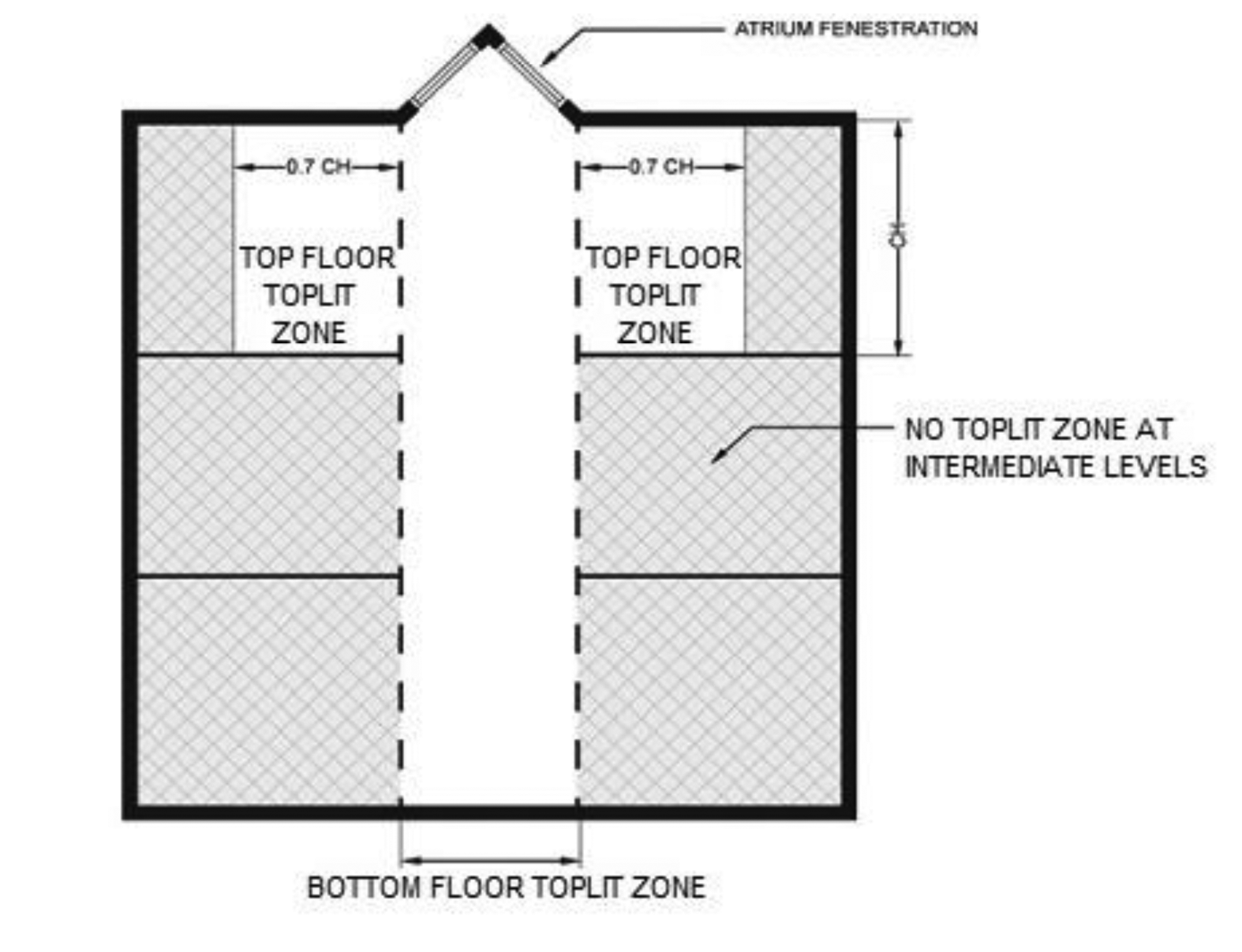

C402.4.2.3 Daylight zones. Daylight zones referenced in Sections C402.4.1.1 through C402.4.2.2 shall comply with Sections C405.2.5.2 and C405.2.5.3, as applicable. Daylight zones shall include toplit daylight zones and sidelit daylight zones.

AMENDATORY SECTION(Amending WSR 22-14-091, 23-12-101, and 23-20-021, filed 7/1/22, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-11C-40241Section C402.5.1—Air barriers.

C402.5.1 Air barriers. A continuous air barrier shall be provided throughout the building thermal envelope. The continuous air barriers shall be located on the inside or outside of the building thermal envelope, located within the assemblies composing the building thermal envelope, or any combination thereof. The air barrier shall comply with Sections C402.5.1.1 and C402.5.1.2.

C402.5.1.1 Air barrier construction. The continuous air barrier shall be constructed to comply with the following:

1. The air barrier shall be continuous for all assemblies that are the thermal envelope of the building and across the joints and assemblies.

2. Air barrier joints and seams shall be sealed, including sealing transitions in places and changes in materials. The joints and seals shall be securely installed in or on the joint for its entire length so as not to dislodge, loosen or otherwise impair its ability to resist positive and negative pressure from wind, stack effect and mechanical ventilation.

3. Penetrations of the air barrier shall be caulked, gasketed or otherwise sealed in a manner compatible with the construction materials and location. Sealing shall allow for expansion, contraction and mechanical vibration. Joints and seams associated with penetrations shall be sealed in the same manner or taped. Sealing materials shall be securely installed around the penetration so as not to dislodge, loosen or otherwise impair the penetrations' ability to resist positive and negative pressure from wind, stack effect, and mechanical ventilation. Sealing of concealed fire sprinklers, where required, shall be in a manner that is recommended by the manufacturer. Caulking or other adhesive sealants shall not be used to fill voids between fire sprinkler cover plates and walls or ceilings.

4. Recessed lighting fixtures shall comply with Section C402.5.8. Where similar objects are installed which penetrate the air barrier, provisions shall be made to maintain the integrity of the air barrier.

5. Construction documents shall contain a diagram showing the building's pressure boundary in plan(s) and section(s) and a calculation of the area of the pressure boundary to be considered in the test.

C402.5.1.2 Air barrier compliance. A continuous air barrier for the opaque building envelope shall comply with the following:

1. Group R dwelling units that are accessed directly from the outdoors shall meet the provisions of Section C402.5.2.

2. All other buildings or portions of buildings shall meet the provisions of Section C402.5.3.

C402.5.2 Enclosure testing for dwelling and sleeping units accessed directly from the outdoors. For dwelling units accessed directly from outdoors, the building thermal envelope shall be tested in accordance with ASTM E779, ANSI/RESNET/ICC 380, ASTM E1827 or an equivalent method approved by the code official. The measured air leakage shall not exceed 0.25 cfm/ft2 (1.27 L/s m2) of the testing unit enclosure area at a pressure differential of 0.2 inch water gauge (50 Pa). Where multiple dwelling units or sleeping units or other occupiable conditioned spaces are contained within one building thermal envelope and are accessed directly from the outdoors, each unit shall be considered an individual testing unit, and the building air leakage shall be the weighted average of all testing unit results, weighted by each testing unit's enclosure area. Units shall be tested separately with an unguarded blower door test as follows:

1. Where buildings have fewer than eight testing units, each testing unit shall be tested.

2. For buildings with eight or more testing units, the greater of seven units or 20 percent of the testing units in the building shall be tested, including a top floor unit, a ground floor unit and a unit with the largest testing unit enclosure area. For each tested unit that exceeds the maximum air leakage rate, an additional two units shall be tested, including a mixture of testing unit types and locations.

3. Test shall be accomplished using either a) both pressurization and depressurization or b) pressurization alone, but not depressurization alone. The test results shall be plotted against the correct P for pressurization in accordance with Section 9.4 of ASTM E779.

Where the measured air leakage rate exceeds 0.25 cfm/ft2 (2.0 L/s x m2) corrective action shall be taken to seal leaks in the air barrier in all units exceeding the target value and all untested units. Post-corrective action testing and repeated corrective action measures will be taken until the required air leakage rating is achieved. Final passing air leakage test results shall be submitted to the code official.

C402.5.3 Building thermal envelope testing. The building thermal envelope shall be tested in accordance with ASTM E779, ANSI/RESNET/ICC 380, ASTM E3158 or ASTM E1827 or an equivalent method approved by the code official. The measured air leakage shall not exceed 0.25 cfm/ft2 (1.27 L/s × m2) of the building thermal envelope area at a pressure differential of 0.3 inch water gauge (75 Pa). Alternatively, portions of the building shall be tested and the measured air leakages shall be area weighted by the surface areas of the building envelope in each portion. The weighted average test results shall not exceed the whole building leakage limit. In the alternative approach, the following portions of the building shall be tested:

1. The entire envelope area of all stories that have any spaces directly under a roof.

2. The entire envelope area of all stories that have a building entrance, exposed floor, or loading dock, or are below grade.

3. Representative above-grade sections of the building totaling at least 25 percent of the wall area enclosing the remaining conditioned space.

4. Test shall be accomplished using either a) both pressurization and depressurization or b) pressurization alone, but not depressurization alone. The test results shall be plotted against the correct P for pressurization in accordance with Section 9.4 of ASTM E779.

Where the measured air leakage rate exceeds 0.25 cfm/ft2 (2.0 L/s x m2) corrective action shall be taken to seal leaks in the air barrier. Post-corrective action testing and repeated corrective action measures will be taken until the required air leakage rating is achieved. Final passing of the air leakage test results shall be submitted to the code official.

C402.5.4 Building test for mixed-use buildings. Where a building is three or fewer stories above grade plane and contains both commercial and residential uses, the air barrier of the R-2 and R-3 occupancy areas of the building is permitted to be separately tested according to Section R402.4.1.2. Alternatively, it is permissible to test the air barrier of the entire building according to Section C402.5.3, provided that the tested air leakage rate does not exceed the rate specified in Section C402.5.3.

AMENDATORY SECTION(Amending WSR 22-14-091, 23-12-101, and 23-20-021, filed 7/1/22, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-11C-40243Section C402.5.5—Rooms containing fuel-burning appliances.

C402.5.5 Rooms containing fuel-burning appliances. Where combustion air is supplied through openings in an exterior wall to a room or space containing a space conditioning fuel-burning appliance, one of the following shall apply:

1. The room or space containing the appliance shall be located outside of the building thermal envelope.

2. The room or space containing the appliance shall be enclosed and isolated from conditioned spaces inside the building thermal envelope. Such rooms shall comply with all of the following:

2.1. The walls, floor and ceiling that separate the enclosed room or space from the conditioned spaces shall be insulated to be at least equivalent to the insulation requirement of below grade walls as specified in Table C402.1.3 or C402.1.4.

2.2. The walls, floors and ceilings that separate the enclosed room or space from conditioned spaces be sealed in accordance with Section C402.5.1.1.

2.3. The doors into the enclosed room or space shall be fully gasketed.

2.4. Water lines and ducts in the enclosed room or space shall be insulated in accordance with Section C403.

2.5. Where the air duct supplying combustion air to the enclosed room or space passes through conditioned space, the duct shall be insulated to an R-value of not less than R-16.

EXCEPTION: | Fireplaces and stoves complying with Sections 901 through 905 of the International Mechanical Code, and Section ((2111.13))2111.14 of the International Building Code. |

AMENDATORY SECTION(Amending WSR 22-14-091, 23-12-101, and 23-20-021, filed 7/1/22, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-11C-40320Section C403.2—System design.

C403.2 System design. Mechanical systems shall be designed to comply with Sections C403.2.1 ((and))through C403.2.4. Where elements of a building's mechanical systems are addressed in Sections C403.3 through C403.13, such elements shall comply with the applicable provisions of those sections.

AMENDATORY SECTION(Amending WSR 22-14-091, 23-12-101, and 23-20-021, filed 7/1/22, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-11C-40332Section C403.3.2—HVAC equipment performance requirements.

C403.3.2 HVAC equipment performance requirements. Equipment shall meet the minimum efficiency requirements of Tables C403.3.2(1) through C403.3.2(16) when tested and rated in accordance with the applicable test procedure. Plate-type liquid-to-liquid heat exchangers shall meet the minimum requirements of AHRI 400. The efficiency shall be verified through certification and listed under an approved certification program or, if no certification program exists, the equipment efficiency ratings shall be supported by data furnished by the manufacturer. Where multiple rating conditions or performance requirements are provided, the equipment shall satisfy all stated requirements. Where components, such as indoor or outdoor coils, from different manufacturers are used, calculations and supporting data shall be furnished by the designer that demonstrates that the combined efficiency of the specified components meets the requirements herein.

C403.3.2.1 Gas-fired and oil-fired forced air furnaces. Forced air furnaces with input ratings ≥ 225,000 Btu/h (65 kW) and all unit heaters shall also have an intermittent ignition or interrupted device (IID), and have either mechanical draft (including power venting) or a flue damper. A vent damper is an acceptable alternative to a flue damper for furnaces where combustion air is drawn from the conditioned space. All furnaces with input ratings ≥ 225,000 Btu/h (65 kW), including electric furnaces, that are not located within the conditioned space shall have jacket losses not exceeding 0.75 percent of the input rating.

C403.3.2.2 Hydronic and multiple-zone HVAC system controls and equipment. Hydronic and multiple-zone HVAC system controls and equipment shall comply with this section.

For buildings with a total equipment cooling capacity of 300 tons and above, the equipment shall comply with one of the following:

1. No one unit shall have a cooling capacity of more than 2/3 of the total installed cooling equipment capacity;

2. The equipment shall have a variable speed drive; or

3. The equipment shall have multiple compressors.

C403.3.2.3 Chillers. Chilled water plants and buildings with more than 500 tons total capacity shall not have more than 100 tons provided by air-cooled chillers.

EXCEPTIONS: | 1. Where the designer demonstrates that the water quality at the building site fails to meet manufacturer's specifications for the use of water-cooled equipment. |

| 2. Air-cooled chillers with minimum efficiencies at least 10 percent higher than those listed in Table C403.3.2(3). |

| 3. Replacement of existing air-cooled chiller equipment. |

| 4. Air-to-water heat pump units that are configured to provide both heating and cooling and that are rated in accordance with AHRI 550/590. |

C403.3.2.4 Water-cooled centrifugal chilling packages. Equipment not designed for operation at AHRI Standard 550/590 test conditions of 44.00°F (6.67°C) leaving and 54.00°F (12.22°C) entering chilled-water temperatures and with 85.00°F (29.44°C) entering and 94.30°F (34.61°C) leaving condenser-fluid temperatures, shall have maximum full-load kW/ton (FL) and part-load ratings adjusted using the following equations.

(Equation 4-7)

(Equation 4-8)

Where: | |

Kadj | = | A × B |

FL | = | Full-load kW/ton values as specified in Table C403.3.2(7) |

FLadj | = | Maximum full-load kW/ton rating, adjusted for nonstandard conditions |

IPLV.IP | = | Value as specified in Table C403.3.2(7) |

PLVadj | = | Maximum NPLV rating, adjusted for nonstandard conditions |

A | = | 0.00000014592 × (LIFT)4 - 0.0000346496 × (LIFT)3+ 0.00314196 × (LIFT)2 - 0.147199 × LIFT + 3.93073 |

B | = | 0.0015 × LvgEvap (° F) + 0.934 |

LIFT | = | LvgCond - LvgEvap |

LvgCond | = | Full-load condenser leaving fluid temperature (°F) |

LvgEvap | = | Full-load evaporator leaving temperature (°F) |

The FLadj and PLVadj values are applicable only for centrifugal chillers meeting all of the following full-load design ranges:

• 36.00°F ≤ LvgEvap ≤ 60.00°F

• LvgCond ≤ 115.00°F

• 20.00°F ≤ LIFT ≤ 80.00°F

Manufacturers shall calculate the FLadj and ((PLVadjbefore))PLVadj before determining whether to label the chiller. Centrifugal chillers designed to operate outside of these ranges are not covered by this code.

C403.3.2.5 Positive displacement (air- and water-cooled) chilling packages. Equipment with a leaving fluid temperature higher than 32°F (0°C) and water-cooled positive displacement chilling packages with a condenser leaving fluid temperature below 115°F (46°C) shall meet the requirements the tables in Section C403.3.2 when tested or certified with water at standard rating conditions, in accordance with the referenced test procedure.

C403.3.2.6 Packaged and split system electric heating and cooling equipment. Packaged and split system equipment providing both electric heating and cooling, and cooling-only equipment with electric heat in the main supply duct before VAV boxes, in each case with a total cooling capacity greater than 6,000 Btu/h shall be a heat pump configured to operate in heat pump mode whenever the outdoor air temperature is above 25°F (-3.9°C) and the unit is not in defrost. The unit shall have reverse-cycle demand defrost.

EXCEPTION: | Unstaffed equipment shelters or cabinets used solely for personal wireless service facilities. |

C403.3.2.7 Humidification. If an air economizer is required on a cooling system for which humidification equipment is to be provided to maintain minimum indoor humidity levels, then the humidifier shall be of the adiabatic type (direct evaporative media or fog atomization type).

EXCEPTIONS: | 1. Health care facilities licensed by the state where chapter 246-320 or 246-330 WAC requires steam injection humidifiers in duct work downstream of final filters. |

| 2. Systems with water economizer. |

| 3. 100 percent outside air systems with no provisions for air recirculation to the central supply fan. |

| 4. Nonadiabatic humidifiers cumulatively serving no more than 10 percent of a building's air economizer capacity as measured in cfm. This refers to the system cfm serving rooms with stand alone or duct mounted humidifiers. |

AMENDATORY SECTION(Amending WSR 22-14-091, 23-12-101, and 23-20-021, filed 7/1/22, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-11C-403323Table C403.3.2(3)—Water chilling packages—Minimum efficiency requirements.

Table C403.3.2(3)

Water Chilling Packages—Minimum Efficiency Requirementsa,b,e,f

| Size Category | | Path A | Path B | Test Procedurec |

Equipment Type | Units | FL | ((IPLV,IP))IPLV.IP | FL | ((IPLV,IP))IPLV.IP |

Air-cooled chillers | < 150 tons | EER(Btu/Wh) | ≥ 10.100 | ≥ 13.700 | ≥ 9.700 | ≥ 15.800 | |

≥ 150 tons | EER(Btu/Wh) | ≥ 10.100 | ≥ 14.000 | ≥ 9.700 | ≥ 16.100 | |

Air cooled without condenser, electrically operated | All capacities | EER(Btu/Wh) | Air-cooled chillers without condensers shall be rated with matching condensers and comply with the air-cooled chiller efficiency requirements | |

Water cooled, electrically operated, positive displacement | < 75 tons | kW/ton | ≤ 0.750 | ≤ 0.600 | ≤ 0.780 | ≤ 0.500 | |

≥ 75 tons and < 150 tons | kW/ton | ≤ 0.720 | ≤ 0.560 | ≤ 0.750 | ≤ 0.490 | AHRI 550/590 |

≥ 150 tons and < 300 tons | kW/ton | ≤ 0.660 | ≤ 0.540 | ≤ 0.680 | ≤ 0.440 | |

≥ 300 tons and < 600 tons | kW/ton | ≤ 0.610 | ≤ 0.520 | ≤ 0.625 | ≤ 0.410 | |

| ≥ 600 tons | kW/ton | ≤ 0.560 | ≤ 0.500 | ≤ 0.585 | ≤ 0.380 | |

Water cooled, electrically operated, centrifugal | < 150 tons | kW/ton | ≤ 0.610 | ≤ 0.550 | ≤ 0.695 | ≤ 0.440 | |

≥ 150 tons and < 300 tons | kW/ton | ≤ 0.610 | ≤ 0.550 | ≤ 0.695 | ≤ 0.400 | |

≥ 300 tons and < 400 tons | kW/ton | ≤ 0.560 | ≤ 0.520 | ≤ 0.595 | ≤ 0.390 | |

≥ 400 tons and < 600 tons | kW/ton | ≤ 0.560 | ≤ 0.500 | ≤ 0.585 | ≤ 0.380 | |

≥ 600 tons | kW/ton | ≤ 0.560 | ≤ 0.500 | ≤ 0.585 | ≤ 0.380 | |

Air cooled absorption, single effect | All capacities | COP(W/W) | ≥ 0.600 | NR | NAd | NAd | |

Water cooled absorption, single effect | All capacities | COP(W/W) | ≥ 0.700 | NR | NAd | NAd | AHRI 560 |

Absorption double effect, indirect fired | All capacities | COP(W/W) | ≥ 1.000 | ≥ 1.050 | NAd | NAd |

Absorption double effect, direct fired | All capacities | COP(W/W) | ≥ 1.000 | ≥ 1.000 | NAd | NAd | |

For SI: 1 ton = 3517 W, 1 British thermal unit per hour = 0.2931 W, °C = [(°F) - 32]/1.8. |

| NR = No requirement. |

| a | Chapter 6 contains a complete specification of the referenced standards, which includes test procedures, including the referenced year version of the test procedure. |

| b | The requirements for centrifugal chiller shall be adjusted for nonstandard rating conditions per Section C403.3.2.4 and are applicable only for the range of conditions listed there. The requirements for air-cooled, water-cooled positive displacement and absorption chillers are at standard rating conditions defined in the referenced test procedure. |

| c | Both the full load and IPLV.IP requirements must be met or exceeded to comply with this standard. When there is a Path B, compliance can be with either Path A or Path B for any application. |

| d | NA means the requirements are not applicable for Path B and only Path A can be used for compliance. |

| e | FL is the full-load performance requirements, and IPLV.IP is for the part-load performance requirements. |

| f | This table is a replica of ASHRAE 90.1 Table 6.8.1-3 Water-Chilling Packages—Minimum Efficiency Requirements. |

AMENDATORY SECTION(Amending WSR 22-14-091, 23-12-101, and 23-20-021, filed 7/1/22, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-11C-40334Section C403.3.4—Boilers.

C403.3.4Boiler requirements.Boiler systems shall comply with ((the following:))Sections C403.3.4.1 through C403.3.4.5.2.

C403.3.4.1 Combustion air positive shut-off. Combustion air positive shut-off shall be provided on all newly installed boiler systems as follows:

1. All boiler systems with an input capacity of 2,500,000 Btu/h and above, in which the boiler is designed to operate with a nonpositive vent static pressure.

2. All boiler systems where one stack serves two or more boilers with a total combined input capacity per stack of 2,500,000 Btu/h.

C403.3.4.2 Boiler system oxygen concentration controls. Boiler system combustion air fans with motors 10 horsepower or larger shall meet one of the following for newly installed boilers:

1. The fan motor shall be variable speed; or

2. The fan motor shall include controls that limit the fan motor demand to no more than 30 percent of the total design wattage at 50 percent of design air volume.

C403.3.4.3 Boiler oxygen concentration controls. Newly installed boilers with an input capacity of 5,000,000 Btu/h and greater and a steady state full-load combustion efficiency less than 90 percent shall maintain stack-gas oxygen concentrations not greater than the values specified in Table C403.3.4.3. Combustion air volume shall be controlled with respect to measured flue gas oxygen concentration. The use of a common gas and combustion air control linkage or jack shaft is prohibited.

EXCEPTION: | These concentration limits do not apply where 50 percent or more of the boiler system capacity serves Group R-2 occupancies. |

Table C403.3.4.3

Boiler Stack-Gas Oxygen Concentrations

Boiler System Type | Maximum Stack-Gas Oxygen Concentrationa |

Less than 10% of the boiler system capacity is used for process applications at design conditions | 5% |

All others | 3% |

a | Concentration levels measured by volume on a dry basis over firing rates of 20 to 100 percent. |

C403.3.4.4 Boiler turndown.Boiler systems with design input of greater than 1,000,000 Btu/h (293 kW) shall comply with the turndown ratio specified in Table C403.3.4.4.

The system turndown requirement shall be met through the use of multiple single input boilers, one or more modulating boilers or a combination of single input and modulating boilers.

Table C403.3.4.4

Boiler Turndown

Boiler System Design Input (Btu/h) | Minimum Turndown Ratio |

≥ 1,000,000 and less than or equal to 5,000,000 | 3 to 1 |

≥ 5,000,000 and less than or equal to 10,000,000 | 4 to 1 |

≥ 10,000,000 | 5 to 1 |

C403.3.4.5 Buildings with high-capacity space-heating gas boiler systems. New buildings with gas hot water boiler systems for space heating with a total system input of at least 1,000,000 Btu/h but not more than 10,000,000 Btu/h shall comply with this section.

EXCEPTIONS: | 1. Where 25 percent of the annual space heating requirement is provided by site-recovered energy, or heat recovery chillers. |

| 2. Space heating boilers installed in individual dwelling units. |

| 3. Where 50 percent or more of the design heat load is served using perimeter convective heating, radiant ceiling panels, or both. |

| 4. Individual gas boilers with input capacity less than 300,000 Btu/h shall not be included in the calculations of the total system input or total system efficiency. |

C403.3.4.5.1 Boiler efficiency. Gas hot water boilers shall have a minimum thermal efficiency (Et) of 90 percent when rated in accordance with the test procedures in Table C403.3.2(6). Systems with multiple boilers are allowed to meet this requirement if the space-heating input provided by equipment with thermal efficiency (Et) above and below 90 percent provides an input capacity-weighted average thermal efficiency of at least 90 percent. For boilers rated only for combustion efficiency, the calculation for the input capacity-weighted average thermal efficiency shall use the combustion efficiency value.

C403.3.4.5.2 Hot water distribution system design. The hot water distribution system shall be designed to meet all of the following:

1. Coils and other heat exchangers shall be selected so that at design conditions the hot water return temperature entering the boilers is 120°F (48.9°C) or less.

2. Under all operating conditions, the water temperature entering the boiler is 120°F (48.9°C) or less, or the flow rate of supply hot water that recirculates directly into the return system, such as three-way valves or minimum flow bypass controls, shall be no greater than 20 percent of the design flow of the operating boilers.

AMENDATORY SECTION(Amending WSR 22-14-091, 23-12-101, and 23-20-021, filed 7/1/22, 6/7/23, and 9/25/23, effective 3/15/24)

WAC 51-11C-40335Section C403.3.5—Dedicated outdoor air systems.

C403.3.5 Dedicated outdoor air systems (DOAS). For buildings with occupancies as shown in Table C403.3.5, outdoor air shall be provided to each occupied space by a dedicated outdoor air system (DOAS) which delivers 100 percent outdoor air without requiring operation of the heating and cooling system fans for ventilation air delivery.

EXCEPTIONS: | 1. Occupied spaces that are not ventilated by a mechanical ventilation system and are only ventilated by a natural ventilation system in accordance with Section 402 of the International Mechanical Code. |

| 2. High efficiency variable air volume (VAV) systems complying with Section C403.6.10 for occupancy classifications other than Groups A-1, A-2 and A-3 as specified in Table C403.3.5, and high efficiency VAV systems complying with Section C403.12 for occupancy classification Groups A-1, A-2 and A-3 as specified in Table C403.3.5. This exception shall not be used as a substitution for a DOAS per Section C406.6. |

Table C403.3.5

Occupancy Classifications Requiring DOAS

Occupancy Classificationa | Inclusions | Exempted |

A-1 | All occupancies not specifically exempted | Television and radio studios |

A-2 | Casinos (gaming area) | All other A-2 occupancies |

A-3 | Lecture halls, community halls, exhibition halls, gymnasiums, courtrooms, libraries, places of religious worship | All other A-3 occupancies |

A-4, A-5 | | All occupancies excluded |

B | All occupancies not specifically exempted | Food processing establishments including commercial kitchens, restaurants, cafeterias; laboratories for testing and research; data processing facilities and telephone exchanges; air traffic control towers; animal hospitals, kennels, pounds; ambulatory care facilities |

F, H, I, R, S, U | | All occupancies excluded |

E, M | All occupancies included | |

a. | Occupancy classification from the International Building Code Chapter 3. |

C403.3.5.1 DOAS with energy recovery ventilation. The DOAS shall include energy recovery. The energy recovery ((ventilation system))device shall have a 68 percent minimum sensible recovery effectiveness ((of the energy recovery device)) as calculated in accordance with Equation 4-9 or provide an enthalpy recovery ratio of not less than 60 percent at design conditions in accordance with Section C403.7.6. The airflow rate thresholds in Section C403.7.6 that define when the energy recovery requirements in that section do not apply, are not applicable to this section. The return/exhaust air stream temperature for heat recovery device selection shall be 70°F (21°C) at 30 percent relative humidity, or as calculated by the registered design professional.

(Equation 4-9)

| Sensible Recovery Effectiveness | = | TOA - TSA | |

| TOA - TRA | |

Where: |

| TOA | = | Design outdoor air dry bulb temperature entering the energy recovery device. |

| TSA | = | Supply air dry bulb temperature leaving the energy recovery device at design temperatures and airflow conditions, as selected for the proposed DOAS unit(s). |

| TRA | = | Design return air dry bulb temperature. |

EXCEPTIONS: | 1. Systems installed for the sole purpose of providing makeup air for systems exhausting toxic, flammable, paint, or corrosive fumes or dust, dryer exhaust, or commercial kitchen hoods used for collecting and removing grease vapors and smoke. |

| 2. Heat recovery and energy recovery ventilators (H/ERV) that are rated and listed in accordance with HVI 920 can demonstrate compliance with the sensible recovery effectiveness requirement using the adjusted sensible recovery effectiveness (ASRE) rating of the equipment at 32°F test conditions. Applied flow rate for ASRE rating shall be no less than the design flow rate or the closest value interpolated between two listed flow rates. |

| 3. The energy recovery systems for Group R-2 occupancies are permitted to provide 60 percent minimum sensible heat recovery effectiveness in lieu of 68 percent sensible recovery effectiveness in accordance with Section C403.7.6. The return/exhaust air stream temperature for heat recovery device selection shall be 70°F (21°C) or as determined by an approved calculation procedure. |

C403.3.5.2 DOAS fan power. For a DOAS that does not have at least one fan or fan array with fan electrical input power ≥ 1 kW, the total combined fan power shall not exceed 1 watt per cfm of outdoor air as calculated in accordance with Equation 4-10 using design maximum airflows and external static pressures. For a DOAS with at least one fan or fan array with fan electrical input power ≥ 1 kW, the DOAS shall comply with the fan power limitations of Section C403.8.1. DOAS total combined fan power shall include all supply, exhaust and other fans utilized for the purpose of ventilation. This fan power restriction applies to each DOAS in the permitted project, but does not include the fan power associated with the zonal heating and cooling equipment.

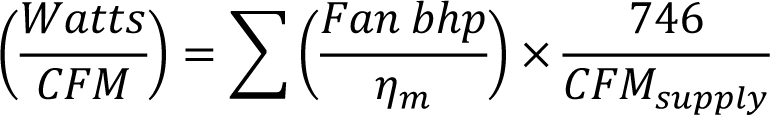

(Equation 4-10)

| DOAS Total Combined Fan Power | | |

Where: |

| Fan bhp | = | Brake horsepower for each supply, exhaust and other fan in the system at design maximum airflow rate. |

| ƞm | = | Fan motor efficiency including all motor, drive and other losses for each fan in the system. |

| CFMsupply | = | Design maximum airflow rate of outdoor (supply) air. |

C403.3.5.3 Heating and cooling system fan controls. Heating and cooling equipment fans, heating and cooling circulation pumps, and terminal unit fans shall cycle off and terminal unit primary cooling air shall be shut off when there is no call for heating or cooling in the zone.

EXCEPTION: | Fans used for heating and cooling using less than 0.12 watts per cfm may operate when space temperatures are within the setpoint deadband (Section C403.4.1.2) to provide destratification and air mixing in the space. |

C403.3.5.4 Decoupled DOAS supply air. The DOAS supply air shall be delivered directly to the occupied space or downstream of the terminal heating and/or cooling coils.

EXCEPTIONS: | 1. Active chilled beam systems. |

| 2. Sensible only cooling terminal units with pressure independent variable airflow regulating devices limiting the DOAS supply air to the greater of latent load or minimum ventilation requirements. |

| 3. Terminal heating and/or cooling units that comply with the low fan power allowance requirements in the exception of Section C403.3.5.3. |

C403.3.5.5 Supplemental heating and cooling. Supply air stream heating in the DOAS system shall comply with Section C403.7.3. Cooling is permitted for dehumidification only. Cooling coil shall be sized to meet peak dehumidification requirement at design outdoor temperatures, and no larger. Cooling coil shall be controlled to maintain supply air relative humidity or zone relative humidity.

EXCEPTION: | Heating permitted for defrost control shall be locked out when outside air temperatures are above 35°F (2°C). Supplemental heating for defrost shall modulate to 10 percent of the peak capacity, and shall be sized to prevent ((frost/damage dame))frost damage to the unit at design temperatures and provide supply air less than or equal to 55°F (13°C). |

C403.3.5.6 Impracticality. Where the code official determines that full compliance with one or more of the requirements in Sections C403.3.5.1 through C403.3.5.5 is impractical, it is permissible to provide an approved alternate means of compliance that achieves a comparable level of energy efficiency as the requirement(s) deemed impractical. For the purposes of this section, impractical means that an HVAC system complying with all requirements in Section C403.3.5 cannot effectively be utilized due to an unusual use or configuration of the building.

AMENDATORY SECTION(Amending WSR 24-03-085, filed 1/16/24, effective 3/15/24)

WAC 51-11C-40341Section C403.4.1—Thermostatic controls.